A wooden house (dacha), not connected to central heating, needs a heat source that allows you to live in it at any time of the year. By tradition, fireplaces or stoves are used for these purposes, which can have a wide variety of designs.

The order of the arrangement of stoves in a wooden house is governed by the current regulations (SNiP), and is also specially stipulated by the requirements for fire safety.

Choosing a place for the oven

Any metal or brick oven in a wooden house is installed based on the following considerations:

- the possibility of arranging a chimney with reference to the design features of the ceiling and roof;

- free access to the stove for the purpose of its maintenance;

- compliance with fire margins, ensuring its distance from flammable surfaces.

For such types of furnace devices as a stove or buleryan, special requirements are imposed on the possibility of free movement of convection air currents.

Note! For the purpose of heating adjacent rooms, a brick oven is sometimes built directly into the partition.

The installation of a stove in a wooden house should be tied to the location of the projected chimney. It is not enough just to move it as close as possible to the flue gas outlet. Correct installation of a heating stove for a wooden house should ensure ease of connection to the chimney, as well as the ability to maintain both.

This requirement is explained by the peculiarities of the design of furnaces, from which it is necessary to remove accumulations of ash all the time, to clean the combustion chamber, and also to clean the walls of the chimney. Leave some distance in the direction of opening the firebox door during installation.

According to the requirements of SNiP, the distance from the furnace to the walls must be at least 110–125 cm. The same gap is left on the side of the door of the furnace combustion chamber. The stove should be positioned within the house so that maximum heat transfer can be obtained from it.

Where is it better to install a stove in a garden house

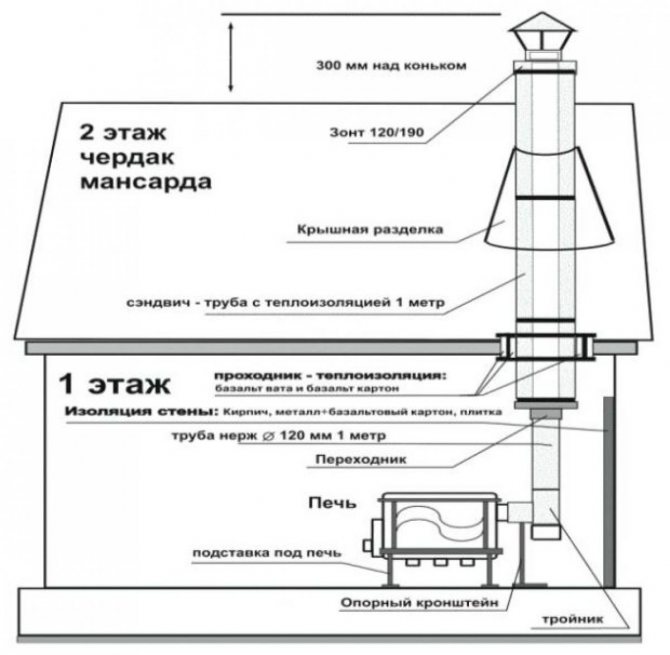

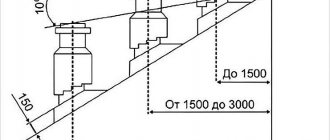

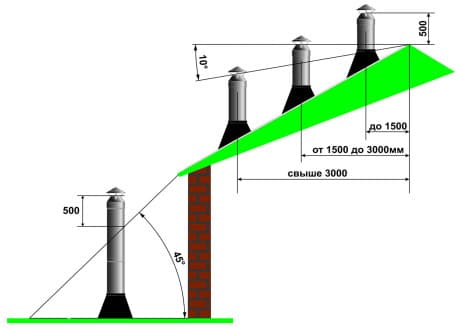

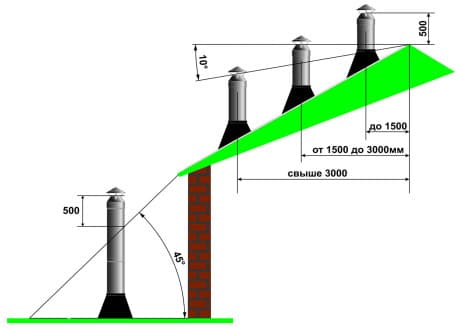

From the point of view of planning, the stove is installed based on the placement of rooms (if any) and the arrangement of furniture. But there is also a technical aspect that affects the location of the oven. The fact is that according to existing standards, in order to create sufficient draft, the height of the chimney from the grate to the head on the roof must be at least 5 meters. Garden houses are not high, and if there is a mansard roof, it often has a significant slope. Based on the foregoing, we can conclude that the best place for a stove in the house is closer to the ridge, the highest place of the roof. Ideally, in the center of the ridge. This arrangement makes it possible to locate almost the entire chimney inside the house. As a result, the heat from the chimney heats the attic, and the draft is stable due to the fact that the chimney is not cooled from the outside.

In accordance with this scheme, the height of the chimney head is determined depending on its distance from the ridge and the slope of the roof. Another reason to place the stove closer to the ridge.

Types of foundations

Among the known types of foundation foundations for arranging furnaces are suitable:

- concrete posts;

- strip foundation;

- monolithic slab.

Each type has its own characteristics. Concrete pillars are suitable for both a heavy metal stove and a massive brick fireplace. The number of supports is selected based on the total weight of the structure and the condition of the soil at the installation site.For their arrangement, holes of the required size are made in the floor, and after installing the posts, a frame of welded metal channels is laid on them.

Strip foundations are erected according to the classical scheme. According to the technique, during their construction, formwork is first made around the perimeter of the supporting structure, into which liquid concrete is then poured. All other operations are performed in the same way as described in the previous case.

Important! The strip base should not have a connection with the foundation of a wooden building, since due to its small mass in winter it can be squeezed out of the ground.

Monolith is mainly used when installing fireplaces in summer cottages. Its thickness can reach 15–20 cm, which is quite enough to withstand the design pressure on the foundation.

Any of the types of foundation considered above, after pouring, should settle for some time. It will be possible to start installing the oven on it in about 28-30 days.

How and with what to heat a stove-stove?

Fuel. Steel potbelly stoves are designed for wood heating. You can also use sawdust-based fuel briquettes, which are sold at construction malls. Furnaces designed for firing with coal are made of cast iron.

Modes of operation. Most ovens of this type can operate in one of two modes: intense combustion and maintaining temperature. For intensive combustion, after laying the firewood and closing the oven door, open the ash drawer to ensure that the maximum amount of oxygen enters the firebox. To put the stove in the mode of slow burning (maintaining the temperature), put the wood again and close the ash pan. The slow burning time depends on the design of the furnace and can be up to 8 hours for models equipped with afterburners.

Adjustment of the draft is carried out by a slide gate: in case of excessive draft, the slide is partially closed.

Remember: you can use the stove in intensive combustion mode for no more than 2 hours a day!

TIP To extend the life of the stove, experts recommend intensively heating the stove for 15-20 minutes after the slow combustion mode: this is necessary to remove the soot formed during slow combustion of the fuel.

Fire safety requirements (PPB)

The PPB requirements stipulate the conditions under which the correct installation of any type of furnace equipment is possible. To a greater extent, they relate to the protection of the floor and walls of the building from accidental fire (due to the contact of wood with hot surfaces).

Protective measures will allow you to protect housing and people:

- The use of special fire-resistant materials that protect the walls and ceiling in the area of the stove and chimney (if the house is two-story, the overlap between the floors should also be protected);

- Impregnation of elements of wooden structures adjacent to the hot parts of the furnace with special compounds.

Compliance with all the requirements of the PPB and the correct use of fire protection means are the main condition for the safe operation of home furnace equipment.

Wood processing

The most common protective agents include special impregnations (flame retardants) and transparent mastics. The following elements of wooden structures are usually processed by them:

- ceiling beams;

- floorboards in the area where the stove is installed;

- the walls adjoining it.

Additional Information! When choosing products, it must be borne in mind that mastic has a higher fire protection rate than colorless impregnation.

Fire-retardant processing of wood elements can be done not only by representatives of the Ministry of Emergency Situations, but also by the owners of the house.In the second case, they will need to get a special certificate confirming the correct installation of the oven.

Sheathing for ceiling and walls

In addition to treating elements of wooden structures with fire retardants and mastics, you can protect them from the hot parts of metal furnaces by upholstery with refractory materials. When preparing for this procedure, it should be borne in mind that the filing of the ceiling in the area of \ u200b \ u200bthe exit to the roof is carried out only with non-combustible materials that do not spoil the interior of the room.

Important! It is strictly forbidden to use combustible panels for upholstery.

The optimal cladding option is fibrous gypsum boards treated with refractory putty. To protect the walls, basalt cardboard can be used, sheathed with steel sheets on top. Most often, special decorative screens made of stainless steel are used. They not only protect surfaces well from burning, but also look quite aesthetically pleasing.

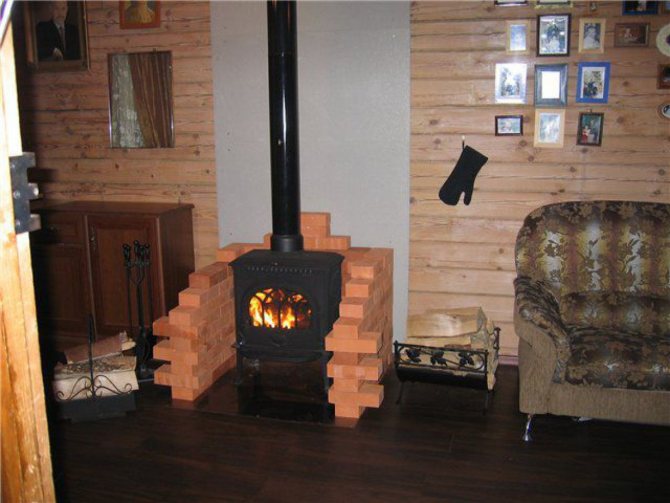

Another option for protecting the walls from hot stove parts involves covering them with bricks placed on the edge.

Wood stove for a summer residence. Construction and installation

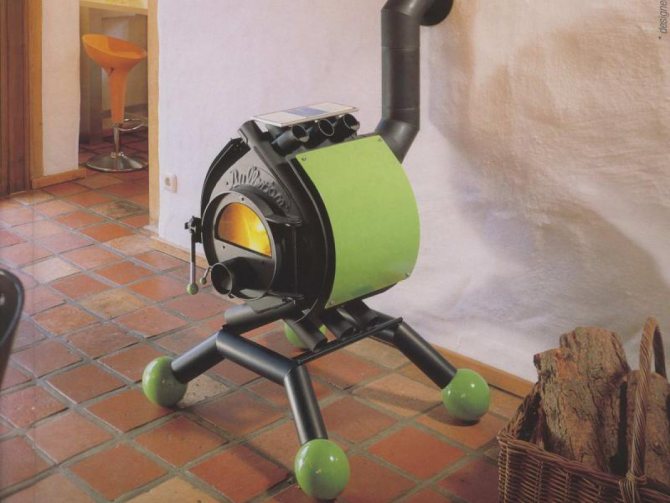

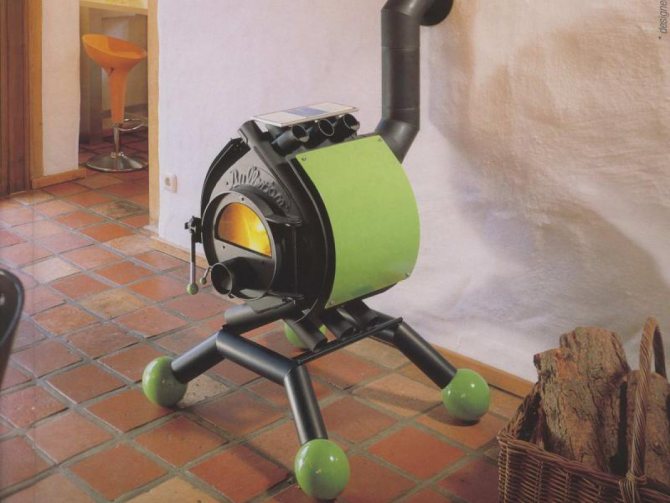

Modern models of wood-burning stoves-stoves have a complex design and good efficiency. For heating a summer cottage or a small country house, it is quite possible to organize effective heating with a factory-made stove-potbelly stove. The range of stoves today is very extensive: there are models exclusively for heating and combined stoves with hobs, and even with ovens.

The classic design and operation of the stove-stove: firewood is burned in the container, and the flue gases are removed through the chimney. The blower as a classical element is absent, and the supply of oxygen necessary to maintain combustion is carried out by a simple slot method - the doors of the combustion compartment are always slightly open during the heating process. Another option to provide air supply is to make holes in the stove body, in the wall under the combustion compartment. The ash pan is also absent in many simple models, but grates are available. It is necessary to clean ash in stoves without an ash pan through the firebox door. Some handicraft models of stoves work well not only without an ash pan, but also without grates. For example, potbelly stoves made from iron barrels.

But an effective and economical modern model of a stove is equipped with all the elements of the stove, as well as many options. Materials for wood stoves are stainless steel and cast iron. The differences between the models are significant, but mostly concern the details of their designs, but there are no fundamental differences. The main difference both in price and in durability is in the material: a cast-iron stove is much more massive, stronger and somewhat more reliable than steel. In appearance - there is a wide range of stoves, from quite simple to masterpiece, decorated with cast iron and forged metal decor. Of course, it is impossible to process cast iron in a garage or a home workshop, therefore all homemade stoves are made of steel and improvised things - barrels, gas cylinders, used sheet and profile steel, etc.

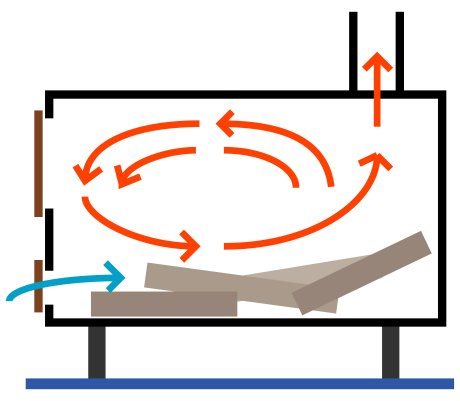

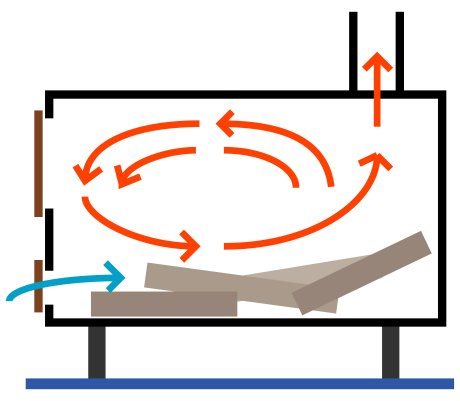

By the type of combustion, the stove can be divided into two positions: a regular stove and a long burning stove. The second type of potbelly stove differs structurally and quite significantly from a simple potbelly stove. To ensure the pyrolysis process (prolonged smoldering with a lack of oxygen with the decomposition of the fuel into solid and gaseous phases), it is necessary to increase the number of furnace chambers and create a system of channels for the intake and circulation of air and flue gases.

There can be two or more chambers, and oxygen is supplied to the furnace, in a limited amount.But in the chamber where the generator gases are afterburned (pyrolysis gas, it is also CO - carbon monoxide, which gives a significant amount of thermal energy during afterburning), a lot of air is required, since CO can only burn in a mixture with oxygen. This mixture, when burned, gives a large amount of heat and increases the efficiency of the stove by 25-30% or more.

According to the functions of the stove - stove stoves can be designed exclusively for heating and combined - equipped with hobs with cooking zones.

Installation of a metal furnace

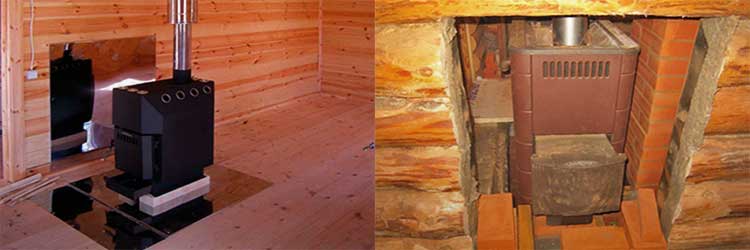

When considering the features of the placement of metal and brick ovens, the approaches to their installation are somewhat different. Iron stoves may not be too heavy, so that during installation they do without a foundation.

Important! According to the provisions of SNiP, only metal furnace products with a mass exceeding 80 kg need a reliable foundation.

With a lower weight index, such a product is installed on a substrate of refractory material directly on the floor. After the place has been chosen, and the issue with the foundation has been resolved, you can proceed to the procedure for installing a metal furnace. When installing the heating device, all the requirements specified in the section on the protection of wooden elements of house structures must be met.

For this purpose, a metal stove with a water boiler is sometimes simply lined around the entire perimeter with ordinary bricks. In all other respects, its installation is reduced to installation in an already prepared place. The only thing that should be paid attention to is compliance with the rules for removing the chimney to the outside.

What is a stove stove

A small historical excursion

Initially, a "stove" was a steel furnace of a certain design, the creation of which took place during the dramatic years of the Civil War for our country. It is not known exactly which of the Russian engineers came up with a very simple, but very effective steel furnace, relatively easily made in a handicraft way from more or less available materials. In the days of "war communism", after the urban economy with centralized heating in large cities collapsed, this tiny stove, which could be installed almost anywhere in the "bourgeois" apartment compacted by the house committee, saved many lives. By the way, the statement that the stove got its name due to excessive consumption of firewood is a stupid legend, born in the vastness of the Internet. In fact, the potbelly stove is very economical for its type. In conditions of the most severe shortage of coal and firewood, the owner of Master Gambs's walnut set had the opportunity to survive the terrible winter, using precious furniture as firewood. The name of the furnace was determined by the fact that at first it became widespread among “former” engineers, civil servants, and intellectuals who did not emigrate from the country. That is, according to the concepts of the proletariat, "bourgeois".

The device and principle of operation of the stove

The efficiency of a potbelly stove is largely determined by an accurate calculation of the ratio of the volume of the furnace and the diameter of the chimney. The pipe is made slightly narrowed (in moderation, otherwise the smoke will tumble into the room), because of this, a significant part of the gases is not drawn out immediately, but first makes several turns inside the firebox. This contributes to a more complete combustion of the fuel. When calculating, the following proportion is used: the diameter of the chimney in mm should be 2.7 times the volume of the furnace, measured in liters

Today the term "potbelly stove" is used, by all means. Often all steel furnaces are called this way. But we believe that only those stoves that have inherited the main design features and properties of the prototype are worthy to bear the proud name "potbelly stove".In the modern version, the stove often has a horizontal design, it is more convenient for laying full-size firewood with a length of about 40 cm, and is also equipped with a blower and grate, which makes it easier and more accurate to regulate the air flow and the rate of fuel burning.

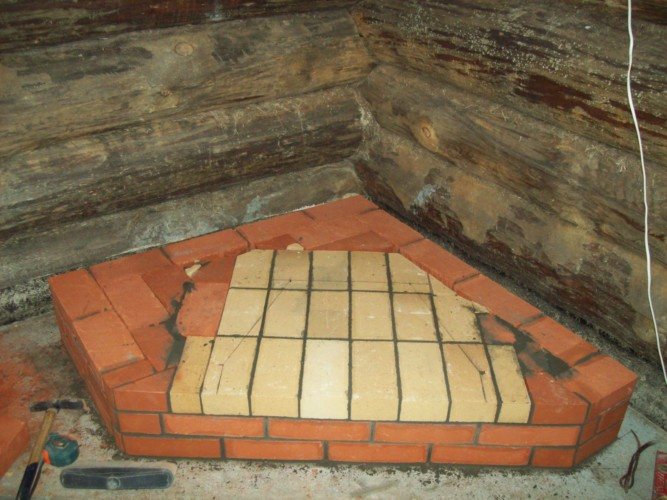

Installing a brick oven

It is preferable to lay out the base of a brick stove in advance (at the stage of designing a house or when pouring a foundation for it). For a brick wood-burning stove weighing about 300 kg, it is best to prepare a monolithic concrete base, poured over the entire area of the structure. If the house has already been built and inhabited, you will have to disassemble the floors in the chosen place, then go deep into the ground by about 25 cm.

After that, it is necessary to prepare a pillow of sand and gravel, tamp it thoroughly, pour a pre-reinforced base with concrete mortar. It is allowed to make a foundation in the form of concrete pillars or a strip structure constructed according to a typical scheme.

Important! The dimensions of the base should exceed the dimensions of the stove or fireplace by about 10-15 cm.

Upon completion of the installation of the fireplace stove in houses from a bar, it remains to insulate the wall in any way convenient for a person.