Fireplace in the bath: what is it and why is it needed?

Well, it is quite simple to imagine a bathhouse and a fireplace separately. Together, they mean that a stove designed to heat the steam room and create the conditions for your favorite type of bath can, among other things, also be a decoration. To do this, it is enough to abandon the solid metal door to the firebox, replacing it with a glass one.

Video in the topic

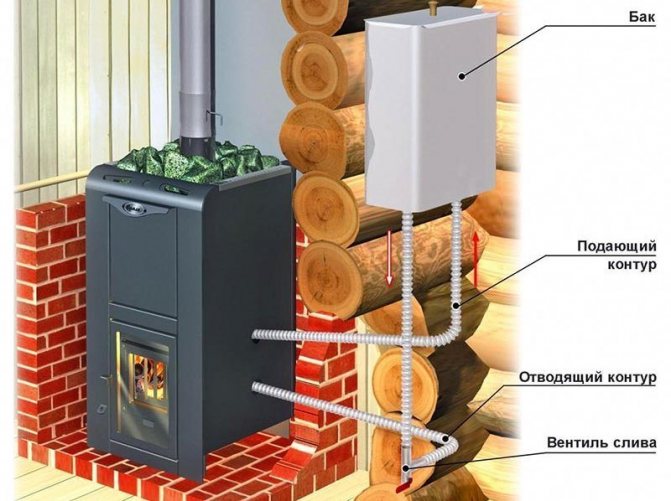

This is how it may look with a metal stove and a firebox with a fireplace door brought out to the recreation room, you get a fireplace in the bathhouse:

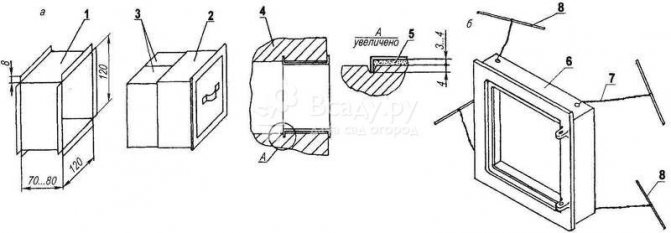

As for such a door, it is metal frameinto which is inserted single or double glazing with special heat-resistant glass... The frame can be made from either becomeor from cast iron... If desired, you can supplement it with forged elements.

However, you should not consider the sauna stove-fireplace solely as a decorative element. The practical application of the transparent door is the ability to visually control the combustion process.

In addition, the door limits convection from the side of the firebox, not allowing heat to escape with the air currents. At the same time prevents sparks from entering the room, which increases fire safetyb. Together with sparks, smoke and soot cannot penetrate.

Alternatively, you can consider the presence in the bath two heaters simultaneously - stoves in the steam room and a separate fireplace in the recreation room. It is cost effective for large baths.

Criteria and distinguishing features

In order for the assembled heating installation to fully justify itself, before proceeding with its installation, we suggest that you familiarize yourself with the main criteria and requirements for such furnaces:

- Full compliance with all fire safety standards and requirements;

- Correct and serviceable work to ensure safety for life and health;

- Economical fuel consumption;

- The ability to manually adjust the power level of the combustion of the flame in the hearth;

- The dimensions of the fireplace must have the correct ratio of the area chosen for the installation of the room;

- The design is based only on strong, durable and environmentally friendly materials;

- With regular use, the premises are warmed up quickly and evenly;

- All main structural elements must have a convenient location for operation and use;

- The appearance and execution are in harmony and intersect with the overall design of the room.

Steel variations heat up quickly and also cool down quickly

Brick models take longer to heat up and for a few more hours are able to release accumulated heat into the room

A homemade design is simultaneously located in the living room and the bath on the other side

Interesting to know: a sauna stove, a fireplace can be designed as a simple heater or a steam generator. In this case, materials such as bricks and metal are used to assemble the structure. The most modern variations include installations that simultaneously combine the features of a fireplace and stove. This option can be assembled with your own hands, or purchased in an already fully assembled state in a specialized store.

Important: the models with a closed hearth have always been considered the safest and at the same time effective. They are characterized by a higher efficiency and full compliance with all fire safety standards and requirements. In order for the unit with a closed firebox not to lose its attractiveness, we recommend giving preference to devices with a ceramic or glass door (heat-resistant glass).

Sauna stove: selection criteria

Let's dot the I.Nobody chooses a stove for a bath because of the beauty of a fireplace insert.

IMPORTANT! First of all, you should target correspondence between the type of oven and your favorite vaping modes: is it a sauna or a Russian bath.

The second equally important criterion is correspondence of the furnace power to the volume of the steam room.

The third criterion is Type of fuel. And here it turns out that the aesthetic pleasure of contemplating burning wood in the fireplace may well outweigh the rational desire to minimize labor costs for taking care of fuel. There will be much more fuss than with gas, and even more so with electricity. But the fire in the stove looks so great! And everyone in the kitchen has seen enough of a gas burner for a long time). Other pros and cons of wood-burning, electricity and gas-fired sauna stoves are presented in the relevant articles.

On our site there are very informative articles that highlight every nuance of choosing a stove, depending on the selected bath mode and other circumstances. I don't want to repeat myself, so we recommend going through the articles.

- Features of stoves for a Russian bath;

- The best stoves for a Russian bath;

- Types of stoves for the steam room: wood, gas, electricity;

- Wood-fired sauna stoves,

- gas

- and electrical.

There are still a couple of specific questions that are specific to fireplace insert. Let's start with what it is most often done remote - few people are eager to admire the flame in the steam room. But from the rest room or (if there is none) from the dressing room is a completely different matter. The question of which room the stove is fired from is automatically resolved.

Wood-burning stoves for baths

Further clarifications concern glass.

Screen size"

If we compare a fireplace with a TV, then the first thing that draws attention to is its diagonal. Fireplaces with transparent doors may be standard, that is, do not differ in size from solid metal, but there are also fireplaces for a bath with large glass... The latter is usually given as a modification to a specific furnace model. In other words, the choice is limited by what the oven manufacturer has. Those who have decided on the model should to clarify the possibility of completing a large-format fireplace door.

BTW! But if the stove is made of brick, then the dimensions of the fireplace portal entirely depend on the taste of the owner. You can make a door of any shape and size. Including double-leaf.

Glass types

Not all glass is suitable for a fireplace in a bath - if you put even an ordinary heat-resistant one, then it will not withstand the heat of the firebox. Therefore, either quartz glassor borosilicate ceramics... Below we will analyze this in detail. For now, it is enough to focus on the price.

Take into account! Borosilicates are cheaper than quartz glass and are somewhat inferior in strength characteristics.

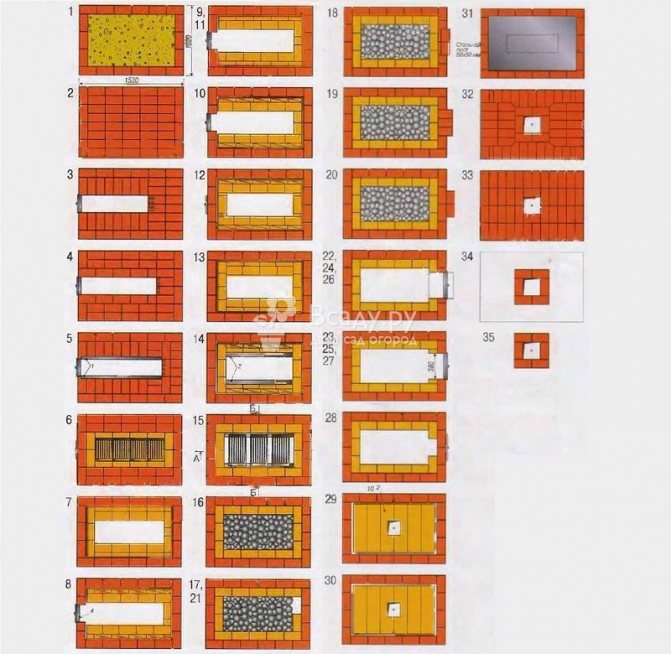

Operational features of brick ovens

A brick stove is an effective heating system for a private house and a bath, which is being built with your own hands. Such a device has a low efficiency (does not exceed 75%) and an attractive appearance. A heat-resistant glass damper is used to protect the portal.

Brick fireplaces in the bath are made to order or erected with their own hands.

Heating devices for a bath with a fireplace insert are complex functional systems that require a professional development of a construction project and adherence to brickwork technology. In addition, they require the arrangement of the foundation foundation.

We suggest that you familiarize yourself with How to make a waste oil oven

A brick fireplace stove has a number of advantages:

- a wide range of different designs, with an open or closed firebox, as well as different variants of the heating system (air or liquid);

- the wooden structure fits neatly into the interior of the private bath, contributing to the creation of a relaxing environment;

- heat-resistant brick has good performance characteristics: fast heating, slow cooling, resistance to destruction;

- low noise level when using the device.

Brick fireplaces for a bath can be used not only for heating, but also for cooking, adding some design changes.

More about glass in a fireplace stove for a bath

All glasses are silicates in composition. but composition may vary, significantly affecting the mechanical properties of the glass. In addition to the composition, the strength and heat resistance can be affected by processing, for example, hardening.

Material and characteristics

Let's go back to the two main categories of glass that are placed in fireplaces for a bath.

Borosilicates

Silicon oxide is the main component of any glass... In addition to it, the composition usually includes soda and limestone... To increase resistance to extreme temperatures (minus, by the way, too), they also add boron oxide... Thanks to this additive, the glass can withstand temperatures from -80 to 500 degrees.

On a note! Borosilicate begins to soften at 525 degrees.

In addition to temperature inertness, it also has chemical resistance. And yet, do not test it with hydrofluoric and phosphoric acids, as well as heated alkalis. Borosilicate is also afraid of a sharp temperature drop.

By the way! Normal glass can break under the influence of temperature, scattering in numerous fragments. Borosilicates do not break like this - they form large fragments without sharp edges.

Quartz glass

This variety is able to withstand even higher temperatures. It is done pure quartz - in the form of sand, or a mineral of rock crystal and vein quartz. Now the production of artificial silicon dioxide has also been established. The melting point of quartz is 1400 degrees... In addition to silicon oxide, ordinary silica glass contains no additives, which is the reason for its high thermal stability and chemical inertness.

When melting the starting components, either transparent glass, or opaque... The only difference is in the presence or absence of gas bubbles, from which the material becomes cloudy and opaque. Of course, only transparent glass is placed in a sauna stove with a fireplace.

Characteristics

When choosing glass for a fireplace stove in a bath, it matters:

- thermal expansion coefficient... The lower it is, the better. It is especially low for pure quartz glass. Note that the next one depends on this parameter.

For your information! When heated, ordinary glass increases 30 times more than heat-resistant glass. This is a consequence of the presence of alkali metal oxides in it. In contrast, aluminum, boron and silicon oxides reduce expansion.

- heat resistance... The limit to which a fireplace door can be heated without destroying it. The range of 500-550 degrees can be considered acceptable - the glass must withstand these temperatures for a long time... When buying a stove or door, please note that with prolonged exposure to higher temperatures, the life of the glass becomes significantly shorter. (The dates themselves are indicated in the passport). Also, the manufacturer indicates the maximum degrees for short-term exposure... Depending on the number of layers in a glass unit, such a maximum can be 760 degrees or more 1000.

IMPORTANT! In order not to overheat the door, it is necessary not to overload the firebox with wood. Remember that a furnace operating at maximum risks not only with glass, it also turns the body metal into scale faster. You can keep the desired temperature even with using the pull - increasing it, you reduce the heating of the door.

- glass thickness. This parameter is important from the point of view of greater or lesser fire hazard. Usually taken 4-5 mm (this is quite enough), but it is possible to put a thicker glass with an aim for greater resistance to flame.

Other characteristics are additional options. For example, glass color, lamination, relief, engraving.

Technologies and popular manufacturers

Let's start with an important distinction: strained glass and heat-resistant - not the same thing. It is perfect different technologies. In the first case, ordinary glass is taken and quickly heats up to more than 600 degrees, after which it is just as quickly cooled by air on both sides.

This option is not suitable for a sauna fireplace.... Heat-resistant is glass with a specific composition, which was mentioned above. Moreover, the name “glass ceramics».

The production of glass ceramics has its own limitations. So you have to follow the rule about the impossibility of cutting, which is why the sheets are made of the size that will be used in the finished product.

Let's take a quick look at the main technologies.

Lamination - the glass is covered with a protective layer, which, when the base is destroyed, does not allow the fragments to separate from the film.

Toning - imparting certain shades to transparent glass. The meaning is mainly aesthetic, but it is also said that toning protects the eyes from excessive brightness.

Thermo-Rite

Most often, warm shades are used - yellow, orange.

For fight against soot, which settles on the inner surface of the door, was invented to apply a thin film of iron oxide, which leads to increased heating and automatic burning off of soot.

Increased strength - a task that has several solutions. There are technologies that use chemical reagents and surface polishing using open flame reflow, which ideally smooths out all possible flaws.

In our market, products of certain manufacturers are most often found:

- Schott Glas is the company that manufactures the brand Robax;

- CrossFire Cerama is a company producing borosilicates.

Installation and maintenance

- Since the door is a combination of metal and glass, the coefficients of thermal expansion must be taken into account. both materials... Recommended to be used as a spacer between them heat resistant cord.

Stove glass soot remedies

- It is also important to ensure that during installation the pressure of the metal on the glass was uniform over the entire area of the joint.

- It is not necessary to completely seal the seams., because this can cause the glass to crack.

- With regard to maintenance, it should be recognized that even the most modern technologies do not eliminate surface soot. I'll have to fight on my own. On sale you will find special means to combat soot.

Danger! In no case do not use abrasives and aggressive cleaning agents... Abrasives leave scratches, and chemical reagents (for example, chlorine) are terrible not for the glass itself, but for the protective films on its surface.

Advice! If you don't want to fiddle with cleaning a lot, choose drier firewood and non-coniferous wood.

How to do it yourself?

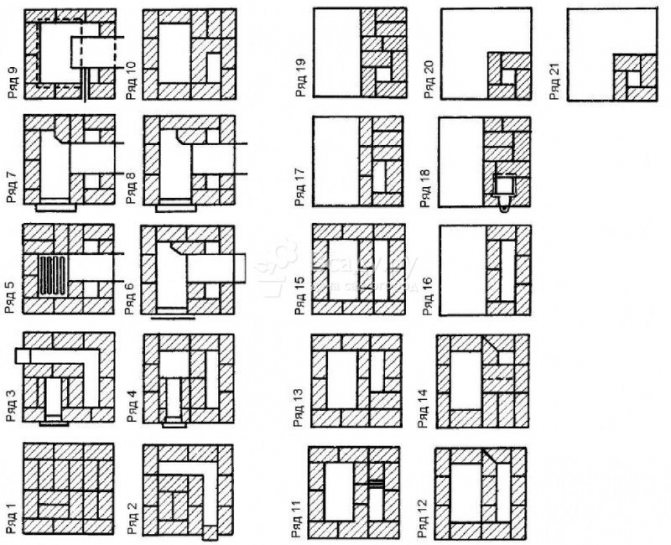

To fold a standard oven yourself, the first step is to choose a suitable brick. The material must be very tough, able to withstand high temperatures and be fireproof. The best option is considered to be a pale yellow brick based on refractory chamotte clay.

It should be borne in mind that it is an expensive material, therefore, when building a homemade stove, it is supplemented with solid red brick. For example, fireclay bricks are used for fragments that are exposed to the most intense heating, and a red hollow M grade with a number from 75 to 150 is used to cover the outer walls, smoke flows and decorative elements.

When choosing a brick, you should adhere to a few simple rules:

- When you hit a high-quality brick with a pick or hammer, you will hear a clear and clear sound;

- The brick must meet the standard parameters: 250 by 120 by 65 millimeters;

- High-quality material has no pronounced damage and defects, with the exception of filamentous cracks and grooves;

- If the brick has a "mica" film, this indicates a marriage.

To build a brick oven, you will need knowledge of block masonry and adherence to a single order. The first step is to equip a waterproofing layer at the base of reinforced concrete in order to cool the foundation. At the same stage, a sub-furnace is formed for storing inventory. Then, the preparation of clay and sand begins to connect the elements, because cement is not suitable in this situation.

Clay is thoroughly cleaned of stones and impurities beforehand and soaked for several days. It is recommended to take samples taken at a depth of 150 centimeters below the surface of the earth. Quarry or river sand is carefully sieved for pebbles or pieces of pebbles. After that, the clay must be stirred, diluted with clean water without a musty smell and combined with sand prepared in the same way.

When using clay with a high fat content, it is recommended to dilute it with sand in proportions of 1: 2. To check if the mixture is correct, use a wooden stick. It is dipped into the solution, and if the resulting layer has a thickness of 2 millimeters, then you can start working. Experts also recommend giving preference to the clay underlying the selected brick, that is, either red or fireclay.

In the next step, it will be necessary to lay out the brick blocks. Typically, this will require ordering, a square, pliers, a broom with a scoop, and an emery wheel. Each brick is pre-placed in water so that all air bubbles come out of the pores and so that dehydration of the mortar is prevented.

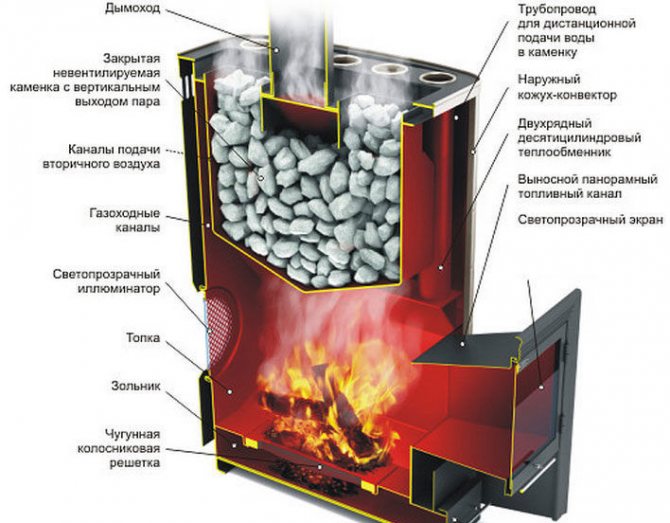

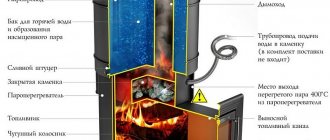

At a certain moment, the installation of the water tank, the stove, and, if necessary, the grate, as well as the fastening of the doors, takes place. Regardless of the method of masonry, the key parts remain the same: a refractory brick firebox, a chimney, a water tank and an ash pan, consisting of a cast iron stove, a firebox and a furnace.

Drying of the sauna stove takes place within 4-5 days with open windows in the room. After this period, you can begin to heat it with small chips 1 time per day, for a maximum of 10-15 minutes. As long as condensation continues to rise to the surface, the oven is not yet ready for full operation. If desired, after that, you can also carry out the finishing, for example, revet with tiles.

Bath with a brick fireplace

It was already mentioned above that freedom in choosing the size and shape of the fireplace door is possible only if the stove is brick, where the portal is made to the taste of the customer. The latter also decides where the firebox will go - into the steam room or into an adjacent room. but most often, a fireplace insert is made exactly if it is located in a room adjacent to the steam room - a rest room or (in its absence) in a dressing room.

Wood-fired sauna stove

Building a brick stove on your own is a rather difficult task. It is easy to find an order on the Internet, but in order for the stove to be suitable for specific conditions, you need to have the experience of a stove-maker. That's why we we advise you to start with something simpler and cheaper... The fireplace door, by the way, is also not cheap, and it weighs a lot. To put it, you need skill, but during operation you will not notice a lot of weight due to the convenient swivel mechanism (this applies to factory models).

Stoves for a brick bath with a fireplace (photo source: Yandex)

Video in the topic

Watch the video, which shows one of the possible solutions for a bath with a fireplace, moreover, with a classic portal, a shelf and a clock above it. However, the dimensions of the door are small and it is located asymmetrically - this slightly spoils the impression.

What is a fireplace stove

Sauna stoves with a fireplace are combined devices, the main distinguishing feature of which is the presence of a fireplace portal, either open or closed, for which a glass-ceramic door is mainly used. Such heating devices began to be used relatively recently, but very quickly gained recognition due to their improved technical and aesthetic characteristics.

What is their advantage over other types? Sauna fireplace stoves have the beauty of a fireplace and the efficiency of a stove.

They can be heated in two ways:

- From the dressing room.

- From the steam room.

The first option allows you to take the firebox outside the steam room and combine bath procedures with a pleasant pastime near the fireplace. Such devices are considered the most convenient and create comfortable conditions for a person, that is, they make his rest more complete. The second option is used less often, since the beauty of a blazing fire cannot be enjoyed for a long time due to the high temperature in the steam room.

Photo of a steel furnace with a built-in firebox (not remote).

A fireplace stove for a bath is a unique equipment for space heating, the design of which consists of a metal casing, a portal, a stove, an ash compartment and a chimney. To ensure long-term operation, such a stove must meet certain requirements:

- Fire safety;

- personal safety;

- air heating temperature control;

- compliance of the size and operating power of the device with the area of the room in which it is installed;

- quick heating of the bath;

- aesthetics and attractiveness of the design;

- economical use of fuel;

- practicality and durability.

Structurally, a sauna stove with a fireplace with a metal and brick casing are two different devices that are equally effectively used to heat rooms.

Sauna stove-fireplace: from which manufacturer to take?

Let's go back to the option of a purchased stove with a fireplace insert. Almost every large company that produces wood-fired sauna stoves offers customers modifications of models with a transparent fireplace door, for example, the cast-iron stove shown in the illustration from the Russian] Vesuvius [/ anchor].

Fireplaces for a bath, wood-burning metal, cast-iron Vesuvius and others

In another article, we have already done a review of various manufacturers of wood-burning stoves for baths, there is no point in repeating. If you find the oven to your liking, then there will certainly be an opportunity to equip it with a glass door. If desired (in the same article), you can refer to the results of our survey, the rating of which is formed by the same readers as you. We are an information resource, not related to sales, so we stick to the facts.

Let's briefly go through a few domestic producers, which definitely have the fireplace stoves we need for a wood-fired bath.

Feringer

The company needs no introduction, many people know about such rulers as "Steam", "Classic", "Baby"... They all fit for both Russian and Finnish baths (of course, any metal stove is suitable for a sauna, but not every one for a Russian bath). Take a closer look at the Feringer models - it will suddenly come up).

By the way! Firewood should only be well dried - in the stoves of this company grate is not provided, you need to kindle the firewood from above, so you can cope with the task only with dry woods.

"Kutkin"

Another name familiar to many. Quality ovens, however, are not inexpensive solutions. To reduce the cost, you can choose a model that you can tile yourself.The fireplaces we are interested in in this article are available for each model. The company's stoves are suitable for Russian baths.

"Termofor" and "Teplodar"

Termofor and Teplodar are domestic manufacturers, whose names are also well known. Everyone has stoves with two modes, with closed heaters and, of course, with fireplaces. Take a look at their websites about the parameters of these ovens.

Actually, we only mentioned domestic companiesbecause their products are quite competitive and somehow more tailored to Russian realities. This does not mean that foreigners are doing worse, but we have a lot of fans to steam "in Russian", and who better to know the national bath, if not Russian? And the prices are reasonable, despite the fact that many companies buy stainless steel abroad.

Wood-burning metal fireplaces for baths "Vira" and "Vesuvius"

However, the decision is always yours, we only express our opinion.

Initial stage of construction

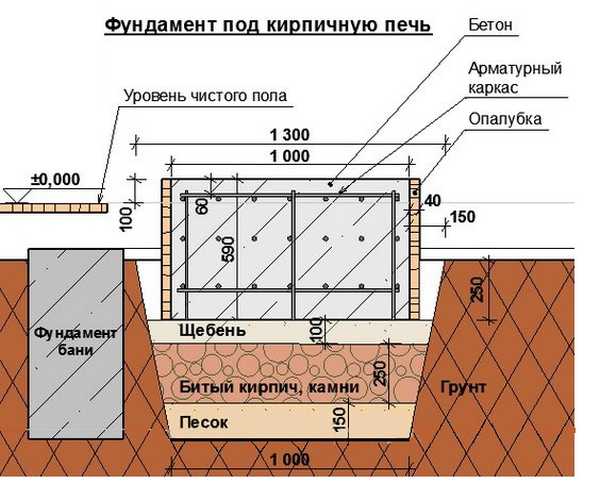

First of all, it is necessary to build a foundation. Since a sauna stove with a fireplace most often has a weight of about semitones, the foundation for it must also be massive. To do this, at the site of the future heating structure, you need to dig a hole for laying the foundation at least half a meter deep. Part of the space is filled with various construction waste, after which it is filled with cement mortar.

Laying the foundation for a brick oven

It is best to complete all the preparation in one day, so it is necessary to calculate in advance the amount of sand and cement that will be needed to fill the base. The proportions of the mortar are determined in the ratio of 1 part of cement to 3 parts of sand. After this, the base should be left to dry for a week and during this time the rest of the materials should be prepared. Also at this time, you can prepare a hole for the future chimney.

Do-it-yourself stove for a bath with a fireplace

The alternative to buying a furnace from a large manufacturer or ordering from a master still remains independent production... In principle, why not, if there is relevant experience?

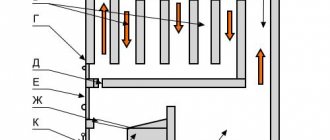

For our part, we recommend that you pay attention to the so-called "Kuznetsov ovens" - this is bell furnacesdesigned by Igor Kuznetsov for heating a house or a bath. There are varieties with fireplaces... The author's website contains ordering diagrams and other useful information on how to put a fireplace stove for a bath with your own hands.

Below we invite you to familiarize yourself with a couple of videos. The first is a good educational film about how to lay a Kuznetsov stove, but it is not for a bath, although the principle does not change.

The second video is about how a fireplace for a wood-fired sauna is made, there is useful information about the nuances of masonry and other secrets of the stove-maker's skill:

***

Well, we hope that soon a fireplace stove will appear in your bathhouse, which will not only warm the steam room, but also gather guests and household members in the recreation room by a live fire.

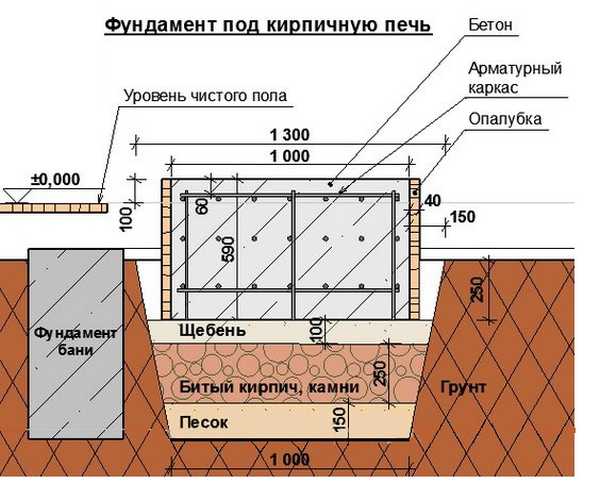

Foundation construction

The base for the fireplace stove must be laid even during the construction of a bath or sauna. But it is also possible when the foundation is being built in an already finished building. To do this, you will need to dismantle the flooring. Moreover, an important point is the distance between the floor and the base of the fireplace stove, which should be from 5 to 10 cm. If you neglect this rule, over time, cracks and fractures may form on your fireplace, which occur when the foundation of the house shrinks.

The first step is to mark the dimensions of the foundation in the place of the future location of the fireplace. And then dismantle the floor covering, going down to continue the marking. When you have precisely determined the location of the fireplace and the beginning of the laying of the basement, you need to disassemble the floor, reaching the basement of the bath.

Now the main work on laying the base of the fireplace will begin.

- In the resulting pit, be sure to cover the walls with polyethylene.

- We tamp the bottom of the pit well.

- We fill up the sand, making a sand pillow 10 cm thick.

- We carefully level the sand and tamp it well.

- We fill it with gravel with a layer thickness of 10 cm.

- We make formwork from the boards for pouring the foundation for the fireplace stove.

- We drive wooden blocks into each corner of the pit and wrap the finished formwork shield with plastic wrap.

- We make waterproofing with roofing material and dense plastic film.

- Using reinforcing bars, which must be laid with a small distance from the waterproofing layer, we create a reinforcing frame with a mesh width of 10x10 cm. The bars must be laid with some distance from the waterproofing layer, placing them on small pieces of brick.

- We fill our frame with a concrete mixture and cover the concrete with a waterproofing material and leave it for 3-4 weeks.

After the concrete has hardened, the base will be ready for further wall construction.