Characteristics of infrared heating film on the ceiling

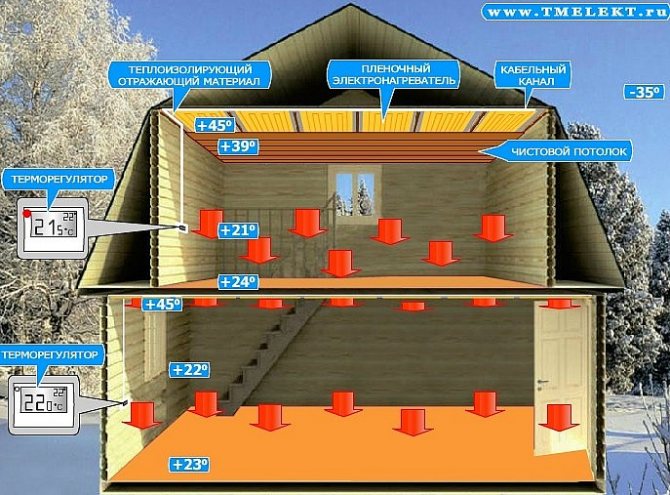

Infrared ceiling heating is a foil with heating elements inside. At the moment when the electricity supply will be carried out, this film will heat up to +45 ° C in a matter of minutes. The transmission of infrared waves is carried out in the same way as with sunlight. After the decorative ceiling is heated, the heat will be directed to the floor, from which it will be reflected in the future.

Thanks to ceiling infrared film devices, not only the air in the room will be heated, but also the existing furniture. Thus, heat will constantly accumulate in the living room, which will subsequently be given off from the surface of objects.

In a room at a level of about 1-1.5 m, it is necessary to install a thermostat, thanks to which the operation of the infrared film heater system, which is mounted on the ceiling surface, will be adjusted.

As a rule, the owner of a living space independently sets the level of the desired temperature regime. The moment the set temperature level is reached, the infrared ceiling heater stops working. It should be borne in mind that after the equipment stops operating, the process of maintaining the set temperature regime will be carried out. Thus, each time after switching on, the infrared film ceiling heater will operate on the electrical network for about 10 minutes.

Among the technical characteristics, the following points should be highlighted:

- the width of the film web can vary from 0.5 m to 1 m;

- the maximum thickness is 1.2 mm;

- maximum temperature heating of installed elements - +50 ° С;

- required voltage - 220 V;

- weight of 1 sq. m of infrared film heater is 50 g.

Many people believe that by installing this type of heating, the floor surface will be constantly cold. It is important to understand that due to the heating of objects, the lack of heat near the floor will be compensated.

Warm infrared ceiling

In addition to the obvious and already mentioned advantages of an infrared ceiling, it also has technical features that will delight modern people.

All infrared ceiling models work completely without extraneous noise

Technical features of the IR ceiling:

- All modern models of the IR ceiling have the ability to control the heating using a regular smartphone. For this, however, you will have to additionally buy a special module. But for the price it is inexpensive.

- The heat radiated from the IR ceiling is environmentally friendly. This is the kind of warmth that the sun radiates.

- It takes only ten watts of energy to heat one square meter.

- The approximate heating time for a standard room is 10 degrees in 40 minutes.

- Even a beginner can install devices.

Types of ceiling film infrared heaters

If we consider the types of infrared film heaters existing today, then they can be divided into 3 groups depending on the method of attachment:

- ceiling models;

- wall models;

- floor models.

Depending on the wavelength and temperature radiation, infrared films are:

- low-temperature - household models of heaters that heat up to +10 ° C- + 60 ° C, the radiation length of infrared waves varies from 5.6 microns to 100 microns;

- medium temperature - in this case, the temperature range is +60 ° C- + 100 ° C, while the wavelength ranges from 2.5-5.6 microns;

- high-temperature - the temperature range exceeds +100 ° С, the radiation of infrared waves is 0.74-2.5 microns.

At the moment, the most popular are ceiling heating elements. Such models can be used as an additional or main source of heat. It is quite difficult to get to such elements, which excludes getting burns, especially if there are small children in the house.

If the installation work is carried out correctly, then the heating process of the ceiling surface will be uniform. Thanks to the attractive appearance of modern models, infrared ceiling heaters will only complement the interior design.

Advice! If necessary, you can install a ceiling PLEN in the living space.

Which infrared ceiling to choose

Infrared ceiling (abbreviated as IR ceiling) is a modern solution to heating problems in residential and non-residential premises.

The term "infrared ceiling" can mean:

- Infrared film;

- Ceiling mounted infrared heater.

Ceiling-mounted infrared heater provides thermal comfort in the room under all circumstances

Both options are in high demand among buyers, especially those whose homes are costly to heat with electricity or water.

But what to choose - a film for the ceiling or a separate heater depends on your own desires.

Nevertheless, if you decide to heat not a living space, but, for example, a nursery, then infrared film will be preferable for you because of the greater safety in operation.

Ceiling heating PLEN

Warm ceiling PLEN has a number of significant advantages:

- since the device is powered by heating electricity, the cost of electricity is minimal;

- a distinctive feature is a high level of reliability and a long service life - the conductors are sealed in a film, there are no wearing elements in the design;

- PLEN can be installed under a covering made of any material; its installation does not require a lot of space;

- thanks to the automated system, it is possible to set any temperature regime.

It is worth paying attention to the fact that the work is carried out silently, while heat losses are completely absent. The manufacturer gives a guarantee for up to 25 years, the operational period is 50 years. During operation, the ceiling heating is maintenance-free.

Installation of an infrared ceiling heater

All work related to the installation of a film ceiling IR heater is based on the requirements of the system. But the main thing is the ceiling area. If it is large, then it is better to shift the burden of responsibility onto the shoulders of professionals. If the ceiling is small, then you can try and install the device yourself.

Like many installation processes, the installation of a film heater is divided into several stages:

- A reflective screen is installed.

- Heating films are mounted.

- An electrical wiring diagram is created.

Stage 1

For him you need a material with a foil layer. It is better if it is a thin insulation, finished on one side with aluminum foil. The optimum thickness is 5 mm.

If the ceiling is made of lumber, a stapler and metal staples can be used to secure the heat insulator. If the ceiling is concrete, then you cannot do without a perforator.With its help, holes are drilled in the ceiling surface every half a meter for a special fastener - UKE. The strips overlap each other with an offset of 2-4 cm.

Stage 2

In fact, the technology for installing a film ceiling IR heater is no different from installing a heat insulator. After all, a heater is a thin film on which carbon paste and carbon threads are applied. That is, it is all the same roll material.

Please note that the design of the heater has special transparent stripes along the edges - these are the places for fastening. Therefore, it is quite difficult to make a mistake and install fasteners in the wrong place. And one more thing - the installation must be carried out only in a heated room.

It is very important to read the instructions in detail several times before installation. A small deviation from it can lead to big problems during operation. Often, home craftsmen simply spoil the film and carbon threads, which requires replacing the whole strip. And these are unnecessary expenses.

Stage 3

Electrical work is the most difficult and crucial stage. To carry them out, you will need a PV-3 wire with one core. A main line is constructed from it, which must be hidden in a canal. The highway must be isolated and camouflaged from the eyes.

If the area of the infrared film heater is large enough, then a magnetic contactor will have to be installed in the electrical circuit. All trunk channels must be routed to the switchboard.

Next, the thermostat is installed. Its place is 1.4 m above the floor. When the entire circuit is ready, the system is tested, minor problems are eliminated and it is prepared for operation.

Installation of infrared ceiling film

In the event that this system will act as the main source of heat, it is recommended to pre-fix the mats on the surface, which will occupy about 80%. If an infrared ceiling heater is used as an additional heat source, then it is sufficient to install mats on 30% of the total area of the entire ceiling surface.

Before proceeding with the installation work, it is necessary to correctly calculate the power level of the heating elements. Thanks to the power calculation, it will be possible to select a thermostat. For example, a thermostat consumes 4 kW, for each sq. m of film accounts for 0.2 kW. In this case, the surface area should be up to 20 square meters. m.

After that, they proceed to the installation of thermal insulation materials. If you plan to install an IR heater in a multi-storey building with a concrete floor, then heat loss can be prevented thanks to thermal insulation. In wooden houses, thermal insulation prevents heat dissipation and, as a result, drying out of the wood.

For insulation, you can use expanded polystyrene, which is covered with a layer of foil on one or both sides. The material should be attached to the ceilings using refractory dowels for these purposes. It is recommended to glue the joints with foil tape. Only then can you start installing the film ceiling heater.

When fixing the infrared film sheet, it is necessary to first retreat about 35 cm from the walls around the entire perimeter. A distance of up to 5 cm should be left between the strips. The infrared film should be located on the ceiling surface parallel to each other. In the process of carrying out work, it is recommended to follow a special scheme, according to which heating elements should not be over sleeping places and electrical appliances.

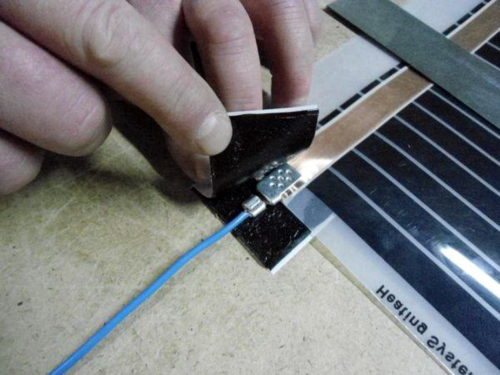

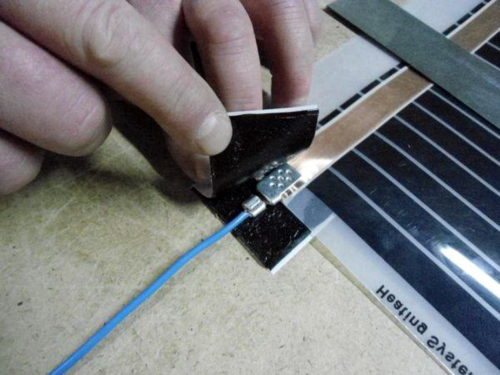

After all the elements have been fixed, it is worth checking the performance of the system.To do this, it is necessary to connect the terminals to the copper buses and clamp them tightly with pliers, the connection points must be reliably insulated.

To interconnect infrared film sheets, electrical copper wires are used, which have a minimum cross section of 2.5 square meters. mm. If necessary, the wires can be masked; for this, a strobe is made in the walls using a perforator, which is then sealed with plaster.

Attention! If necessary, you can install infrared floor heating on the ceiling.

Choice of decorative in-line coating

The basic rule when choosing the optimal decorative coating for a warm ceiling is to prevent the formation of an extensive air gap between the heating elements and the ceiling material. Hence the main difficulty of installation - if the floors have significant distortions, then they need to be leveled, to eliminate all surface differences.

An excellent option for decorating a warm ceiling is a stretch PVC film. The most ideal options for this are stretch ceilings with microperforation. They easily allow warm air currents to pass through. Installation of stretch ceilings is carried out directly on the walls, respectively, contact with heating elements is minimized.

Perhaps, use as a finishing layer - wooden materials, for example, euro lining. But in this case, you should limit the heating of the ceiling using a thermostat for a temperature not exceeding + 28 ° C. Otherwise, the tree may lead or crack.

- Content:

- Can IR underfloor heating be mounted on a wall or ceiling

- How to fix a film underfloor heating to the wall

- How to install infrared thermal film on the ceiling

- How can I cover the IR film on top

- Which is better, infrared heating of the floor, walls or ceiling

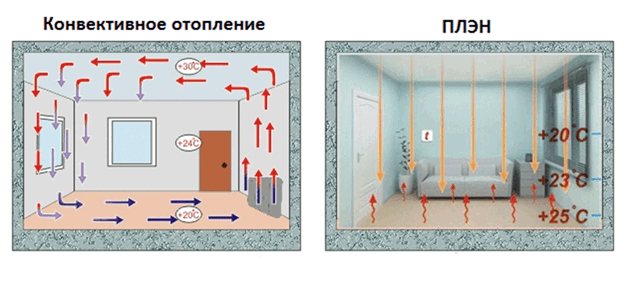

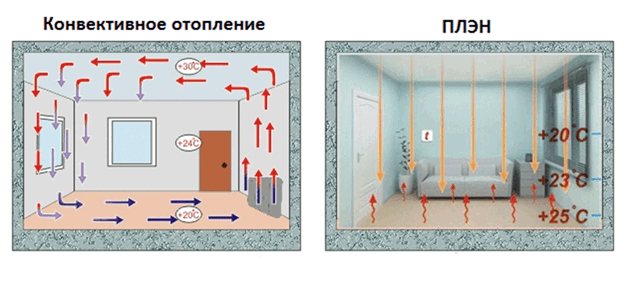

Traditional heating systems use the principle of heating the ambient air by radiation of thermal energy. In contrast, infrared floors heat the surface of any solid objects, and the excess heat is transferred to the air masses in the room. This is what makes it possible to lay a film warm floor on a wall or ceiling, without reducing performance and heat efficiency.

Outside IR coating for ceiling

When choosing an IR film for heating a room, it is necessary to pay special attention to the quality of the system, which must correspond to a number of basic parameters:

- the base must be made of high quality film, the polymer used must be fireproof;

- the conductive strip must be undamaged and made of copper materials, the minimum permissible width must be 15 mm;

- the silver strip must have a clear outline, without gaps, while it must go 2 mm onto the copper bus;

- the location of carbon emitters should be striped or solid, geometric shapes have no effect on the operation of the ceiling heating system;

- external lamination of the infrared film should be made of the same polymer as the base, it is not recommended to use materials with a lower thickness;

- standard films must withstand exposure to temperature conditions up to +80 ° С, high-temperature materials - up to +110 ° С;

- if high quality materials were used in the production process, then there should be no deformation during operation;

- A high-quality IR film should heat up evenly in a short period of time - about 5-10 seconds.

As practice shows, the wider the film is, the niche is the probability of its overheating during operation.

Important! If the polymer is transparent, then it deforms much faster during operation.

Infrared ceiling: customer reviews

The best way to learn about a new product is to read reviews from people who have already tried it. We invite you to get acquainted with the opinions of people who have already installed an infrared ceiling in their home.

By the way, IR ceilings are especially popular among residents of the northern regions of our country.

Infrared ceiling brings high savings to your budget, since it does not waste time heating unnecessary air flows

A few reviews about the infrared ceiling:

“I live in a city where you have to pay a lot of money for heating. And two years ago, my husband found out from someone at work that there is such a new type of heating - PLEN. We read reviews on the Internet, of which there were very few, and so we got acquainted with the information about this product. And at that time in Russia, infrared ceilings were not yet so popular, and there was very little material, but we nevertheless decided and ordered. The cost of PLEN has already been completely repaid, and we are pleased with the result. Heats well! "

“I am especially pleased with the auto-shutdown system. I live in my house, so a wood-burning stove was the main heating means. And, as you can imagine, leaving it burning is not always safe. Therefore, I had to heat only in the evenings, and come home to a cold house. In this regard, PLAN is a lifesaver! I do not embellish its role in the least, it is a very convenient system. I recommend."

“I can’t say that this is the best heating option - I haven’t tried all the alternatives, and I haven’t dealt with the film system, but there’s an IR heater at home, and I can’t say anything bad about it.”

Varieties of film heater

One of the main differences between film type electric heaters is their format and size. PLENs are produced in the form of belts of various lengths and widths. Self-correction of the sizes of such films is impossible, therefore PLENs are produced in a wide range of dimensions, allowing you to choose the best option. The most common are three standard sizes of belts in width: 35, 51 and 65 cm.

Films with a width of 35 and 51 cm have two zones, free from the location of resistive elements and intended for installation with a stapler - at the edges. Ribbons 65 cm wide have three such zones - two along the edges and one along the middle (as an option - two along the edges and between them transverse with a certain pitch).

Flexible film infrared heaters can be installed both on vertical and horizontal surfaces - the design of film-type electric heaters does not depend on the place of its installation, with the exception of PLEN-pictures, which, by definition, should be located in places of the best view - on the walls. The classification of a particular foil heater as a wall, floor or ceiling device is determined only by its design location - an important factor affecting the efficiency of this IR device. Thus, a film heater on the wall, after being installed on the ceiling, in everyday life turns into a ceiling heater.

Consider the options for placing PLENs in the premises in order of increasing efficiency of their use.

Wall arrangement of foil heaters

Placing PLENs on the wall is the least effective due to the limited sector of influence of infrared radiation on the enclosing structures - most of the infrared rays heats the surface of the wall opposite, almost without affecting the floor and ceiling.

Stationary film devices mounted on the wall are effective as the main means of heating only if the opposite base has a significant area - then the heat transfer from its heated surface to the air will be quite noticeable.

If the area of the film heaters installed on the wall is not significant, and the base on the contrary, moreover, has window openings, then the efficiency of such an IR heater will be low.But stationary wall-mounted film heaters of a small area are convenient as an additional heating means - to increase the comfort of the temperature regime of a certain place or zone in the room.

The principle of operation of PLEN

When the power cable is connected to the mains, the resistive elements heat up within 10 seconds to the preset temperature value (35-50 degrees). Non-household film heaters (for mini-saunas, agricultural dryers), used in rooms with a ceiling height of more than 3.5 m, have wire, tape, plate-type resistive elements made of nichrome, fechral or multicomponent alloys in their design, providing a higher temperature heating.

The heat of the heaters is transferred to the foil and, due to the high thermal conductivity of aluminum, is evenly distributed over its surface, which allows the heater to generate infrared radiation of equal intensity over its entire area. When the air in the room reaches the set temperature, the foil heater is turned off by a signal from the temperature sensor in the thermostat, and objects heated by radiation continue to give off heat. When the temperature in the room drops by 1 degree, the thermostat will turn on again, and the foil heater will perform a new cycle of operation for radiation.

A correctly calculated combination of the material of the reflecting layer, its thickness, the arrangement of resistive heaters ensures the conversion of electricity into heat, and then into infrared radiation with a wavelength of 8-15 Mkm favorable for human perception.

Important! With an increase in the current strength or failure of the thermostat, the temperature of the resistive graphite heaters will increase, which will lead to their destruction and failure of the household film heater as a whole, that is, the resistive elements also perform the protective function of fuses.

How to make a warm ceiling in a house with your own hands?

Installation of infrared film on the ceiling takes place in several stages:

- thermal insulation of the ceiling;

- calculation of the area of the film;

- installation of film, thermostat and sensor;

- network connection and health check.

Before installing the thermal film, it is necessary to complete all construction and finishing work on the ceiling, excluding finishing. Also carry out all the work on laying communications and lighting wires.

Now let's consider the stages of installing a warm ceiling in more detail.

Ceiling insulation

It is necessary in order not to warm the attic or neighbors on the floor above. A properly insulated ceiling will return all the heat to the room, thus increasing the efficiency of the device and reducing energy costs. Thermal insulation with a reflective layer is attached to the entire surface of the ceiling and extends a few centimeters to the walls. This will prevent heat loss through the gaps between the ceiling and wall. The joints in the insulating material are sealed with tape. The material itself must be at least 5 mm thick.

How to calculate the area of an infrared film?

To correctly calculate the required area, you need to consider the following:

- how well the building itself is insulated. For a brick house or a light frame structure, these data will differ;

- whether it is planned to live in the house during the winter period, permanently or occasionally;

- the volume of the heated area. It can be either the whole room or a part of it;

- whether infrared heating will be primary or additional.

If a warm ceiling is planned as the main type of heating, it should occupy at least 70% of the entire ceiling area. As an additional option, this figure can be reduced according to the capacity of the main heating system. The average film power is approximately 0.2 kW per 1 square meter.By dividing the power of the thermostat by this number, you can find out the area of the film that can be connected to it.

Installation of thermal equipment

The thermal film can only be cut along the special lines marked on it. Each type of film has its own maximum cut length. This information can be found in the attached documentation or ask the seller. There should be no gaps or air spaces between the film and the ceiling insulation.

Next, you need to connect the copper contacts of the conductive bus to the electrical wires using contact clips. One half of the clip should be on the copper rail and the other half inside the heater. After that, the ends of the film are insulated with bitumen tape on both sides.

The sensor is mounted in a cut-out in the thermal insulation and connected to the regulator and heating elements.

Electrical connection

Connect the thermal film through the regulator to the network in parallel. If the warm ceiling will have a lot of power, it is better to connect it through a separate machine.

A properly mounted warm ceiling, when switched on, should emit comfortable uniform heat, not overheat anywhere and turn off in time when the set temperature is reached.

Finishing

Next, the ceilings are finished. It can be a stretch ceiling with special microperforation. It perfectly transmits infrared waves. In this case, the stretch ceiling is mounted along the edges of the wall without affecting the ceiling itself.

You can also close the structure with a suspended ceiling: plasterboard sheets, clapboard or plastic panels. A small gap must be left between the stretch or false ceiling and the infrared heating system. For finishing the ceiling, you should choose waterproof materials with a thickness of no more than 16 mm.

The infrared heating system for ceilings is the most modern, safe and efficient of all electric heating options. With proper installation, it will last a long time, filling the house with warmth and comfort, and at the same time remaining completely invisible.

In the winter period in Russia, housing must be heated even in the southern regions, which determines the demand for many types of stationary and portable heating equipment among our consumers. An extensive niche in the Russian market of heaters offered by foreign and domestic manufacturers is occupied by a group of infrared devices with a general principle of influence on the environment, but consisting of subgroups that differ in design and, as a result, in functionality and efficiency.

Dignity

This heater has a number of advantages:

- It allows you to create a heating scheme for rooms by zones or covering the entire space.

- Has a low price.

- It makes it possible to save up to 40% energy compared to other heating systems.

- The infrared film heater located on the ceiling does not take up useful space.

- It practically does not reduce the height of the ceilings.

- Differs in silent operation and high efficiency, and also heats up instantly.

Experts believe that a film infrared heater is the most effective way to heat any room for its intended purpose today.

Heating a home with electricity is considered the most costly, but if other fuels are not available, it is worth considering the most popular types of wall-powered heaters. The most economical are infrared. Their efficiency is much higher due to a different operating principle. Unlike conventional electric reflectors or radiators, infrared does not heat the air, but the surrounding objects: floors, walls, furniture, people.Heated objects release heat evenly, creating a feeling of comfort and dryness.