In many private houses, wood heating and stoves remain a priority. Someone has a metal stove, someone has a brick, but one thing unites them - this type of heating is not the most convenient. Too much attention and not enough comfort. Output - stove heating with a water circuit.

Stove heating with a water circuit - an opportunity to combine tradition and comfort

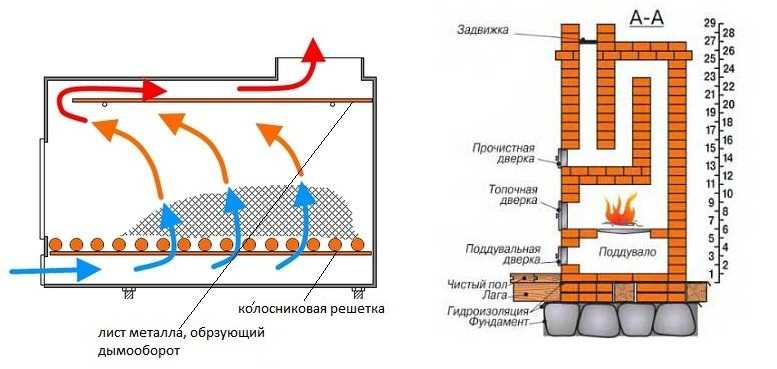

First, let's understand the terminology. When they say "stove", most often they mean a heating device made of bricks, which is fired with wood. But often this is also called a metal stove with wood or coal. The principles of operation for brick and metal units are the same, the method of heat transfer is changing. Metal has a greater convective component (most of the heat is carried by air), while brick is dominated by thermal radiation - from the walls of the furnace and heated walls of the house. In our article, we are mainly talking about brick stoves, but most of the information can be applied to metal wood (coal) units as well. Stove heating with a water circuit can be made on the basis of any kind of stove.

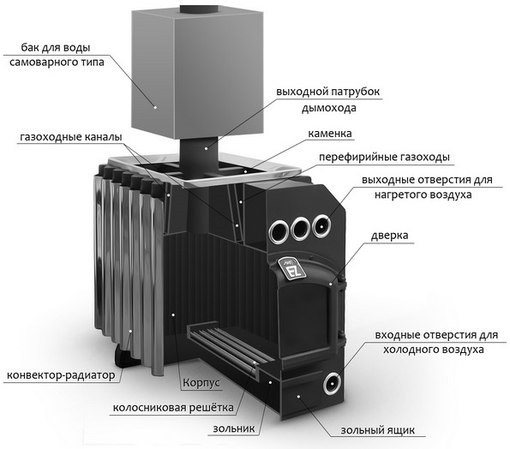

Device

In fact, almost any wood stove, even an old brick stove, can be converted and supplied with a water circuit. Nevertheless, it is better to give preference to ready-made solutions with a well-arranged structure, where the heat exchanger is inscribed harmoniously and does not spoil the combustion process and traction.

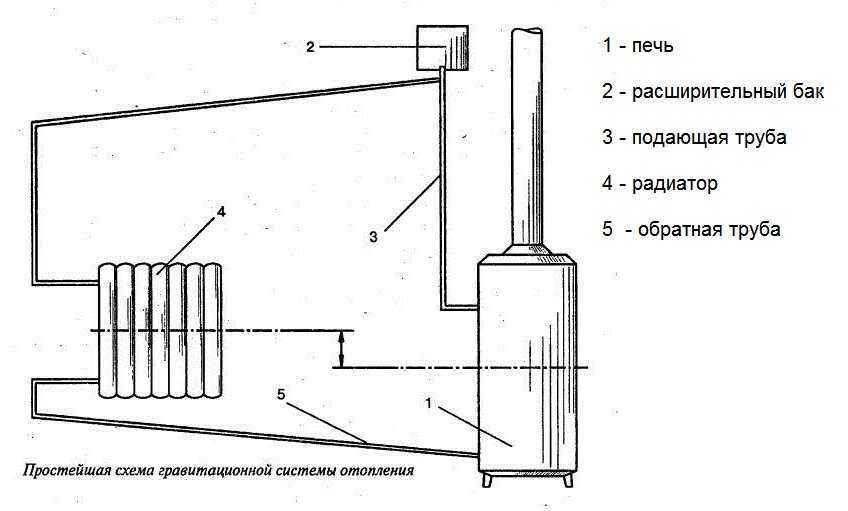

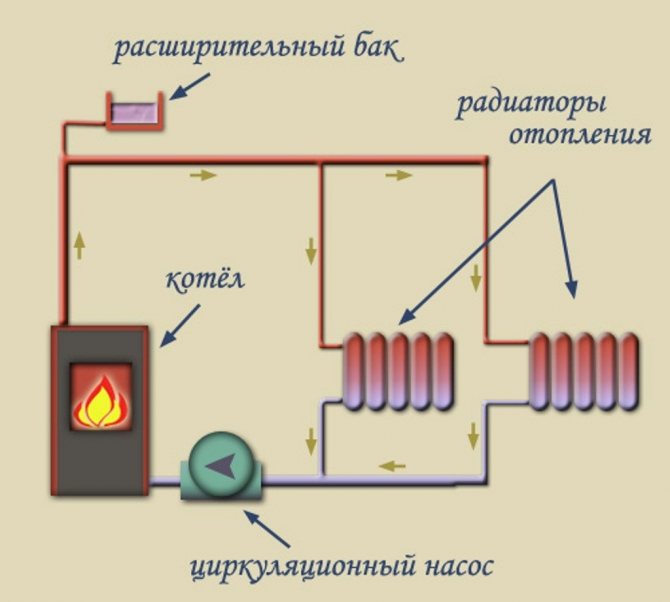

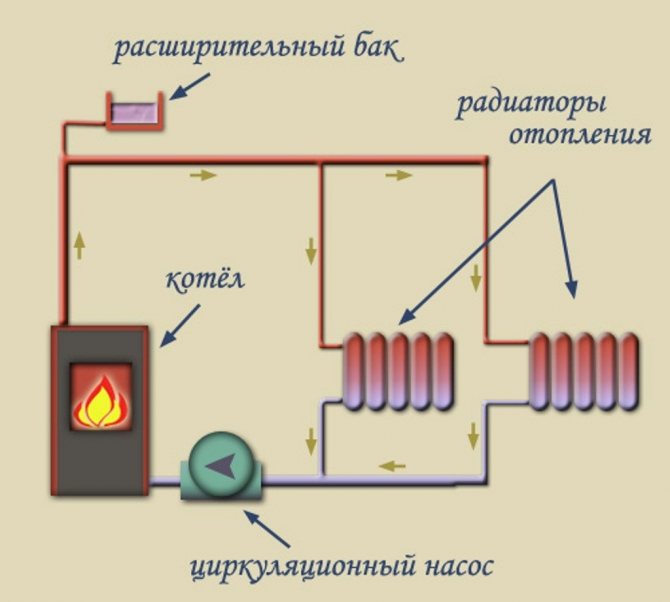

The idea is to place a water heat exchanger directly in the combustion chamber or in front of the chimney. Depending on its design and location, it is possible to organize radiator heating throughout the building.

There are five main types of heat exchangers:

- coil;

- register of pipes inside the furnace;

- built-in boiler, storage tank;

- pipe register on the outer wall of the oven, convection;

- chimney heat exchanger.

Coil

+ Simple execution.

+ Maximum heat dissipation.

- Forced circulation only.

Inside the furnace, often at the entrance to the chimney, there is a plate heat exchanger, approximately the same as installed in gas boilers. Due to the hot air and combustion products, the coolant is heated. Since there is no natural convection of liquid in this case, and for circulation in the heating system, it will be necessary to install a circulation pump. This already makes the heating dependent on the availability of electricity.

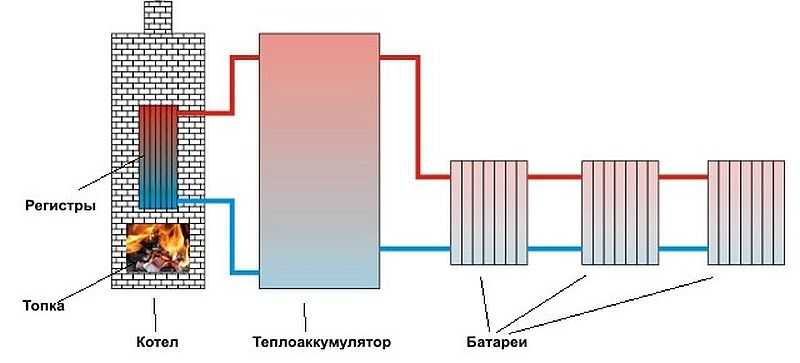

Register of pipes inside the furnace

+ Fast heating.

+ Simplicity of design.

- Weak heating regulation.

A tubular direct-fired heat exchanger is formed inside the combustion chamber. A number of "П" -shaped pipes installed parallel to each other and united by two collectors, respectively, inlet and outlet. The heat from the fire and smoldering wood heats the coolant in the pipes. A rather risky option, since in the absence of circulation, the coolant boils. If there is no additional volume for expansion and removal of vapors, a burst of the heat exchanger is possible. However, this is the simplest and most affordable option for self-execution and alteration of an existing wood-burning stove. In stoves originally equipped with such a register, a heat regulator is installed, which, depending on the heating of the water, adjusts the position of the damper, reducing the activity of burning wood.

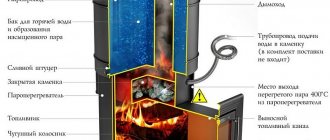

Boiler

+ Heat reserve, high inertia.

- Strong influence on the combustion process.

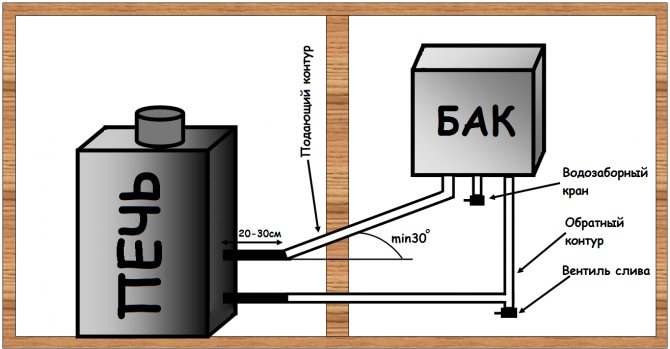

The storage tank is formed directly on the sides of the firebox and additionally on top. It is a direct alternative to the pipe register, only the heat exchanger is formed from sheet steel.In fact, the structure forms the main walls of the furnace itself. Replacing, for example, brickwork. Disadvantages are similar to the previous version. The advantage is more active convection and the ability to organize a heating system with natural circulation of the coolant. It is only important to provide cold water supply at the lowest point of the heat exchanger and hot water intake at the highest point.

Butakov's furnace with a boiler and a water circuit

Register of pipes along the furnace body

+ Good heat transfer.

+ Smooth heating.

+ Ability to regulate the temperature of the coolant.

+ The water circuit has little effect on the combustion process.

The convection type is typical for most modern wood-fired ready-made stoves. A register of shaped pipes is formed along the perimeter of the furnace, and also partially along the chimney channel from the outside of the main body of the furnace. The best option for organizing heating with natural circulation and with minimal risk that the coolant will boil.

Chimney heat exchanger

+ Simplicity of design.

+ Compatible with any oven design.

- Has a negative effect on cravings.

A chimney heat exchanger is a special case for organizing water heating based on a stove that is not equipped with a built-in heat exchanger. It is more often a cylindrical tank, fixed to the chimney so as to grip it around the perimeter. The water is heated by the heat of the gases emanating from the firebox. There is also a variant with a coil wound around the pipe. The first option is suitable for natural circulation heating, in the second case a pump is required. Both options are bad in that they significantly lower the temperature of the walls of the chimney, causing condensation and rapid clogging of the chimney.

The difficulty in designing a water circuit in a furnace is a strong heat removal from the combustion chamber or chimney. Due to this, the combustion temperature and, most importantly, the heating of gases can be significantly reduced, which affects the magnitude of the thrust. This is especially true for long-burning furnaces with a water circuit. Not only do they create a weak draft by themselves, heat removal can stop the smoldering of wood and thereby cause a dangerous situation when the stove dies out or, even worse, the draft collapses, and carbon monoxide, along with unburned flammable gas, will begin to flow into the room.

The main disadvantage of furnaces with a water circuit is the inability to regulate the temperature of the coolant and turn off the heating during the operation of the furnace. If the wood is already burning, then circulation must be maintained in the heat exchanger, otherwise the water will boil, and the metal will break from the excess pressure, and the stove will deteriorate, as will the interior situation in the house.

The problem is partially solved for external registers and plate heat exchangers. External convectors are capable of working as an air convector even without being connected to the heating system or quickly enough to dump the heat coming from the firebox. In the case of a coil and plate radiator, it can be positioned so that it is possible to shut off the flow of flue gases through it.

Features of a sauna stove with a heat exchanger

A sauna stove equipped with a heat exchanger has certain design features.

These include, in particular:

- tube supply system for coolant circulation;

- thickened body walls;

- increased volume of the heater;

- the presence of a mandatory air distributor;

- firebox door made of heat-resistant glass.

The heat exchanger functions due to the constant circulation of water through all the devices that make up the heating and heating system in the bath.For efficient use of the heat exchanger, the length of each of the connecting pipes should be a maximum of 3 m. Especially in the absence of external thermal insulation of the pipe.

Subject to fire safety rules, as well as in the presence of forced ventilation and thermoregulation systems, a heat exchanger can be equipped with a universal stove for a bath and home heating. The stove itself can be located in the bathhouse and connected to the living quarters of the house using a heat-insulated heating pipeline and hot water supply to the home.

To organize the circulation of water in the centralized heating system, as well as to supply hot water to the premises of the house and to the washing section of the bath, an automated pumping station is used to maintain a constant pressure in the line.

The simplest design of a universal stove is an electric stove with separate electric heaters for the heat exchanger and heater sections.

Such a furnace can operate in several modes, namely:

- In the mode of heating the residential premises of the house and its hot water supply (DHW) with the maintenance of the minimum required temperature in the premises of the bath in the cold season.

- In the heating mode of the bath and the whole house with hot water supply during the cold season.

- Organization of heating a bath and a heater in the summer.

A similar stove for a bath and heating can simultaneously be created in the form of a continuous operation device on natural gas or fuel pellets. The use of charcoal or wood as fuel is in this case difficult and has certain technical difficulties. Indeed, in wood or coal stoves, the possibility of automatic temperature control is not provided. This can lead to sudden temperature fluctuations in the heating main.

If it is possible to connect to a natural gas main or an electric cable of industrial voltage, it is possible to make a stove for a bath from a heating boiler operating, respectively, on gas or electricity. Such a stove can serve as a heating and water heating system. Together with the heating boiler in the sauna, you can also install a small steel wood-burning stove in the steam room.

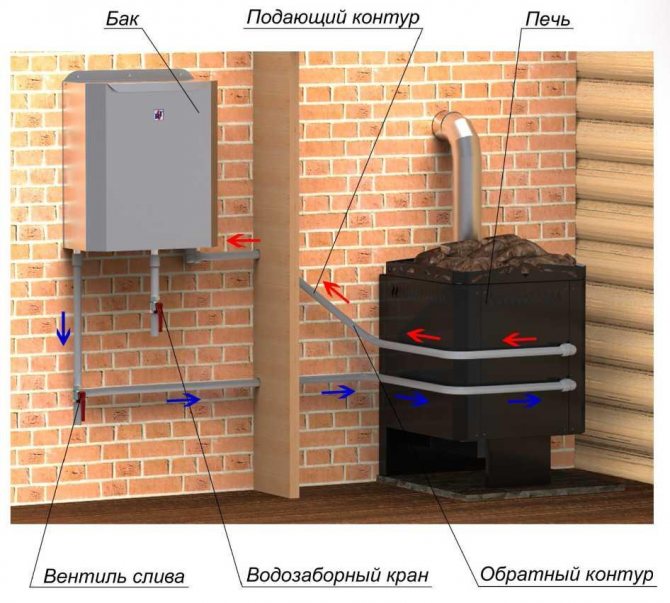

For a bath

For a bath, the main emphasis is on the heating rate. The stove is used sporadically and it is necessary to quickly heat the room. Water is needed to heat the dressing room using classic radiators or warm skirting boards and, possibly, for the underfloor heating system.

You can use any option with the exception of the boiler, which, by definition, picks up the temperature for a long time. Taking into account the active combustion of firewood in the heater, even a heat exchanger for the chimney is relevant. The temperature of the gases is more than enough to maintain traction and heat the coolant.

In this case, it is impractical to organize heating with natural circulation, when the steam room is already ready in the bath, the heating will just start to warm up. Variants with extremely high heat transfer rates are not suitable.

It is easier and more efficient to install a pump and pump the coolant through radiators and floor heating pipes, build heating to use the coolant temperature in the range of up to 60 ° C and no higher.

Operating rules

It is not difficult to operate a water heated floor from a self-assembled sauna stove, and does not require much effort. The main thing is to adhere to several rules:

- in the cold season, water should be drained from the pipes every time;

- you need to maintain a constant working pressure;

- timely eliminate breakdowns in the pump and shut-off valves.

If, when assembling a heated water floor in a bath from the stove, you followed all the rules, then the system will delight you with comfortable conditions in the bath, and trouble-free long-term operation.

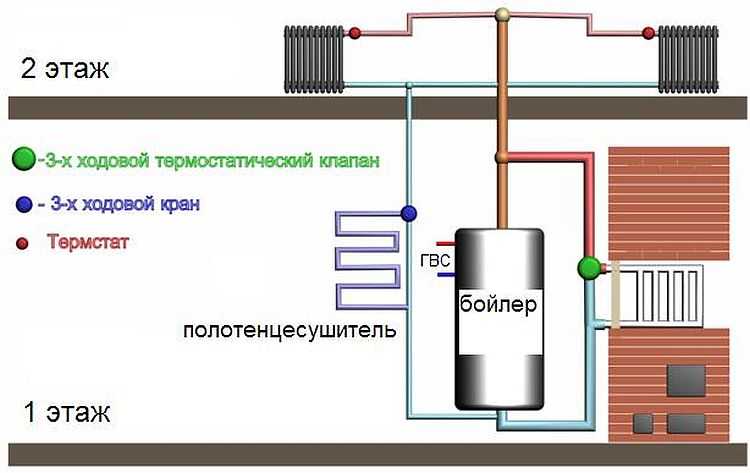

For home

The house needs heating for the entire cold period of the year, so proposals related to moderate and constant maintenance of the coolant temperature come to the fore.

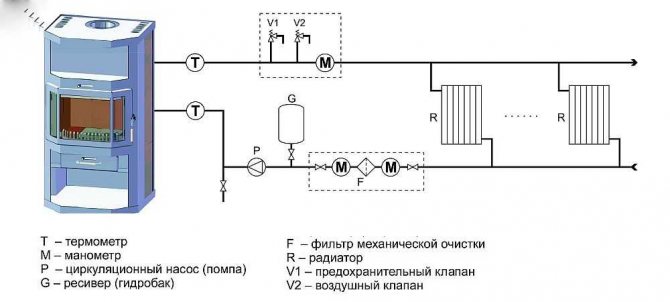

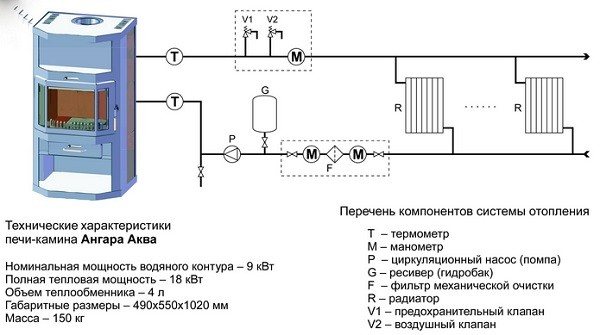

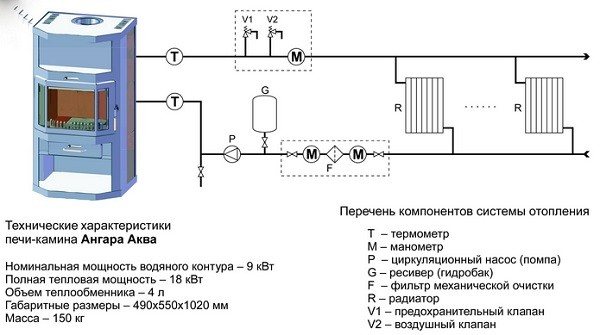

The principle of building a heating system is identical to that of solid fuel boilers. Preference is only given to a closed design with an expansion tank and a low pressure in the system not exceeding 2 atm., Which should be coordinated with the permissible pressure of the water circuit in the furnace.

Diagram of the organization of heating of a furnace with a water circuit Hangar Aqua

What is a potbelly stove with a water circuit: the advantages and disadvantages of a popular stove

The stove-stove is characterized by high heat transfer and fuel burning rate. These qualities are given to it by the materials from which the firebox is made (cast iron, steel, iron). The potbelly stove quickly flares up and heats up, and if a water circuit is connected to it, then the warm flue gases along the way also have time to warm up the water for domestic needs.

When choosing a material from which it is better to make a potbelly stove, you need to be guided by the following indicators:

- Thermal conductivity is the property of metals, liquids and gases to conduct heat through themselves. The faster heat is transferred, the faster the object heats up or cools down. Foam plastic has low thermal conductivity - 0.036–0.050 W / m * С. Taking it in our hands, we will immediately feel that it is warm, because the foam does not transfer heat, but accumulates. If you take a metal bar, you will feel cold due to the high heat transfer.

- Heat capacity - the property of a material to accumulate heat. Water has the highest heat capacity, followed by air, at the end of the list cast iron, steel and iron. Therefore, the metal stove heats up quickly and cools down just as rapidly. In city houses, central heating radiators are filled with water, which gives off heat for a long time, heating the house.