Ways to connect the DHW subsystem to the heat supply system

- Hot water is supplied to the consumer directly from the general heating system. With this connection, the quality of water in the tap and inside the radiator (battery) heating is the same. That is, people consume directly coolant

... In this case, the heat supply system itself is called

open

(that is, through

open

taps from the heat supply system, the coolant flows out).

- Cold drinking water taken from the water supply is heated in an additional heat exchanger with network water, after which it is supplied to the consumer. Hot water and heat carrier are separated, hot water consumed by people practically does not differ from cold water in its drinking qualities (hot water pipes rust faster than cold water pipes). In this case, the heat supply system is called closed

, since it transfers only heat to consumers, but not a coolant.

- Hot water is heated in a boiler room or central heating point, after which it is supplied to the consumer separately from the heat supply system. Such a hot water system is called independent

... It is most often used in low-rise buildings, if the installation of indoor heaters is economically unjustified or impossible; however, it does not have the disadvantages of an open system in terms of low water quality. Another advantage of this system is the possibility of separate maintenance and repair of hot water and heat supply pipelines.

Typical DHW schemes

DHW schemes are of three types: storage, flow, combined (flow + storage). Accordingly, each type of circuit uses its own components and circuit solutions.

- Storage type DHW circuit

- as a rule, such a scheme is used for domestic hot water supply of cottages. The analysis of hot water in the house has a periodic peak character, that is, it is more intense during breakfast, lunch and dinner. A boiler is used as a storage tank.

- Flow type DHW circuit

- a flow-through type DHW circuit, as a rule, is used in industries for technological lines that use a constant analysis of DHW. Heat exchangers of various types (plate, tubular, etc.) are used as a heating element for hot water supply; however, plate-type heat exchangers have gained great popularity.

- Combined DHW circuit

- Combined DHW circuit (i.e. flow + storage water heaters), as a rule, is used in production for technological lines that use constant and periodic peak analysis of DHW. A flow-through heat exchanger is used as a DHW heating element. The boiler is used as a thermal energy storage device for a peak DHW analysis. The heat exchanger in the boiler is not used as it is more inert than the flow type heat exchanger.

Page 1

A closed hot water supply system is used in a number of large cities and has the following main advantages: the ability to ensure a stable quality of hot water, the same as the quality of the city water supply; ease of control of the density of the system; simplicity of sanitary control. The main disadvantage of a closed system is the complication and rise in the cost of subscriber inputs due to the installation of water-to-water heaters with appropriate communications.

With a closed hot water supply system, it is connected to the heating network through high-speed water-to-water heaters, in which heating water passes through the annular space, and heated water through brass tubes rolled into the tube sheets. Such a scheme for supplying heated water is adopted because in hot water supply systems, when tap water is heated, oxygen dissolved in it is released, which causes increased corrosion of the ferrous metal of the water heater body; brass is less susceptible to corrosion.In addition, brass tubes have a higher coefficient of linear elongation than steel tube bodies. When water with a lower temperature passes through them than in the annular space, some equalization of the absolute values of the thermal elongation of the brass tubes and the steel body occurs. This allows the use of water heaters with brass tubes in hot water supply systems without lens compensators on the body, which greatly simplifies their design.

| Scheme XI. Thermal imp. |

With a closed hot water supply system, it may sometimes be advisable to use makeup water treatment methods that would allow the plant to have one water treatment plant and, therefore, subject the makeup water to the same treatment (sometimes partial) as the supplementary feed water for boilers. although this is by no means always required by the operating conditions of heating networks.

With a closed hot water supply system, it is connected to the heating network through high-speed water-to-water heaters, in which heating water passes through the annular space, and heated water through brass tubes rolled into the tube sheets. Such a scheme for supplying heated water is adopted because in hot water supply systems, when tap water is heated, oxygen dissolved in it is released, which causes increased corrosion of the ferrous metal of the water heater body; brass is less susceptible to corrosion. In addition, brass tubes have a higher coefficient of linear elongation than steel tube bodies. When water with a lower temperature passes through them than in the annular space, some equalization of the absolute values of the thermal elongation of the brass tubes and the steel body occurs. This makes it possible to use water heaters with brass tubes in hot water supply systems without lens compensators on the body, which greatly simplifies their design.

In closed hot water supply systems (see Fig. 5.3), water from the external water supply network is heated in water heaters.

A serious drawback of a closed hot water supply system using water-to-water boilers is the difficulty of leveling the flow of heated water. A storage tank must be installed at each boiler, which is practically not always feasible. The use of the thermal inertia of residential buildings to equalize the peaks of water withdrawal by sequential two-stage switching on of hot water boilers does not solve the issue, since with such a scheme only fluctuations in heat consumption are partially smoothed, and the consumption of tap water in the boiler pipes remains the same sharply variable, as in any closed circuit without storage tanks.

| Scheme XI. Thermal imp. |

Heating networks with closed hot water supply systems, as well as purely heating systems, are characterized, if properly operated, by small leaks and, therefore, small amounts of make-up water.

AMO-25 UHL4 devices are intended for closed hot water supply systems; all other types, including those currently being developed, are for hot water supply and recirculation cooling systems.

In central heating points with a closed hot water supply system, installations for deaeration and stabilization of water are provided, and with a water hardness of more than 4 mg-eq / l - and for its softening.

In contrast, with a closed hot water supply system, in which all the network water circulates in a closed loop, and the added cold water compensates only for leaks, and therefore its amount is insignificant, the turbine output elements can be heated to excessively high temperatures.To ensure the reliability of the T-250-240 turbines, it has been recognized that it is expedient to significantly reduce the temperature of the reheating of the steam when installed in systems with a closed draw-off for the period of operation with heating the network water in the condenser bundle. According to preliminary data obtained on the basis of computational studies, the value of this decrease should be about 120 C, which significantly exceeds the capabilities of the adjusting means used in serial boilers.

With a closed hot water supply system, two make-up pumps of a heating network are installed, with an open system - three, including in both cases a backup pump.

A number of enterprises still have a so-called closed hot water supply system, in which water for showers is heated in water-to-water boilers with district heating network water. For the operation of boilers, it is necessary to maintain the temperature Tc not lower than 70 C, which further aggravates the mode of operation of the heaters. Due to the above reasons, the temperature schedule by which the CHPP operates differs sharply from the optimal schedule for heating industrial enterprises.

The DHW circuit of a double-circuit gas boiler is used to prepare hot water in the house. To provide comfort in the house is not only to create a reliable heating system (CO), but also to supply all residents with a sufficient amount of hot water. Considering, in previous posts, hot water supply systems (DHW) with a storage and instantaneous water heater, we did not associate them with a house heating system, that is, with a heat source - a boiler room. In this case, it would be appropriate to consider the option of heating with a double-circuit boiler. What it is? The very name double-circuit itself implies the presence of two circuits - a heating circuit and a DHW circuit. By combining these two circuits in one device, we get a double-circuit boiler. Wall-mounted double-circuit boilers use 2 methods of heating water for household needs:

- For the first method of heating water, it is characteristic that the heating of water for hot water supply occurs in the same heat exchanger in which the heating liquid is heated.

- In the second method of heating water, the heating fluid is heated in the primary heat exchanger, and heat exchange between it and the DHW water occurs in the secondary plate heat exchanger.

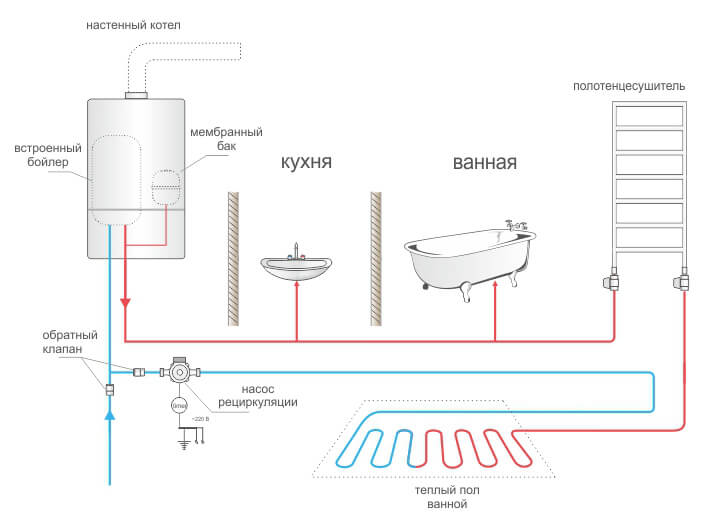

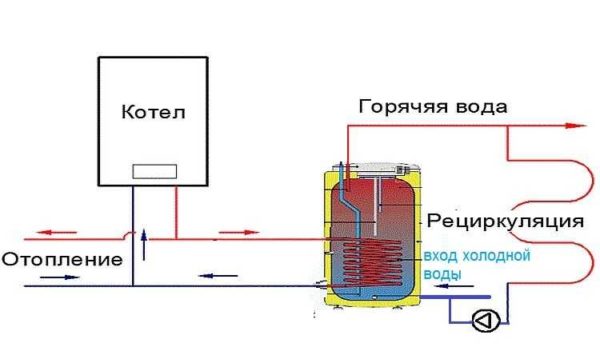

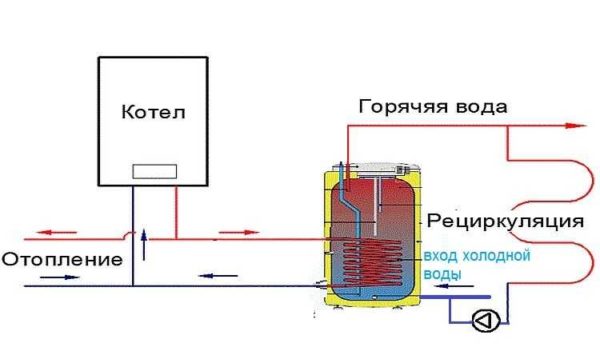

Boiler recirculation diagram

Recirculation of water in the DHW system is necessary in order to provide hot water to any point in the system without additional spilling. For this, a circuit is installed along which water from the boiler passes through the entire system, and then returns back to the boiler. Recirculation is carried out using a small pump that runs completely silent. Such a system helps to maintain a stable hot water temperature anywhere in the house.

Among the common recirculation schemes, there are several main options:

- Installation of a three-way or servo-driven valve. This method is used for wall and floor models of boilers. Two pipes are connected to the boiler (two circuits). One circuit is for heating, the other for hot water. The water heater in this system acts as the main heat carrier. When the water temperature drops, a servo-driven or three-way valve is used, which starts to work to heat the water. Heating is shut off at this time. After heating the water to the desired temperature, the heating resumes;

- Installation of two circulation pumps in one system. With this scheme, one of the pumps is designed to recirculate hot water through the heating system, and the other through the boiler circuit. This system initially provides a normal water temperature in the boiler, and then in the heating system. A feature of this scheme is the presence of a thermostat and a mode switch, which allows you to turn off, if necessary, one of the systems;

- Application of the hydraulic arrow.It is used if there are more than two circuits in the house (heating, hot water, underfloor heating). This scheme is aimed at heating water, due to which all circuits are heated. This system has a significant drawback - when parsing water. The coolant may not be able to cope with meeting the needs of all people at the same time.

The choice of the method of heating water and heating, as well as the methods of its recirculation through the boiler, should be carried out in accordance with clear calculations of all consumers and the power of the heat carrier. Boilers with three-way or servo-driven valves have an advantage among the main schemes.

Hot water recirculation video

Hot water in taps has long ceased to be a luxury. Today it is one of the essential requirements of a normal life. One of the possibilities for organizing hot water supply for a private house is the installation and connection of an indirect heating boiler.

The principle of operation of a double-circuit boiler with a bithermic heat exchanger

The principle of operation of a double-circuit boiler will not be clear to you until you understand how a bithermal heat exchanger works and works. Structurally (Fig. 1), a bithermal heat exchanger can be characterized by the term "pipe in pipe", that is, it is a water-to-water heat exchanger familiar to us. Water circulates through the inner pipe for the needs of hot water supply, through the annular space - water for the needs of the heating system (CO). The heat exchanger is located directly in the boiler combustion chamber - above the burner.

DHW bithermal heat exchanger

Fig. 1. Bithermal heat exchanger ("pipe in pipe"): 1. DHW outlet; 2. DHW input; 3. Supply to the heating circuit; 4. Return from the heating circuit

From the figure, we see that hot water flows through the inner pipes, and the heating medium of the heating system in the cavities between the inner pipe and the outer one. Moreover, household water flows sequentially through all 6 pipes, and heating water flows through 3 pipes in parallel in one direction and three in parallel in the opposite direction.

Heating mode.

High-temperature heat, from gas combustion, is perceived by the outer surface of the heat exchanger and transferred to the water circulating in the annular space. Water is heated to a certain temperature and enters the radiators of the heating system. The inner pipe of the DHW system is filled with water, but the water does not circulate - it stands still, but this water is hot. This is the "heating" mode, for which the circulation pump must necessarily work, the burner power is selected from the outside temperature, provided that the air temperature in the house is at least 20-22 ° C. In the "heating" mode, the water consumption in the DHW circuit is zero.

DHW mode.

And in this mode, high-temperature heat, from gas combustion, is perceived by the outer surface of the heat exchanger and is transferred to the already standing water of the annular space (the circulation pump does not work). And from this water, through the wall of the inner pipe, heat is transferred to the water of the DHW circuit. The water heats up to a certain temperature and flows to the taps. The CO annular space is filled with hot water, but the water does not circulate - it stands still. This is the DHW mode, for which the circulation pump must necessarily not work, the burner power is selected from the required hot water temperature. And it is necessary, dear friends, to accept that when the boiler is operating in hot water supply mode, the heating batteries will cool down and it will get colder in the apartment. But how much is another question. Everything will depend on the duration of the DHW circuit, on how the house is insulated and its accumulating ability to keep heat, etc.

Method of heating water in various DHW schemes

Features of a double-circuit gas boiler

Knowing the features of its design will help to understand the principle of operation of a double-circuit gas boiler. It includes a number of units that contribute to heating the coolant and are responsible for switching to the DHW circuit.

Uninterrupted operation of the unit is possible only if all the constituent modules work harmoniously. General information about the main components will be enough to understand the principle of operation of a double-circuit gas heating boiler.

The principle of operation of a double-circuit boiler with two separate heat exchangers and a three-way valve

Heating mode.

High-temperature heat, from gas combustion, is perceived by the outer surface of the CO heat exchanger, which is located above the burner at the top of the furnace and is transferred to the water circulating through the heating system. The circulation of water is carried out using a circulation pump, which works constantly, both in the heating mode and in the DHW mode. Water is heated to a certain temperature and enters the radiators of the heating system. The 3-way diverter valve prevents water from entering the secondary plate heat exchanger of the DHW circuit.

DHW mode.

When the hot water tap is opened, the water flow sensor is triggered and issues a command to switch the 3-way valve to DHW mode. That is, hot water CO, as a heating medium, enters the secondary plate heat exchanger of the DHW circuit, heating cold water for the needs of DHW. The burner power is selected according to the required hot water temperature. As in the scheme with a bithermal heat exchanger, the CO and DHW circuits cannot work at the same time, therefore, when the boiler is operating in DHW mode, the heating batteries will cool down and it will get colder in the apartment.

Each of the considered boilers has its own advantages and disadvantages. The main disadvantage of a boiler with two heat exchangers is its high cost, and the advantage is that it is less susceptible to corrosion and the formation of deposits (scale) on it. If the secondary heat exchanger fails, it is possible to operate the boiler in heating mode. So without hot water - but warm. The main advantage of a boiler with a bithermal heat exchanger is its compactness and low cost, and there is only one drawback - if the heat exchanger fails, you are left without heat and hot water. In addition, replacing a bithermal heat exchanger will cost you significantly more than replacing a secondary one. From the foregoing it follows that if the main criterion for choosing a boiler is not a low price, then it is better to make a choice in favor of a boiler with two separate heat exchangers and a three-way valve. It will provide 100% comfort in your home.

A small digression from the topic. Dear friends, the link below will lead you to the training course of Zinaida Lukyanova Photoshop from scratch in video format 3.0. The course contains 82 lessons that are excellent in content and understandable for a beginner. Here are 5 free lessons, after watching which, I applied for the full course and do not regret it.

I recommend this course to everyone who is not alien to the sense of beauty and who wants to try their hand at remote work as a designer. Having acquired this course, you will not walk from corner to corner in the evenings, you will not scratch your belly while lying in front of the TV - you will work, creating beauty. And, how to say, maybe this will become your meaning of life. I sincerely wish you the best of luck. Here is this link. Go for it!

https://o.cscore.ru/28gig49/disc149

How to approach the issue of choosing the power of this boiler? When buying a double-circuit boiler, it is worth, first of all, to calculate the consumption of hot water consumed. The power of water heating by the boiler must correspond to this consumption and it depends on the size of the heated area and the required amount of domestic hot water.In this case, the priority of the DHW circuit must be respected. Below is (Table 1) technical characteristics of a double-circuit boiler of the Italian wall-mounted brand DOMINA PRO 20F with a bithermal heat exchanger and a Korean double-circuit wall-mounted boiler with two separate heat exchangers and a three-way valve NAVIEN Ace TURBO 20.

Technical characteristics of a double-circuit boiler brand DOMINA PRO 20 F and NAVIEN Ace TURBO 20K

Table 1

| p / p | Name | Dimension | DOMINA PRO 20F | NAVIEN Ace TURBO 20 |

| 1 | Thermal power of the heating system (CO) | kw | 6,8-20 | 9-20 |

| 2 | Thermal power of the DHW system | kw | 20 | 20 |

| 3 | Boiler efficiency | % | 93,2 | 90-92 |

| 4 | DHW performance at Δt = 25 о С | l / min | 11,7 | 12,4 |

| 5 | Natural gas inlet pressure | mbar | 20 | 15-25 |

| 6 | Nominal consumption of natural gas | m 3 / hour | 1,57 | 2,0 |

| 7 | Heating water temperature | o C | 30 – 85 | 40-80 |

| 8 | DHW temperature | o C | 35 – 55 | 30-60 |

| 9 | Electrical parameters: voltage; power | V / Hz; W | 220/50; 110 | 220/50; 150 |

| 10 | Connecting dimensions for CO / DHW / Gas | inch | G3 / 4- G1 / 2- G3 / 4 | G3 / 4- G1 / 2- G1 / 2 |

| 11 | Overall dimensions (H * W * D) | mm | 655 * 350 * 230 | 695 * 440 * 265 |

| 12 | Weight without water | Kg | 26,0 | 28,0 |

| 13 | The cost | rub | 32210 | 37239 |

And now, dear friends, I suggest you solve the following problem. In the previous post, we opted for an EVAN V1-18 instantaneous water heater with a capacity of W = 18 kW. This water heater was not on sale, but there was a double-circuit boiler NAVIEN Ace TURBO 20, with a DHW circuit capacity of 20 kW. A consultant wearing a tie and glasses assured us that this boiler will provide comfort in the house no worse than the EVAN V1-18 water heater, since the boiler's DHW circuit capacity is even slightly higher than the required one. After installation, we filled the bathtub for 15 minutes (comfortable time) with hot water, but taking a bath was out of the question - the water was a little lukewarm. Using the technical characteristics of a double-circuit boiler, explain what the consultant made a mistake when offering us this boiler.

There will be water, there will be fish. Money will appear, a woman will appear

Today we have completed the 4th point of our house plan - we have analyzed in detail the method of heating water in the DHW circuit of a double-circuit gas boiler. Who has not joined yet, join!

Best regards, Grigory

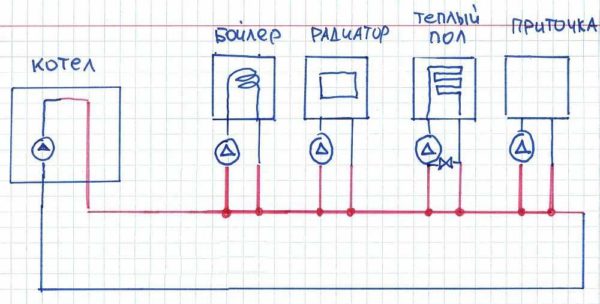

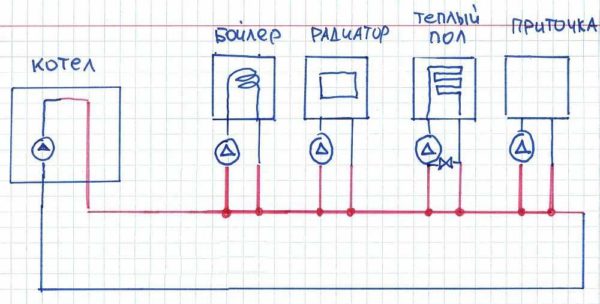

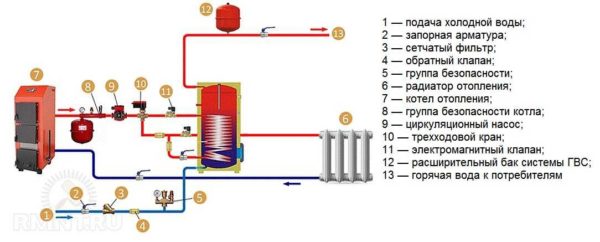

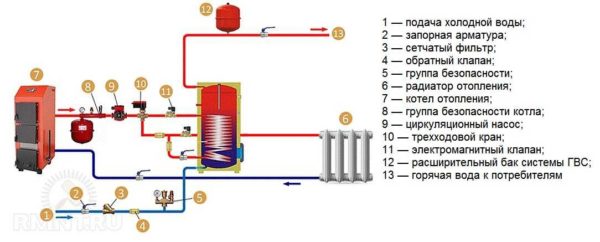

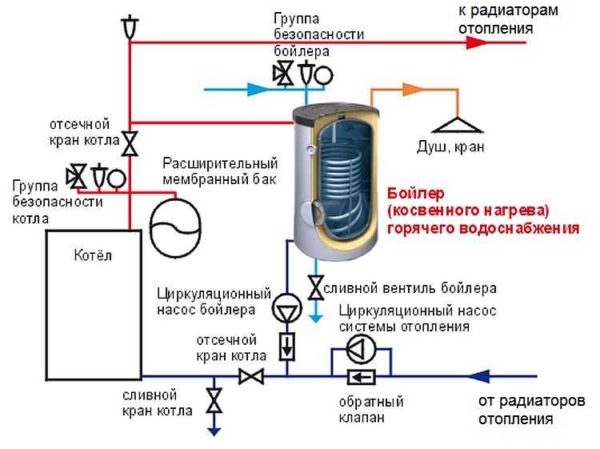

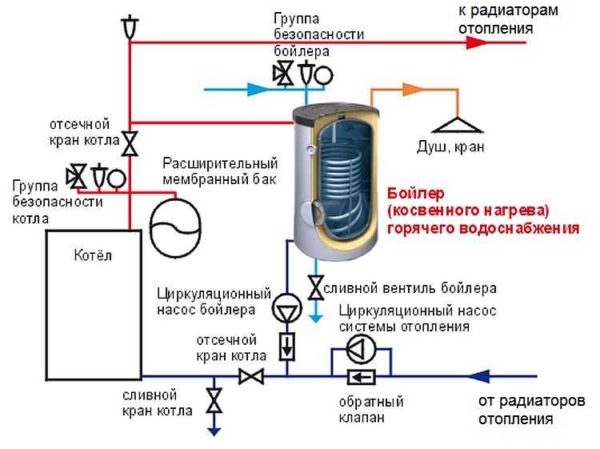

Schemes and connection features

There are two principles for connecting an indirect heating boiler: with and without hot water heating priority. When heating with priority, if necessary, the entire heating medium is pumped through the boiler heat exchanger. Heating takes a little time. As soon as the temperature reaches the set one (controlled by a sensor, thermostatic valve or thermostat), all the flow is directed back to the radiators.

In schemes without water heating priority, only a certain part of the coolant flow is directed to indirect water heating. This leads to the fact that the water is heated for a long time.

Scheme without priority

When connecting an indirect heating boiler, it is better to choose a scheme with a priority - it provides hot water in the required amount. At the same time, heating does not suffer much - 20-40 minutes are usually enough to heat the entire volume of water, and 3-8 minutes to maintain the temperature at a flow rate in general. During such a time, no house can cool down enough to feel it. But this is provided that the capacity of the boiler is comparable to the capacity of the boiler. Ideally, the boiler is more efficient, with a margin of 25-30%.

General rules

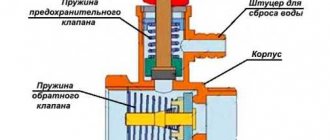

To ensure the normal operation of all appliances connected to the hot water rail, an expansion tank for hot water is installed at the outlet of the boiler (not for heating). Its volume is 10% of the volume of the tank. It is required to neutralize thermal expansion.

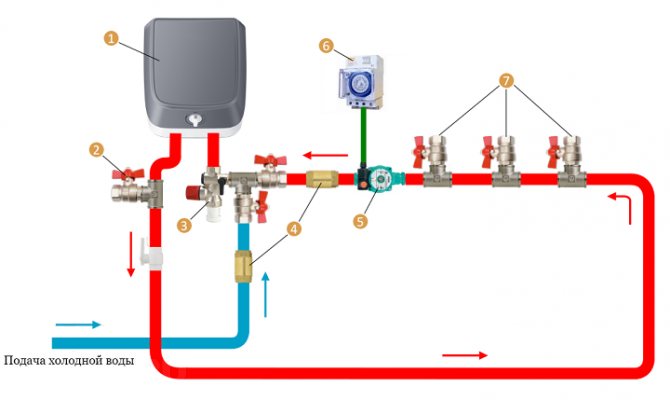

Detailed piping diagram of the indirect heating water heater

Also, shut-off valves (ball valves) are installed in each branch of the connection. They are needed so that every device can be used - a three-way valve, a circulation pump, etc. - if necessary, disconnect and service.

Check valves are usually also installed on the supply pipelines.They are necessary to exclude the possibility of counterflow. In this case, the connection of an indirect heating boiler will be safe and easy to maintain.

Installation next to the boiler in a forced circulation system (with 3-way valve)

If there is already a circulation pump in the system, and it is installed on the supply, and the forced heating boiler can be placed next to the boiler, it is better to organize a separate circuit that goes from the heating boiler. This connection of an indirect heating boiler is realized with most wall-mounted gas or other boilers, in which a circulation pump is installed on the supply pipe. With this connection scheme, it turns out that the water heater and the heating system are connected in parallel.

If there is a pump in the flow line and a water heater located next to the boiler

With this method of piping, after the circulation pump, a three-way valve is installed, controlled by a temperature sensor (installed on the boiler). One of the outputs of the three-way valve is connected to the boiler branch pipe for connecting the heating. A tee is cut into the return pipe before entering the boiler, a branch pipe is connected into it to drain water from the heat exchanger. Actually, the tie-in to the heating system is over.

The procedure for this scheme is as follows:

- When the sensor receives information that the water temperature is lower than the set one, the three-way valve switches the coolant to the boiler. The heating system is turned off.

- The entire flow of the coolant goes through the heat exchanger, the water in the tank heats up.

- The water heats up enough, the three-way valve redirects the coolant to the heating system.

As you can see, the scheme is simple, its work is also clear.

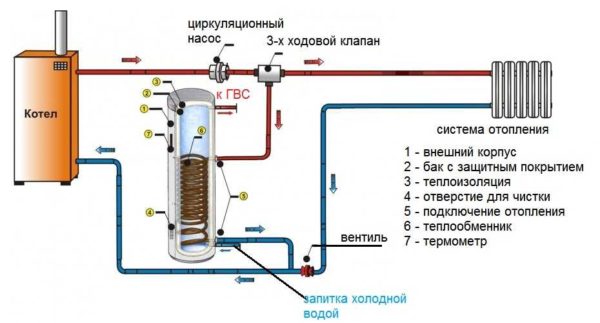

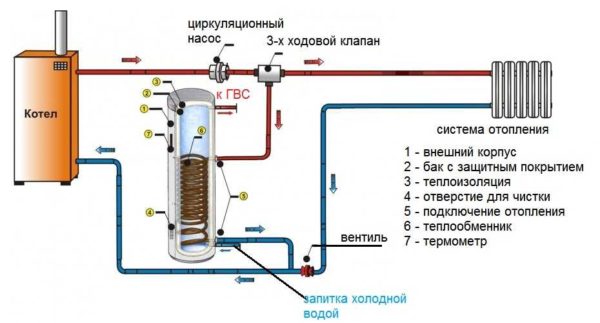

Scheme with two circulation pumps

When installing a water heater into the system in a circulation pump, but not next to it, but at a certain distance, it is better to install a circulation pump in the circuit on the water heater. The connection of an indirect heating boiler for this case is shown in the diagram below.

Wiring diagram for a boiler with automatic control

The circulation pump can be installed either on the supply pipe, or on the opposite. In this scheme, there is no three-way valve, the circuit is connected through ordinary tees. The switching of the coolant flow is carried out by turning the pumps on / off, and it is controlled by a temperature sensor that has two pairs of contacts.

If the water in the tank is colder than the one set on the sensor, the power circuit of the circulation pump in the boiler circuit is turned on. When the specified degree of heating is reached, the contacts of the pump are closed, which drives the coolant into the heating system.

Scheme for a non-volatile boiler

In a scheme with a non-volatile boiler, in order to ensure the priority of the boiler, it is desirable that it be higher than the radiators. That is, in this case, the installation of wall models is desirable. Ideally, the bottom of the indirect water heater is above the boiler and radiators. But this arrangement is not always possible.

The circuits will also work when the boiler is located on the floor, but the water will heat up more slowly and in the lower part it will not be hot enough. Its temperature will be comparable to the degree of heating of the return pipe, that is, the supply of hot water will be less.

With non-volatile heating, the movement of the coolant occurs due to the force of gravity. In principle, it is possible to connect an indirect heating boiler according to the traditional scheme - with a circulation pump in the circuit for heating it. Simply in this case, when the electricity is off, there will be no hot water. If you are not satisfied with this turn, there are several schemes that will work with gravity systems.

Diagram of connecting an indirect heating water heater to a gravitational system

When implementing this scheme, the circuit that goes to the water heater is made with a pipe with a diameter of 1 step larger than the heating one. This is what gives priority.

In this scheme, after a branch to the heating system, a thermostatic head with a patch sensor is installed. It runs on batteries and does not require external power. The desired temperature of water heating is set on the regulator of the thermal head (not higher than the temperature at the boiler supply). While the water is cold in the tank, the thermostat opens the supply to the boiler, the coolant flow goes mainly to the boiler. When heated to the required degree, the coolant is redirected to the heating branch.

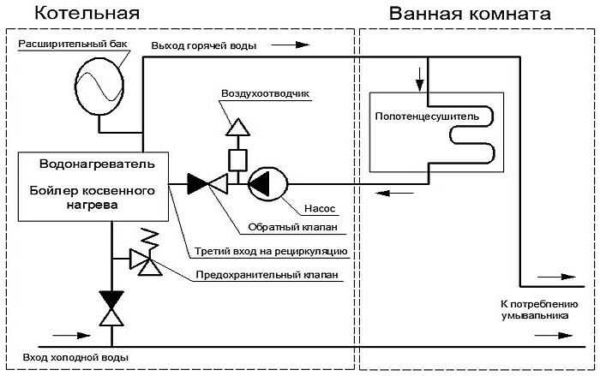

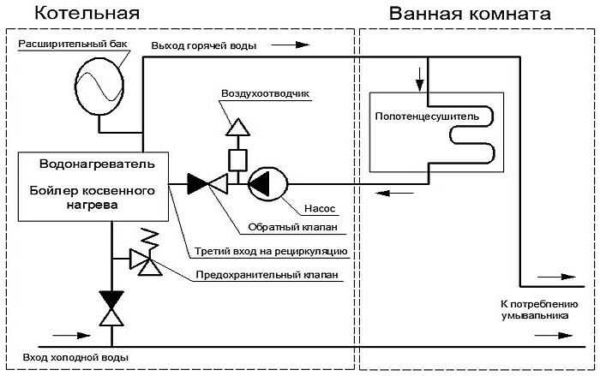

With heat transfer medium recirculation

If there is a water heated towel rail in the system, constant circulation of water through it is necessary. Otherwise, it won't work. All consumers can be connected to the recirculation loop. In this case, hot water will constantly be chased in a circle by the pump. In this case, by opening the water at any time, you will immediately receive hot water - you will not need to wait until cold water flows out of the pipes. This is a positive point.

The negative one is that by connecting recirculation, we increase the cost of heating water in the boiler. Why? Because running along the ring, the water cools down, therefore the boiler will more often be connected to heating the water and spend more fuel on it.

Connecting the recirculation ring to a special output of the indirect circuit

The second disadvantage is that recirculation stimulates mixing of water layers. In normal operation, the hottest water is at the top, from where it is fed to the DHW circuit. With stirring, the overall water supply temperature drops (at the same settings). Nevertheless, for a heated towel rail, this is perhaps the only way out.

How to implement the connection of an indirect heating boiler with recirculation? There are several ways. The first is to find special indirect devices with built-in recirculation. It is very convenient - the heated towel rail (or the entire loop) is simply connected to the corresponding nozzles. But the price of such options for water heaters is almost twice as much as the price of an ordinary tank of the same volume.

Connection of an indirect heating boiler with recirculation

The second option is to use models that do not have an input for connecting a recirculation loop, but connect it using tees.

In order to avoid problems with hot water, no sudden shutdowns, interruptions, an indirect heating boiler is installed. In addition to heating water, its functions include heating living quarters. It can be not only a country house, as many believe. The boiler can also be installed in an apartment, at a production site. The range of applications is very wide.

But, the installation efficiency of such a system is determined by the piping scheme, and it is not necessary for professionals to install it. Installation and piping can be done by yourself. You just need to understand the complex strapping scheme.

Connection rules

An indirect heating system is another circuit, in addition to the existing one, which heats an additional tank, which is called a boiler. It is supplied with the most common water from the mains, which is heated by a coil. In such a system, there is no direct interaction between the coolant and the resulting hot water. Therefore, it received the name indirect.

Before proceeding with the installation, it will not be superfluous to familiarize yourself with some of the rules.

- The water must enter the bottom of the boiler. And the exit must be done from the top.

- The circulation of the coolant of such a system should go from top to bottom.

If you use these rules, then the system will operate at maximum efficiency.

The following video clearly shows some of the piping options for the indirect heating boiler.

Types of strapping

The piping of the indirect heating boiler means the connection of the pipelines of the boiler itself with the water supply. The operation of the system as a whole depends on how the installation is carried out.

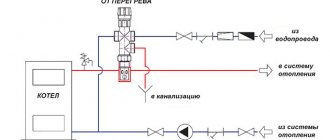

Piping with servo and 3-way directional valve

This is the easiest strapping method. It is used when a large amount of water is consumed.

The boiler is connected to the main circuit and the additional one. The first one is used to distribute heat to the batteries, the second circuit heats the water in the boiler itself. For proper flow separation, a three-way control valve is connected.

The thermostat monitors the temperature of the water in the tank, and when it reaches the set value, a signal is sent to the servo. And he already sends a stream of heated water to the main circuit for heating. If the water temperature drops again, a switch will take place in the opposite direction and the coolant will return to the coil.

The most important point in the setting is that the temperature set on the thermostat must be set higher than the temperature set in the heater! There is no other way to heat the water up to the mark at which it will switch to the heating circuit.

Piping with two pumps

Another piping option is with the parallel use of two pumps. One is mounted on the heating circuit, the other on hot water supply. The control of the pumps, as in the first case, is entrusted to the thermostat. It is he who switches the operating mode.

The heating quality remains at a high level. The main thing is that when piping with two pumps, it is imperative to mount check valves at the outlet of each. This is done to prevent mixing of counter flows inside the coolant.

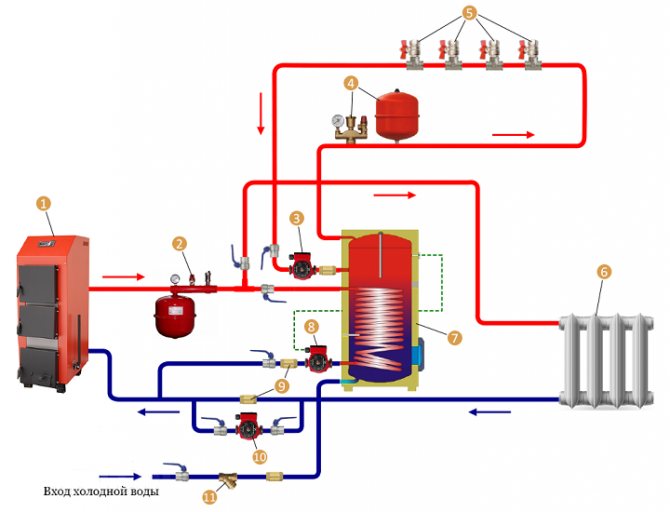

Strapping with hydraulic boom

If the heating system has many branches, such as a multi-circuit battery system or a separate branch to a warm floor, then it makes sense to use this type of piping. To avoid difficulties with a system in which each of the circuits is equipped with its own recirculation pump, a hydraulic distributor is used.

The water gun must balance the pressure in each direction and prevent heatstroke. As for this type of strapping, difficulties are possible here. Therefore, it is better to entrust such a task as installation and subsequent adjustment of such a system to professionals.

Heat carrier recirculation

In the event that hot water is needed as quickly as possible, then it would be more correct to use a recirculation system. Due to the fact that an annular coolant line is formed in the system. The constant movement of water through it leads to heating. That is why the waiting time for hot water is minimized.

To ensure the continuous movement of water, a recirculation pump is installed in such a system. Such a flow of hot water must be installed so that it passes through installations that constantly require heating. A semi-heated dryer is an example of such a device.

Connecting the boiler to a gas boiler

For the proper functioning of a boiler with a gas boiler, it includes a temperature sensor. In order for them to work together, a three-way valve is connected. The valve regulates the flow between the main circuit and the DHW circuit.

To a single-burner gas boiler

For such a connection, a piping with two pumps is used. It is she who is able to come to replace the circuit with a three-way sensor. The main thing is to separate the coolant flows. In this case, it would be more correct to say about the synchronous operation of the two circuits.

To a double-circuit gas boiler

Two solenoid valves will become the main one in this connection diagram. The bottom line is that the boiler is used as a buffer. Cold water comes from the water supply network. The valve for the DHW inlet is closed.If you open it, then first water will flow from the buffer, which is the boiler. The buffer contains heated water, the consumption of which is regulated by the capacity of the boiler and the set temperature.

Scheme using a hydrocollector

To equalize the flows of the coolant in systems using several circuits, there is a device called a distributor or it is also called a hydraulic manifold. It then allows you to balance different pressures in the circuits. It can be eliminated, but this will cause additional difficulties associated with adding balancing valves to the circuit. And this complicates the installation and commissioning of the entire system.

Connection of a solid fuel boiler with an indirect heating boiler

Connecting a water heater with a solid fuel boiler solves two problems at once:

- receiving hot water supply;

- obtaining a way to discharge the coolant in the event of an accident.

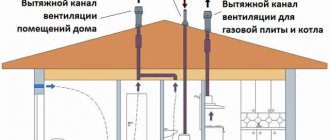

Thanks to the fact that such a system has a thermostatic valve on the battery, the comfort is increased. But there is a danger of the boiler overheating. The same threat arises during power outages. If a larger capacity boiler is installed, this process poses no danger. Because the excess heat is spent on heating the water in the water heater. Accordingly, for the normal operation of this system, a boiler with natural ventilation is needed.

One of the options for piping a solid fuel boiler with a boiler, see the following video.

Frequent installation mistakes

During installation or during the setup process, you need to try to avoid a number of mistakes:

- Boiler and boiler are installed far from each other. Their installation should be made not only as close to each other as possible. But, and to simplify installation, the pipes are correctly exposed.

- Incorrect connection of the pipeline with the heating medium.

- Illiterate installation of the circulation pump.

Competent installation, commissioning and adjustment guarantee a stable hot water supply and allow all systems and devices to operate normally. This will prevent wear of parts and save on premature repairs.