Hey! On this page I have collected the names of the elements of the Russian stove... If you have something to add, write to the mail or in the comments.

Read: Project of a Russian teplushka stove with a stove bench, stove and underfloor heating. Project of a budget stove "Finca stove". Design of a stove for a smoke sauna. The project of the Russian steam sauna stove with drawings and procedures for the Russian steam bath.

Layout of the heating stove masonry from two tiers

The device of bunk heating stoves, shown in the photo, is a structure of two parts, located one on top of the other. The parameters of each of them are 165x51x238 centimeters. The heat transfer from the bottom of the furnace is 3200 kcal / hour, and the top is 2600 kcal / hour.

In furnaces for private households, a brick lining with voids is provided in order to lighten the weight of the structure and save material consumption. Both parts of the bunk ovens have exactly the same design. In such heating units, a channelless smoke circulation system is used. According to the layout of the stove, gases from the firebox enter the upper bell with a nozzle. After cooling down, the gases go down and, at the location of the bottom of the firebox, go through the roll-up into the stacked chimney.

At the lower furnace, the chimney passes through the upper half of the structure. For this reason, the latter has a smaller heating surface. The upper part of the structure has a separate chimney.

The device of a two-tier heating furnace is distinguished by the simplicity of laying bricks, and the gas movement pattern is simple. The lower half of the unit is cleaned through a door located in the rear wall, and for the upper part, such a door is located in the side wall (in more detail: "Heating stoves for the house - do-it-yourself masonry"). For the functioning of the heating structure, coal or anthracite is used. The pipes for both parts are equipped with two smoke dampers.

Usually, the upper part of the voids in two-tier heating furnaces is covered with solid reinforced concrete slabs, which contributes to the strength and stability of the entire structural array.

The laying of such stoves must be carried out at a high professional level, since their alteration or repair is not an easy task (read: "How to repair a brick stove with your own hands"). Carefully lay out the chimney for the lower part of the heating two-tier structure. If leaks are allowed in the masonry, the wall separating both pipes in the upper part will allow heat to pass even if the two smoke dampers are closed.

In a single array, if desired, you can combine different types of furnaces that have a rectangular or square shape and operate on different types of fuel. The two-tier system has established itself as a good source of heat supply for a country house.

Varieties of hearth furnaces

According to the purpose, the ovens with underfloor heating can be divided into kitchen and heating ovens. For fuel - gas, electric, wood. According to the material, brick and metal devices are distinguished.

Kitchen

Kitchen ovens are used for cooking - baking bread or making pastries. Differs in diminutiveness and simplicity. Can be installed in a private house. Restaurant models are large in size and have various additional functions.

Heating

Used for space heating. They do not have separate areas for kitchen trays and furniture. They are distinguished by a high level of safety and environmental friendliness. In Europe, it is the deck ovens that are approved for indoor installation.

Gas

The body houses the burner and annular tubes. Their number can reach 19 pieces. Kitchen models have 2-5 tiers for installing baking trays, the temperature is regulated on each floor. You can work with such a product around the clock.

Electrical

Outwardly, they practically do not differ from models powered by gas. All the differences are inside. Instead of a gas burner, there is a heating element in the electrical device. Kitchen appliances can also have 2-5 independent temperature controlled chambers.

From the point of view of operational safety and ease of use, it is more profitable to buy electric ovens. Moreover, gas is a more economical fuel.

Wood burning

Classic wood stoves have been in use for decades. They add coziness to the house, during the burning process, a pleasant aroma of wood is heard. Wood is one of the most affordable types of fuel, so such devices are often installed in country houses. The disadvantages include the complexity of handling. It is necessary to put firewood on your own and watch it burn out. The condition of the fuel must also be monitored. The tree should not be wet. Great attention is paid to the choice of the breed.

Metallic

Metal products are made from cast iron or steel alloy. The positive qualities include ease of installation and maintenance. During operation, the case becomes very hot, so you cannot touch it. The service life is about 50 years. Such models do not tolerate temperature extremes, which can lead to cracks.

Brick

Brick appliances are distinguished by good heat accumulation and the duration of its release. Externally they look stylish and complement the interior. The service life reaches 100 years. Disadvantages - high cost, complexity of self-installation. The hearth brick oven must be installed by a professional.

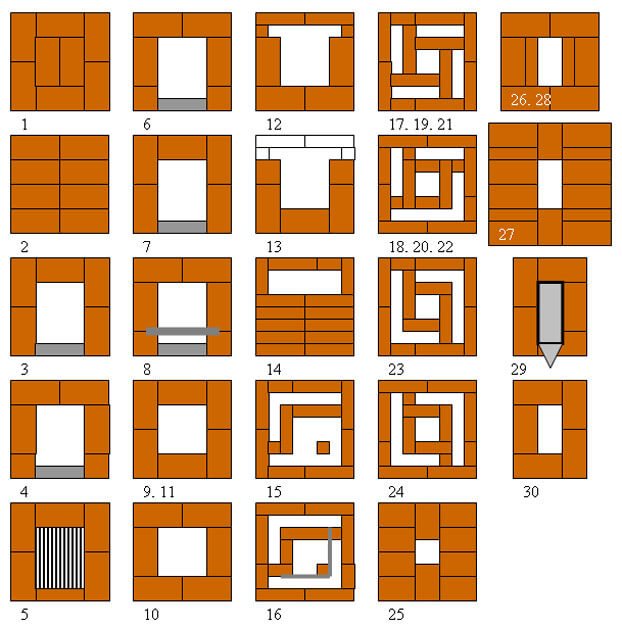

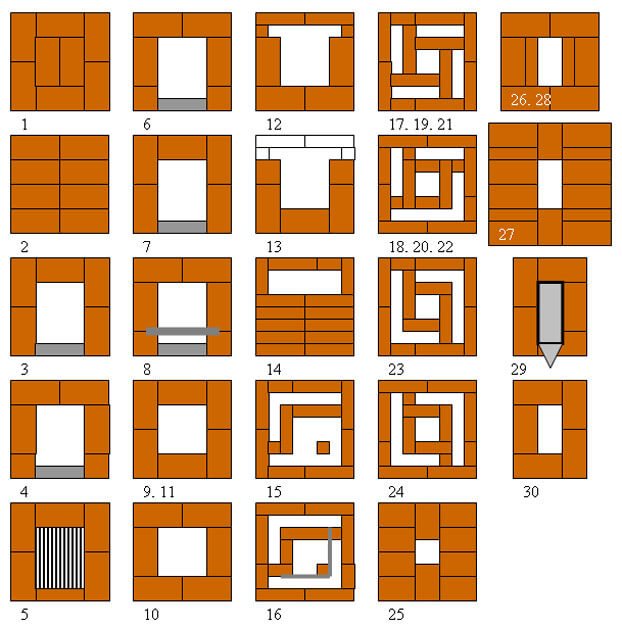

Masonry of a square stove with bottom heating

The stove in the photo is distinguished by a combined or mixed smoke system. The parameters of this design are 102x102x238 centimeters. Its heat transfer is equal to 4200 kcal / hour.

The device of square-shaped heating stoves with bottom heating assumes that the firebox in it has a relatively high height. Side holes (2 each) located symmetrically on both sides serve to drain gas into the chambers. They are located in the outer side walls of the structure. The gas is then lowered through chambers connected by a channel under the firebox behind the ash compartment.

From the side chambers, gases enter the risers through the lower rolls and go up through them. There, the side chambers all together form the so-called upper dome, which consists of three U-shaped cavities. These cavities are located in parallel. The heated gases are retained in the upper part of the middle and rear of them, and the already cooled waste products pass through the holes into the front plane, which at the top is connected to the stacked chimney and evaporates into the atmosphere. See also: "Heating stoves for mining."

Consequently, the schemes of furnaces for a square-shaped house with a bottom heating have 3 hoods - an upper hood and 2 large chambers. Any type of solid fuel can be used in such a heating structure.

If it is planned that the stove will operate on coal or anthracite, the walls of the firebox should be laid out exclusively from refractory bricks.

Furnace schemes for a house with predominant bottom heating

If the heating structure has a predominant bottom heating, its size, as a rule, is 115x56x231 centimeters with a heat transfer rate of 2640 kcal / hour. In accordance with the smoke circulation system, this stove is classified as a combined channel heating unit with bottom heating.

When a scheme of stove heating of a private house is created using such a design, it is understood that flue gases will first descend from the firebox, and then rise up the riser to the ceiling (

Furnace masonry, designed by V. Grum-Grzhimailo

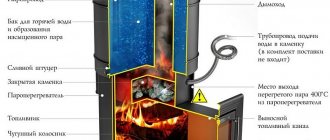

The channelless scheme of the heating stove masonry shown in the photo was developed by Professor V. Grum-Grzhimailo. There is no smoke circulation in this heating structure. It has a rounded shape and is housed in a case made of sheet steel. The gases move in the furnace not due to the draft created by the chimney, but due to the force of gravity. As a result, cooled and heavier gases descend to the bottom, and hot light ones rise to the top.

This device of a stove for a house consists of two parts - a firebox is located at the bottom. In its ceiling there is a small hail (mouth), which ensures the passage of flue gases to the upper part, which is a chamber without smoke circulation.

It looks like an overturned cap, shaped like a glass. Due to this feature, such heating structures are called channelless or bell-type.

The heated gases in them do not enter their mouths into the chimney, since they first go up under the ceiling, and when they cool down, they descend along the walls to the base. From here, they enter the chimney and, under the influence of the draft, are carried away into the atmosphere. One vertical cut is located across the firebox, and the second horizontal cut along it.

Along the walls of the structure, from the ceiling in the direction of the vault, there are buttresses designed to increase the internal surface of heat absorption and for better heat absorption by the brick mass from the exhaust gases. The fins heated by gases allow the stove to retain heat for a longer time.

The efficiency of the structure developed by Grum-Grzhimailo reaches 80%. The iron case allows you to carry out masonry with a thickness of only a quarter of a brick, moreover, the unit heats up quickly enough.

Hearth fireplace - 5 advantages

"Under or grate?" - a question that professionals argue about and which every customer inevitably asks. Grizzly burning can be called traditional for our country, but recently hearth burning fireplaces are actively gaining popularity. There are several reasons for this, each of which we will discuss in detail in this article.

- The primary combustion air in the hearth furnaces is supplied through a special guide plate , located in the lower part of the firebox, under the door, across the entire width of the firebox, which ensures even burning of firewood. While in grate fireplaces you can often observe how a long log burns brightly above the grate, but in the corners of the firebox it only smolders and smokes.

- Since the primary air does not come from below, under the wood, but "from the side", and the secondary air from above and "from the side", the flame does not stretch into long tongues. Tangential air supply not only creates a "swirling flame" effect, but also delivers air to each log, breaking one large "torch" into many small ones, which significantly reduces the height of the flame at high combustion speed and efficiency. This increases the efficiency of the fireplace, improves the quality of combustion.

- A layer of ash with a thickness of 10-20 mm, which must be kept at the bottom of the flameless firebox, is a combustion catalyst. In this "cushion" with each fire, ash accumulates, which is a mineral residue. The minerals that make up the ash improve the combustion process by lowering the ignition temperature of the gas-air mixture (flue gases) from 700 degrees to 500 degrees and even lower. The amount of not only CO, but also dust particles decreases - which means that the chimney stays clean longer, less unburned products settle on its walls.

- High efficiency of the furnace, clean combustion, reliability - these important characteristics of the fireplace are inextricably linked with the possibility of using ignition from above. When laying firewood from above, it flares up gradually and burns down more slowly than with the classic method of laying firewood. As a result, the structure does not experience thermal shock, which is very important for the durability of the firebox, but, most importantly, since combustion develops gradually, the firebox transfers heat more efficiently. Less heat is released per unit of time than with another method of burning firewood, but the efficiency is significantly increased. Only in the hearth furnace is it possible to effectively use the ignition from above. The combination of all the features of the hearth furnace and ignition from above gives a tangible effect in performance, beauty of combustion, and durability of the product.

- The hearth furnaces are easier to use and maintain. The ash formed during combustion does not need to be cleaned out every time after heating. Accumulating on the hearth of the furnace, it not only does not interfere with the combustion process, but also helps. Thanks to more efficient combustion and complete burning out of the coals in the furnace, you can admire the fire for a longer time. And even with daily kindling, it is enough to clean the hearth fireplace once a month.

Hearth fireplace inserts (Russia)

Manufacturing (Russia, Voronezh) offers a wide range of fireplace inserts with hearth (throatless) combustion. Fireplace inserts "ASTOV" are equipped with all modern technical options, while the model range is wide enough to choose a firebox for any project

The range of hearth fireplace inserts under the ASTOV brand includes: furnaces with straight, L-shaped (corner), U-shaped (three-sided), prismatic glass, as well as tunnel inserts (through, so-called "double-face"). All models have a lifting door mechanism.

Under the fireplace insert, lined with fireclay bricks.

The furnace part lining is offered in several versions: wide steel plates (SHSP), 3D ribbed panels, light ceramics, dark ceramics, fireclay.

Lining options for fireplace inserts "ASTOV"

The set includes legs, adjustable in height. Each firebox is equipped with an adjustable "Clean glass" system and an adjustable additional supply of secondary and tertiary air. The efficiency of ASTOV furnaces with the door closed in the nominal mode is 82%. The combustion rate is 88%. All ASTOV furnaces are provided with a 5-year warranty, subject to the instructions and SNiP.

Hearth fireplace insert "ASTOV"

Article source: Fireplaces & Stoves

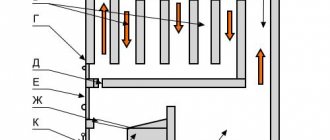

Furnace masonry, created by the Thermal Engineering Institute

Furnace schemes for the home, developed at the Thermal Engineering Institute by engineer Kovalevsky, have a size of 100x85x217 centimeters. They use a mine-type firebox designed for the use of coal.

Through the channel, flue gases enter under the ceiling, from where they enter two side channels. Then they follow to the very bottom and move along the collecting channel to the smoke stack. If the smoke damper is open, then the gases are vented to the atmosphere.

The peculiarity of the furnace arrangement scheme lies in the different thickness of the walls of the smoke circulation channels. The first of them, coming from the firebox, is called the fire channel. It has a 3/4 brick outer wall. The rest of its walls are placed in half a brick.

This heating structure does not fit into an iron casing. Its masonry is simple. The efficiency of the furnace of engineer Kovalevsky is 75-80%. The disadvantage of the heating unit is the possibility of overheating its upper part, since the hottest gases are sent to it. Down the oven, they will fall completely cooled, as a result of which the degree of heating of the lower part is insufficient.

A certain amount of gases from the firebox enters the side channels through the screws, which increases the heating of the lower part of the outer walls (about

Advantages and disadvantages

Stoves of this type have advantages and disadvantages over other types of heating and kitchen devices. The main advantages are:

- It is possible to arrange several tiers to prepare many dishes at the same time.

- Heats up large rooms quickly.

- Does not pollute the atmosphere with its smoke (unlike grate stoves).

- Easy to handle.

- Durable (subject to the rules of operation).

It is also worth noting the high efficiency of the stove (79-82%), a long burning period (in a wood-burning stove, 10 kilograms of briquettes burn out in 10-12 hours).

The downside is that the design assumes only one source of heat (wood, electric heating or gas). There are no hearth furnaces operating on peat or coal.