Type of autonomous heaters for diesel fuel

According to the established terminology, autonomous diesel heating units are divided into the following types:

- small stand-alone diesel oven;

- powerful diesel thermal furnace (heat gun);

- self-made autonomous stove with diesel fuel;

- the stove is a dropper powered by diesel fuel.

Any stove with diesel fuel has its own advantages and disadvantages. To evaluate each of them, you need to understand the characteristics of such devices.

Furnace characteristics

All types of autonomous diesel fuel stoves can be divided according to the following criteria:

- heating method;

- constructive scheme;

- allocated power;

- diesel fuel consumption rate;

- the possibility of connecting additional heating devices or systems;

- weight and size characteristics.

Stove stove

By the way they are heated, they can be divided into two broad categories:

- autonomous devices using direct heating;

- devices using indirect heating.

A feature of direct heating devices is the absence of an equipped chimney. They are called "potbelly stoves".

The most widespread devices are indirect heating.

A homemade diesel stove is assembled according to one of the following schemes:

- double-circuit or as it is called gas-air;

- wick;

- drip;

- using steel sheets;

- using an ordinary gas cylinder.

Homemade stove on diesel fuel

In terms of the heat output and the diesel fuel consumption rate, factory-made units start from 2.5 kW with a consumption of 180 milliliters of diesel fuel per hour and up to 20 kW with a capacity of 550 m3 per hour. The consumption of diesel fuel increases by 1.5 liters. These units are called heat guns.

Possibility of connecting additional heating systems, such as air ducts. The continuous operation time varies depending on the characteristics. This time varies from 6 to 28 hours of operation without refueling.

Miracle oven design

- removable fuel tank equipped with a valve;

- adjusting screw;

- a block with a wick that can be changed;

- lattice;

- body;

- reflector;

- burner.

A metal reflector is located on the body, which is powder painted. It is thanks to the reflector that efficient heating premises. The burner is located in the center of the miracle furnace, and the fuel flows by gravity from the fuel tank located on the rear panel. Through adjusting screw the required room heating temperature is set. This is a general design of a diesel-fueled stove, but it may differ slightly in different models from different manufacturers. For the manufacture of the stove use heat-resistant steel.

The weight of the miracle stove can be 10 kg, which allows you to transfer it, depending on the need, to another room. Dimensions: height from 3500 to 6000 mm, depth and width from 2500 to 4000 mm. Such light weight and small dimensions allow it to be moved by the force of one adult.

Ignition

Before firing up, the tank is installed in the designated place and fuel is poured into it. Then it is necessary to remove the grate with the burner and make wick installation into the block. After the wick is inserted, the burner and grate are reinstalled. After all the preparatory work is completed, the adjusting screw opens and you will need to wait half a minute for the wick to be saturated with fuel. Then the burner is already ignited. As soon as it starts intense burning, the adjusting screw must be tightened to the end and, after waiting for a while for the flame to settle, open it back, setting the required degree of heating. The stopping of the miracle oven is carried out by screwing in the adjusting screw until it stops. It is imperative to make sure that the fuel burns out to the end and the fire goes out. Fuel consumption, depending on the design of the stove, can be 150-400 ml / hour.

Video illustrating the process of igniting the miracle of the stove:

Precautions

It is prohibited:

- use a heating device in a poorly ventilated room;

- install the stove in close proximity to furniture and flammable objects;

- use fuel that does not correspond to that specified in the passport data;

In addition, it is necessary to exclude contact with the working oven. water and it should only be operated under the supervision of adult family members.

https://youtu.be/o8B02TsjWSM

Some features of such a furnace

The features of a homemade diesel stove can be divided into two categories:

- manufacturing features;

- application features.

Features in the manufacture are determined by the choice of the design of such a stove. This will require the selection of a certain material (appropriate steel: sheet, angle, pipe), certain finished products or home-made production (nozzles, pipes, chimneys and air ducts), containers for diesel fuel. The need to use the appropriate tool and metalworking equipment (drill, grinder with a set of cutting wheels, welding machine) hardware for fastening individual parts of a homemade stove.

Application features include: the specifics of the ignition of such a stove, the organization of the removal of combustion products. Using diesel fuel as fuel will require periodic maintenance of the existing nozzle and burner. This is due to the presence of sulfur in the diesel fuel.

If a diesel fuel stove is used in which the fuel flows by gravity, it is necessary to place the diesel fuel tank above the burner itself at a certain distance in order to exclude its uncontrolled heating.

Manufacturing instruction

There are many instructions on the Web that describe the manufacturing procedure in detail. But such a stove can be of various types, each of them has its own advantages and disadvantages, so an ignorant person often finds it difficult to choose the right option. Also, when choosing a particular model, you need to take into account the conditions of future operation.

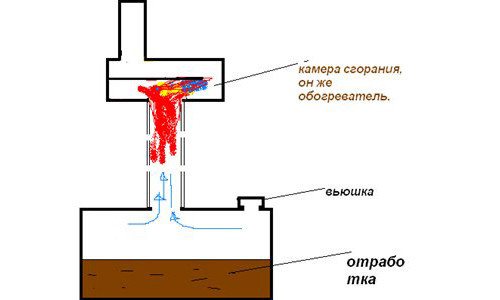

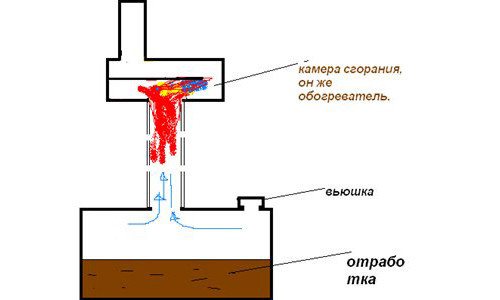

Drip oven

Drip oven

The best option for home use. Manufacturing does not require much time, and the finished structure will take only a few square meters of space (if we talk about the most dimensional version). But in most cases it is made portable, which is why it is very popular among tourists when heating tents.

The technology for manufacturing a drop structure is as follows.

First step. First, a medical burner is taken (its capacity usually does not exceed two liters).

Second phase. The burner is equipped with a rubber hose with a copper tube of the corresponding diameter connected to it, after which the tube is bent at an angle of 90 ° C.

Stage three. Then the hose should be bent in half.

Stage four. A clamp equipped with a screw is taken and attached to the fold.

Important! The screw is required to adjust the fuel supply to the burner.

If a larger drip furnace is required, sheet metal must be used for fabrication. In this case, the structure will consist of a pair of parts nesting into each other and placed further from the front door. It must be remembered that the principle of operation of such structures is based on the periodic supply of diesel fuel to the fuel tank.This allows furnaces to be built in a wide variety of sizes and shapes.

Two-tank stove

Two-tank stove

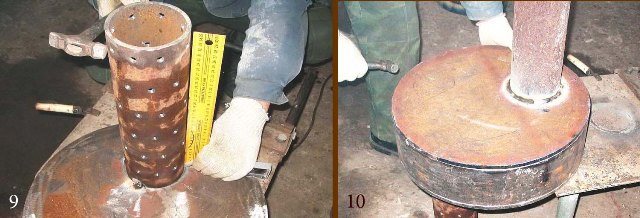

There is another equally popular manufacturing method based on the use of several tanks, interconnected by perforated (that is, with numerous holes) pipes. In this case, the lower tank serves not only as a fuel tank, but also as a combustion chamber. The capacity of this design is impressive - about 12 liters. For the manufacture of the case, steel sheets with a thickness of 3 mm to 5 mm are used, which prevents the walls from burning out and, therefore, increases the service life of the device.

Two-tank stove

A hole is made in the upper tank with a closing lid. A branch pipe is welded to the lower part of the body, on which the exhaust pipe is installed. For the manufacture of this pipe, it is necessary to use only galvanized steel, since the temperature of this element during operation can reach 250ᵒС. If the room in which the stove is installed has a small area, then it is advisable to make the upper part of the structure removable for more convenient cleaning.

What objects can be heated by a miracle stove?

Modern stoves that use diesel fuel as fuel, regardless of their shape and design, are capable of heating various rooms. They successfully cope with the task of maintaining comfortable temperature conditions in the following buildings:

- suburban buildings that do not have supplied communications;

- separate rooms of residential suburban buildings;

- additional country buildings (sheds, outbuildings);

- outbuildings, basements, basements;

- garages, workshops;

- stand-alone greenhouses and hotbeds;

- they can heat individual tents and campgrounds.

Precautions

The use of homemade stoves on diesel fuel is always associated with the presence of an open fire. Therefore, certain precautions must be taken. They will allow you to avoid many troubles and even tragedy.

Garage stove

These precautions are fire safety measures:

- the stove must not be installed in places where drafts are possible (they contribute to the activation of the combustion of the mixture);

- it is necessary to create a space around the stove (approximately 1.5 meters), free from combustible and flammable objects (especially this must be provided in a garage or workshop);

- provide access to a fire extinguisher;

- chimney length must exceed 4 meters;

- after using the stove, it is necessary to clean and prevent it;

- for residential premises, it is advisable to use factory-made diesel fuel stoves that have special permits.

How does it work

The main physical principle on which almost all diesel stoves work is the principle of converting combustion energy into thermal energy. Diesel fuel usually flows by gravity into the chamber, where it mixes with air and is heated. This mixture then enters the combustion chamber.

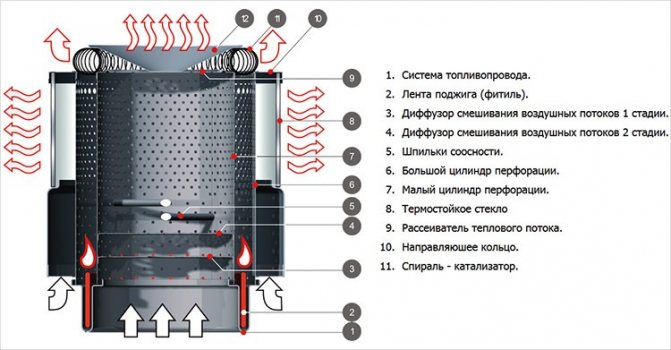

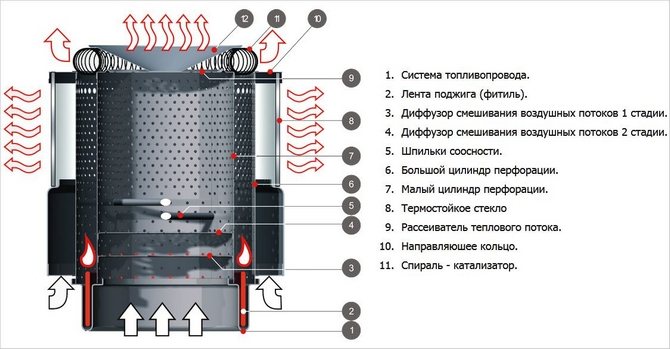

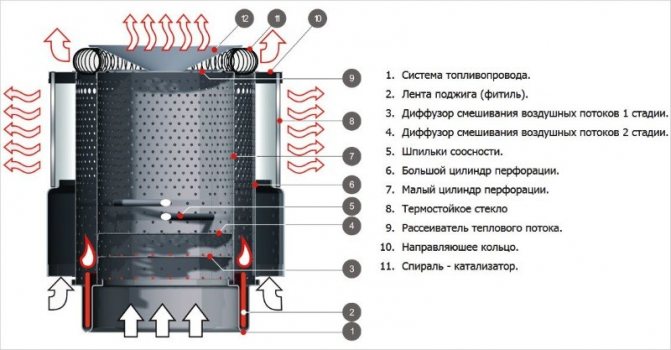

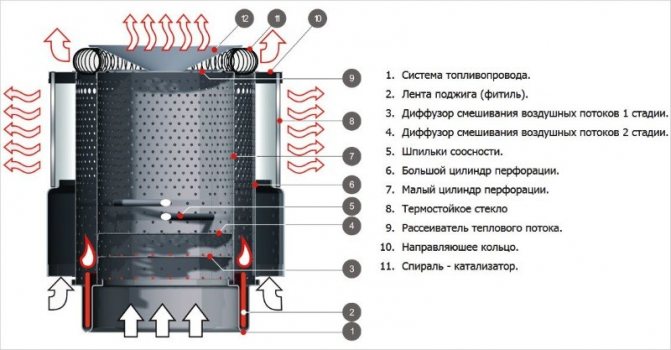

The device of the miracle oven

In this chamber, when it burns, it heats either the walls or a special heating element that serves as a heat exchanger. Combustion products are discharged through a special chimney to the outside. In addition to the stove itself, such a chimney also serves as a heat exchanger and heats the ambient air in the room.

Metal sheet stove

In short, it looks like two large canned food or discs connected by a pipe with many holes and a pipe for exhausting combustion products at the top. The device consists of two containers connected by a large-diameter pipe (wick bowl) with rows of holes for air intake and flue gas outlet.

Kerosene or diesel fuel from the fuel chamber enters the wick container by gravity. There the fuel heats up - a gaseous mixture is obtained.It goes into the combustion chamber and burns there. A spiral is placed in its upper part, it acts as a heating element and heats up to 800 ° C, combustion waste is removed through the chimney.

A self-made device can be compact in size and has a high level of safety. It is very economical: the fuel mixture and combustible compounds burn out completely. You will need metal sheets with a thickness of 5 mm or more. The pipe has 2 elbows, nested into each other, and is located far from the door. The lower container serves as a firebox and at the same time as a fuel tank; it has an opening for filling fuel. An average such device holds about 2–12 liters of diesel fuel.

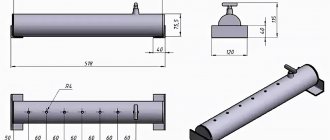

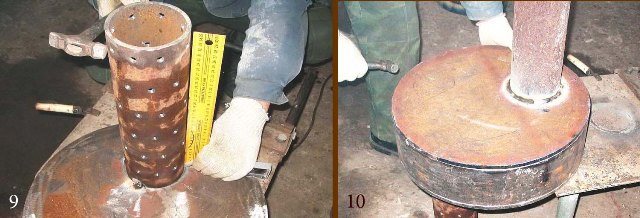

Pipe and branch pipe

A hole is created in the upper segment of the structure, a door is attached to it. With its help, the operation of the apparatus will also be adjusted, the supply of air in the required amount, and the force of combustion will be controlled. The pipe and the upper part serve as heating elements. They are capable of heating up to 800 ° C. A branch pipe is welded to the upper part, a chimney is attached to it, which is made of galvanized steel. The top can be detachable for easy cleaning.

The bottom of the top segment is created from a 6 mm sheet of metal. A round piece of 35.2 cm is cut out of it. A 10 cm hole is made on it, not far from the edge. Between the middle of the circle and the hole there should be about 11 cm, where the pipe and the hood will be inserted. A branch pipe is a piece of pipe 13 cm long and 10 cm in circumference.A rectangle 7 * 33 cm is cut from the same sheet of metal.It will be a partition, it is welded to a 35.2 cm circle closer to the 10 cm hole. An exhaust pipe is inserted into it.

Burner tube and exhaust pipe

Next, make a pipe for the burner. At the bottom of it, at a distance of about 36 cm, a 48 hole of 9 mm is made. There will be 6 rows of 8 pieces each. The distance between them is 6 cm. This pipe is inserted into the fuel tank cap, it is made from a sheet of metal 4 mm. It should be fixed evenly and tightly, it does not need to be welded. With a grinder and a file, it can be adjusted for the tightness of the connection.

A hole is also made in the tank for an exhaust pipe 16 cm long. The top and bottom of the tank are connected, but not welded. The details just fit very tightly. A ring is put on top for a seal with a diameter of 35.4 cm. The fuel tank is welded to the pipe with holes. You also need to make a damper for the hole for filling with diesel fuel, like the one on the door peephole. At the bottom, four legs are welded from the corner.

Do-it-yourself stove design

For independent design, it is necessary to have minimal knowledge in the field of thermodynamics (in order to understand how the formation and combustion of a combustible mixture of diesel fuel and oxygen is carried out), to be able to understand elementary drawings. It is desirable to have the simplest skills in the field of processing ferrous and non-ferrous metal (cutting, drilling and welding technology). If you don't have such experience, you can always contact a specialist.

A diesel fuel stove with your own hands can be made in a garage, home workshop.

Construction from a conventional gas boiler

Elements of an old gas boiler can be used as a body. The boiler body must be cut into two halves. One will be the bottom of the stove, the other will be on top. The nozzles available in it must be expanded in order to ensure free supply of diesel fuel to the mixing chamber and further to the combustion chamber.

Homemade stove from a gas boiler

The duct system can be converted into a chimney. It remains only to place the diesel fuel tank and the stove is ready.

Gas cylinder heater

An unused gas cylinder can be used as the body of the future stove. Before using it, you need to make sure that it is empty. In addition to the cylinder, you will need two pipes with a length of about 4 meters and an outer diameter of about 100 mm, a container for storing diesel fuel (on average from 10 to 15 liters), two copper pipes (for the production of a burner). The support should be made from steel corners with a 200mm shelf. In addition to the material, you will need tools: a drill and drills for metal, a grinder (grinder) with cut-off wheels, any welding machine.

Using a grinder, the cylinder is cut into two equal parts. The upper part will be the cover of the future stove, the lower one will function as a combustion chamber. For the stability of the entire structure, metal corners are welded from below, which are the legs of the future stove.

A hole is made in the upper half. An exhaust pipe will be installed in it. It must be welded securely. Make sure that it is located strictly vertically. A hole is made in the pipe. It functions as an air intake regulator.

Having departed from the pipe about 10 cm, make another hole up to 3 mm in size. There should be at least ten such holes. The latter should be at a distance from the welding point no more than 50 centimeters. In addition, a hole with diameters up to 8 centimeters is prepared in the upper part for pouring diesel fuel. A hole 5–8 cm in size is made in the upper part of the cylinder for filling the fuel.

Drip stove

They are quite economical and easy to manufacture. For example, to obtain a power of 10 kW, a diesel fuel consumption of only 0.6 liters per hour is required. By increasing the size of the structure, the heat transfer power can be increased to 20 kW.

The technology of manufacturing a dropper stove on diesel fuel does not present any particular technical difficulties. First, the dimensions of the future unit are calculated. The calculation is based on the following considerations. For heating a room with an area of 9 sq. m, there will be enough stove, the dimensions of which are equal to 30x30x45 cm. These dimensions allow you to calculate the volume of the stove itself. Most often, they use ready-made structures and not necessarily rectangular. For small stoves, the lower parts of fire extinguishers are used, for more powerful stoves, the bottom of metal barrels is used.

The supply of diesel fuel is organized using elements of a medical burner. The rubber hose present in it is fixed on a specially prepared copper tube. This tube is bent at right angles. Then it is fastened with a clamp or a specially prepared fastening. As a wick, you can use an improvised rag, which is pre-impregnated with diesel fuel.

Homemade stove dropper

The principle of operation of such a stove is to constantly wet the wick with diesel fuel, which flows by gravity through a hose and tube from a container with diesel fuel.

A door is made in the stove body, and a hole is made on top for a copper tube.

Steel sheet stove

It is shaped like two metal discs. There is a steel pipe between them. Several holes have been drilled in it. They are designed to supply external air from below and remove harmful combustion products.

Typically, such a unit has a fairly compact size. The specifics of the design make it safe enough. Another advantage of such stoves is their efficiency. This is due to the fact that the fuel mixture burns out completely and the most efficient heat transfer occurs.

For the manufacture of such a furnace, you will need sheet steel with a thickness of at least 5 mm, a steel pipe. It needs to be cut into two shorter pipes and two bends made. They must be made in such a way that it is possible to insert one into the other. After connecting these elements, a chimney design is obtained. I make two containers from steel.One, the lower one, serves as the firebox of the stove itself, the second upper one is the fuel tank. The size of the tank is determined by the manufacturer himself. Usually its volume does not exceed 12 liters. This is due to the convenience of pouring diesel fuel.

The location of the tank above the level of the combustion chamber is based on the principle of diesel fuel supply. It flows by gravity. In a special chamber, diesel fuel is mixed with air and heats up. Thus, a combustible mixture is formed. Further, the combustible mixture enters the combustion chamber. In it, during combustion, the spiral heats up. This coil acts as a heating element. With proper operation, it heats up to a temperature of about 800 ° C.

Making a diesel fuel stove with your own hands

Typically, the design consists of two tanks connected to each other using a perforated pipe. The lower tank is intended for primary combustion and evaporation of the fuel, while in the upper tank the vapors burn out. Openings in the connecting pipe provide fresh air intake. The natural supply of oxygen is due to the strength of the chimney draft.

Details about the principle of work

First, oil is poured into the tank, which is ignited with a homemade torch. After the oil warms up, part of the substance evaporates from its surface and enters the upper reservoir, where it burns out and additional heat is released. Oxygen is required for combustion in the lower tank, which gets inside through the throttle valve, with its help they regulate the power of the stove, without disrupting the combustion process itself.

Gases from combustion move through a pipe with holes, enter the second chamber, from there the combustion products are thrown into the chimney and leave the structure outside. For combustion in the upper tank, oxygen is supplied through the holes in the pipe and, together with the gas, flows upward. In some cases, the upper tank is made in the form of an incomplete partition at the junction of the outlet from the chamber and the horizontal chimney, but such a temperature jump is necessary, otherwise the hot vapors will simply leave the outside air without giving off useful heat.

The popularity of such a homemade diesel garage stove arises from its simple design, which is easy to do with your own hands. Almost any metal from the subsidiary farm is used in the manufacture. The stove heats well, the disadvantage is an unpleasant smell, so living rooms cannot be heated in this way, you can get poisoned with nitrogen oxides.

Safety engineering

Homemade oil ovens have an increased fire hazard. Each owner who decides to install such a structure assumes full responsibility in the event of a fire. A fire occurs if moisture (water) gets into the fuel, because of this, small explosions-pops appear in the pipe with holes, which can reach a certain force. Because of this, hot oil splashes are splashed through the holes, igniting the surrounding objects and materials.

Operating the stove on diesel fuel and oil in a private courtyard nullifies all provisions for insurance against fire, explosion and volatile gas poisoning, and the owner is automatically found guilty of any consequences after the accident.

The dangers of diesel and oil vapors should be mentioned in more detail.... The smell from them comes from an unpleasant, but this is their easy side, it is much more difficult to deal with their carcinogenicity and toxicity, or rather, impossible. The design is completely unsuitable for residential premises, and in places where animals are kept, only industrial production of liquid fuel heaters with accompanying documents is allowed. At the same time, the conditions for keeping livestock or poultry are taken into account and certification documents for the unit are issued for the oven for operation in precisely such conditions.

In the manufacture of a diesel stove, the principle of operation is studied and the design is made based on the recommendations of specialists.Diesel fuel belongs to volatile substances, and it is impossible to use a gravity burner with regulation of the oxygen supply by a throttle in the case of using diesel fuel. In this case, the adjustment is insufficient, and the fuel in the tank boils over the entire mass, and everything ends in an explosion.

Features of operation

When operating diesel furnaces on liquid fuel you need to know the following provisions:

- after reaching a temperature above 900 ° C, nitric oxides are actively formed, their concentration becomes maximum;

- at high temperatures, excess oxygen in the mixture of gas and air reacts with heating particles, and nitrogen oxides slip further along the chimney;

- when a temperature of about 600 ° C is reached, the oxidizing ability of nitric oxides is noticeably activated, it exceeds that of oxygen, therefore, nitrogen oxides participate in the oxidation of unburned fuel particles, as a result of which harmless substances (carbon dioxide, hydrogen and nitrogen) appear;

- If the temperature in the furnace decreases and becomes at the level of 400˚С, then nitric oxides are not able to oxidize unburned fuel particles, therefore they actively go outside and poison the air in the room.

The store bought a diesel oven for use in the summer kitchen in winter. We are there only during the day, preparing food. We cook on an electric stove, and for heating we use a heater with diesel fuel. The smell is there when firing up, then it somehow disappears. Of the convenience, we can note a special heating grid, on which the prepared dish remains hot and does not need to be additionally reheated before serving.

Larisa Petrovna, Nizhnevartovsk

I made a similar unit with my own hands with the help of workers. I am a private entrepreneur; in winter, workers repair spare parts in a hangar, the walls of which are made of OSB sheets. We use the stove, into which we fill the waste oil (fortunately, we drain an incredible amount of it from the car parts brought for repair). Well, what can I say? It is unprofitable to make other heaters because of the free oil, so we came to this decision.

The hangar room is at a normal temperature for work, about 15 ° C, all combustion products are removed by means of a pipe, there are options for ventilation with the help of opening window sashes. The pipe has to be cleaned every week, it is removable, so it is easy to maintain. The smell, of course, is, but as without it, especially since the work is only 8 hours a day. The joints of the walls are not sealed, the inflow of fresh air goes through the cracks. So far, this is the only possible option and there are no complaints from the workers, but I am not in a pocket. For the manufacture, a thick stainless steel was used, a pipe diameter of 200 mm, holes with a diameter of 15 mm.

Ivan Petrovich Lysenko

I use a purchased miracle stove in the country, I bought it with a built-in fan. I use it in the garage to service the car. I often don't go to the dacha, so I use it to quickly warm up when visiting, the stove heats up quickly enough and the warm air immediately mixes in the right direction (usually on me). You can also change spare parts in the car, see the electrician. Unlike an unheated garage, it is heaven. Although I tried to measure the air temperature after an hour of burning, it shows 13 ° C, as if cold, but normal for work, all the time in motion.

Drovchenyak Anatoly Igorevich, Belgorod