Heating devices that generate heat due to the combustion of fuel are not able to work normally without a chimney or simply a chimney. Through the chimney, toxic combustion products are discharged into the atmosphere, which are dangerous to human health and life. However, together with the exhaust gases, a rather large amount of useful heat is carried away into the chimney, which could still serve to heat the premises. In order to prevent precious heat from leaking into the chimney, a special heat exchanger can be installed, which significantly increases the efficiency of the heat generating device.

Principle of operation and design

Currently, there are different options for chimney heat exchangers, the design and principle of operation of which are generally similar. The heat exchanger consists of a hollow body with inlet and outlet pipes. A "brake" mechanism is mounted in the casing for the exhaust gases. Typically, this is a system of axle-mounted notched valves. The dampers can be rotated, creating a zigzag chimney of different lengths. Adjusting the valves makes it possible to set the most effective ratio of heat exchange and draft in the chimney, while not violating safety standards during operation. There are also simpler models of heat exchangers, without a variable valve system.

The need to install a heat exchanger on the chimney and the principle of operation

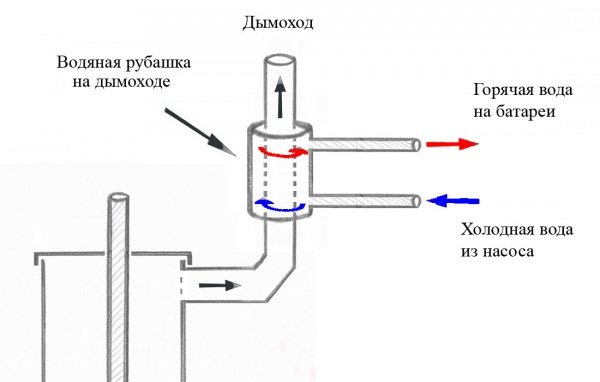

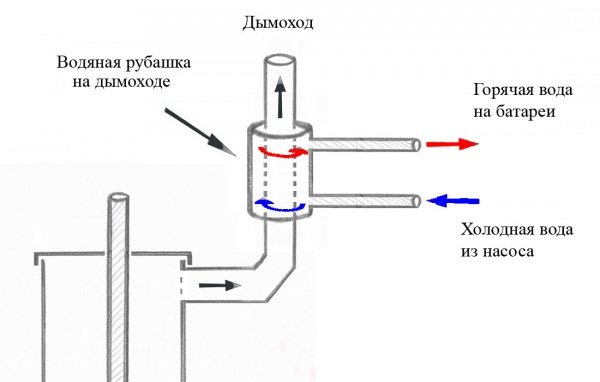

So that warm air is not wasted, a heat exchanger is mounted on the chimney

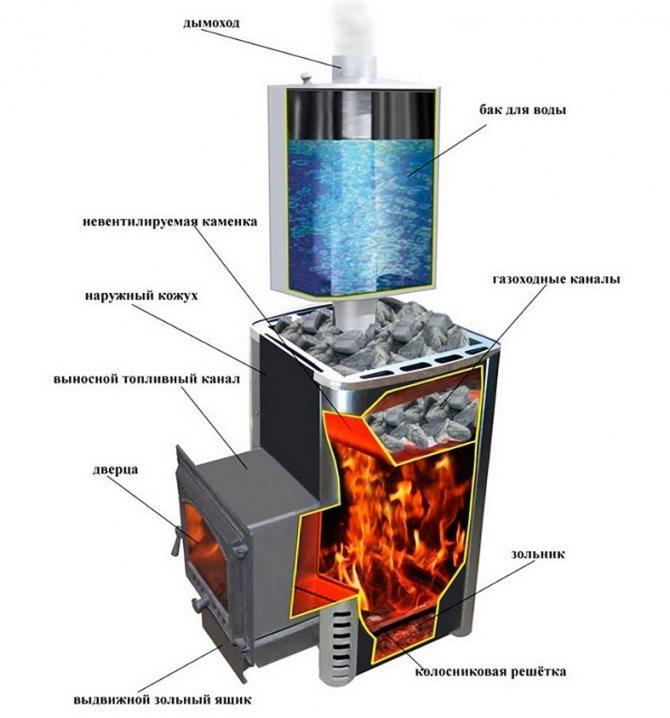

Modern sauna stoves are designed so that devices can reach the maximum temperature inside the firebox in a short time and keep it at this level for a long time. During operation, a significant amount of unused heat escapes through the pipe from the chimney. Heat energy of such a plan is suitable for heating water or heating rooms located next to the steam room. It is best to use the heat that is released during the combustion of wood and supplement the device with a factory or home-made heat exchanger. Such elements for heating water are divided into three types:

- coil for a standard chimney built into the inside of the heater;

- a heat exchanger for an external chimney, heated from the furnace wall;

- a water circuit that collects heat energy from flue gases.

The coil is built into the firebox and positioned so that the tube is not exposed to direct flame. This element must be placed in the path of the outgoing combustion products, in which case it will serve as long as possible and will not start to burn out. In structures of this type, the water will heat up quickly enough, but at the same time the device will begin to reduce the power of the device for heating. The device for outdoor use is simple in design and affordability, but it is not very easy to maintain and requires constant replenishment of water supplies. Such tanks are suspended from the sides of the firebox and heated by infrared radiation from it.

The best option is considered to be sauna category stoves with heat exchangers on the chimney, which are flow-through heaters with a capacity of 5-10 liters. To an element of this type, you can attach a part with a remote storage, the volume of which ranges from 60-120 liters, taking into account the power characteristics of the device. During the heating process, the water inside the tank reaches the required temperature.

What material should be used

It is better to make a heat exchanger for a chimney from food grade stainless steel. Even at high temperatures, the physical parameters of this metal do not change, since the welds are quite strong, and nickel, when reacted with oxygen, creates a protective film that is resistant to acids and salts.

If we talk about the use of zinc, then when heated to 200˚C, it begins to evaporate, and at 500˚C, the concentration of vapors in the air reaches a critical level for humans. But if you have installed galvanizing on the device, and at the same time it does not heat up above 200˚C, then you do not need to worry. And you can use galvanized material, since it enhances the mixing of the air around the device. And although such a heat exchanger is not provided for constant heating of the room, but in order to quickly warm up, for example, a bath or an attic, this is a suitable option.

Self-installation of the heat exchanger is quite easy and simple. This device can be mounted on an ordinary stove and then bricked, like the oven itself. Laying bricks can also be performed on the edge - the stability of the structure will not suffer from this.

Purpose and features

The heat exchanger is designed to take heat from the heated air circulating in the chimney. The design of the device depends on the diameter and shape of the chimney, the material used to create the heat exchanger, the power of the heat-generating device and the heat carrier.

Heat exchangers are classified, depending on the heat carrier, into liquid and air. Air-type devices are the easiest to manufacture, however, they are not the most effective. Such devices require better material and performance, but are more efficient than devices with an air coolant.

Types of heat exchangers

During the selection of the described device, you can find products of various types. Coil-shaped heat exchangers are most commonly used. Corrugated devices are also popular. In addition, many people use products in which air acts as a coolant.

By the type of heat carrier, almost all devices can be divided into those that use air and products that heat water. Devices of the first type have a simpler structure, but are less efficient.

If you wish, you can create a heat exchanger for installation on a chimney with your own hands. This will require tools such as a grinder and a welding machine.

Liquid heat exchanger

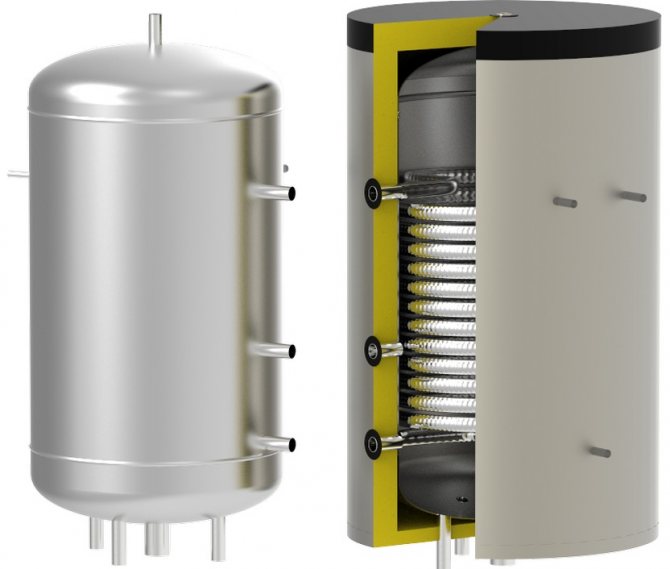

The standard heat exchanger used with heat transfer fluid is a metal coil with a high coefficient of thermal conductivity in direct contrast to the inner surface of the chimney. For better heat exchange and safety, the coil is placed in a metal case and well insulated from the inside with a non-combustible insulation, usually basalt wool.

The entire structure is mounted on the chimney section. The ends of the coil are led out through the body of the heat exchanger and connected to the heating system, at the top of which an expansion tank is placed. Annealed copper tubing is best for making the coil. In addition, such a heat exchanger, due to its high coefficient of thermal conductivity, will have dimensions 7 times smaller than a device made of steel.

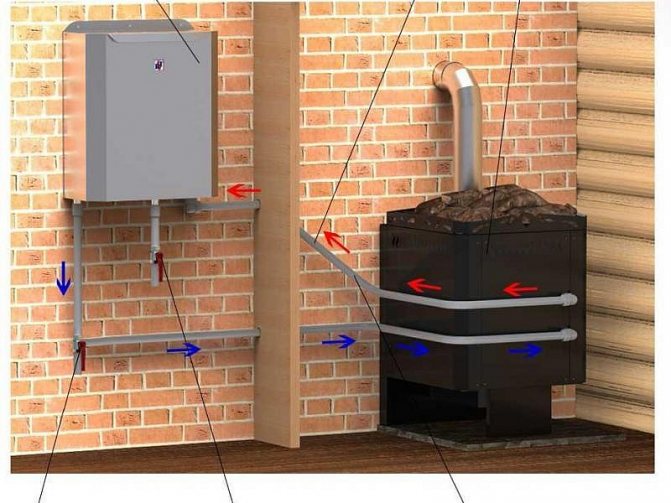

The liquid heats up, and, expanding, rises along the coil, after which it flows through the pipe by gravity to the heating radiator. When it enters the radiator, the heated liquid displaces the cold coolant, which heats up again in the coil. Thus, the natural circulation of water through the system is carried out.To create a circulation of the coolant through the system, it is required to accurately calculate the length and diameter of the coil, maintain the angles of inclination of the supply and return, and much more. The significance of these calculations should not be underestimated, since an inoperative device is simply not as bad as the consequences of a water hammer that can occur when the coolant boils.

However, this type of heat exchanger also has its drawbacks, namely:

- the complexity of calculations and manufacturing;

- constant monitoring of temperature and pressure in the system;

- high flow rate of the coolant caused by the evaporation of liquid from the expansion tank. And if water is used, then if the system is not used in the winter, the liquid must be drained;

- a significant decrease in the temperature of the exhaust gases, which can cause a decrease in thrust and incomplete combustion of the type of fuel used.

However, despite these shortcomings, such a heat exchanger can be made independently by any person who knows how to handle the instrument and has at least school knowledge of physics.

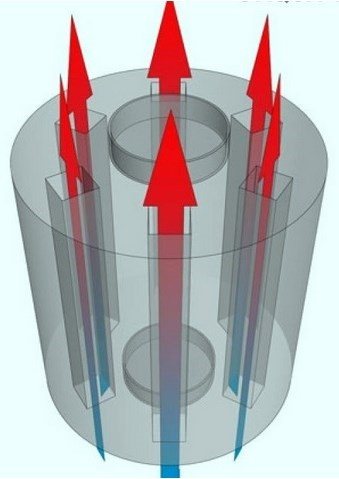

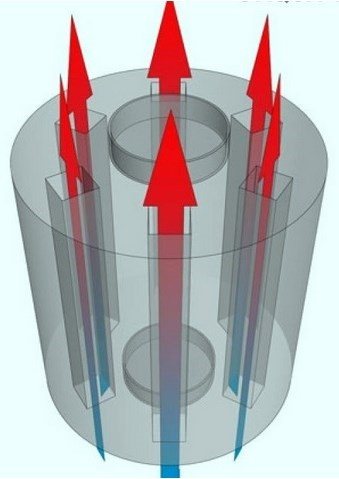

Air heat exchanger

A similar structure, which is installed on the chimney of a heat-generating device, as a rule, consists of a metal case, in which several inlet and outlet pipes are mounted. The principle of operation of this type of heat exchanger is quite simple.

From below, according to the principle of convection, cold air entering the nozzles, after heating, leaves the upper part of the heat exchanger directly into the heated room. This principle of operation makes it possible to significantly increase the efficiency of the heat-generating device and reduce fuel consumption by 2-3 times.

It is quite simple to independently make a heat exchanger for a chimney, having a welding machine, a grinder, metal pipes of various diameters, desire and ability to handle the tool.

Material:

- metal sheet 350x350x1 mm;

- a pipe with a diameter of an inch and a quarter and a length of 2.4 m;

- a piece of pipe with a diameter of 50 mm;

- metal container or 20 l bucket of engine oil.

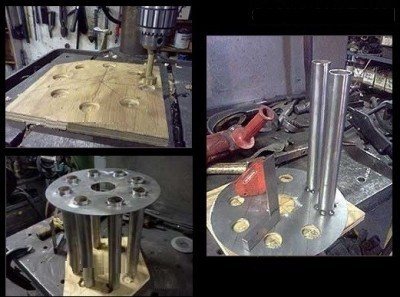

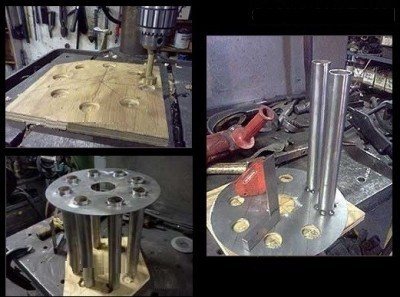

Manufacturing:

- create end parts, for which you need to cut circles from a sheet of metal. It is necessary that the diameter of the plugs corresponds to the diameter of the container prepared in advance;

- in the middle of the plug, a hole is cut out for a 60 mm central pipe;

- mark and cut an inch and a quarter pipe holes along the edges of the circle;

- there should be two such circles;

- cut a pipe with a diameter of 1¼ with a grinder into 8 equal pipes approximately 30 cm long;

- weld a 300 mm piece of pipe with a diameter of 60 mm to the central hole of the plugs;

- weld 8 sections of 1¼pipe around the circumference;

A similar construction should come out

Next, you need to make a heat exchanger body from the prepared container. This will require:

- cut the bottom of the container with a cutting machine;

- make a hole in the center from the sides of the body along the diameter of the chimney;

- it is necessary to weld pipes of the corresponding diameter to the side holes of the body;

- Insert the prepared core into the housing and weld it to the casing. The finished structure must be painted with heat-resistant paint.

Now you need to install the heat exchanger on the chimney pipe and enjoy the warmth.

You can also watch the video of the whole process of making a heat exchanger with your own hands.

How to make a homemade chimney convector to heat the air? (+ detailed video)

To create the simplest convector that will improve air heating in the same room where the boiler is located, you will need:

- Welding machine.

- At least 8-10 thin steel tubes with a diameter of about 32 mm and a length of about 50-60 cm. Ideally, take food grade stainless steel. Worse, but also galvanized steel will do.In shape - usually take round tubes, but square or rectangular sections are also suitable.

Installation is carried out as follows: these pipes must be welded in a circle around the chimney, as close as possible to the firebox.

Overview of Furanflex polymer chimneys: characteristics, pros and cons

How to clean the chimney from soot with potato peelings?

Similar posts

Trumpet on Tin

This type of heat exchanger is quite practical and simple. Basically, the chimney is wrapped in a metal or copper pipe, which heats up constantly and the air moving through it quickly becomes warm. A spiral can be welded to the chimney using semi-automatic or argon welding. You can also fix it with tin, having previously degreased the chimney with phosphoric acid.