- Stoves, boilers, chimneys "

- Catalog »

- Heating stoves "

- Heating stoves Breneran (Buleryan)

Long-burning heating furnaces Breneran (Buleryan) are reliable equipment for uniform heating of premises in private houses and dachas, operating on solid fuels.

The principle of operation of such a furnace is based on air circulation. The Breneran firebox is surrounded by 3-6 pipes on each side. Cold air is blown into them from below, it passes through the heated metal pipes, comes up already warm and is evenly distributed over the heated room. The pipes warm up in 10-15 minutes after kindling, their temperature quickly reaches 100-120 degrees.

- 1

Types of heating stoves Buleryan

In the catalogs of the online store R-sauna.ru you will find:

- Conventional ovens Breneran. They have one task - uniform heating of the room by convection under conditions of prolonged burning of fuel.

- Fireplace type. This is a heating equipment with a glass door. This is a convenient and aesthetic kind of stoves in which you can control the flame without opening the firebox door.

- With a water circuit. Heating of premises is carried out by heating the water passing through the circuit or a special liquid for heating systems.

- With a hob. An ideal type of stoves for summer cottages, which are not supplied with gas, in this case, Breneran is used for cooking.

In our online store you can buy the ovens themselves and everything you need for their installation, in the catalogs you will also find: special heat-resistant sheets for installing Buleryans, as well as supports and thermal protection.

Advantages and disadvantages of Breneran-type equipment

The main positive qualities of long-burning heating furnaces Buleryan include:

- High efficiency of work. Up to 80% of the generated heat goes to heating and heating the fluid in the circuit.

- Uniform heating. Thanks to the convection system of work, all parts of the room are warmed up.

- Fuel economy. The device works on the principle of long burning, first the firebox heats up with an intense flame, then the temperature is only maintained: the wood smolders.

- Simple installation. There is no need to carry out complex preparations: to mount the foundation, you only need to protect the walls and floor from heat.

- Durability. Buleryan furnaces are made of heat-resistant materials, which significantly extends their service life.

This equipment also has several minor features:

- The need to install a high chimney: at least 3 meters from the upper surface of the stove.

- Condensation forms, which must be removed periodically to avoid unpleasant odors.

- Considerable dimensions, which requires the allocation of a large amount of space for placing heating equipment.

Furnace Breneran-Aquathen AOTV-06 type 00 up to 100m3

Description

| Indicator name (norms for the device) | AOTV-6 \ 00 |

| Loading hole diameter, not less, mm | 286 |

| Overall dimensions, no more, mm: | |

| - length | 700 |

| - width | 535 |

| - height | 934 |

| diameter of the flue pipe, not less, mm | 120 |

| Apparatus weight, no more, kg | 86 |

| Room volume, cubic meters | 100 |

ZAO Laotherm has developed and patented the Breneran-AQUATEN oven, which has no analogues in the world. It runs exclusively on solid fuels: wood, cardboard, wood and peat briquettes.

The stove is a powerful liquid heater for a water heating system. It can be used to heat domestic and industrial premises with a volume of 100 to 1000 cubic meters.Thanks to its unique design, the furnace efficiency reaches 70%, and depending on the model, it works on one tab from 6 to 12 hours. The “Breneran-AQUATEN” furnace is an all-welded steel structure covered with heat-resistant paint. So, in terms of appearance and material, it is fully consistent with its time. And you can install it in the boiler room or basement.

The unit itself consists of two combustion chambers: a lower one, a gasification chamber and an upper gas afterburner. The stove is equipped with two regulators: a power regulator is mounted on the door, and a regulator-gasifier is mounted on the chimney at the rear of the stove. Due to the fact that the pipes that form the furnace body are in the furnace by two thirds, the maximum heating of the coolant circulating through the pipes (batteries) occurs. The furnace is designed to operate in an open system, and the liquid is lifted by gravity. Thanks to the injectors, which function as a kind of "afterburners", the maximum CO2 combustion is achieved. To maintain a positive temperature in the system in winter (when it is not possible to ensure the operation of the device using solid fuel), an electric heating element with a capacity of 1 kW is provided. Subject to all the requirements of the instructions and fire safety, the manufacturer's warranty for the stove is 2.5 years.

OVEN "BRENERAN-AQUATEN" - a unique design, perfect for our winter. Read these instructions carefully and use the oven correctly.

DESCRIPTION AND PURPOSE

Furnace "BRENERAN-AQUATEN" intended for heating household and industrial premises, workshops, greenhouses, workshops, garages, construction sites, as well as for drying mushrooms, fruits, grain, lumber, etc.

Furnace "BRENERAN-AQUATEN" - this is an all-welded steel structure, covered with heat-resistant paint (during the first heating, it is completely polymerized, which is accompanied by a characteristic odor).

Furnace "BRENERAN-AQUATEN" consists of two combustion chambers: the lower chamber - the gasification chamber, the upper chamber - the afterburner chamber. There are two manifolds with injectors on the side surface of the furnace. The stove is equipped with two regulators: on the door (power regulator) and on the chimney at the back of the stove (regulator-gasifier).

Efficiency ovens "BRENERAN-AQUATEN" up to 70%.

Furnace "BRENERAN-AQUATEN" has certificates of compliance with the requirements of the state standard of russia, fire safety of russia, as well as a sanitary and epidemiological conclusion on compliance with state rules and regulations and is approved for use in Russian cities.

TRANSPORTATION

It is necessary to transport the BRENERAN-AQUATEN stove in closed vehicles, avoiding the ingress of moisture on the stove surface.

INSTALLATION

INSTALLATION LOCATION. The “BRENERAN-AQUATEN” stove is installed in the boiler room or basement. The stove must be covered with insulating material so as to provide free air access to the side manifolds of the injectors. It is recommended to install the stove no closer than 1 meter from walls and combustible surfaces (wood, wallpaper, etc.), at a minimum distance from the existing chimney (if any), and the free distance in front of the firebox should be at least 1.25 m Walls made of combustible materials in the immediate vicinity of the stove must be protected with brickwork or asbestos sheets with a thickness of at least 10 mm to a height from the floor to the upper surface of the stove.

FOUNDATION. For better air circulation through the “BRENERAN-AQUATEN” pipe system, raise the stove at least 500 mm away from combustible structures and install it on a base made of non-combustible material (brick, slabs, stone or other). For ease of maintenance, it is possible to install the furnace at a height of 300 - 400 mm on metal structures.To ensure fire safety, in front of the firebox there should be a metal sheet measuring 500x700 mm, at least 0.5 mm thick, located with its wide side towards the furnace.

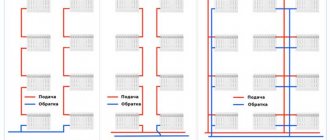

CHIMNEY. According to SNiP 41-01-2003 “Heating, Ventilation, Air Conditioning” (clause 6.13), chimneys should be designed vertical, without ledges, made of bricks with walls at least 120 mm thick or of heat-resistant concrete at least 60 mm thick. It is necessary to provide at their base pockets with a depth of 250 mm with holes for cleaning, closed with cast-iron doors.

A stainless steel liner with a thickness of at least 0.5 mm must be installed in brick and concrete pipes in order to avoid the destruction of the chimney from the effects of condensation. It is allowed to install prefabricated chimneys made of stainless steel with a thickness of 1 mm (coaxial steel pipes (sandwiches) with an internal filling of non-combustible heat-insulating material).

The dimensions of the cuts of these chimneys at the junction of building structures and the distance between the outer surfaces of chimneys and the wall, partition and other structures of the building should be carried out taking into account the requirements of the appendix to SNiP 41-01-2003 “Heating, ventilation, air conditioning”. The distance from the outer surfaces of brick or concrete chimneys to rafters, battens and other parts of the roof made of combustible or slow-burning materials should be provided in the light of at least 130 mm, from ceramic pipes without insulation - 250 mm, and in the presence of non-combustible thermal insulation with a transfer resistance of 0, 3 sq.m. x degree C / W - 130 mm. Metal and asbestos-cement chimneys must have thermal insulation made of mineral wool, expanded clay or similar materials with a thickness of at least 80-120 mm - this will prevent condensation and ensure optimal operation of the furnace.

Chimneys should be placed in places convenient for the consumer inside or outside the building according to the attached diagrams. It is allowed to place the chimney in fireproof walls. The diameter of the chimney should not be less than the diameter of the chimney of the furnace. The stove must have a separate smoke duct. Your chimney pipe should always be higher than the ridge of the roof of your house. If the roof is flat, the pipe should rise 0.5 m above it. Recommended height of chimneys for “BRENERAN-AQUATEN” stoves is not less than: -type 00 - 5 m; -type 01 - 6 m; -type 02 - 7 m; -type 03 - 8 m; -type 04 - 9 m.

The chimney of the stove should not have horizontal sections longer than 1 m. The chimney should be tight (when using metal pipes, the joints should be sealed with a non-combustible sealant). To clean the chimney, a removable part (glass) or an opening with a door should be provided at its base. Installation of chimney cleaning holes in attic rooms is not allowed. Before the start of the heating season and every three months of the entire heating season, the chimney should be checked and, if necessary, cleaned of ash and soot deposits. Installation of additional dampers (“view”, dampers) in the chimney is prohibited!

If the BRENERAN-AQUATEN stove is installed in the premises of organizations or legal entities, the stove installation must be handed over to a fire brigade representative according to an act. It is forbidden to install and operate the Braneran stove in children's, preschool, outpatient clinics, in living quarters for sleeping and resting. The installation of the stove and the installation of the chimney must be carried out by specialized organizations licensed to carry out these works, both for legal entities and for individuals (in case of self-installation, the buyer assumes responsibility). The firm "Laotherm" does not install the stoves "BRENERAN-AQUATEN" and accordingly, it is not liable in the event of improper operation of the oven caused by violation of the basic rules for its installation.For the installation of the BRENERAN-AQUATEN furnace, it is recommended to contact specialized installation organizations and firms.

EXPLOITATION

FUEL. The “BRENERAN-AQUATEN” furnace operates on all types of solid fuels: wood, cardboard, wood, peat briquettes with a calorific value of not more than 13.8 MJ / kg. It is best to use large round logs (no need to chop wood!). In all cases, it is necessary to strive to fill the entire volume of the lower combustion chamber - only under this condition a period of continuous operation on one fuel load of 6 - 12 hours, depending on the furnace model, is achieved.

KINDLING. Before firing, set the power regulator and the gasifier regulator to the fully open position. Then, using paper and wood chips, melt the oven. It is imperative to fill the water circuit with water before the first kindling.

ADJUSTMENT. After the fire has flared up, you put the main fuel, trying to fill the volume of the lower chamber as much as possible. after the main fuel has flared up and the chimney has warmed up (15 - 20 minutes), you must close the regulator-gasifier at least 45 degrees from its longitudinal position. This puts the oven into gasification mode. The position of the regulator-gasifier, which ensures the best gasification process, is individual for each chimney height. With a flue exceeding the above minimum values, the regulator can be closed more than 45 degrees from the longitudinal position. Only in this mode does the furnace have maximum efficiency and heat transfer, and only in this mode is its operation allowed.

ATTENTION! IT IS PROHIBITED TO OPERATE THE OVEN WITH THE FULLY OPEN GASIFICATOR!

After the oven has warmed up the entire room, you can set the desired temperature by closing the power regulator flap. It is not recommended to close the regulator completely.

In order to extinguish the furnace, it is necessary to set the regulator-gasifier in the longitudinal (open) position, put the power regulator in the vertical (closed) position - the furnace will slowly go out.

ADDING FUEL. Before opening the door of an oven already operating in gasification mode, be sure to fully open both shutters and wait 5 - 10 minutes. Only then open the door and add fuel, and then return the flaps to their original position.

ASH. Ash formation is negligible. It is not necessary to completely remove it from the oven. On the contrary, you must ensure that the lower pipes in the firebox are always covered with ash, which is necessary for normal gasification of the fuel.

FORBIDDEN

-to operate the furnace without a completely filled water circuit; - melt the stove with flammable or flammable liquids; - use coal, liquid and gaseous fuels as fuel; -use firewood, the length of which exceeds the dimensions of the firebox; - dry clothes, shoes and other items on the parts of the oven; - remove soot from the chimney by burning; -to remove ash and coals from the uncooled oven; - to operate the furnace in the kindling mode for more than 20 minutes; - to operate the stove with an open fire door; - use the stove not installed in the way specified in this manual; -fill the fire in the firebox with water; - make changes to the design of the furnace and use it for other purposes.

The operating manual has been drawn up taking into account the fire safety requirements set forth in the following regulatory documents: - Fire safety rules of the Russian Federation PPB 01-03; - SNiP 41-01-2003 “Heating, ventilation, air conditioning”; - Rules for the production of pipe and furnace work, repair of furnaces and smoke channels. VDPO, M., 2006.

Delivery of the order in Moscow and the Moscow region, as well as in any regions of Russia. Buy Furnace Breneran-Aquaten AOTV-06 type 00 up to 100m3 price 17 400 rubles.

Where to buy quality oven equipment?

To purchase Breneran heating stoves in Moscow, the region and regions of the Russian Federation, contact the specialists of our online store. We offer:

- Prompt delivery throughout Russia. Sending to remote regions is carried out in 1-2 days after payment for the equipment.

- Low prices. We work directly with suppliers, we exclude markups from intermediaries, which allows us to make the best offer on the market.

- Warranty from 2 years.

- Quality control and equipment compliance with domestic and foreign standards.

To buy a Buleryan stove or get advice, contact the company's managers by phone or leave a request for a call back.

The long-burning furnace manufacturer Breneran has an impressive track record in the manufacture of such equipment. These products are in great demand in the Russian market. The company gives a 2.5-year guarantee for the reliability and safety of its products.

The production company Laotherm has been present on the Russian market since 1993. Previously, it produced equipment under the Buleryan brand. Since 2005, the products have received a modern brand name - Breneran. Also, this company produces more budgetary models - Buran ovens. They are in no way inferior to their predecessor.

Description and purpose of the Breneran gas generator

The "Breneran" oven is intended for heating domestic and industrial premises, workshops, greenhouses, workshops, garages, construction sites, as well as for drying mushrooms, fruits, grain, lumber, etc.

Furnace "Breneran" - it is an all-welded steel structure covered with heat-resistant paint (during the first heating, its complete polymerization occurs, which is accompanied by a characteristic odor). The "Breneran" furnace consists of two combustion chambers, the lower chamber - the gasification chamber and the upper chamber - the afterburner chamber. The front pipes have afterburner injectors.

IF YOU GET SMOKE THROUGH THESE PIPES, YOUR CHIMNEY IS EITHER OUT OF THE HEIGHT OR CLOGGED.

The stove is equipped with two regulators: on the door (power regulator) and on the chimney at the back of the stove (regulator-gasifier).

COEFFICIENT OF USEFUL ACTION OF THE FURNACE "BRENERAN" - 70 - 80%.

Furnace "Breneran" with sight glass. If you have purchased a model with a sight glass, you must, after removing the oven door, replace the transport shield with heat-resistant glass. In the process of work, soot settles on the glass. After complete cooling, the soot is washed off with hot water with the addition of detergents.

ATTENTION! THE GLASS MUST ONLY BE INSTALLED INTO THE MOUNTING, EXCEPTING IT STRONGLY CLAMPING. WHEN INSERTING THE FUEL, MAKE SURE IT DOES NOT TOUCH THE GLASS.

The operating manual has been drawn up taking into account the fire safety requirements set forth in the following regulatory documents: Fire safety rules in the Russian Federation PPB 01-93, SNiP 41-01-2003 "Heating, ventilation, air conditioning", Rules for the production of work, repair of furnaces and smoke ducts ... VDPO, M., 1991.

FURNACE "BRENERAN" HAS CERTIFICATES OF COMPLIANCE WITH THE REQUIREMENTS OF THE STATE STANDARD OF RUSSIA, FIRE SAFETY OF RUSSIA, AND ALSO A SANITARY AND EPIDEMIOLOGICAL DECLARATION OF COMPLIANCE WITH THE STATE STANDARD OF RUSSIA.

When used correctly the service life of the Breneran furnace is UNLIMITED.

It should be borne in mind that each type of furnace is responsible for heating its own volume of the room with the so-called residential insulation (double window frames, insulated walls, floors and ceilings).

Fuel

The "Breneran" furnace operates on all types of solid fuels: wood, cardboard, wood, peat briquettes with a calorific value of not more than 13.8 MJ / kg. It is best to use large round logs with a moisture content of 20-22% (no need to chop wood!).In all cases, you SHOULD TRY TO FILL THE FULL VOLUME OF THE LOWER COMBUSTION CHAMBER - ONLY UNDER THIS CONDITION, THE PERIOD OF CONTINUOUS OPERATION ON ONE FUEL BOOK IS 6 - 12 HOURS DEPENDING ON THE MODEL

Advantages of heating furnaces Buleryan (Breneran)

- High ergonomic qualities.

- Ease of use.

- Safety when using and working with fuel materials.

- Aesthetically pleasing appearance.

- An excellent combination of cost and quality and technical characteristics.

The R-sauna company offers to buy a Buleryan stove at economical prices. The variety of assortment in different price categories is an excellent opportunity for the consumer to choose the optimal furnace equipment. There are also models equipped with a hob. Such devices are used not only for heating premises, but also for cooking - this is an excellent solution for country houses and premises without centralized utilities.

Our catalog contains gas generator and sauna models, equipment with a hob, solid fuel boilers for hot water heating, fireplaces, barbecues, barbecue ovens, as well as spare parts, accessories and add-ons for stove equipment.