To minimize heat loss in the home and reduce heating costs, it is advisable to take measures to insulate PVC window sills. Before doing it, it is necessary to understand the intricacies of how to insulate the sill of a plastic window and the procedure for carrying out the work. Directly before the thermal insulation of the plastic window sill, it is dismantled.

This is necessary in order to thoroughly repair chips and cracks on the surface of the window sill slope. In this way, sources of drafts are eliminated. To cover up cracks, use polyurethane foam or acrylic sealants. Then the window sill plate is mounted in the reverse order and the joints are processed.

Thermal insulation of window sills

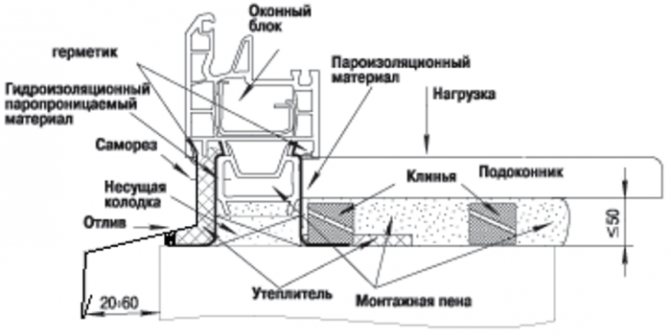

The source of heat loss in the room is the cracks between the wall and the window sill. Before starting thermal insulation work, they determine the vulnerable spot of the window sill - the point from where the cold penetrates. Heat leakage can occur between the plastic frame parts and the window sill, for example. To eliminate the source of the draft, use a sealing compound.

Blowing is also possible between the wall and the window sill. Thermal insulation is carried out before the installation of the window sill slab, laying the insulation, followed by foaming the gaps between the window sill and the brickwork or concrete wall.

Instrument preparation

To carry out work on the thermal insulation of window sills of plastic window systems, you will need a set of tools:

- Building level.

- Perforator.

- A hammer.

- Putty knife.

- Chisel.

- Fine-toothed hacksaw.

- Knife.

Expert opinion

Konstantin Alexandrovich

During installation and dismantling, you will need a brush with stiff bristles or a broom, a vacuum cleaner for cleaning the rooms.

Materials for thermal insulation

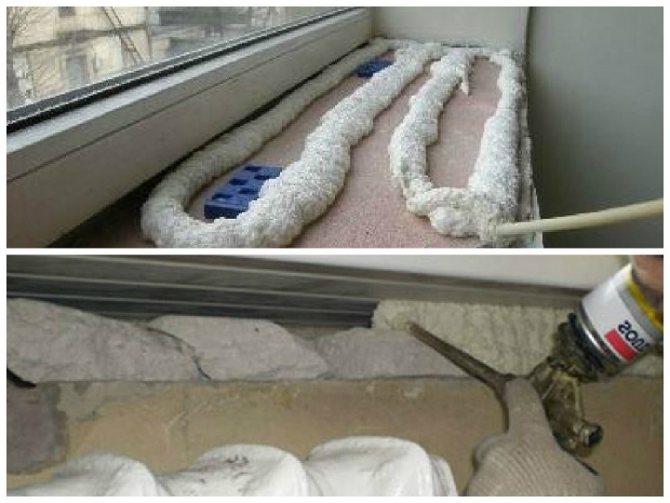

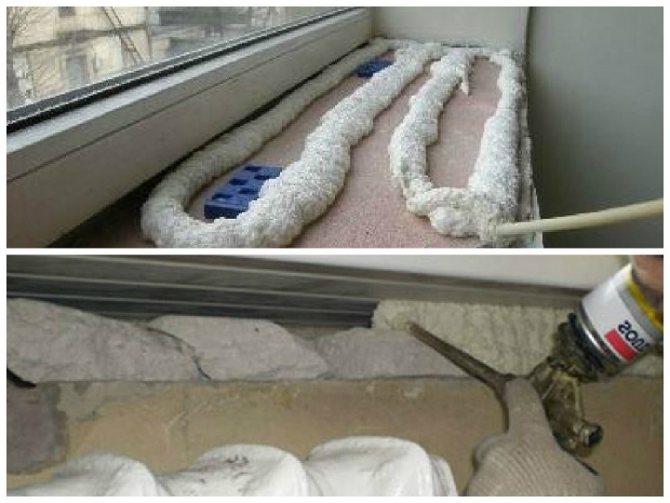

When the cause of the drafts becomes known, insulation work can begin. It is necessary to purchase thermal insulation materials. An excellent option for eliminating sources of blowing through the window sill is polyurethane foam. It covers the entire perimeter of the PVC window sill. The foam is applied in the center with two crossing lines to facilitate the attachment of the window sill to the base of the window. The next step is to mount the structure to the base of the opening in the window.

Reference. The polyurethane foam tends to expand within a day after application. The window sill must be securely fixed for 24 hours to prevent movement.

Acrylic sealant can be used as an alternative to foam. It is a non-toxic polymer suitable for indoor and outdoor use.

How to insulate a modern plastic window sill?

The simplest and most frequently used method is to add a new insulation layer on top of the existing one, with a greater width, and properly glue and insulate it under the window opening. For such purposes, a PVC plate made of modern polymer of various densities is ideal. The additional trim will not look bulky and stand out from the overall interior. Plastic thresholds are very cheap and easy to install.

Another option would be a solid piece of stone or concrete - along the entire length of the window. In this case, a monolithic slab will be installed on a concrete base across its entire width. For such an installation, waterproofing mixtures or cement with the addition of liquid glass are used. Visible areas of the cement masonry are treated with a starter or topcoat to give the window an aesthetic appearance.

If you don't feel like messing with plastic or stone, there is another option - a self-leveling base made of XPS Liquid Powder. This technology ultimately offers an innovative and stylish finish that can imitate any surface (stone, wood, plastic and even sand).

How to install a plastic window sill?

The installation of the window sill begins after the preparation of the frame surface. The portable window sill is applied to the base of the window structure. Wooden supports are prepared, which will provide the calculated stiffness of the slab during operation. To do this, make internal and external measurements of the actual distance from the base to the bottom of the window sill using a tape measure. When the window sill lies at the base, use an acrylic sealant or polyurethane foam. Close the joint of the inner surface of the plastic window sill and the installation profile to prevent the formation of "cold bridges".

To securely fix the wooden supports, use foam. The final stage is foaming the installed window sill slab and the external wall joint.

Window sill installation, joint processing

Sealing of polyurethane foam under the windowsill

For installation, you need to find the horizontal position of the window sill, use wooden blocks of various sizes for this. When you have found the optimal position of the window sill canvas, polyurethane foam is applied along the perimeter of the slope, and two intersecting lines are applied in the center. You can check the installation using a level. Since the foam will still expand, you should fix the window sill for a day by placing cans of water or a stack of books.

After the foam has hardened, a dry mixture is applied to the slope with a spatula. The surfaces are allowed to dry for a while and are covered with a finishing filler, which is smoothed with sandpaper. After that, the plastered slopes are painted, and the wallpaper peeled off at the edges is glued back. The joints between the window sill, window frame and PVC panels on the slope are sealed with a waterproof sealant.

No. 4. Replacing the seal

Ideally, a rubber seal can last long enough, but certain conditions must be met for this. According to the rules for the operation of plastic windows, the sealant must be regularly lubricated with special substances, but which of us does this? So it turns out that after 5 years, the rubber dries up and starts to let the cold breeze from the street. The problem may be in the seal, which is located under the glass, or in what is along the contour of the sash. Replacing the seal in a plastic window is not so difficult as it is responsible. If you are in doubt about your skills, it is better to call a specialist.

What does the "Warm Windowsill" consist of?

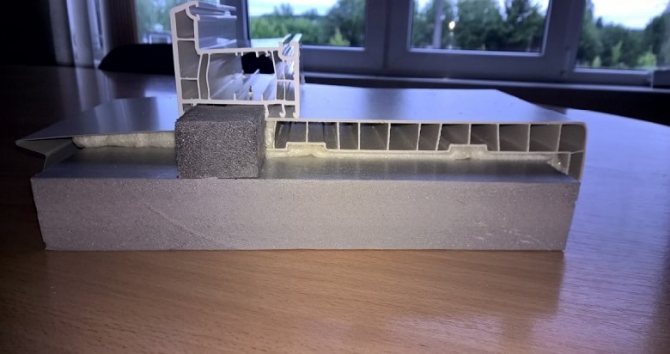

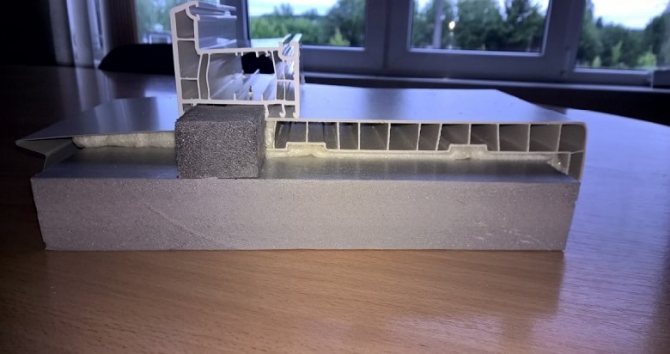

The scheme of this type of warm window sills is quite simple. Its main part is enclosed in a window-sill block made of expanded polystyrene with increased rigidity, which perfectly transfers loads. This material is inexpensive, so the purchase of material for insulating all windows in the house will not amount to a giant figure that can ruin your budget. Expanded polystyrene creates a tightness that is not broken for a long period of time, even if the weather outside the window is not encouraging.

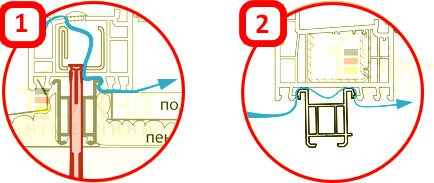

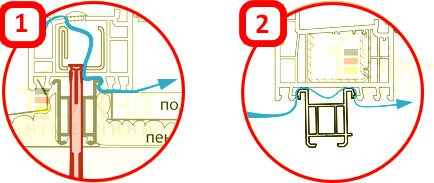

The junction of the window sill with the frame is considered the most problematic, since it allows the most cold air to pass through. It is in this place that the window is thinnest, it touches the wall, creating an excellent path for the flow of cold air. And when the wind is outside, this flow is quite noticeable if you are near the window. And due to the difference in temperature conditions inside and outside the room, condensation forms.The "Warm Windowsill" system is aimed at combating this phenomenon, due to which residents of standard houses have suffered for many years. The polystyrene slab, which underlies it, has the following positive features:

- Good thermal insulation. Its coefficient for such slabs is 0.04 W / m * ° C. If we compare a layer of this material with a layer of brick, then expanded polystyrene will be about 16 times warmer than a brick.

- Good moisture resistance. The polystyrene board is not able to absorb or dissolve in water. It is guaranteed to protect your window and the walls around it from moisture.

- High strength index. Roofs, foundations and even railways and swimming pools are insulated with the same slabs, which testifies to the reliability of such a material.

- Safety for human health. Scientists say about expanded polystyrene that it does not decompose and is completely inert in a chemical sense. It retains such properties for at least fifty years.

- Price policy. This material is available for all categories of the population of our country.

Possessing such remarkable characteristics, expanded polystyrene easily copes with increasing the thermal efficiency of window blocks, eliminating the possibility of cold penetration into the house and preventing condensation. It also helps to improve the level of waterproofing of the window as it moves it away from the walls. Thanks to the "Warm Windowsill" system, the quality of installation of the entire window structure is significantly improved, since all window elements receive a rigid support base.

Warm windowsill. Views

When the customer says that he would like to see warm window sills in the project of his house, the architect always finds out what kind of system he has in mind. After all, “warm window sills” are often called electric warm windowsills, inside which heating elements are laid, and a warm water window sill, which is heated with the help of constantly circulating hot water. Both of these innovative systems, as well as an infrared warm window sill with a heating film, are an ideal way out of a situation if for some reason it is impossible to install a warm floor or warm skirting boards in the room. They can quickly heat the room to the desired temperature, you can control them using the remote control, and even using an SMS message if you want to turn on the heating while away from home.

Related article: DIY installation of window sills and slopes

Warm electrical window sills create a rather tangible load for electrical wiring in the house, therefore, before installing such systems, you need to make sure that the wiring can withstand their frequent use. In order to install a warm water sill, you need to create a whole web of copper pipes, the beginning of which cuts into the central heating system. An infrared warm window sill with a heating film also uses a certain amount of energy. All three of these options are economically disadvantageous, since their operation will be accompanied by impressive utility bills.

The fourth type of warm window sills, the installation of which will be discussed further, is the patented "Warm window sill" system. Its essence lies in the installation of such a window structure, which will be absolutely airtight and due to this, the heat that is inside the house will not get outside, and the cold and wind will not get the opportunity to get inside. When this system appeared on the market, its popularity immediately became immense. Today, almost all construction companies use it and recommend it to their clients as the most profitable type of warm window sills in material terms.

Everyone knows that most often the cold gets into the room precisely because of improper installation of windows. There is always a draft under the windowsills, the sections of the wall under them are most often prone to dampness. Even warm electric windowsills and warm water sill unable to stop the flow of cold air that seeps between them and the wall surface on which they are installed. Thus, a lot of heat, and with it your money, goes to heating the street. Thanks to the innovative system "Warm Windowsill", this problem is now completely solvable. If you use it for all windows in your home, then its thermal efficiency will rise by several points at once.

Identifying critical spots

It is very important to know exactly how cold air enters the room. To do this, you need to take a lighter and hold it around the entire perimeter of the plastic window. Pay special attention to the places where the frame is adjacent to the wall. The windowsill and slopes are also worth checking out. If you don't have a lighter, use an open hand.

To carry out effective insulation of plastic windows, you must first figure out where the tightness is broken. Immediately from the list of suspects, only the frame can be deleted: multi-chamber plastic is a good heat insulator, it does not dry out, unlike wood.

Cold air can penetrate such structural elements:

- clamping elements that tend to loosen over time;

- the detached glazing bead that holds the glass unit;

- worn out seal;

- polyurethane foam, if it was applied in violation of the technology;

- windowsill;

- slopes.

A double-glazed window rarely causes a violation of thermal insulation (the exception is its depressurization), but it can also be additionally insulated. "Extra" warmth in winter will not hurt in any way.

It is easy to identify leaking elements of the window - just hold your palm along and across the entire structure, and you will feel that in some places it is blowing decently. Some people advise using a lighter for this purpose. If you light a flame and hold it around the perimeter of the window, keeping a safe distance, then it will tilt in those places where there is even a slight draft. Be extremely careful with this method!

As a rule, work on the insulation of a plastic window can be done by hand. The exceptions are cases when it is necessary to insulate the slopes from the outside, and the apartment is located above the second floor. It is necessary to be prepared that complex insulation may be needed if several zones of warm air leaks are found, but first things first.

New windows or warm windowsill?

Any resident of an apartment or a private residential building ultimately asks the question: is it possible to make warm windowsills on their own? As a rule, the sill is not insulated, but protrudes over any insulating layer. If we look from the inside of the room, then cold air will blow from such a window, because there is no insulation between the lid itself, the window block and the stove. Outside, the situation is similar, but here also water can be poured during rain, and moisture can simply seep under the inner layers of external insulation.

The ebb should stick out from the wall so that water can drain normally and not collect under the window frame. Without it, rainwater will flow down the walls, saturating the entire structure and foundation with moisture. Ultimately, this will cause certain problems.

Initially, the materials under the window frame are as follows: concrete or brick slab - plastic or metal - window block frame. As a rule, many people make a mistake and leave everything in that order. As a result, the owners of the dwelling receive obvious design flaws with such an installation:

- Wet insulation (inside and outside).

- Mold growth.

- Poor indoor air quality.

- Cold air infiltration.

- Cold floors.

- Low energy efficiency for the whole house.

- Additional cooling of heating devices (radiators).

- Reduced efficiency of window openings.

- Premature decay of the timber frame.

Window sill insulation

Currently, a huge number of people need to insulate the windowsill of plastic windows or the place under the windowsill. Let's look at the main reasons for this interest in this issue:

- Condensation or icing on the windows. In rooms with high humidity, when the temperature changes, the windows begin to either "cry" or become covered with a crust of ice. This problem is troublesome not only for residents of residential premises, but also for users of commercial premises. For example, in banquet halls and restaurants, the most favorable conditions for visitors should be created, besides, wooden furniture does not tolerate changes in temperature and humidity, like many other interior and household items. In this regard, warming the place under the window sill or the window sill itself is the best way out of the situation.

- Creation of favorable conditions for potted plants and indoor flowers in the winter. Often, owners of a mini greenhouse complain that plants die in winter due to non-compliance with the temperature regime, but not everyone has the opportunity to move flower pots from the windowsill to other places. In addition, any plant, in addition to the temperature regime, requires compliance with good lighting conditions, which can be observed exclusively on window sills.

- The need to organize an additional source of heating. In the off-season for residents of city apartments, the issue of additional heating becomes relevant, since after turning off the central one, it is often necessary to increase the temperature in the room in other ways, due to the fact that the regulation of central heating does not occur quickly and flexibly, and weather conditions can change dramatically.

All of the above tasks have one very good solution: to make PVC window sill insulation or do insulation under the windowsill: it all depends on what goals are set, and what conditions exist for the organization of such heating.