23.01.2017

It is no longer a novelty to hear of the pipe type connection as "American". Despite the fact that this is a fairly new device and originates in America, it has already become quite used. This is due to properties that can solve the problem of many pipelines. An American woman for polypropylene pipes very often becomes an indispensable structural element.

- 1 Specifications

- 2 What are they made of and how to install

- 3 Prices for American women for PVC pipes

- 4 Installation of the connection using American women

- 5 Difference in connection types

- 6 Scope 6.1 Conclusion

Specifications

The material from which the pipes are made is very soft and plastic, it is a completely synthetic component. Such qualities of PVC pipes become an obstacle when it comes to connecting pipeline elements to each other. Many who used standard techniques for connection were convinced of their poor quality and negative result. The reason for such results is the quality of the fastener material and its characteristic features, due to which the deformation of PVC pipes occurs.

To avoid troubles in the construction of the pipeline structure, you should resort to using the American connection, for polypropylene pipes it is ideal, because it has:

| Characteristic | Description |

| Simplicity | Obtained due to the fact that pipes are dismantled very easily, and there is no need to rotate the pipe elements. |

| Ease of installation | The pipe structure is connected due to the fact that the American has a cap nut. This is a convenience, because in addition to this element in the pipeline, all the others retain their stationary position; |

| Tightness | This parameter is ensured due to the fact that in the connecting elements, like an American, for polypropylene pipes, a special kind of cushioning material is used, which, when connected, is tightly pressed against the pipes. |

Varieties

American couplings are classified depending on a number of factors. By construction type:

- a union nut is fixed at one of the ends, the second is intended for soldering;

- the thread is located inside or outside;

- combined design with different types of attachment to pipes at the same time.

Depending on the material:

- Cast iron. Rust quickly.

- Steel structures. Most often, stainless steel is used in production.

- Chrome plated brass. Chromium protects metal surfaces from rust.

- Combined. Various types of metals with the addition of polymers.

Combined fittings often have plastic inserts.

By form:

- crosses - used to combine 4 pipes into a single pipeline;

- simple couplings;

- corners for creating turns;

- stubs;

- ball valves with the ability to adjust the flow rate of gas or liquid;

- shut-off valves.

- adapters - allow you to connect pipes of different diameters into one pipeline;

- water sockets;

- saddles are inlets that can be used to cut into the finished contour.

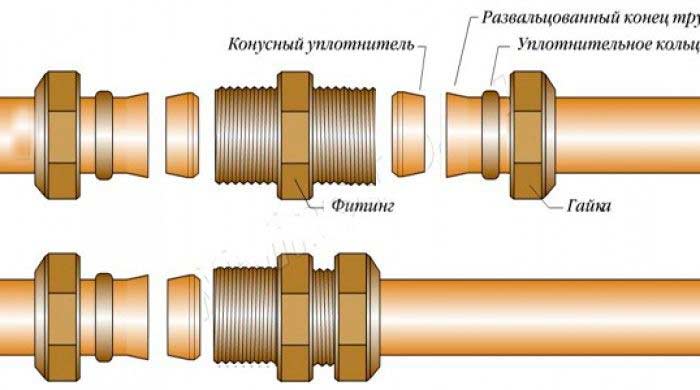

Depending on the type of connection, American women are cylindrical or conical.

Polypropylene pipes and fittings (Photo: Instagram / teploenergiya)

What are they made of and how to install

The material from which the American is made can be:

- cast iron;

- brass;

- steel;

- stainless steel;

- polypropylene.

Depending on what material you need to purchase an American woman, its cost will vary.Additional parameters that can increase the duration of operation should be taken into account when choosing a material, such as:

- the quality of the liquid that will pass through the pipeline;

- what is the temperature indicator of water;

- at what level of pressure the liquids pass through the pipeline.

In addition to the main material for the manufacture of American women, nickel is additionally used. They spray on the inner and outer surfaces of American women, for polypropylene pipes this is necessary in order to create conditions for reliable operation and to provide a protective film from negative influences. In addition, this coating gives the fittings a pleasant appearance.

Considering that pipelines are increasingly being constructed from polypropylene, the connecting devices were made of a similar material, which began to make it possible to attach elements to the structure system using soldering or welding.

Key for American women

For all its simplicity and attractiveness The American woman has a secret that does not lie on the surface, but everyone who is engaged in editing should know it - do you know how to twist it? The fact is that the union nut is controlled by the usual open-end wrench but there are still press fittings for metal-plastic pipes, which must be screwed into the landing site with an internal key. And this can be either a hexagon, which is simpler, or a cylinder with recesses for the hooks, which is more difficult, but more reliable.

Prices for American women for PVC pipes

| Compound | Price, rub |

| American straight type 1 ″ TIM | 258 r |

| American straight type 1 1/4 ″ TIM | 669 r |

| KALDE PP-R American НР? 50 х 1-1 / 2 ″ | 730 RUB |

| American straight type chrome 1 ″ TIM | 368 r |

| American angle type 1/2 ″ TIM | 168 RUB |

| Threaded connection Gas (American) G 1 1/2 "AISI 316 w / w | 2000 RUB |

| Coupling of the combined type VALFEX, split | RUB 250 |

| American made of cast iron, split, 1/2 ″ vn / plank bed SANHA | RUB 185 |

| American transitional type 1/2 ″ bunk x 3/4 vn TIM | RUB 85 |

Installation of a connection using American women

The technological process for the installation of a pipe structure in a combination of polypropylene pipes or them with a metallic look is quite simple. For such purposes, an American woman is very well suited according to the principle of connecting a coupling, in which there is a metal insert, as well as a union nut, or a polypropylene fitting and a union nut can be used.

When using fittings of the American type for polypropylene pipes, you need to know what tool to carry out the working process. If you purchased an American woman in which there is a union nut, then you should use a wrench of the appropriate size. In the case of fittings, with existing press connections, you will need either a hexagonal inner wrench or a special cylinder with a recess for the hook.

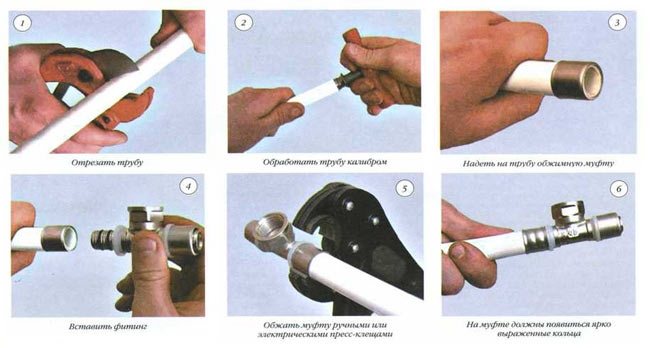

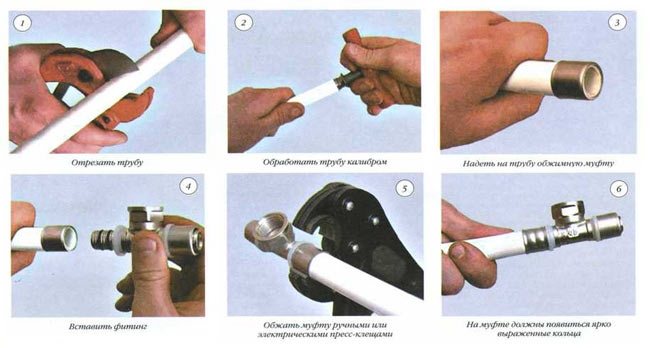

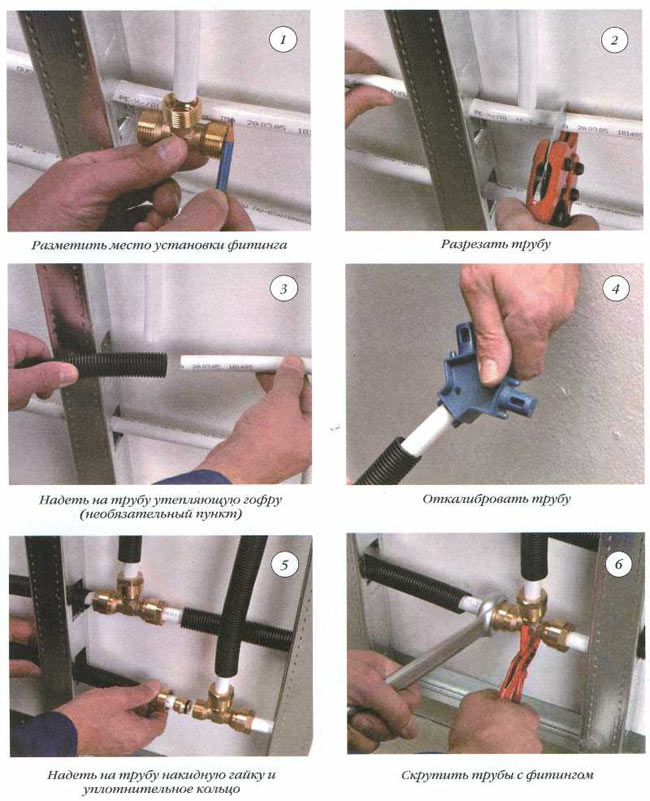

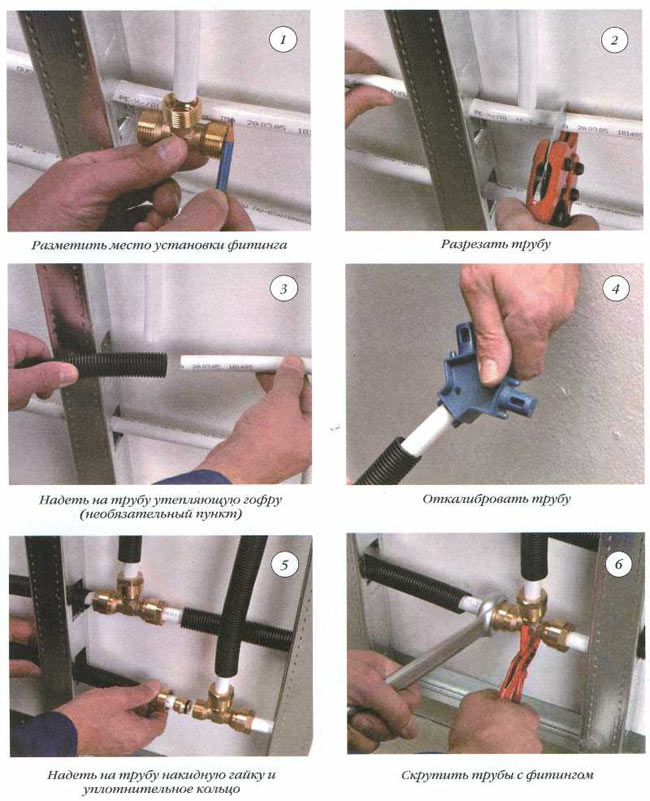

The process of connecting pipes to each other is easy, but it needs to follow a certain sequence of actions:

| Stage | Description |

| Preparatory stage | Before proceeding with the installation process, you should carefully examine all pipes and connections for integrity, before that, removing all chamfers, if any, in places where it is required. In the case of polypropylene pipes, a calibration process must be carried out. |

| Fitting element connection | The fixation is started from the part that is designed for the welding process, after which they proceed to join the place on the back of the element where the threaded notches are located. |

| Pre-tightening | Next, tighten the fittings so that they are fixed to? from the maximum possible attachment. This must be done for the reason that you can check how well the pipeline system is working and, if necessary, fix the problems at this stage. |

| Full tightening | After the operation of the system has been checked, you can begin to fully tighten the fixing element of the fitting. The union nut should be screwed on as tightly as possible, since the degree of tightness of the connecting element depends on this. |

| Completion of installation | In principle, the previous stage can be final, however, for those who like to play it safe, it is possible to use Teflon tape, which is used to wind the choke thread. This will provide additional reliability of the pipe connection. |

Using a structure that has an American connection, for polypropylene pipes, the service life can reach 50 years, if cold water passes through the system. If the water temperature is increased, as is the case with the heating system, then the operating rate will most likely decrease by half. It should not be forgotten that the indicator of the duration of use of the fittings depends on the characteristics of the liquid passing through them, mainly on the temperature regime and the pressure level of the supplied water.

Fitting installation rules (American)

To do the work, you need keys: adjustable, open-end and universal. Using gas keys will deform the product.

An American woman with a thread cut inside connects two sections of the pipeline into one. In the absence of a threaded notch on the pipe, it is cut, 7 turns at least. The thread is wrapped with fum - tape or tow and the fitting is screwed on, on the other hand, the seal is also wound, and the parts are connected by tightening the American union nut.

Attention! If tow or linen is used, it is worth applying a sealant. Installation of a fitting with a thread cut from the outside is carried out in the same way, with one difference, the fitting is wrapped with a sealant directly.

Difference between connection types

Before considering the varieties by which connections can be made, where an American woman is used for polypropylene pipes, some of its characteristics should be highlighted:

- represented by a special element that has a thread that can be disassembled and reassembled, which allows such an element to be used repeatedly;

- it is also very important that with the help of American women, a high speed is ensured during the installation of the structure, and also such a process does not need special skills or efforts;

- repairing the pipeline, if necessary, is also easy if an American was used as a connecting element for polypropylene pipes.

In addition, the generalized concept of a compound "American" contains many more adaptations. A distinctive feature of all devices is the presence of a union nut in the design of the element:

- couplings;

- cranes;

- corners.

If we consider the options in which an American woman can be used for polypropylene pipes, then they may have:

| Internal thread | Any combination in combination of the listed options. |

| External thread | |

| Union nut |

Reference: if we consider the coupling-type connections, then it has the ability to be disassembled and reused. At the same time, the set includes fittings (2 pcs.), Gasket rubber material and a union nut. The dimensions of the device are small, there is no rotation when installing the pipe elements.

Connections that are threaded always need fittings. it is not possible to build a threaded element on PVC pipes yourself, and therefore you can use Teflon tape material in combination with a sealant. Together they will be able to ensure the strength of the joints.

Types of American women for polypropylene pipes

The connecting element "American" for PP pipes is a threaded dismountable part with its own seal.

Design

Connections differ in design features:

- With an external thread - in the design of the part there is a union nut and two unions.

- With a union hex nut and a polypropylene nipple that allows soldering with PP pipe.

- Combined type.

- With internal thread.

Material

The following material is used for manufacturing:

- Brass - fittings are additionally protected with nickel or chrome plating.

- Steel - in most cases, stainless steel is used.

- Cast iron - available in black or galvanized.

Combined versions are also available. One of the varieties is metal elements with a PP insert.

Varieties of couplings

Appointment

The connections differ in functionality. When installing the connection, you can use:

- Couplings for joining 2 parts of engineering communications.

- Equal bore tees and elbows that allow you to branch off or rotate the system 30 °, 45 ° or 90 °.

- Sockets for connecting mixers, ball valves and so on.

- Plugs.

- Crosspieces to create 3 branches at once.

- A saddle to insert into the existing utilities.

- Adapters that allow you to change the flow area of the network by connecting sections with different diameters.

- Ball valves.

Connection type

Manufacturers produce conical and cylindrical American women. They differ in the type of connection. For example, the design of the conical shapes makes the most tight joints without the additional use of a sealant. Such connections, where there are no gaskets, are created during the connection of, for example, thermostats.

Cylindrical ones also allow for hermetically joining two parts of the engineering system. In this case, a reliable connection is ensured by using gaskets made of rubber, paronite or polyurethane.

In addition, cylindrical fittings need to be retightened periodically. In them, the sealing material may wear out over time. Therefore, it will have to be changed. The frequency of action depends on the frequency of use of the connecting elements.

The advantages of cylindrical parts include the ability to manufacture individual parts of the assembly with less than ideal accuracy.

With the help of conical American women, it is allowed to dock pipes, in which the deviation along the axes does not exceed 5 °. Only in this case a reliable tightness is ensured.

Fittings of this type have a long service life. As a result, there are no additional seals. Due to the homogeneity of the compounds, they are highly resistant to temperature extremes and reagents of chemical origin.

Application area

Many areas of application are captured by such a simple device as an American, for polypropylene pipes it is especially indispensable. If we consider in detail the possibility of using a connecting fitting of this type, then the following can be distinguished.

| Where and how | Description |

| Cranes, complex nodal structures in water and heat supply systems. A device serving as a measuring element of various indicators. | In this case, such a fitting, depending on its design, can even become the main and irreplaceable element. |

| Home plumbing communications system | Serves as a transient component in the system of counters and control devices. All connections to the input direction and vice versa are made in them. This provides a convenient removal of the counter if necessary, for example, for checking. |

| Installation and repair work in the heating system | In the event of a malfunction in the heating system, the American woman used for polypropylene pipes will significantly reduce the time spent on repairs. |

| Systems where high pressure and high temperature conditions are used | It is quite in demand due to its ability to create a high degree of tightness in the joints in the structure. |

| Combination of plastic and metal-plastic pipe material | With such a combination of materials and the need to combine them, it does not matter what kind of materials there is a need to connect, an American woman will be selected for them in any case. |