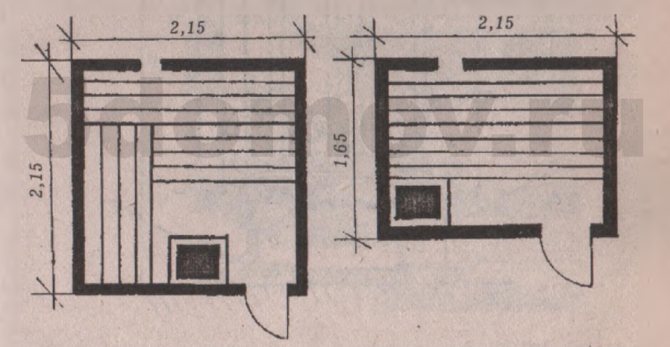

The size of the cellar room primarily depends on how much things you plan to store in it, and in shape it can be round, square and multifaceted. The structure of the cellar includes: the lower part, which goes into the ground, and the ground part (cellar), which is designed to protect the premises from high summer temperatures and winter frosts.

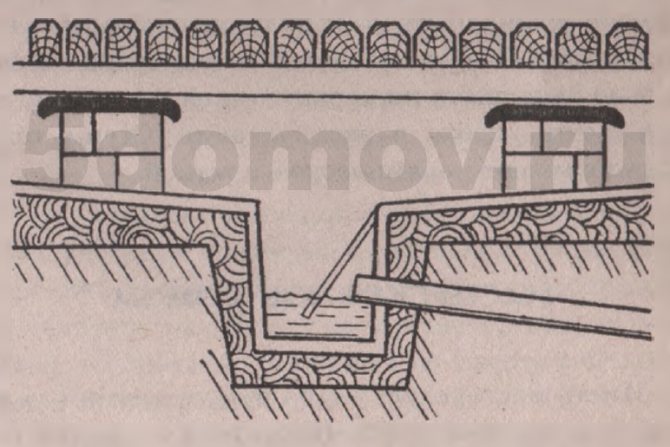

Overlapping scheme over a ventilated rise.

It will be about how best to overlap the cellar, what are the nuances and what you need to pay special attention to in certain options for building a basement.

External arrangement of the basement

For the construction of the cellar, various building materials can be used, such as wood, concrete, natural stone, brick or boards with their further backfilling. The cellar can be used as a regular storage room. Above the cellar, an overlap is made in the form of a flooring of boards on pre-assembled beams, and from above it is covered with heat-insulating material.

It is necessary to take a very responsible attitude to the construction of the vault of the cellar:

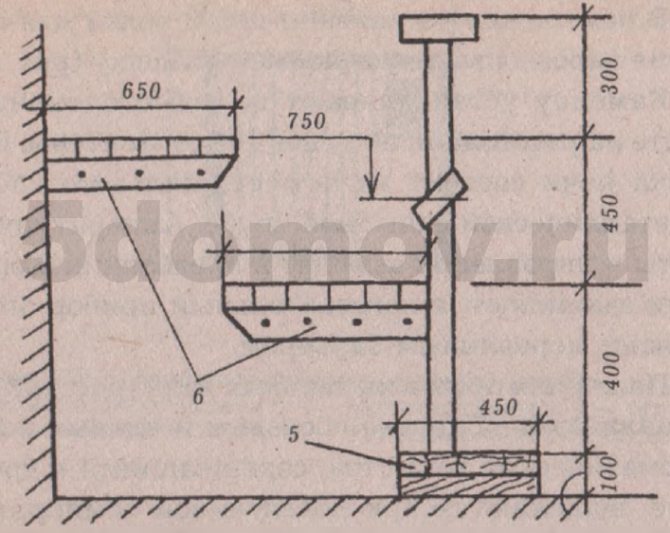

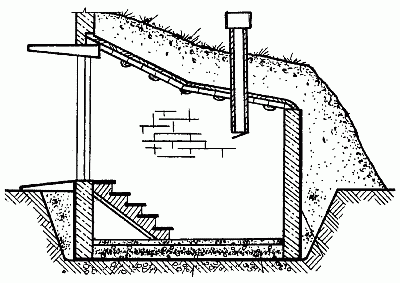

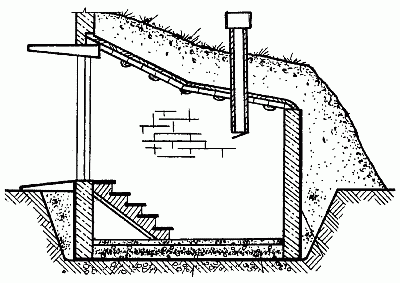

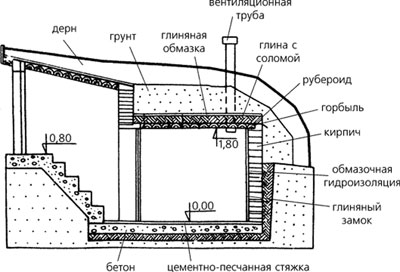

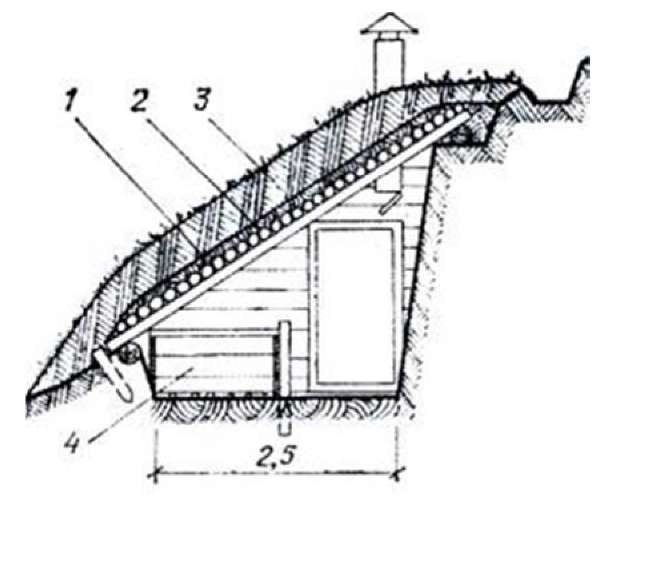

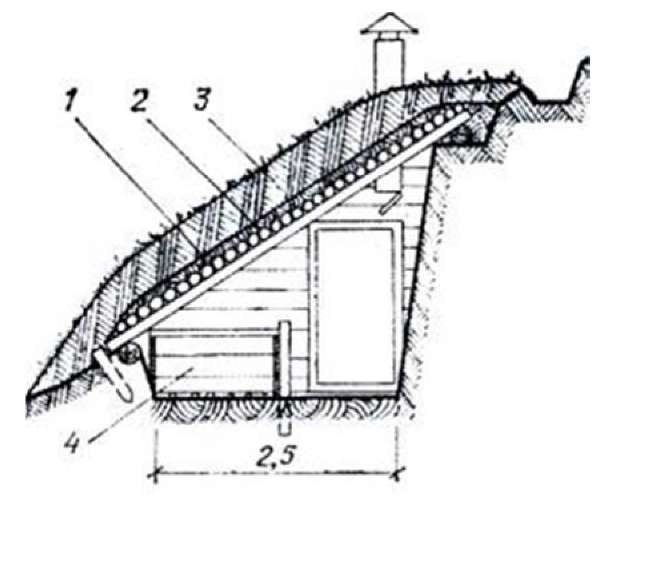

A diagram of the construction of a cellar with a chimney.

- an earthen cellar should have a gable roof that descends to ground level. For its construction, you can use reeds, branches or straw, which is mixed with clay. The roof lathing itself is made of boards, under the bottom of which roofing material or roofing felt is placed. Often, in order to exclude freezing, the overlap is insulated with peat;

- the roof of the cellar, in the design of which the cellar is provided, is made pitched, and to ensure the dryness of the walls, the overhangs must be protruding;

- performing the correct calculation and laying of the vaulted roof of the stone cellar will ensure the strength and reliability of the entire building. It is done on timber formwork with circles, which must be carried out simultaneously from both sides. In the presence of dry places, vaults can be built from unbaked red brick;

- the roof of the deboned ground cellar is made of clay, which is mixed with straw. After that, polyethylene or roofing material is applied to it.

Basement overlap options

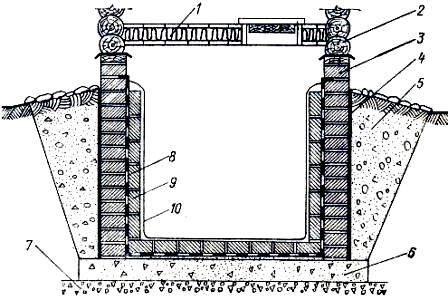

Waterproofing scheme from the side of the cellar: 1- overlap of the cellar; 2- wooden frame; 3- brick wall of the cellar; 4- coating with bituminous mastic; 5- filling the sinuses; 6- concrete base; 7- preparation from compacted rubble; 8- glued anti-pressure waterproofing; 9- protective wall; 10 - cement plaster.

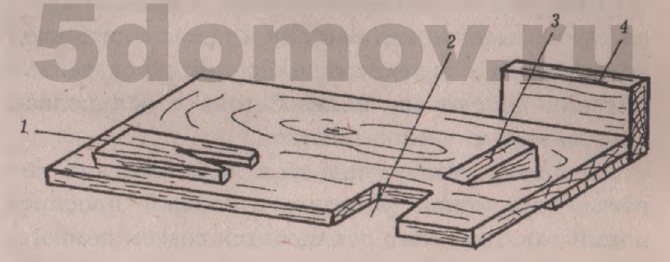

After the pit is filled at ground level, the next stage of construction follows - the overlap of the cellar. As a rule, for this purpose, a kind of cornice is built around the entire perimeter of the pit made of ceramic red brick. It should be borne in mind that the laying of each row of bricks should protrude outward by about 3 cm more in comparison with the previous row. Then the cornice is covered with roofing material, on top of which any of the bulk insulation should be laid. After that, you need to make a cement screed, the thickness of which is at least 2 cm, and paste over with roofing material.

For the construction of a vault, various materials can be used, it all depends on the type of structure and the availability of funds for this, but in any case, the structure must be strong, since a large load will act on it. In addition, close attention should be paid to the implementation of waterproofing of the basement floor.

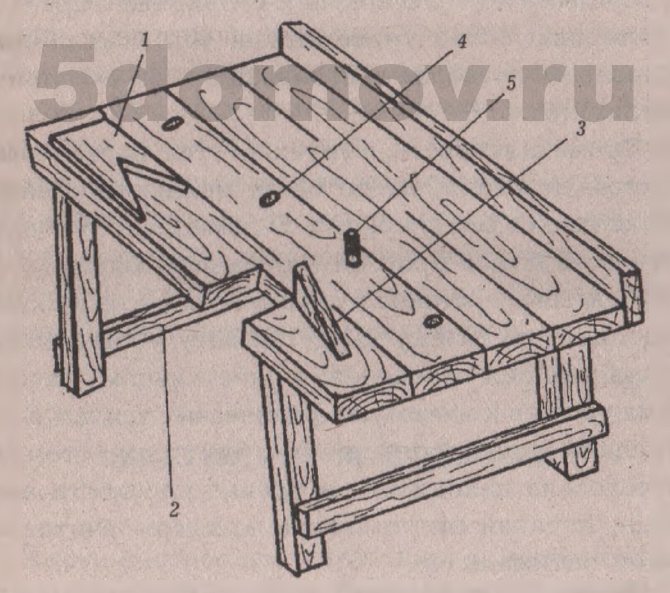

You can also make a basement overlap from wood.For this, beams are initially made, and after that they are covered with beams or boards. It should be noted that when using wood for the construction of the basement floor, it must be treated with an antiseptic.

After the installation of the flooring from the boards, thermal insulation material is applied. Alternatively, you can use ordinary clay, which is subsequently covered with dry earth. The thermal insulation layer must be at least 0.5 m thick.

There is one but a very significant drawback in using wood for the construction of a basement floor - wood lends itself to decay.

The cellar overlap scheme is made of a slab insulated with clay grease and earth.

Therefore, wooden floors often have to be repaired.

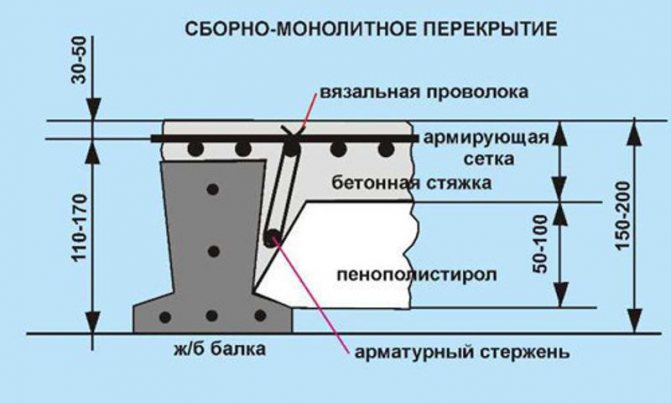

According to experts, the best material for overlapping a basement is a reinforced concrete slab or concrete mixture. Of course, due to the presence of reinforcement in a reinforced concrete slab, it is much stronger than concrete. With this design of the floor, special attention should be paid to the sealing of the seams. For this purpose, you need to use a cement mortar. Often, it is necessary to make concrete, and even a mortar, at home, while it is best to give preference to cement with the M 200 or M 300 brand.

Features of using concrete slabs

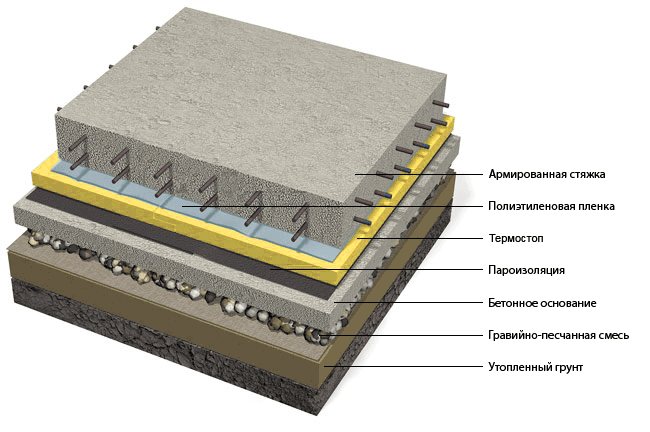

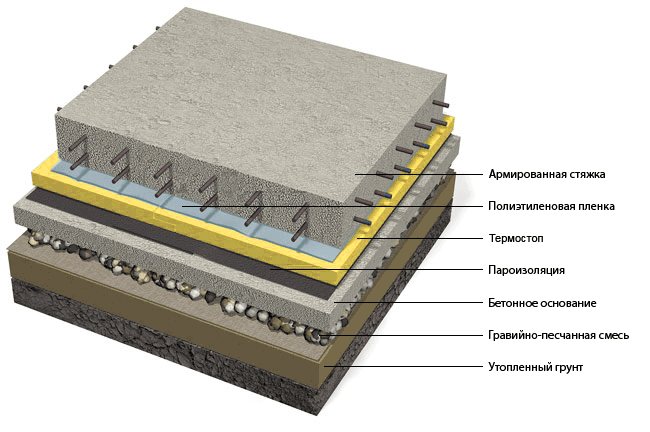

Cellar floor insulation scheme.

After the reinforced concrete slabs are laid, and the joint joints are sealed with cement mortar, their surface is covered with 2 layers of heated bitumen, and sheet roofing material is laid on top of them. For insulation of the slab, as a rule, slag wool is used.

Often, a cellar is built above the cellar with such an overlap, this will create additional protection for it. The shelter of the cellar itself is recommended to be made of materials that poorly transmit heat. Experts also argue that the door must be built from the north side so that on a hot summer day it is less heated by the sun's rays.

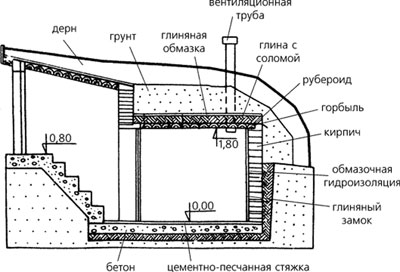

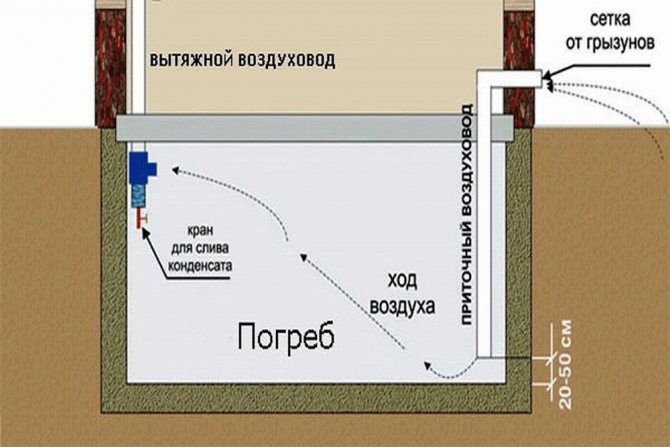

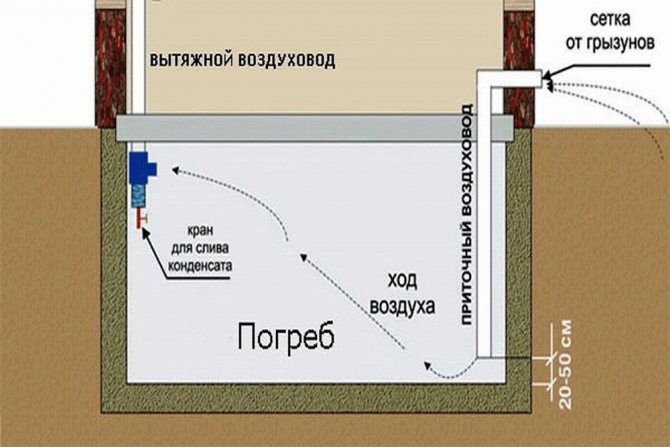

A hatch is often made in the basement floor, which is intended for the intake of fresh air. It is recommended to build a ventilation system in the basement. This requires only two pipes, which are led out into the street through a hatch or directly through the ceiling.

A cellar can be built either under a building or in an open area. In the first version, the floor is always built flat, and in the second it can be made gable.

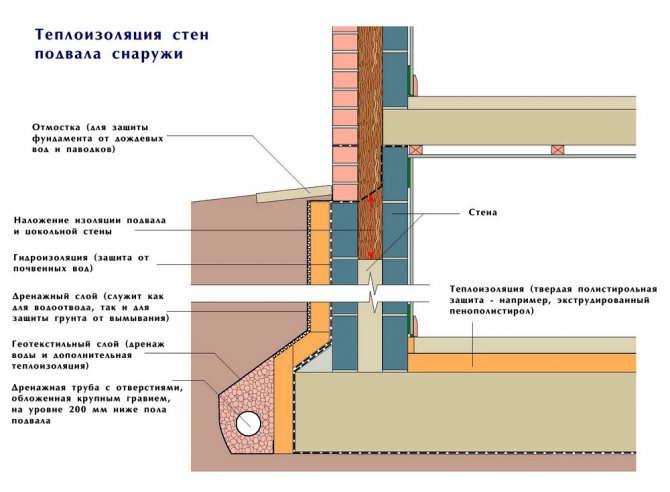

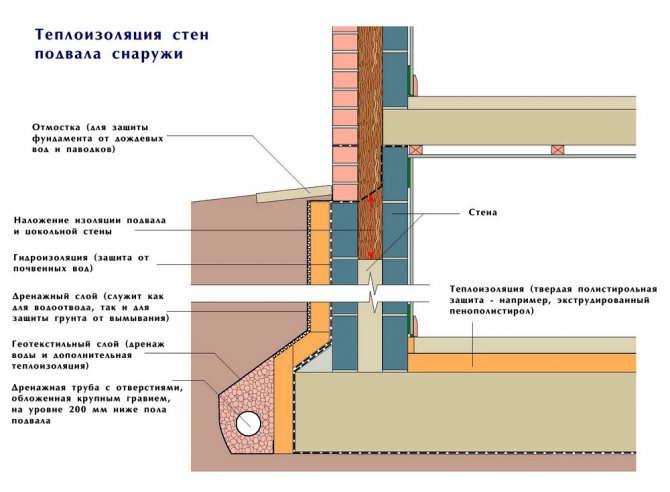

The scheme of thermal insulation of the walls of the basement from the outside.

The correct floor created under the building must be supported by the ground or beams. In both options, it is best to use large-panel reinforced concrete slabs. Do not forget that before installing them, you must first lay the boards under the plates, which will be necessary for hemming the ceiling surface. The resulting ceiling voids must be filled with heat-insulating material before filing. The slabs should be welded on their crest and rest on the beam, and the lower part on the ground. This position of the slabs will reduce the load on the walls.

How to make a basement overlap in the absence of large-panel reinforced concrete slabs? According to experts, you can use slate, under which you pre-mount a solid foundation. In this case, the seams of the floor are sealed with cement mortar, after which the slate floor is covered with soil, which is compacted tightly.

Ventilation in the technical underground

Fresh air must be regularly supplied to technical rooms through exhaust ducts and windows. According to SNiP, in the technical underground of a residential apartment building, air vents are necessarily made to circulate air, reduce condensate and for fire safety purposes.

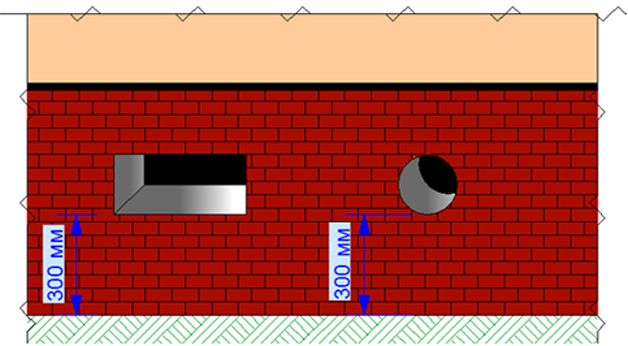

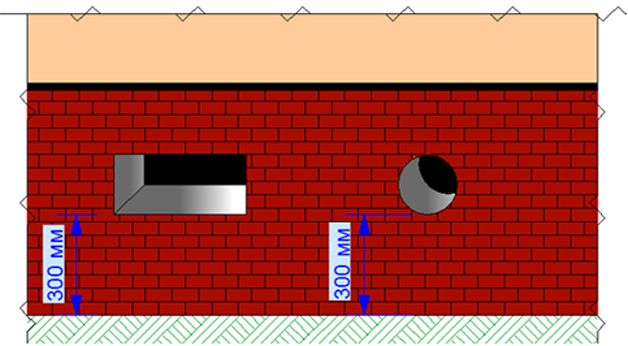

The standards prescribe to make ventilation openings with a total area of at least 1/400 of the area of the basement itself or the technical underground. The holes are placed symmetrically on both sides of the house. It is recommended to make airflows approximately 20 x 20 cm at a height of 30-40 cm from the level of the outer blind area of the foundation.

Examples of airflow devices.

Also in technical undergrounds they make dry insulated chambers with equipment for supply and exhaust ventilation. They are provided with access for inspection and repair.

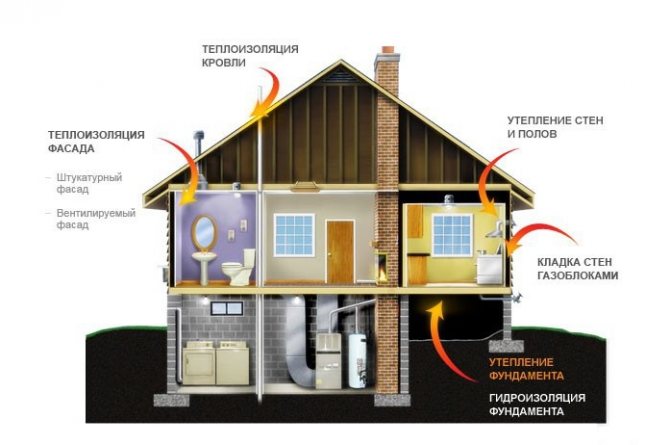

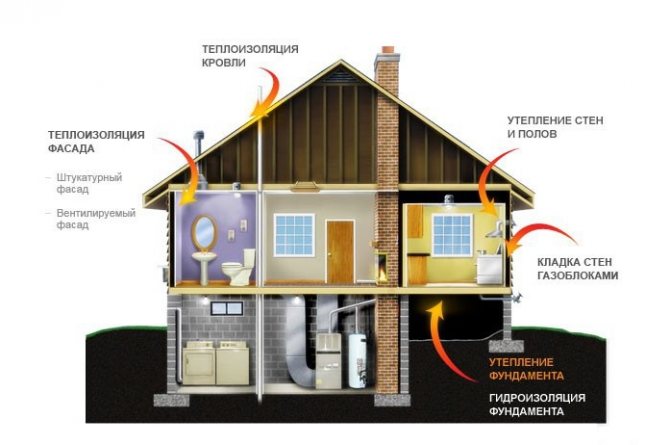

In winter, in basements and technical undergrounds, the air temperature is maintained at least 5 ° C, while the relative humidity should be no more than 60–70%. To eliminate heat loss in the technical underground, walls and ceilings are insulated. Heating and water pipes are wound with heat-insulating materials.

If excess condensation or mold appears on the equipment in the technical underground, additional waterproofing should be done and ventilation should be carried out through the doors and windows, installing protective grilles on them. In blank walls, at least two air vents are knocked out for each section from both sides of the foundation.

Overlapping the basement when building a garage

Basement diagram of an apartment building.

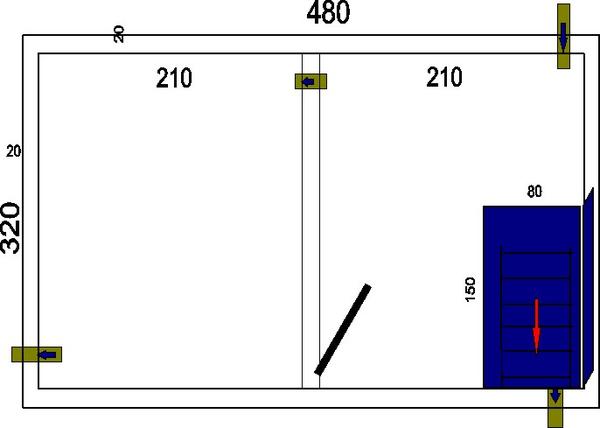

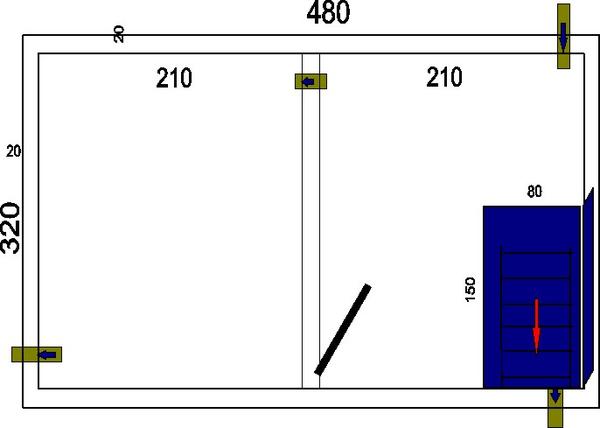

Many vehicle owners have a garage that has a concrete block basement. Such a garage will allow you to store not only equipment and spare parts, but also food in it. In order to feel completely safe while in the garage, you need to adhere to some basic conditions when building a cellar.

When building a basement, the main attention should be paid to the structure of the floor itself, since its variety depends on the size of the garage, the size of the basement, and, of course, on the amount of equipment that will be left in the garage. Experts recommend providing a basement in terms of construction work even before they begin. Then, when organizing the sequence of work, it will be possible to take into account all the requirements imposed on the design in an optimal way.

One of the important parameters of the overlap is its strength. It should not be forgotten that it primarily depends on the strength of the support of this floor. In the complex construction of a garage with a basement, it is best to use standard concrete slabs as a floor. Thus, the basement walls will act as a supporting foundation for the entire garage building and at the same time as a support element.

Basement and cellar classification

Before proceeding with the construction of a cellar in a private house, it is necessary to study the features of the available options. There are several types of building structures. Each of them pursues its own goals.

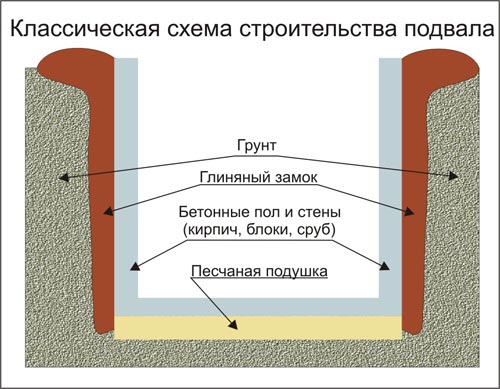

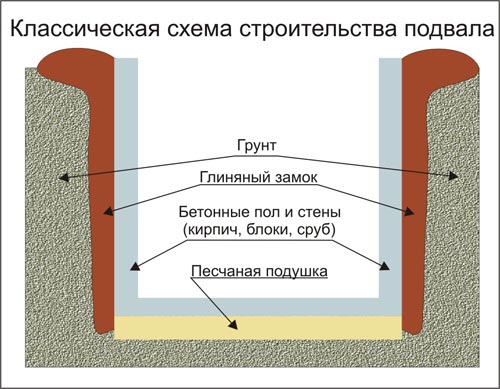

The classic basement construction scheme.

So, for example, a basement cellar is perfect for storing vegetables and fruits, preparations for the winter, etc. However, in the case of the construction of such a cellar, the heating device is prohibited, which is not entirely good for the foundation.

The technical basement will allow placing various engineering structures, such as boilers, water heaters, filters, etc. This makes it possible to get rid of bulky structures in the kitchen or bathroom and use the usable space with maximum efficiency.

The basement can be equipped with a billiard room or study. It all depends only on your needs and wishes. If you want, such a basement can even be turned into a gym.

A spacious basement equipped for a workshop is a real salvation for everyone who loves to make something with their own hands. The room can be divided into 2 functional areas: a warehouse for storing various kinds of tools and a workshop.

One of the most popular options is building a basement garage.It is important to take into account that the main condition in this case is the availability of a convenient entrance.

The basement of the house should be very spacious, because you will need to worry not only about organizing the proper conditions for storing the car, but also for carrying out repair work.

The cost of building a basement can vary widely. To a large extent, it all depends only on your requests. You can always choose an option with an acceptable construction cost.

Influence of soil on the construction of a basement

Scheme of a cinder block wall and a partition in the middle of the cellar.

During operation, horizontal forces will act on the walls of the basement from all sides of the surrounding soil. These forces are trying to deform them. Based on this, the thickness of the walls being erected should increase in proportion to the depth of the pit. The walls of the cellar are best constructed from concrete blocks. If there is not enough money to purchase them, concrete walls can be built using slip formwork instead.

The bottom of the cellar is covered with a layer of rubble approximately 10 cm thick and a layer of sand at least 5 cm thick. After that, a strip foundation is built. It should be noted that this foundation will be affected by the walls of the cellar, its overlap and the entire structure of the garage room.

In order to do everything properly, experts recommend conducting exploration work at the construction site. This will make it possible to find out if underground utilities are located below, for example, an electric or telephone cable, or, perhaps, groundwater is close enough to the surface.

When the garage is planned to be placed on soil that is abundantly saturated with moisture, it is necessary to create a circular drainage system - this will allow moisture to be removed from the area adjacent to the garage. But under any circumstances, it is necessary to perform external waterproofing of the basement of the cellar.

Diy cellar construction scheme.

If the construction will take place on a sufficiently dry ground, waterproofing can be done by applying two layers of hot bitumen. If the soil at the construction site is wet, you will need to pasting concrete blocks with rolled roofing felt, which has a bitumen base.

Polystyrene foam is considered an excellent waterproof and at the same time insulating material. This material is highly resistant to decay and mildew. Installation of this type of insulation is done by pasting over concrete blocks from the outside. It should be borne in mind that the size of the slabs is carefully adjusted to each other, and the joints are also subject to finishing.

Cellar construction

Before proceeding directly to the construction of the storage, it is necessary to choose a place for the construction of the cellar. The place for the construction of a grocery store may well be a site with a hill, where atmospheric moisture cannot enter and accumulate. With high groundwater, it is necessary to build a ground cellar.

To determine the level of groundwater, it is recommended to drill a well with a depth of more than 2.5 m. If the groundwater is located above 1 measure, it is impossible to deepen the basement.

Advice!It is recommended to equip a semi-buried building with a groundwater height of 1.5 m.

The construction of the cellar is carried out in stages:

- Preparation of the pit.

- Laying of a drainage pad made of gravel, expanded clay, crushed stone, sand.

- Laying a waterproofing layer.

- Reinforcement and concreting of the floor.

- Formwork preparation for wall erection.

- Installation of fittings.

- Wall concreting.

- Sealing with a vibrator.

- External waterproofing.

- Internal waterproofing.

- Ceiling and wall plastering, cladding.

- Arrangement of space with racks and shelves.

- Ventilation equipment.

- Ceiling arrangement.

Basic principles when laying a cellar

Laying the foundation

When laying the foundation for the cellar in the basement, you must follow the recommendations:

- The size of the pit along the perimeter must be increased by 30-40 cm from the actual size.

- The minimum foundation depth is 30cm.

- The perimeter is reinforced with formwork to prevent the earth from shedding.

- Pillars with a height of 10 cm are installed in the corners.

After installing the foundation, they proceed to waterproofing and pouring concrete into the floor. Waterproofing is equipped with a layer of crushed stone, gravel or construction debris. For greater effect, dry mixes are filled with heated bitumen. Sheets of roofing material are laid on top. On top of the waterproofing layer, the basement cellar floor is covered with sand.

Walling

If the site is wet, the walls of the cellar are mounted from reinforced concrete grade 350. The most suitable replacement for concrete is brickwork or stone. But the use of these building materials is recommended on dry soils. Stages of installation of basement walls:

- Formwork installation.

- Installation of reinforcing mesh.

- Layer-by-layer concrete pouring with careful compaction.

- The top of the reinforcement sheet is attached to the ceiling.

- After careful and prolonged drying, the formwork can be disassembled. Dismantling should be done after 4 weeks.

Arrangement of the vestibule

A vestibule with two doors is being built in front of the storage. The air that accumulates in the vestibule acts as thermal insulation. Thanks to him, the necessary microclimate is created in the storage. When creating a cellar scheme, it is necessary to carefully consider the number of steps in the staircase. The width of each tread is at least 200mm. A well-designed space will provide access and accessibility to any shelf and storage rack.

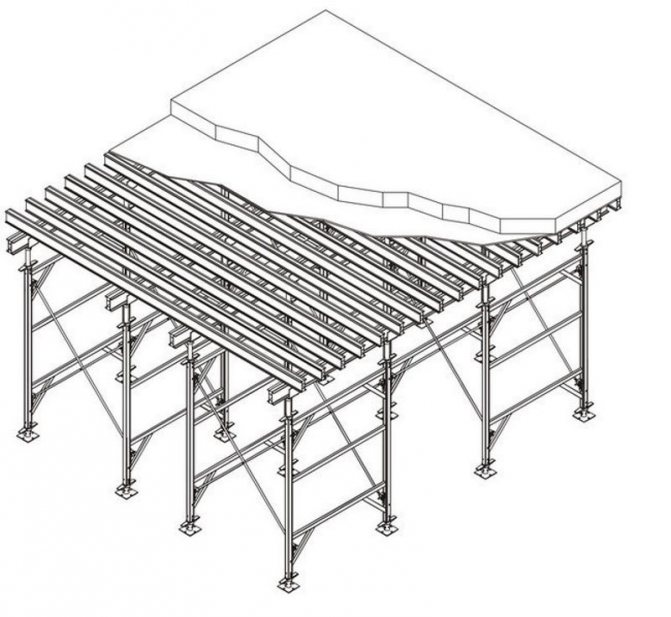

Ceiling slab

The basement ceiling is made using the non-removable formwork method. Concrete grade 250 is used as the main material. Stages of installation of the ceiling slab:

- A transverse frame is made of wooden beams.

- A reinforcing mesh with 20 cm cells is laid on top of the frame.

- The wall fittings are connected to the ceiling fittings using a knitting wire.

- Formwork is being built.

- Pouring with concrete takes place in several stages. Each layer must be thoroughly tamped and allowed to dry.

Complete solidification of the ceiling fill occurs after 3 weeks.

Waterproofing

The basement requires careful waterproofing. The device of a moisture-protective layer in the cellar is carried out using mastic and bituminous liquid mixtures.

Sheets of roofing material are fused over the walls, which is carefully connected to the floor covering, additionally smearing the seams with mastic. The outer walls and ceiling are protected with expanded polystyrene plates. The ceiling is insulated with a double layer of roofing material. A layer of crushed stone with sand is poured on top. Then, geotextiles are laid. The final covering is the earth shaft. Soil is natural thermal insulation. To strengthen the earthen embankment, it is necessary to plant ground cover plants with a developed root system.

Waterproofing the cellar in the garage

Cellar ventilation

Without constant air exchange, food will not be stored indoors. Therefore, a very important stage in the arrangement of the cellar is the installation of the ventilation system. The principle of arrangement of ventilation:

- The chimney is secured. It must be fixed at the highest point under the ceiling.

- The supply pipe must be placed slightly above the floor covering.

- The ends of the pipes are led out.

- The formed vents in the walls between the pipes must be insulated with polyurethane foam.

- On the outer ends of the pipes, visors from moisture and a net from rodents and insects are hung.

Ventilation vents can be made of concrete. Using the formwork, mount the pipe and insulate with mastic and roofing material.

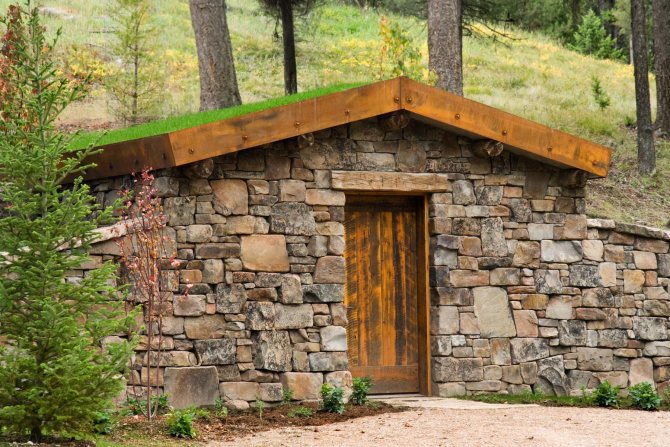

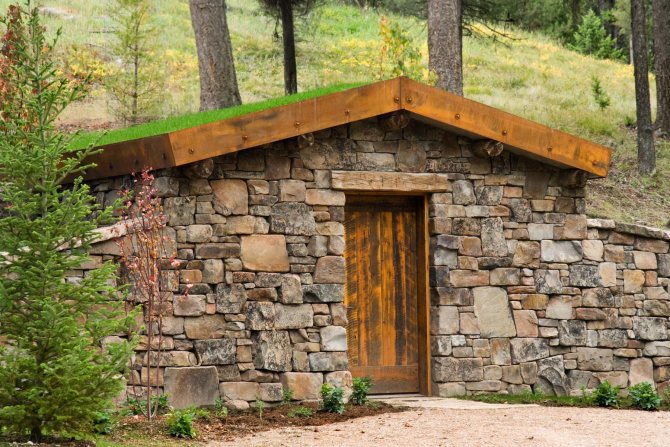

Facade decoration

The facade of the outer cellar must meet increased requirements for the durability of the material. In addition, the door must fit snugly, excluding the occurrence of drafts.

A cozy hillock-cellar fits perfectly into the landscape of any personal plot. By laying out a beautiful path to the basement and revetting the facade of the storehouse with natural natural stone, an ordinary cellar will turn into the most beautiful part of the site.

Cellar in the house

Cozy cellar under the terrace

Overlapping the basement in an already erected garage

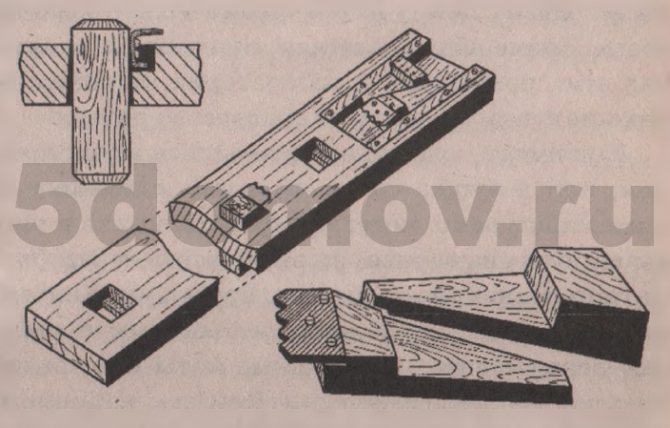

Diagram of an earthen cellar on a slope: 1- reel; 2- clay; 3- soil, 30 cm.; 4- bins.

How to overlap the basement if the garage has already been built? Of course, in the built garage it is impossible to use standard reinforced concrete slabs to overlap the cellar, since special equipment is required for their installation. But the answer to this question is still there.

In this case, the floor is constructed using the installation of load-bearing beams. Experts recommend using beams with an I-section for this purpose. Often, motorists use railway rails for this, pieces of which can be purchased at any scrap metal collection point. It should be borne in mind that for the supporting beam, the mine rails will be weak. They are ideal as cross members that are laid perpendicularly to the load-bearing beams.

You need to know that for the ends of the bearing beams on the walls of the basement, you need to provide a bed. Thus, the basement walls will act as the foundation for the entire garage structure. After the bearing beams are mounted, reinforcement is laid in the space formed between them. Then the lower formwork is mounted and concrete is poured. You will get a self-made reinforced concrete slab.

When the planned cellar is small in comparison with the area of the garage, then there is another option for constructing a basement floor. In this case, the cellar will be located in a place where there is no load from the weight of the equipment, and its overlap can be made more lightweight.

In all versions of the construction of the floor over the basement, the structure needs insulation.