Appointment

A heat energy metering unit is being organized for the following purposes:

- Controlling the rational use of heat carrier and heat energy.

- Controlling thermal and hydraulic modes of heat consumption and heat supply systems.

- Documenting the parameters of the coolant: pressure, temperature and volume (mass).

- Implementation of mutual financial settlement between the consumer and the organization engaged in the supply of thermal energy.

Blog

The State Housing Inspectorate is the most frequent monitoring guest in management organizations. It just so happened that in most cases the inspectors of the Civil Inspectorate take the side of the residents and literally look for violations. In this connection, a huge part of the working time of lawyers and other employees of the management company is spent on litigation to appeal against the orders that GZI issues in response to complaints from residents. At the same time, the owners' dissatisfaction is often caused by the procedure for calculating the payment for the heating (heat supply) utility service in an apartment building with several inputs.

Today we would like to share with you the latest Decision of the RF Armed Forces No. 310-ES19-3922 dated 04/10/2019, in which the most humane court sided with the management company and agreed with the arguments of the Nineteenth Arbitration Court of Appeal to cancel the order of the Kursk Region GZI.

The managing organization appealed to the Arbitration Court of the Kursk Region to declare illegal the GZhI's instructions on the obligation to calculate the payment for the communal heating service

from February 2020 to April 2020

taking into account the total readings of all common house heat metering devices in the MKD.

By the decision of 06/15/2018, upheld by the decision of the Nineteenth Arbitration Court of Appeal of 09/28/2018, the claim was refused.

As indicated by the trial court

, the house is equipped with collective (general) metering devices for heat energy for heating, installed at heating input No. 1 (entrance 1 of the house), heating input No. 2 (2-3 entrances of the house) and heat input No. 3 (4-5 entrances of the house). Hence,

heat energy metering devices installed at heat inputs No. 1, No. 2 and No. 3 of the disputed house together formcollective (common house) metering device.

Taking into account the clarifications given in the Letter of the Ministry of Construction of Russia dated 10.07.2015 No. 21519-OD / 04, as well as the legal position set forth in the Decision of the Supreme Court of the Russian Federation dated 14.01.2014 No. AKPI13-1157,

the court of first instance concluded that the calculation of heating charges for each collective (common) metering device, based on the area of a part of an apartment building (a separate entrance), and not the entire area of the specified house, contradicts the norms of current legislation.

By the decision of the Arbitration Court of the Central District of 12/21/2018, the decision and ruling of the Nineteenth Arbitration Court of Appeal were canceled; the prescription is invalidated.

In a cassation appeal filed with the Supreme Court of the Russian Federation, GZI requested the annulment of the district's judicial act, citing significant violations of substantive law and the discrepancy between the courts' findings and the actual circumstances of the case.

The RF Armed Forces indicated the following: taking into account the general construction of the named MKD, the supply

heat energy is supplied to it through three inputs:

thermal input No. 1 (entrance 1 of the house), thermal input No. 2 (2-3 entrances of the house) and thermal input No. 3 (4-5 entrances),

each of which has its own metering device for heat energy and coolant flow.

The heating system of each input is looped and operates autonomously.

February 2020 to April 2020

the calculation of the payment for heating for the apartments of the said house was made according to the indications of each collective (common house) metering device for heat energy for heating installed on the heating inputs in the house, separately and based on the area of residential premises and common areas related to each thermal input

.

Based on the appeal of the owner of the apartment, the inspectorate conducted an unscheduled documentary audit of the company, based on the results of which an act was drawn up and an order was issued on the need to recalculate the payment for the communal one, taking into account the area of the entire apartment building and the total readings of all common house heat meters... The conclusion of the courts of first and appeal instances on the need to determine the volume of heat energy consumed by residents by summing up the readings of metering devices recording the volume of the supplied energy resource in a part of the house was recognized as erroneous.

The appeal court took into account that

readings of heat meters reflect the real amount of heat that was spent on heating specificSince each separate part of the apartment building was heated separately, when determining the payment for heating, the readings of heat energy meters installed at the input of the corresponding heating system and the area of residential and non-residential premises of this part of the house should be taken into account.

Determination of the payment for heating by summing up the readings of all three metering devices can lead to payment by the owners of the premises for those services that they actually did not receive.

Regulation No. 354 does not provide for the possibility of taking into account the total readings of common house metering devices installed in different parts of the building, equipped with independent heat supply systems.

A different interpretation by the applicant of the substantive law does not indicate their incorrect application by the district court or a miscarriage of justice.

We hope that our article was able to save you time on studying judicial practice. Well, if GZI is not asleep, and time is running out, then you can always contact the line of legal support. All the necessary information about the service is here.

You can discuss the article and ask questions on our forum or use the form below.

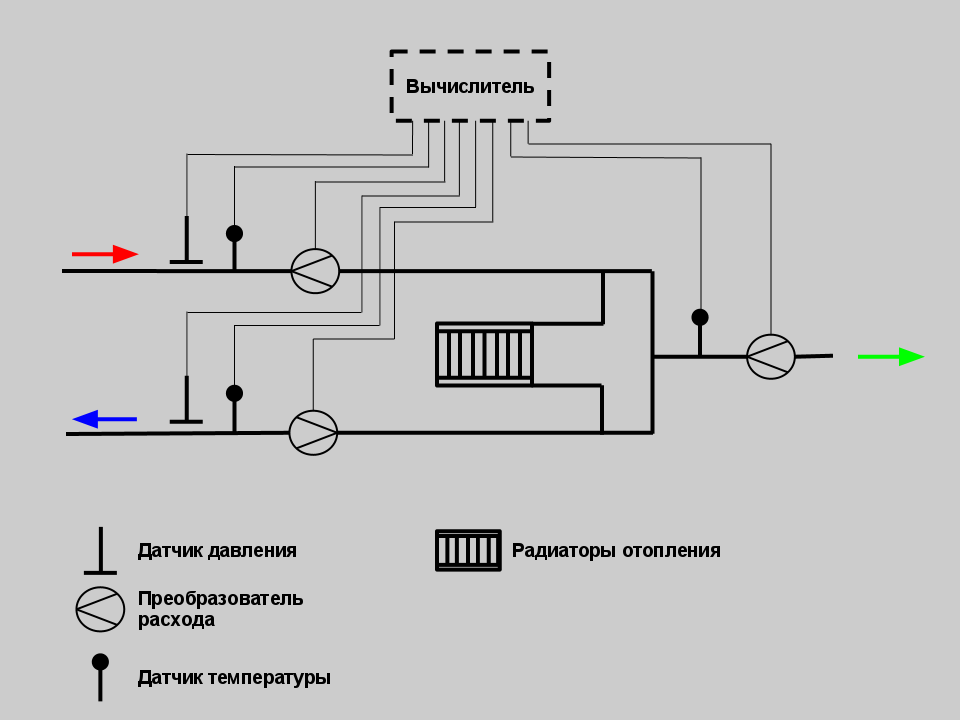

Main elements

The heating unit consists of a set of devices and metering devices that ensure the performance of both one and several functions at the same time: storage, accumulation, measurement, display of information about the mass (volume), the amount of heat energy, pressure, temperature of the circulating liquid, as well as the operating time ...

As a rule, a heat meter acts as a metering device, which includes a resistance thermocouple, a heat calculator and a primary flow transducer. Additionally, the heat meter can be equipped with filters and pressure sensors (depending on the model of the primary converter). Heat meters can use primary converters with the following measurement options: vortex, ultrasonic, electromagnetic and tachometric.

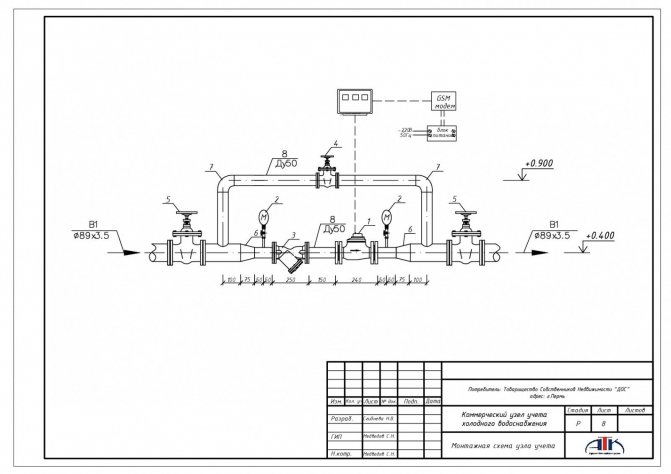

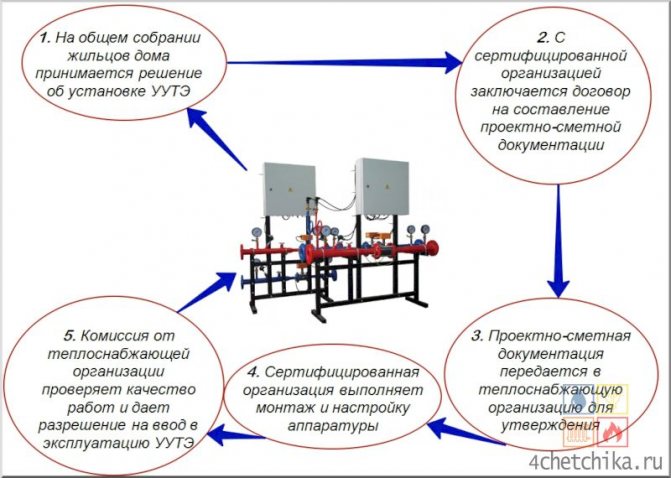

Installation UUTE

To mount a heat metering unit, you need to follow certain instructions:

- Depending on the form of management of an apartment building, a meeting is held, which should allow work and agree on the procedure for payments (targeted spending of funds).

- Initially, settlement processes are carried out. The procedures are performed by specialists who are engaged in the design of heat supply facilities. Only after drawing up the technical documentation can you proceed to the next stage.

- An application is submitted for approval of work to the heat supply organization. The company cannot refuse to install without a legitimate reason.

- After specifying the nuances and obtaining permission, the installation is carried out according to the approved scheme. The equipment is programmed and configured.

- The commission from the heat supply organization checks the operability of the heating unit and accepts a system for commercial metering of resource consumption.

All devices should be located so as to provide ease of control, removal and debugging.

Preparation of design and estimate documentation, installation and adjustment of equipment must be carried out by an organization that has a certificate and admission to such work, otherwise the selection committee will not give permission to put UUTE into operation

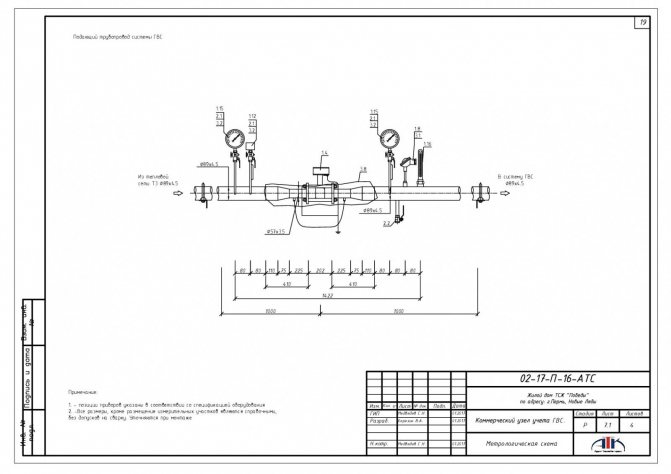

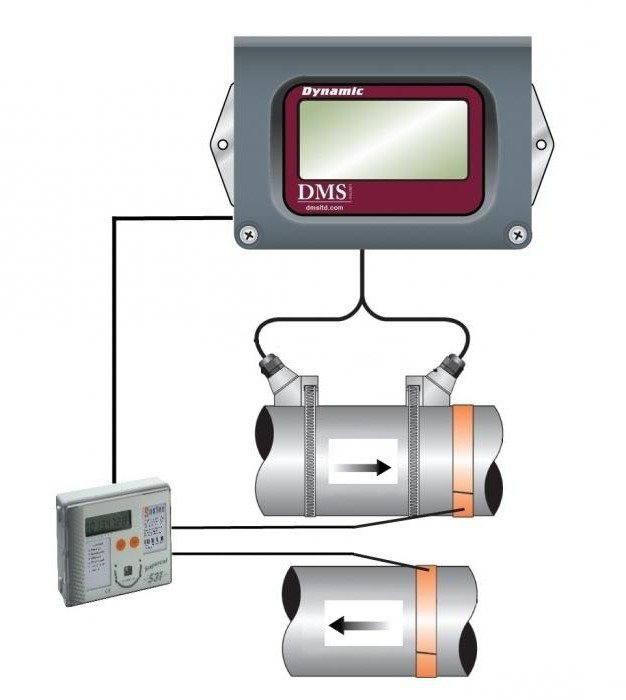

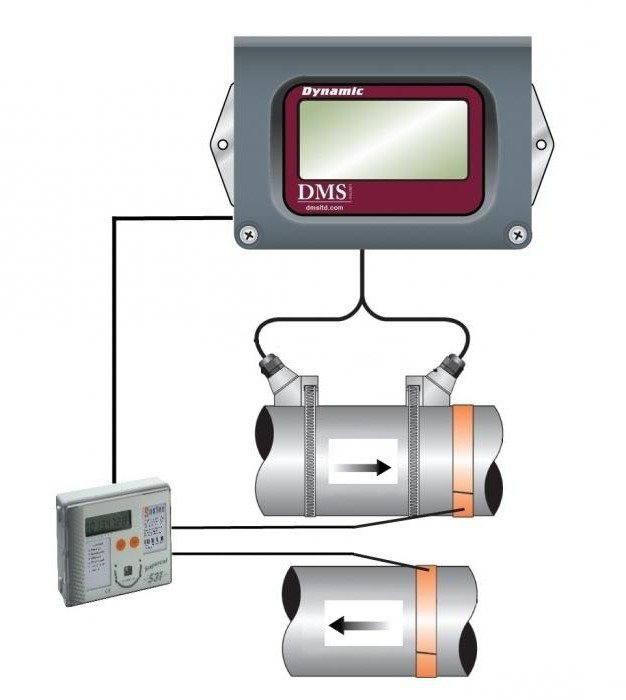

Heat meter

The heat meter is the main element of which the heat energy unit should consist. It is installed at the heat input to the heating system in close proximity to the boundary of the balance sheet of the heating network.

When installing a metering device remotely from this border, heat networks add losses in addition to the meter readings (to account for the heat that is released by the surface of the pipelines in the section from the balance separation border to the heat meter).

Who installs a common house heat meter?

The answer to this question depends on the legislative acts in force in a particular state of the post-Soviet space. If we take the Russian Federation, then there is already a decree on the installation of such metering devices without fail. At the same time, the implementation of the task is entrusted to organizations that supply heat to houses. On their shoulders lies the maintenance and calibration of common house devices for metering heat energy, until the tenants create their own association of co-owners (OSBB).

Note. The organizations undertake a considerable cost of the equipment and its installation, but compensate for these costs by charging additional funds from all residents over several years.

The question is not so categorical in Ukraine. There, individual heat meters are installed on the whole house, entrance or apartment at the request of residents and completely at their expense. The meeting of co-owners appoints a responsible person whose task is:

- obtain permission from the heat supply organization;

- conclude a contract for design work with a licensed firm;

- guided by design solutions, determine the cost of equipment and installation;

- collect funds;

- agree on the design documentation with the heat supplier;

- purchase equipment and hire a contractor to install it;

- put the object into operation.

Note. The heat supply company sets the period for verification and maintenance of devices in accordance with regulatory documents. In other CIS countries, there is approximately the same procedure for installing and legalizing heat metering devices.

Heat meter functions

An instrument of any type must perform the following tasks:

1. Automatic measurement:

- Duration of work in the zone of errors.

- Operating time with the supplied supply voltage.

- Excessive pressure of the fluid circulating in the piping system.

- Water temperatures in pipelines of hot and cold water supply and heat supply systems.

- Coolant flow rate in hot water supply and heat supply pipelines.

2. Calculation:

- The consumed amount of heat.

- The volume of the coolant flowing through the pipelines.

- Thermal power consumption.

- The temperature difference between the circulating fluid in the supply and return pipelines (cold water supply pipelines).

Thermal sensor

This device is mounted on the return pipeline together with shut-off valves and a flow meter.This arrangement allows not only to measure the temperature of the circulating fluid, but also its flow rate at the inlet and outlet.

Flow meters and temperature sensors are connected to heat meters, which allow calculating the consumed heat, storing and archiving data, registering parameters, as well as their visual display.

As a rule, the heat meter is housed in a separate cabinet with free access. In addition, additional elements can be installed in the cabinet: an uninterruptible power supply or a modem. Additional devices allow you to process and control data that is transmitted by the metering unit remotely.

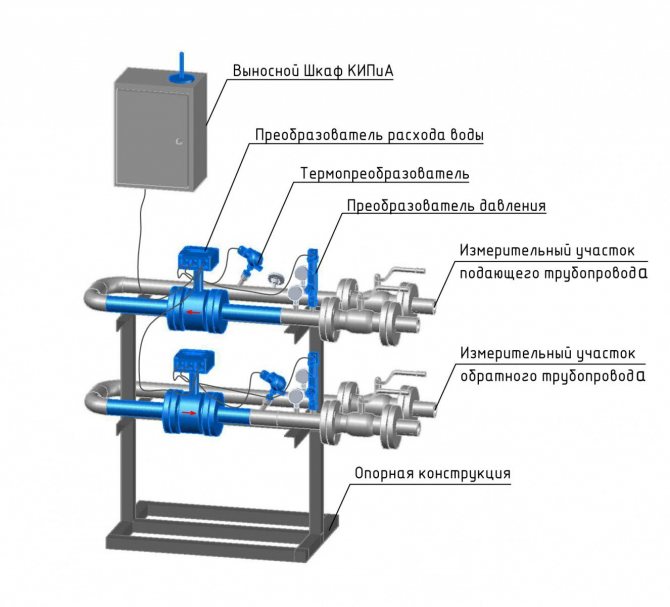

Heat metering options and components

A heat metering unit is a measuring and computing complex, for the creation and operation of which, depending on the specific task and field of application, various measuring equipment is required. It can be divided into several categories, among which the most important are:

- Split heat meters. Such meters in various configurations are mainly installed for the mainline (for example, with “Sharky 474” devices) and general metering of heat energy (DU50-DU900). The components include: Calculators. They are electronic calculators with a microprocessor and autonomous or external power supply, equipped with connectors for connecting pulse and current cables from flow meters, temperature sensors and pressure sensors. In heat calculators (for example "Сlassic S3"), the consumed heat energy is calculated on the basis of the data obtained by the measuring devices.

- Flow sensors (flow meters). They are of different types, basically the same principles are used as for measuring in cold water meters - mechanical (single-jet, multi-jet and turbine), as well as ultrasonic methods. However, in contrast to water meters, the volume measured by flow meters (for example, ultrasonic flow meters "VMT 473") serves for further calculation of thermal energy through the mass of the coolant, that is, taking into account the temperatures and pressure of the coolant.

- Temperature sensors. Platinum resistance thermometers with a positive temperature coefficient of resistance are used, for example PT500. Temperature sensors are immersed either directly into the coolant (for example, through a special ball valve with a socket), or they are inserted into special immersion sleeves, which in turn are in direct contact with the coolant. Temperature sensors are connected to the heat meter using a two, three or four-wire connection method.

- Pressure Sensors. Serves to determine indicators of water density. As temperature sensors, they are also connected to the heat meter.

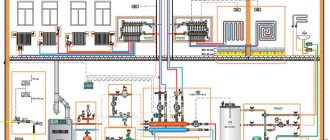

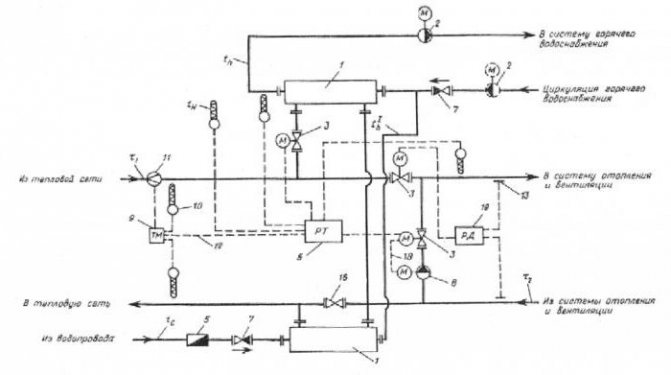

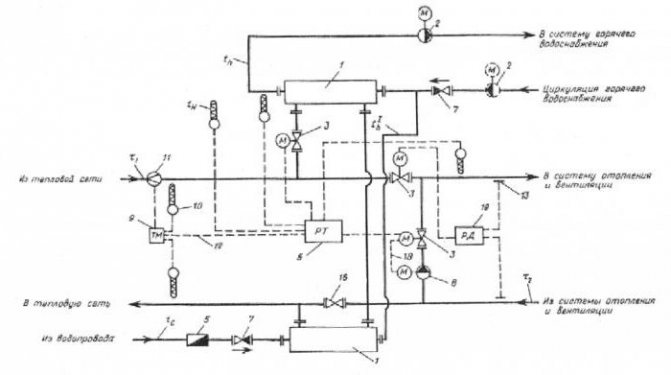

Basic diagrams of heating systems

So, before considering the diagrams of heating units, it is necessary to consider what the diagrams of heating systems are. Among them, the most popular is the design of the upper distribution, in which the coolant flows through the main riser and is directed to the main pipeline of the upper distribution. In most cases, the main riser is located in the attic room, from where it branches into secondary risers and then is distributed over the heating elements. It is advisable to use a similar scheme in one-story buildings in order to save free space.

There are also diagrams of heating systems with lower wiring. In this case, the heating unit is located in the basement room, from where the main pipeline with warm water comes out. It is worth noting that, regardless of the type of scheme, it is recommended to also have an expansion tank in the attic of the building.

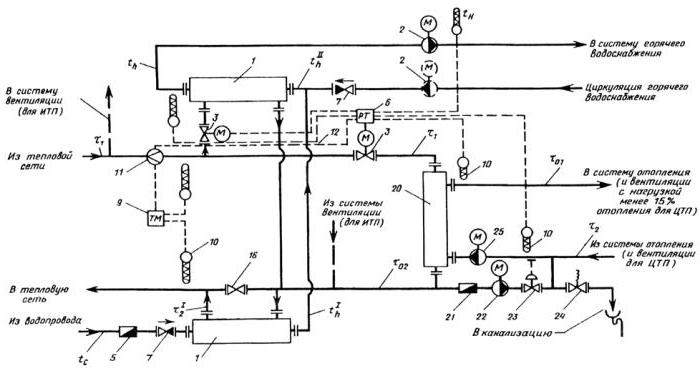

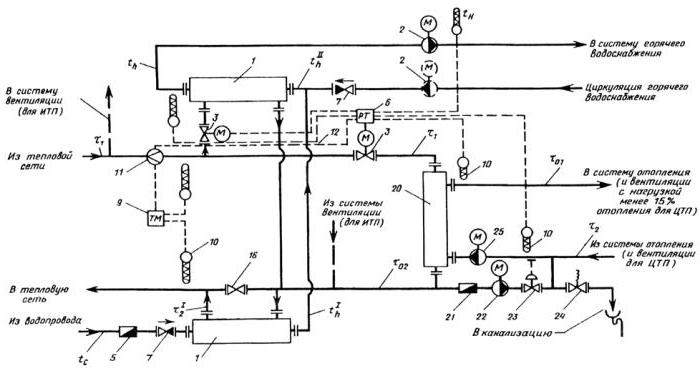

Heating unit diagrams

If we talk about schemes of heat points, it should be noted that the following types are the most common:

- Heating unit - a scheme with a parallel one-stage hot water connection. This scheme is the most common and simplest. In this case, the hot water supply is connected in parallel to the same network as the building's heating system. The coolant is supplied to the heater from the external network, then the cooled liquid flows in reverse order directly into the heat pipe. The main disadvantage of such a system, in comparison with other types, is the high consumption of network water, which is used to organize hot water supply.

- Scheme of a substation with a sequential two-stage connection of hot water. This scheme can be divided into two stages. The first stage is responsible for the return pipe of the heating system, the second for the supply pipe. The main advantage that heating units connected according to this scheme have is the absence of a special supply of heating water, which significantly reduces its consumption. As for the disadvantages, this is the need to install an automatic control system to adjust and adjust the heat distribution. It is recommended to use such a connection if the ratio of the maximum heat consumption for heating and hot water supply is in the range from 0.2 to 1.

- Heating unit - a scheme with a mixed two-stage connection of a hot water heater. This is the most versatile and flexible connection scheme. It can be used not only for a normal temperature schedule, but also for an increased one. The main distinguishing feature is that the connection of the heat exchanger to the supply pipeline is carried out not in parallel, but in series. The further principle of the structure is similar to the second scheme of the heat point.Heating units connected according to the third scheme require additional consumption of heating water for the heating element.

Varieties of counters

There are a number of criteria that make it possible to distinguish several types of heat meters. For example, according to the area of application, meters can be individual and general. The first type of equipment allows to take into account the heat consumption in a separate dwelling, operates in the measuring range of 0.6 ... 2.5 m³ / h and has small channel diameters up to 20 mm. For a general house meter, the calculation of the utility resource is carried out as a whole for the house, the diameters of the channels vary in the range of 25-300 mm. The indicator of accurate accounting of the amount of consumed heat is calculated in the sum for all tenants. Based on the data obtained, the tariff for the whole house is calculated and divided by the number of apartments, taking into account their area.

Also, a heat meter can be of several types, depending on the principle of its operation. The most popular models are:

- Mechanical. The heat meter works on the principle of accounting for the number of rotations of the main element. The rotation of parts occurs when the coolant moves. The main element is a rotor or impeller through which water flows. According to the number of revolutions, depending on the flow rate in a special block, heat consumption is subsequently calculated. Such devices are easy to install and maintain. The operation of the device is negatively affected by accumulations of scale, rust and other contaminants contained in the water. In order for the mechanisms not to wear out quickly, you will need to install a special filter mesh.

- Ultrasonic. Thanks to the installed emitter and signal receiver, which are located in the system pipe, it is possible to calculate the water flow rate in the supply pipe. According to this indicator, a further calculation of the amount of water that has passed to the radiator takes place. Such devices allow obtaining the most accurate flow readings, however, they require the installation of an additional cleaning filter. They can be frequency, time, correlation and Doppler.

When choosing a suitable counter option, it is necessary to take into account all the features of the housing and the existing heating system. For limited space, it is advisable to choose compact models. In addition, the differential pressure for the specific heating system must be taken into account. We recommend giving preference to models with the lowest level of sensitivity to water pollution and increased pressure in the pipes. To install a heat energy meter, contact the specialists who will not only carry out installation work, but also seal the meter.

You can find out more about how to buy a heat meter here.

The order of installation of the metering unit

Before installing a heat metering unit, it is important to inspect the facility and develop project documentation. Specialists who are engaged in the design of heating systems, make all the necessary calculations, carry out the selection of instrumentation, equipment and a suitable heat meter.

After the development of design documentation, it is necessary to obtain approval from the organization that supplies heat. This is required by the current rules for accounting for heat energy and design standards.

Only after agreement, you can safely install heat metering units. Installation consists of inserting locking devices, modules into pipelines and electrical work. Electrical installation work is completed by connecting sensors, flow meters to the calculator and then starting the calculator to measure heat energy.

After that, the adjustment of the heat energy meter is carried out, which consists in checking the operability of the system and programming the calculator, and then the object is handed over to the agreeing parties for commercial accounting, which is carried out by a special commission represented by the heat supply company. It is worth noting that such a metering unit should function for some time, which for different organizations ranges from 72 hours to 7 days.

To combine several metering nodes into a single dispatching network, it will be necessary to organize remote recording and monitoring of information accounting from heat meters.

Apartment heat consumption metering units with individual balancing AQUA-S

Apartment heat consumption metering units with individual balancing (UUTKB) - designed for individual metering of heat energy consumption in apartments and offices in accordance with Federal Law No. 261 dated 23.11.2009 "On energy saving and on increasing energy efficiency".

Metering units can be incorporated at the design stage of the heating system and implemented during the construction of a residential facility, as well as during the modernization of heating systems and heat metering in existing buildings.

UUTKB metering units are delivered assembled. They can also be supplied in special metal collector cabinets, in which the supply and return lines are installed on movable brackets.

UUTKB functions:

- Connecting heating devices to the central distribution riser of the heating system;

- Hydraulic balancing of the apartment heating circuit;

- Hydraulic adjustment of radiator heating circuits;

- Distribution of the coolant flow between heating devices within the apartment;

- Individual metering of heat consumption in the apartment;

- Coolant filtration;

- Coolant draining and air removal;

- Centralized collection and transmission of data on consumed heat energy and heat carrier consumption.

Benefits of using UUTKB

When developing apartment metering units, a modular principle was taken as a basis, which allows to design and create metering units of any configuration from a certain set of standard modules that meet both the requirements of the design documentation and the design features of the facility.

The special arrangement of metering unit modules and their equipment with detachable connections significantly reduce and simplify the installation time of the entire unit, which also leads to a decrease in capital costs.

Due to the special design, metering units have a high maintainability, which allows optimizing maintenance and repair work, which has a positive effect on reducing operating costs.

High quality materials of the constituent elements of metering units provide high reliability and long service life.

UUTKB modifications

- UUTKB-15

- UUTKB-20

The modification includes the abbreviated name of the type of unit, an indication of the number of outputs / remote control of the heat meter, which is part of the metering unit.

Scheme and composition of UUTKB

Permit to use

When the heating unit is admitted to operation, the correspondence of the serial number of the metering device, which is indicated in its passport, and the measurement range of the set parameters of the heat meter to the range of measured readings, as well as the presence of seals and the quality of installation, is checked.

Operation of the heating unit is prohibited in the following situations:

- The presence of tie-ins into pipelines that are not provided for in the design documentation.

- The operation of the meter is beyond the accuracy standards.

- The presence of mechanical damage on the device and its elements.

- Breaking of the seals on the device.

- Unauthorized interference with the operation of the heating unit.

Documents Statistics on documents and execution of orders

GOVERNMENT OF THE RUSSIAN FEDERATION

RESOLUTION

dated November 18, 2013 No. 1034

MOSCOW

On commercial metering of heat energy, heat carrier

(As amended by decrees of the Government of the Russian Federation dated 09.09.2017 No. 1089, dated 13.02.2019 No. 137)

In accordance with the Federal Law "On Heat Supply", the Government of the Russian Federation decides:

1. To approve the attached Rules for commercial accounting of heat energy, heat carrier.

2. The federal executive bodies shall, within 3 months, bring their normative legal acts in line with this resolution.

3. The Ministry of Construction, Housing and Communal Services of the Russian Federation shall approve, within 2 weeks, the methodology for commercial metering of heat energy and heat carrier.

Prime Minister

Of the Russian Federation D. Medvedev

APPROVED by Decree of the Government of the Russian Federation No. 1034 dated November 18, 2013

RULES for commercial metering of heat energy, heat carrier

(As amended by decrees of the Government of the Russian Federation dated 09.09.2017 No. 1089, dated 13.02.2019 No. 137)

I. General Provisions

1. These Rules establish the procedure for organizing commercial metering of heat energy, heat carrier, including:

a) requirements for metering devices;

b) characteristics of heat energy, heat carrier, subject to measurement for the purpose of commercial metering of heat energy, heat carrier and quality control of heat supply;

c) the procedure for determining the amount of supplied heat energy, heat carrier for the purposes of commercial metering of heat energy, heat carrier (including by calculation);

d) the procedure for the distribution of losses of heat energy, coolant by heating networks in the absence of metering devices at the borders of adjacent heating networks.

2. The methodology for the implementation of commercial metering of heat energy, heat carrier is determined by the methodology approved by the Ministry of Construction and Housing and Communal Services of the Russian Federation (hereinafter referred to as the methodology).

3. The concepts used in these Rules mean the following:

"Commissioning of a metering unit" - a procedure for checking the compliance of a heat metering unit with the requirements of regulatory legal acts and project documentation, including drawing up an act of commissioning a heat metering unit;

"Water meter" - a measuring device designed to measure the volume (mass) of water (liquid) flowing in a pipeline through a section perpendicular to the direction of the flow velocity;

"Operating time of metering devices" - the time interval during which, based on the readings of metering devices, heat energy is recorded, as well as the measurement and registration of the mass (volume) and temperature of the coolant;

"Outlet of the heat network" - the outlet of heat networks from a source of heat energy in a certain direction;

"Calculator" - a component of a heat meter that receives signals from sensors and provides calculation and accumulation of data on the amount of heat energy and parameters of the coolant;

"Dependent connection diagram of a heat-consuming installation" - a diagram of connecting a heat-consuming installation to a heating network, in which the heat carrier from the heating network enters directly into the heat-consuming installation;

"Closed water heat supply system" - a complex of technologically interconnected engineering structures intended for heat supply without taking hot water (heat carrier) from the heating network;

"Measuring metering system" - a multichannel measuring instrument that includes channels for measuring thermal energy with measuring components - heat meters, as well as additional measuring channels for the mass (volume) of the coolant and its parameters - temperature and pressure;

"Individual heating point" - a set of devices for connecting a heat-consuming installation to a heating network, converting the parameters of the heat carrier and distributing it by type of heat load for one building, structure or structure;

"Quality of thermal energy" - a set of parameters (temperatures and pressures) of the heat carrier used in the processes of production, transmission and consumption of heat energy, ensuring the suitability of the heat carrier for the operation of heat-consuming installations in accordance with their purpose;

"Saturated steam" - water vapor in thermodynamic equilibrium with water in contact with it;

"Independent scheme for connecting a heat-consuming installation" - a diagram for connecting a heat-consuming installation to a heat network, in which the heat carrier coming from the heat network passes through a heat exchanger installed at the heat point, where it heats the secondary heat carrier used later in the heat-consuming installation;

"Malfunction of measuring instruments of the metering unit" - the state of the measuring instruments in which the metering unit does not meet the requirements of regulatory legal acts, regulatory and technical and (or) design (project) documentation (including due to the expiration of the verification time of measuring instruments included in the composition of the metering unit, violation of the established seals, as well as with work in emergency situations);

"Open water heat supply system" - a complex of technologically interconnected engineering structures intended for heat supply and (or) hot water supply by taking hot water (coolant) from a heating network or taking hot water from hot water supply networks;

"Superheated steam" - water vapor with a temperature higher than the saturation temperature at a certain pressure;

"Make-up" - a coolant additionally supplied to the heat supply system to replenish its technological consumption and losses during the transfer of heat energy;

"Metering device" - a measuring instrument that includes technical devices that perform the functions of measuring, accumulating, storing and displaying information about the amount of thermal energy, as well as about the mass (volume), temperature, pressure of the coolant and the operating time of the devices;

"Coolant flow" - the mass (volume) of the coolant passing through the cross-section of the pipeline per unit of time;

"Flow meter" - a device designed to measure the flow rate of a heat carrier;

"Calculation method" - a set of organizational procedures and mathematical actions to determine the amount of heat energy, coolant in the absence of metering devices or their inoperability, used in the cases established by these Rules;

"Cutting off the temperature schedule" - maintaining a constant temperature of the heat carrier in the heating network regardless of the outside air temperature;

"Heat meter" - a device designed to measure the thermal energy given off by a coolant or consumed with it, which is a single structure or consists of components - flow converters, flow meters, water meters, temperature (pressure) sensors and a calculator;

"Technical operation of the metering unit" - a set of operations for the maintenance and repair of the elements of the metering unit for heat energy, ensuring the reliability of the measurement results;

"Metering unit" - a technical system consisting of measuring instruments and devices that provide accounting of heat energy, mass (volume) of the coolant, as well as control and registration of the parameters of the coolant;

"Coolant leak" - water (steam) losses through leaks in technological equipment, pipelines and heat-consuming installations;

"Form of the metering system of accounting" - a document drawn up in relation to the metering system of the metering unit and reflecting, among other things, the composition of the metering unit and changes in its composition;

"Functional failure" - a malfunction in the system of the metering unit or its elements, in which the metering of heat energy, mass (volume) of the coolant stops or becomes unreliable;

"Central heating station" - a set of devices for connecting heat-consuming installations of several buildings, structures or structures to a heating network, as well as for converting the parameters of the heat carrier and distributing it according to the types of heat load.

4. Commercial metering of heat energy, heat carrier is organized in order to:

a) making settlements between heat supply, heating network organizations and consumers of heat energy;

b) control over thermal and hydraulic operating modes of heat supply systems and heat-consuming installations;

c) control over the rational use of thermal energy, heat carrier;

d) documenting the parameters of the coolant - mass (volume), temperature and pressure.

5. Commercial metering of heat energy, heat carrier is carried out using metering devices, which are installed at the metering point located on the border of the balance sheet, if by a heat supply agreement, a heat energy (power), heat carrier supply agreement or an agreement on the provision of services for the transfer of heat energy, heat carrier ( hereinafter referred to as the agreement) no other accounting point has been specified.

6. Metering units put into operation before the entry into force of these Rules can be used for commercial metering of heat energy, coolant before the expiration of the service life of the main metering devices (flow meter, heat calculator) that are part of metering units.

7. After 3 years from the date of entry into force of these Rules, heat meters that do not meet the requirements of these Rules cannot be used for installation in both new and existing metering stations.

8. Heat supply organizations or other persons have no right to demand from the consumer of thermal energy the installation of devices or additional devices at the metering unit that are not provided for by these Rules.

9. The heat supply organization, the heating network organization and the consumer have the right to install additional devices at the metering unit to control the mode of supply and consumption of heat energy, heat carrier, including for remote reading from a heat meter, without interfering with the implementation of commercial metering of heat energy, heat carrier and not affecting the accuracy and quality of measurements.

10. In the case of installation of remote reading equipment at the metering unit, the heat supply (heating network) organization and the consumer have the right to get access to the specified system in the manner and on the terms determined by the contract.

11. In the event that a single consumer of thermal energy is connected to the heating network leaving the source of thermal energy and this heating network belongs to the specified consumer of thermal energy on the basis of ownership or other legal basis, by agreement of the parties to the contract, it is allowed to keep records of consumed thermal energy according to the readings of the device metering installed at the metering station of the heat source.

12. If one of the parties to the agreement, obliged in accordance with federal laws to install a metering device, does not fulfill this obligation, the other party to the agreement is obliged, in the manner prescribed by the legislation of the Russian Federation, to install a metering device for making settlements under the agreement.

thirteen.If both parties to the agreement have installed a metering device, for commercial metering of heat energy, heat carrier, according to the agreement, the readings of the metering device that is installed on the border of the balance sheet are applied.

In the presence of 2 equivalent metering units on opposite sides of the balance sheet boundary for commercial metering of heat energy, coolant readings are taken from the metering unit, which ensures metering with a minimum error. The error in this case is the sum of the value of unmeasured heat losses from the boundary of the balance sheet to the metering unit and the reduced measurement error.

14. The metering devices used must comply with the requirements of the legislation of the Russian Federation on ensuring the uniformity of measurements, in force at the time of putting the metering devices into operation.

After the interval between verifications has expired or after metering devices fail or are lost, if this happened before the expiration of the calibration interval, metering devices that do not meet the requirements of the legislation of the Russian Federation on ensuring the uniformity of measurements are subject to verification or replacement with new metering devices.

15. Commercial metering of heat energy, heat carrier is organized at all points of delivery and points of reception.

16. Commercial metering of heat energy, heat carrier supplied to consumers of heat energy, heat carrier can be organized both by heat supply organizations, heating network organizations, and by consumers of heat energy.

17. Organization of commercial metering of heat energy, heat carrier, unless otherwise provided by the provisions of these Rules, includes:

a) obtaining technical specifications for the design of the metering unit;

b) design and installation of metering devices;

c) commissioning of the metering unit;

d) operation of metering devices, including the procedure for regularly taking meter readings and using them for commercial metering of heat energy, heat carrier;

e) verification, repair and replacement of metering devices.

18. Issuance of technical specifications for the installation of a metering unit (device), commissioning, sealing of metering units (devices) and participation in commissions for the acceptance of metering units (devices) is carried out without charging the heat energy consumer.

19. Metering units are equipped in a place as close as possible to the boundary of the pipeline balance, taking into account the real possibilities at the facility.

20. On heat energy sources, metering units are installed at each outlet of the heat network.

21. The selection of heat energy, coolant for own and economic needs of the heat source is organized up to metering units at the outputs. In other cases, the selection of heat energy, coolant must be carried out through separate metering units.

The withdrawal of the coolant for replenishment of heat supply systems with the installation of a separate meter is carried out from the return pipeline after the flow sensor along the flow of the coolant. Pressure sensors can be installed both upstream and downstream of the flow sensor. Temperature sensors are installed after the flow sensor along the flow of the coolant.

22. In the event that sections of the heating network belong to different persons on the basis of ownership or other legal basis, or if there are jumpers between the heating networks belonging to different persons on the basis of ownership or other legal basis, metering units should be installed at the border of the balance sheet.

23. Collecting information on the readings of metering devices, on the amount of supplied (received, transported) thermal energy, heat carrier, the amount of thermal energy as part of the supplied (received, transported) hot water, the amount and duration of violations arising in the operation of metering devices, and other information , provided by the technical documentation, displayed by metering devices, as well as taking readings from metering devices (including using telemetric systems - remote reading systems) are carried out by the consumer or the heating network organization, unless otherwise provided by the contract with the heat supply organization.

24.The consumer or the heating network organization shall provide the organization providing water supply and (or) sewerage, before the end of the 2nd day of the month following the billing month, information on the readings of metering devices as of the 1st day of the month following the billing month, if other terms not established by the legislation of the Russian Federation, as well as information on the current readings of metering devices within 2 working days after receiving a request for such information from a heat supply organization. Such information is sent to the heat supplying organization in any available way (mail, fax, telephone message, electronic message using the information and telecommunication network "Internet"), which allows confirming the receipt of the specified information by the heat supplying organization.

If the technical characteristics of the metering devices and metering units used allow the use of telemetry systems for transmitting meter readings and there is financial and technical support for installing telemetry modules and telemetry software, the meter readings are presented (taken) remotely using such telemetry systems.

25. A consumer or a heating network organization is obliged to provide unhindered access for representatives of a heat supply organization or, at the direction of a heat supply organization, for representatives of another organization to metering units and metering devices to verify meter readings and verify compliance with the operating conditions of metering unit devices.

26. If, in the course of reconciliation, a discrepancy is found in the information on the readings of the metering devices of the consumer or the heating network organization in relation to the amount of supplied (received) heat energy, heat carrier with the information provided by the consumer or the heating network organization, the heat supply organization draws up an act of reconciliation of the meter readings signed by representatives consumer or heating network organization and heat supply organization.

If the representative of the consumer or the heating network organization disagrees with the content of the act of reconciliation of the readings of the metering devices, the representative of the consumer or the heating network organization makes about the act and affixes the signature. The objections of the consumer or the heating network organization are indicated in the act or sent to the heat supply organization in writing in any way that allows confirming the receipt of the document by the consumer or the heating network organization. If the representative of the consumer or the heating network organization refuses to sign the act of reconciliation of the readings of metering devices, such an act is signed by the representative of the heat supply organization from Fr.

The act of reconciliation of meter readings is the basis for recalculating the volume of supplied (received) heat energy, coolant from the date of signing the act of reconciliation of meter readings until the day of signing the next act.

27. In order to control the volumes of supplied (received) heat energy, heat carrier, a heat supply organization or a consumer or a heating network organization has the right to use control (parallel) metering devices, provided that one of the parties to the agreement is notified of the other party to the agreement on the use of such metering devices.

Control (parallel) metering devices are installed on the networks of a heat supply organization, a heating network organization or a consumer in places that allow for the commercial metering of heat energy, coolant supplied to the consumer, a heating network organization.

If the readings of the control (parallel) metering devices and the main metering devices differ by more than the measurement error of such metering devices for a period of at least one settlement month, the person who installed the control (parallel) metering device may require the other party to conduct an extraordinary metering. verification of the meter operated by this side.

28. The readings of the control (parallel) metering device are used for the purpose of commercial metering of heat energy, coolant for the period of malfunction, verification of the main metering device, as well as in case of violation of the terms for submission of meter readings.

29. Installation, replacement, operation and verification of control (parallel) metering devices are carried out in accordance with the procedures provided for the installation, replacement, ex