Basement insulation from the outside, from the inside and whether it is worth doing what it will give.

Modern construction dictates its own rules for the functional use of free areas of the house, both new and old, becoming one of the most important tasks in the design and construction of a house. On one area of the site, you can build an underground floor - a basement. The construction of a basement becomes a profitable measure, as the usable area of the building increases without increasing the area of the building site.

Previously, using a basement without insulation made it possible to use it for storing canned food, vegetables, or as a cold warehouse. Today, the functionality of using the basement has expanded significantly. Now in the basement you can make a garage, an office, a hookah room, a storage room.

It does not matter for what purpose this room will be used, its normal use is possible only if there is an acceptable temperature for life in it. If the height of the ceilings in the basement does not allow it to be fully used, it still needs to be insulated, since basement insulation is the only way to reduce heat loss in the house and, as a result, reduce heating costs, especially if the house does not have a gas boiler room.

It is worth noting the fact that basement insulation outside the house during construction is cheap and cannot harm the foundation of a house under construction, in contrast to insulation from the inside. If the house has already been built, it will be cheaper to insulate the basement from the inside.

Basement insulation options

In general, the basement can be insulated in three ways, and each has its own advantages and disadvantages, we will talk about them below:

- Insulation inside the basement... If you have an already built house, then this method is most suitable. Requires calculations and additional work to identify the causes of moisture and their elimination. Mistakes in the installation of basement insulation will make all efforts to insulate it meaningless, since condensation will still form and dampness and fungus will appear.

- Insulation outside the basement... Usually this method is used when building a house. This method will make it impossible to freeze the foundation and walls, since the construction of the house takes place at a positive temperature, this allows you to perform a high-quality connection of the thermal insulation material and the wall surface. The obvious advantage of using this method is that useful space inside the basement is additionally saved. However, as mentioned above, this method of thermal insulation in the basement of a country house is suitable only under the condition of current construction and it is very expensive to insulate the basement from the outside of an already constructed building.

- Combined insulation... Fundamentally high-quality and, as a consequence, the most expensive method. It is the most effective because thermal insulation occurs from the outside and from the inside of the basement. This method is great for brick and concrete houses. In this case, the heat loss of the house will be the most minimal, a method of insulation should be foreseen in advance so as not to overpay for repeated work that occurs when installing thermal insulation in the basement room.

To choose a suitable method of basement insulation, 4 criteria must be determined.

- How the basement will be used in the future.

- Room humidity mode.

- Will a drainage drainage system be installed around the basement?

- Will the basement be heated in the future?

Dampness in the basement. Why?

In order to ultimately correctly perform the thermal insulation of the basement room, you should understand the causes of moisture on the walls inside the premises. Why does condensation form (fires of water on the walls) and what are the reasons for its occurrence.

Why condensation forms in the basement

1. Typically, the basement is below ground level into the room itself through the pores and leaking joints between building materials can seep water. Due to the poor condition or poor quality installation of the drainage system on the site, poor sealing of the walls also affects.

2. The transformation of water into condensate occurs from the temperature drop of the warm air entering the house, especially in summer. This happens because non-insulated basement walls will always be colder, the ground is always colder than the ambient temperature.

To insulate the basement from the inside is forced by circumstances when it turns out that it is too expensive to insulate the basement from the outside and it is not advisable to carry it out. The inside of the basement should be insulated only on dry and defrosted walls of the foundation of the house. It should be understood that with this method, the risk of premature destruction of the foundation increases, since it has been defrosted. This is due to the different coefficients of expansion of materials at different temperatures.

Insulate the basement? Yes or no?

Despite all the fears and doubts, it becomes obvious that it is better to insulate the basement. There are several arguments for this, for those who still think and doubt.

The consumption of electricity and gas for heating is significantly reduced.

There is an additional area in the house that can be useful.

The appearance of dangerous fungi and mold in the basement is excluded, due to which an unpleasant smell of mustiness and humidity appears in the house;

The air temperature in the insulated basement does not drop below +5 degrees.

The braided basement protects the foundation of the house from sudden temperature changes and thus prolongs its service life before destruction.

In the end, there is GOST 9561-91 which says: Reinforced concrete floor slabs must be insulated over the floor that separates the floor of the first floor of the building from the non-insulated zone. A similar requirement is indicated in SNiP 2.08.01-85

How is the basement waterproofing and ventilation

Without the correct ventilation and waterproofing of the cellar, any insulation will very quickly become unusable. For any foundation, a mandatory attribute is the construction of a blind area, which will protect the cellar so that streams of melted snow or rain do not penetrate into it.

Additional protection around the foundation is provided by a system of drainage channels. In addition, you can equip a drainage ditch.

In this case:

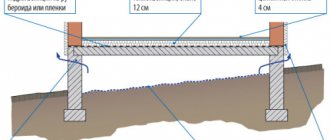

- A ditch is dug outside the house, the depth of which is 30 centimeters below the floor in the cellar.

- Geofabric is being laid.

- Crushed stone is poured.

- A drainage pipe is being laid.

- From above, everything is covered with geotextiles.

- It is covered with soil or sand.

- Tamped down carefully.

Such methods are used as additional methods if high groundwater is present. But there are a number of activities that must be performed without fail.

These include:

- Treatment of its walls from the inside and outside with a waterproofing compound.

- The device of special containers - caissons for the cellar, which are metal sheets or plastic.

Even the listed works performed correctly will not provide long-term storage of vegetables, they do not "breathe" in it. The formation of condensate inside prevents the maintenance of a constant optimal microclimate in it.

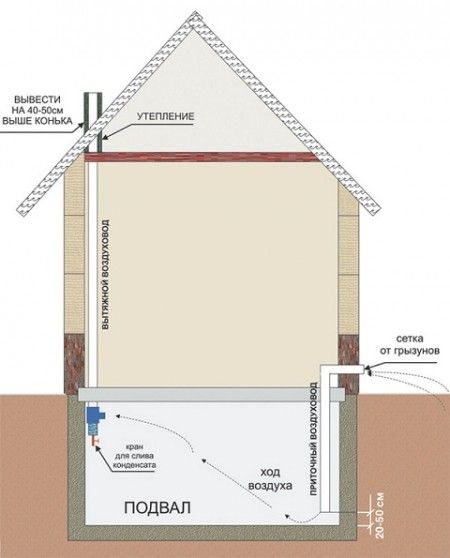

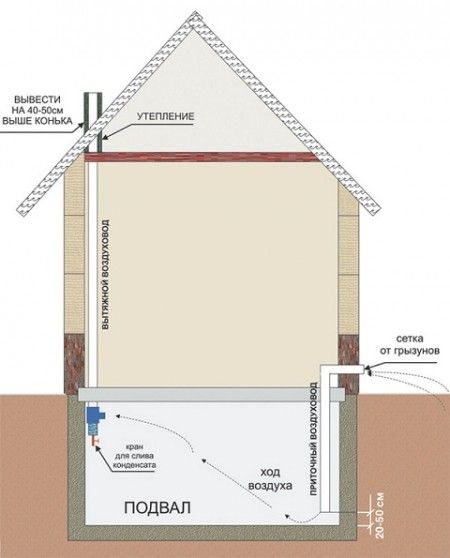

The easiest way to ventilate a room is:

- Installation of two ducts to provide supply and exhaust ventilation. For this, PVC pipes with a diameter of 10 to 50 mm are used. The temperature difference between the air in the basement and the air entering the outside creates the correct functioning of the system.

- Installation of air vents in the foundation.

Diagram of the ventilation device in the cellar

Why insulate the basement

Regardless of the purpose, the premises of any building should be warm and free from moisture. In the basement, dampness and large fluctuations in temperature most often appear, which leads to the penetration of a bad microclimate under the house and in living quarters:

- The floor will become cold.

- Mold and mildew will gradually grow on its surface and on the walls.

The appearance of such troubles leads to:

- Damage to the repair performed.

- Accelerated destruction of the structure.

- Deteriorates the health of people living in the house.

Insulate the basement with your own hands

To insulate the basement cheaply, you need to work with your own hands, and this is not as difficult as it seems at first glance. Consider the common cases when thermal insulation is made. The first option is when water enters the basement from the outside and it is constantly wet. The second option for insulation with a dry basement.

The first case is a wet basement:

The flow of water occurs through the walls of the foundation, which means that it is strictly forbidden to insulate such a basement from the inside! Insulation of the foundation inside will cause even more and without that strong foundation moisture, and when the ambient temperature drops, thermal expansion will destroy the foundation of the building for several years.

First of all, it is necessary to stop the flow of water into the room. To do this, it is necessary either to equip the drainage system circuit or, if there is an existing drainage system, to revise or repair it. If there is water in the basement, this is a sure sign of an error in the design and installation of the drainage system (drainage).

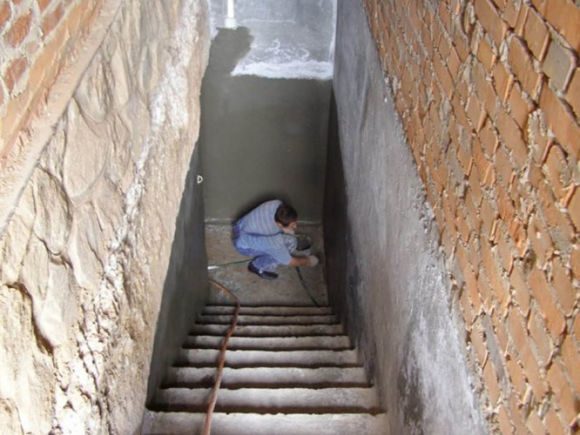

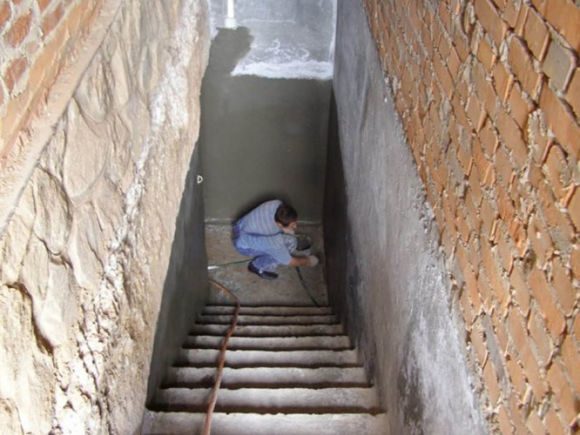

After correcting the drainage, it is necessary to dig out the foundation of the house from the outside. Measures are being taken to waterproof the foundation of the building, and in this case it is cheaper to insulate the basement from the outside.

If we are talking about a village or a group of houses, then it is possible to solve the problem of draining the plots by laying a drainage system.

If there is a flow of water under the basement, a small well is mounted in the basement and a pump with a float is installed, as soon as the water level rises to a certain level, the pump works and pumps out the required amount of water. In harsh conditions, Grundfos water pumping equipment is good at pumping water. If there is a large amount of spring water in the well, this water can be supplied for home heating or water supply. A wet basement can be insulated in only one way - this is to first drain the basement and insulate it from the outside, with preliminary waterproofing.

If the plans are to build a basement with heating, then the thickness of the insulation should be no thinner than 15 cm. The minimum thickness of the insulation layer for the basement is 10 cm. Depending on what material the insulation is made of, the thickness of the insulation layer may vary.

If you are lucky and you have a dry basement, it would be more expedient to carry out insulation inside.

What you need to consider to insulate the basement from the inside

In the basement of a house, condensation or condensed steam is formed due to the temperature difference between the soil itself and the wall itself with the ambient temperature in the basement or the so-called dew point.

The dew point is usually called the temperature of the air at which the vapor (humidity) that is contained in the air will begin to turn into drops of water (condense).

It is necessary to insulate the basement from the inside according to a certain technology, the most important thing is to exclude the empty space between the wall and the surface of the basement insulation.It is also not allowed to use materials that absorb or let water through when insulating a basement, since they will quickly get wet from the formed condensation and it will become meaningless to insulate the basement.

The best and most commonly used materials for insulation inside the basement are extruded polystyrene and sprayed polyurethane foam (PPU). The use of polyurethane foam insulation allows filling the space between the wall surface tightly and without voids, it also turns out to place the material in all the cracks. This will only work when the work is carried out by experienced craftsmen; outwardly, such insulation does not look aesthetically pleasing and requires additional work on refinement.

On top of the polyurethane foam layer, false walls are usually erected, which are attached only to the load-bearing floors. Installation should be carried out in such a way as not to damage the basement insulation.

Extruded expanded polystyrene Listar does not have these disadvantages. This material is a building board, before mounting the panels on the walls, either level the wall or use polymer glue, which with a layer thickness will level the unevenness of the wall. In difficult places, the necessary pieces of any surface shape are cut out of Listar building panels.

It is worth remembering that you cannot attach basement insulation to plastered surfaces without processing or peeling fragments of the concrete surface. Before starting the installation of basement insulation, it is better to clean the entire surface of the wall from fragments of rough or fine finishing to clean concrete and brick. The wall is usually leveled with glue during the installation of polystyrene boards. In case of significant damage to the surface of the walls, the cavities are leveled using a DSP 300 raster.

It is also worth paying attention to the fact that it is not allowed to use dowels and self-tapping screws for mounting polystyrene plates for basement insulation. The insulation itself must be attached to the wall surface exclusively with glue, so that the plates fit snugly and evenly to the wall surface.

Engineering components

Now let's turn our attention to the engineering components, because the uninterrupted operation of communications is an integral part of a comfortable life. And the disadvantages in their work are time, nerves and a lot of money. So…

1) Electricity supply: it is necessary to check with the neighbors about the quality of electricity and voltage. Because these shortcomings lead to unstable operation or breakdowns (sometimes fatal) of engineering equipment, household appliances. And no stabilizers can solve this issue. Evaluate the fastening of the self-supporting insulated wire at the entrance to the house - it should be special, with a stretch and a sliding element. Pay attention so that nothing can rub. There was a case when the wire frayed on the siding caused a fire. Metering unit: a two-tariff meter installed on the street in a weatherproof box is desirable. The rules for installing metering stations outside the home have already been spelled out and then you still have to follow them. Evaluate the availability of machines and RCDs, the distribution of supplies by groups. Energy-intensive equipment (electric stove, washing machine) must have its own cable and machine. The quality and cross-section of the wire used for wiring. Installation quality. If the wiring is hidden - the Fire safety diagram. If the house is equipped with an electric heating system, double your partiality and attention to the quality of materials and installation.

2) Water supply: we talked about the depth of the water source and the aquifer earlier, as well as about the quality of the water. Here only about the engineering component: if the house is equipped with a well - in addition to the depth, the diameter is important. It must be large to allow re-drilling inside the pipe for deepening. Specify the depth of installation and the method of isolating the water supply - if these factors are insufficient, the water can freeze.Ideally - the presence of a self-regulating heating cable in the piping strapping under a layer of thermal insulation. Water supply station - evaluate the presence of automation, the volume of the buffer tank, the place of installation and the noise from work. Evaluate the quality of the installation and the material of execution of the internal pipes of the water supply. If metapol is used, this is a reason to think. If the pipes are recessed and walled up in floors and walls - this is also a reason to think. Especially PP hot water pipes. Placing hot water in the grooves without taking into account linear thermal compensation (which is often the case) will definitely lead to breakthroughs and costly repairs. The presence of a layout scheme and photos with links for hidden communications is a tough and unambiguous rule!

3) Sewerage: examine the septic tank. What type and volume is it? If it is open, then how far is your well / well (at least 25 m!). If it is closed, then it depends on the volume how often the sludge pump will need to be called. Is there a possibility for his entrance without dismantling the fence? Remember - what type of septic tank should be depends on the level of groundwater (see above). Evaluate the work of the internal networks - how easily and quickly the water leaves in all the toilets, whether there are no “breakdowns” of water through the water seal. The depth of the pipes (the risk of freezing of the sewer is low, but there is).

4) Ventilation: if we are talking about a wooden house, then the presence of ventilation in the residential part is not necessary, the wooden house itself evens out the parameters of humidity and air exchange. However, even in a wooden house, ventilation of the attic and a cold basement (if any) are required. Ventilation of the living area: check availability (must be!), Work: correct direction of work and volume. The simplest test is the so-called. "On a sheet of paper." In the presence of fireplaces, the presence and tightness of the gates, the quality of the internal walls of the chimneys, the stability of the draft! And just be sure to flood it.

5) Gas supply: a specific topic that requires a professional approach. Therefore, we will restrict ourselves to publicly available moments. Necessarily - a conversation with neighbors about the sufficiency of gas pressure in the gas pipeline. If it is not enough, then there will be serious problems. And if your house is not yet connected to the gas network at the time of purchase, then it may not be possible to connect it. Check all documents for connection - permission, tie-in certificate, gas equipment inspection report, the presence of a meter and a seal on it. The quality and characteristics of the boiler should be checked by a professional, therefore, first at least assess the sufficiency of power: at the rate of 1 kW per 10 m2 of heated area + 30% margin. The presence of ventilation ducts in the boiler room or near the installation site of the boiler. There should be 2 of them: supply and exhaust, their performance. Correspondence of the chimney to the boiler type. Check the boiler in operation - under full load.

6) Heating system: also a very broad and specific topic. Briefly: if the system is "warm floor" - then the material of execution (cheap and low-quality is guaranteed to break in the first couple of years). The presence of separation through the collector by branches with the possibility of adjustment and shutdown. The presence of pressure sensors on the branches. It is imperative to have a stacking scheme or photographic images with reference to rooms!

If the system is on heating radiators, then the material of execution (pipelines) and the method of installation (remember about the PP in the grooves and linear expansion). Correctness of installation of radiators: in window openings with an extension beyond the window sill cut. Assess the sufficiency of the number of radiators The simplest algorithm: 1 section of a typical radiator ~ 0.15 kW of thermal power. Further, based on the number of sections x 0.15 = the power of the entire radiator. The heat load is assumed to be sufficient at the rate of 1 kW per 10 m2. If possible, assess the balance of the system at different points - this is especially important for multi-storey buildings, but requires special knowledge and equipment.

Basement insulation materials

For insulation of the basement from the outside and from the inside, a lot of materials are presented, we will consider the most effective and proven ones from the point of view of the economic feasibility of their use.

Polyfoam for insulation

Styrofoam... The cheapest material for thermal insulation Usually, foam with a density of 25 kg / m3 is used for insulation.

Polyfoam for insulation is worth buying for a number of qualities: excellent thermal insulation characteristics, light weight, does not rot and does not contribute to the development of fungus and is not subject to destruction from time to time. Styrofoam slightly absorbs moisture, but is suitable for cheap insulation. Therefore, basements are most often insulated with foam, but there is one significant drawback. Polyfoam is an easily combustible material and it is not worth laying electricity networks next to it, since the material is capable of accumulating static electricity. Styrofoam should not be used in rooms with a high degree of fire. When burned, it releases caustic and life-threatening substances. Reviews about the use of foam are contradictory and for the most part boil down to the fact that if there is an opportunity not to use this material, it is better not to use it.

Expanded polystyrene for insulation

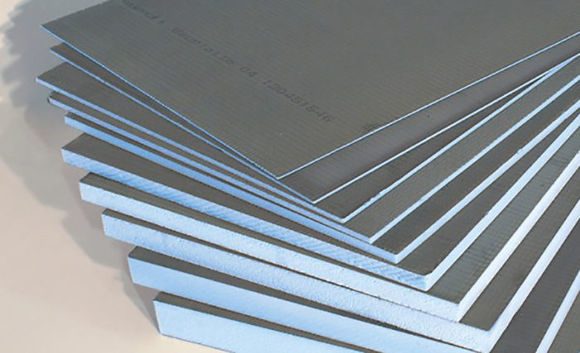

expanded polystyrene... Material with a denser structure and therefore does not crumble. It has all the positive characteristics of foam, which made it possible to connect the panels to each other along the groove system.

Therefore, the insulation for the basement made of expanded polystyrene is characterized by the speed and ease of installation and processing of the sheets themselves. Unlike expanded polystyrene, a sheet of expanded polystyrene does not paint into pieces during cutting and installation). It resists static and dynamic loads better. Therefore, this basement insulation is somewhat more expensive than foam. Most often, it is expanded polystyrene that is used for external insulation of the basement or from the inside, when they plan to carry out finishing work after insulation.

Extruded polystyrene for insulation

extruded polystyrene the most innovative and, as a result, allows you to significantly reduce the cost of work on the basement insulation from the inside and outside. The material is based on extruded polystyrene, which has all the advantages of expanded polystyrene and, unlike them, is not afraid of fire. Such panels are worth buying with a reinforced layer. This will allow you to get rid of the work on the preparation of the finishing layer of the insulated wall. Of the manufacturers of extruded polystyrene reinforced panels, Listar panels are most often used. Less commonly, Ruspanel and Vedi panels. Most of the reviews about Listar panels are positive.

For installation of panels, glue is used, and the side reinforced with fiberglass mesh and impregnated with a cement-polymer composition will allow you to immediately apply the finishing layer of finishing the room. These plates are more expensive than expanded polystyrene, but in the end, due to the lack of additional work on the lathing and plastering, it is cheap to use construction panels for the insulation of Listar. The main advantage is also the fact that work on warming the basement from Listar slabs can be done by hand without the help of craftsmen or specialists and without using a complex and expensive tool.

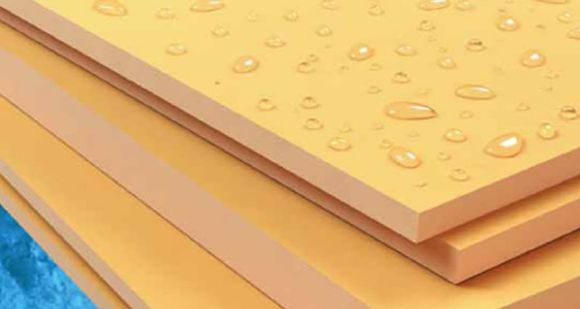

Urethane foam for insulation

polyurethane foam... This is a material sprayed onto a surface that should be insulated. A significant feature of polyurethane foam or polyurethane foam for short is the ability to fill inaccessible places. Polyurethane foam, like extruded polystyrene, is resistant to fire and moisture absorption, it also does not form a fungus, the method of application allows you to make the most tight connection between the surface and the insulation.A strong layer of thermal insulation is obtained when using polyurethane foam and craftsmen with "hands from the right place", but there is a significant disadvantage when using it if you want to insulate the basement cheaply. The main disadvantage is the high cost of the material itself and the fact that it is not possible to do insulation in PU foam with your own hands, special equipment and tools are required, the purchase of which is not economically feasible if this is your business for insulation in PU foam.

Mineral wool for insulation

Mineral wool or mineral wool... We do not recommend insulating the basement with mineral wool. In dry rooms, it is allowed to use soft insulation, but mineral wool is not suitable for the basement because it is hygroscopic (passes water) and during operation, when wet from condensate, loses itself as a material for warming the basement.

Expanded clay for insulation

expanded clay... We consider it only as a material that can be used to insulate the floor. It is also justified to use expanded clay stone for insulation of the foundation from the outside, since expanded clay stone is a good help to the drainage system of the site. And it provides the drainage of groundwater.

In each case, the type of insulation is selected based on the requirements for the future room and what will be there. It is better to contact specialized companies and order the development of a house project, in which there will already be a calculation of heat losses and a suitable insulation for your tasks. In other cases, you can get technical advice on the choice of the type and thickness of the material from the companies producing insulation. Not all insulation options are suitable for certain materials. LISTar and Wedi specialists provide high-quality and free consultations on the choice of material thickness for basement thermal insulation using building panels based on extruded polystyrene.

Reasons and features of basement insulation

At depth, the temperature is stable throughout the year, but they are far from optimal. To bring the temperature in the basement back to normal, the basement is insulated. It costs only once to properly and correctly insulate the basement from the inside, and you will be able to use this room with benefit.

Thermal energy, which could be spent on heating the living space of the house, heats the non-insulated basement, which leads to a very noticeable increase in the consumption of electricity, gas or other heat carrier. If you do not insulate the basement, you will have to pay extra money for unnecessary "overspending".

A dry insulated basement reduces heat loss by 20% or more, and also saves the walls of the house from dampness.

Insulation of the floor above the unheated basement.

In addition to saving energy resources, there is another important reason for warming the basement with mineral wool, foam or expanded polystyrene. It is generally accepted that the floor temperature should not be lower than 3 ° C from the temperature of the living area of the house. Floor slabs are common to the basement and rooms located on the ground floor of the house. And if the cold of the cellar does not cool the floor in the living quarters (and the cold air spreads just below), then the legs will be warm and comfortable.

You can insulate the basement in a variety of ways. The most effective method is considered to be external basement insulation. With this method, the heat-insulating material is arranged outside, thereby preventing the walls of the basement from freezing. If you insulate the basement from the inside, then condensation may begin to form at the joints of the walls and the heat-insulating material, which will ruin the entire coating.

Therefore, it is important not to forget about the correct and high-quality waterproofing of the entire surface of the walls. Use an insulating material that will tolerate moisture normally. Styrofoam is a great option for these purposes.Of course, it is best to insulate the basement even at the stage of building a house, because when carrying out such work at this time, it is possible to combine insulation with a drainage system and waterproofing.

How to insulate a basement with your own hands

Below we will talk about how to insulate a basement with your own hands using building boards based on extruded polystyrene and expanded polystyrene.

To do this work yourself, you will additionally need to purchase:

- Interior fittings

- Polyurethane foam "Macroflex"

- Reinforced polymer mesh to harden the surface of the slabs (not required if using Listar panels)

- Waterproofing material to insulate the surface before fixing the insulation (not required if Listar panels are used);

- Prepared glue solution.

- External plaster or DSP for sealing strong cavities in the wall (not required if Listar panels are used);

- Hand tools (spatula, hammer, hacksaw, knife, gloves, etc.).

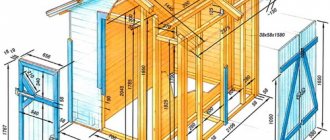

Insulate the basement outside on your own

- First of all, it is worth knowing that the installation of basement insulation must be carried out exclusively in wet weather in sunlight, this is necessary so that the moisture content of the soil and foundation is minimal;

- Thermal insulation works start from the development of the earth and soil at the foundation, it is better to use a manual method of excavation;

- after excavating the foundation, the surface is inspected for damage and flaking of the waterproofing

- the surface of the wall is cleaned and a layer of waterproofing is applied to it, in the case of using construction panels Listar - you will not need to waterproof the walls, although this will not be superfluous for reliability.

- We attach panels for insulation to the walls. Extruded XPS or PU foam panels are preferred. These materials adhere best to concrete and provide a long service life, on average, with proper installation of basement thermal insulation, 20-40 years.

The insulation for the basement should go 50 cm (half a meter) above the ground level, in other words, stick out of the ground at least 50 cm.This is due to the correct technology of insulation and the reviews of people who have already made mistakes at this stage.

Only glue is used for the installation of the insulation. As mentioned above, damage to the insulation by dowels and self-tapping screws is not allowed. The glue is applied to the panels with a notched trowel, which will avoid uneven application and the formation of empty spaces under the insulation sheet. The gaps formed during the work are filled with a special sealant or polyurethane foam.

- A layer of waterproofing is reapplied to the installed insulation. For double-sided Listar panels - this is not required, but it will not be superfluous. Waterproofing should be applied to those areas of the surface that will be under the ground.

- A drainage drainage system is being installed so that the groundwater near the house and is quickly discharged from the insulation itself.

- In the end, it is necessary to decorate the basement of the house in order to even better close the insulation from the effects of a harmful environment. In this case, siding or plaster is suitable. When using Listar panels, the surface is already ready for gluing artificial stone and other finishing materials.

When insulating the basement from the outside with your own hands, you should understand that it is necessary to completely insulate all the plates and not leave voids in them. The insulation layer must be completely sealed and not allow air and liquid to pass through. Only in this case, condensation will not form under the layer of thermal insulation and the basement will be really insulated.

See in detail how to insulate a basement on your own using an example house facade insulation see here:

Floor insulation technology above the basement

With any method of insulation, waterproofing is first laid.In this capacity, ordinary plastic wrap is suitable. The adjacent strips are overlapped and fixed with mounting tape. You definitely need an overlap on the walls. Its height depends on the thickness of the cake, including the screed, if any.

You can use PVC film as a material for waterproofing.

1. On a flat base, the insulation slabs are laid out end-to-end on the floor, connected with tape.

2. When laying on wooden logs, the slabs are placed between the logs by a strap, fixation is not required.

3. When pouring the screed, put another layer of waterproofing on top.

We offer you to familiarize yourself with Black Moth how to deal with it

4. When installing underfloor heating under pipes / cables, a layer of foil is placed on top of the insulation, which reflects all the heat from the system into the room.

5. Loose materials are most conveniently placed between the logs and covered with subfloor boards on top: this way they do not reduce the height of the room. When mounted on a flat base, instead of lags, wooden partitions are installed, on which the subfloor boards will then rest.

6. Before pouring the screed, a waterproofing membrane (preferably PVC) must be laid on top of the expanded clay. The screed is poured over the lighthouses and leveled with the rule.

7. When installing the screed on top of the underfloor heating system, it is necessary to lay a damper tape around the perimeter of the room, otherwise the concrete will crack when heated.

8. The composition of the sawdust mixture: 85% sawdust, 5 - gypsum, 10 - lime. The components are mixed dry, then diluted with water. The recommended layer is 25 centimeters.

Sawdust screed is not used for underfloor heating. It should be fenced off from the furnace with refractory bricks.

The top coating can be anything: planed boards, linoleum, parquet, laminate, ceramic tiles. Some of them require a solid base. In the absence of a screed, sheets of chipboard or fiberboard can be used in this capacity.

- Tags: basement floor insulation

Insulating the floor in a wooden house from the bottom of the basement is not an easy task. There are several ways to solve it, which will help to implement the recommendations of experts and those who personally insulated the underground at home. At the same time, they get rid of dampness: wet floors create discomfort for residents.

Insulate the basement from the inside with your own hands

The procedure for work on the internal insulation of the basement, according to the principle of operation, is the same as for external insulation, with the exception of without earthwork:

- The walls are cleaned of dust and dirt, strong irregularities are plastered with cement mortar, as well as when insulating outside, and protruding parts are also knocked down.

- We fix a fiberglass or polymer mesh on the wall (if Listar panels are used, then this is not required).

- Applying waterproofing to the wall with mesh. In order for the soil layer to dry quickly and evenly, it is necessary to organize ventilation in the basement. The easiest way is to make two holes in the basement walls.

- Insulating panels and joints are coated with glue or sealant to the prepared surface with glue.

- The assembled panels are plastered and prepared for finishing. No plaster is required when using Listar thermal insulation panels, the panels are ready for the finishing coat.

If finishing the room requires (frame) for further finishing the basement with plasterboard, then after the walls are insulated, the guides should be attached to the non-insulated parts of the room (floor, ceiling).

The thickness of the insulation should be on average 10 cm when using polystyrene and not less than 8 cm when using polyurethane foam. If the basement is planned to be heated, it is recommended to increase the thickness of the insulation to 15 cm. This will keep the temperature in the basement at 20-25 degrees. If you use Listar panels, then the thickness of the panels should be 8-10 cm.

Methods for insulating the floor above the basement

There are two ways: to process the basement ceiling with heat-insulating material and to insulate the floor from the side of the house.In the first case, the choice of insulation is small: either sheet / plate materials that are glued to the ceiling and fixed with mushroom-type dowel-nails, or spraying with liquid polyurethane foam.

When insulating the ceiling from above, various bulk substances are also used.

In addition to laying thermal insulation in the house, you can install a "warm floor" system, water or electric. The construction of the underfloor heating cake also includes waterproofing and insulation - otherwise, most of the heat from the cable or pipes will go into the basement.