Double-circuit gas appliances make our life more comfortable and enjoyable. They are quite practical to use, suitable for heating country houses and small apartments. They are used for heating industrial or warehouse buildings, the area of which is not more than 500 sq.m.

The advantages of Ariston boilers are that in addition to heating buildings in winter, they heat water used in everyday life all year round. It is quite convenient and does not require the installation of additional equipment.

General characteristics of Ariston boilers

The description of Ariston gas units must begin with the characteristics of their main part - the burner. This element is used to burn fuel and to transfer thermal energy to the heating system.

Types of boiler burners:

- common

- modulation

The modulating burner is more convenient to use. It provides for automatic power regulation depending on the temperature of the device.

By the type of removal of combustion products, burners are divided into:

- closed type

- open type

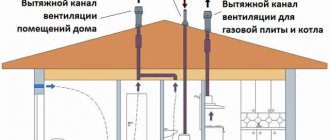

Units with a closed burner are safer to operate. In this case, the combustion products of natural gas do not enter the room. The use of a chimney is not required. A coaxial pipe is simply connected to the device and brought out.

The design of the coaxial pipe provides for the presence of two layers, which ensures the simultaneous removal of waste and the flow of air from the street into the burner.

Equipment with an open burner provides for the mandatory use of a chimney to remove combustion products.

Ariston Gas Appliances Technical Data

- Ariston boilers are used for heating and water heating, that is, they are double-circuit. Each modification has its own characteristics, but the common thing is the type of fuel - gas.

- The gas combustion chamber can be either open or closed. In the presence of a chimney, units with an open chamber are used. And in apartments of multi-storey buildings, where chimneys are not always available, equipment with a closed combustion chamber is used.

- Power. This indicator is used to calculate the gas consumption required to heat the room.

- Compactness. Wall mounted appliances are used in small, narrow rooms. Floor-standing units used in production or storage areas are heavier and require more installation space.

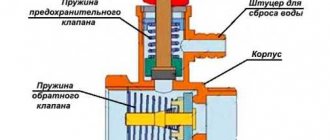

- The presence of a control unit. This element is indispensable when the water is turned off, the gas drops sharply. In case of any malfunction, the unit will immediately turn off the device, which will prevent damage. It also helps to save fuel consumption.

Ariston boilers are used for heating and heating water, that is, they are double-circuit

Choosing a gas appliance for heating

Ariston products can be found in catalogs. There are many models of gas appliances. The main mistakes when choosing the wrong unit are made from a lack of information. Therefore, before visiting the store, you should familiarize yourself with the basic tips for choosing a wall-mounted gas appliance.

When choosing a boiler, take into account the following points:

- The size of the kitchen, as the place where the heating device is most often installed. In the store, the choice begins with considering the overall dimensions of the device and selects it individually for your kitchen.

- Next, they go to the technical data and study the type of water heater in the apparatus. If there are a large number of people in the family, then it is not recommended to purchase a boiler with an instantaneous water heater.

- In this case, it is more rational to purchase a boiler with a storage tank for hot water. and select equipment for the amount of water that you will need for everyday use.

- The combustion chamber of the gas equipment is evaluated. It can be closed and open. It is recommended to choose a boiler with a closed chamber, due to the fact that it is safer in operation. The presence of a chimney is optional, which is important in multi-storey buildings. Enough to buy and bring out a coaxial pipe.

Operating instructions for gas boilers Ariston

Before purchasing a gas boiler Ariston, you need to understand that if the buyer does not understand its installation, it is better to contact experienced specialists and entrust all the work to them. After all, even with the most detailed instructions, it is not a fact that the case will end successfully. In this case, there is every chance of damage to the equipment, after which you will have to call repairmen, and this will result in additional costs.

You will be interested >> Advantages of a double-circuit gas boiler

It is very important to keep children away from the equipment. To do this, after installing the gas boiler, it is necessary to have a conversation with them and explain in plain language that nothing can be twisted and displayed on the unit, only an adult should do this. If the family leaves, for example, on vacation, after the boiler is turned off, it is also necessary to shut off all pipes for the supply of gas and water. Only then is the equipment disconnected from the network.

If a display is provided on any model, all the indicators that it displays must be strictly controlled. It can display malfunctions or deviations from normal operation that occurred during the heating process.

One of the most important points in the instructions for gas equipment is safety precautions. Before connecting the boiler, you need to familiarize yourself with it first.

Reviews of double-circuit wall-mounted boilers Ariston

The Ariston gas boiler manufacturer has taken a leading position in the market thanks to the quality of its units. This is evidenced by many customer reviews throughout Russia:

A user named oixx1979 from Volgograd notes the quiet operation of the boiler and its endurance. Gives advice on the maintenance of the gas appliance.

The user lenka-angel007 from Kislovodsk, as the advantages notes the compact size and economical mode of gas consumption. The disadvantages include work from electricity.

DrKey from Moscow indicates that this is a very good boiler. Compact and economical. Indicates easy boiler control.

Georgstar from Krasnodar writes that the boiler is convenient and easy to maintain. Mentioned that almost no wall-mounted gas appliance works without electricity.

Sibiriya from Barnaul describes the compactness and good design of Ariston boilers

Malfunctions and repair of boilers Ariston

He turned on the ariston bs 24 ff boiler in heating mode, set the coolant temperature to more than 60 degrees and the following began to happen - after the burner turns off, after 5 seconds crackles begin in the boiler, approximately in the upper part in the heat exchanger area. What is this malfunction? The boiler has been in operation for 2 years. Maintenance was carried out, except for cleaning the inside of the heat exchanger from scale and other things! The technician who carried out the maintenance said that there is no need to descale! The device, as it worked 2 years ago, still works unchanged, except for crackling after the burner goes out, but only at coolant temperatures above 60 gr. Carried out the installation and installation of the wall-mounted boiler Ariston. It works great for heating. On the hot water supply it turns on, heats up for about a minute and turns off the flame, green 40-80 are on, then the green 40-50 error and the yellow chimney "Alert for insufficient water under pressure" blinks. After which the flame appears and heats further, then turns off again. The Ariston Uno boiler is set to summer mode. I turn on hot water in the tap, the boiler works normally (heats the water).After turning off the hot water, gas is ignited on the radiator circuit, and the boiler continues to heat the water already in the system. After a while, he either stops (it seems as if he "remembers" that he is in summer mode) or make attempts to re-ignite the gas to the heating system. But he can't do it. Most likely, you will have to reflash the program memory. Installed a gas boiler Ariston Uno 24 MI. At first it worked fine, but about 3 months ago problems started, first with hot water, and then with heating. During ignition, the boiler ignites, but the ignition clicks are heard for 7-10 seconds, and then the protection is activated, the boiler goes out, the red light is on. After pressing the restart button, it lights up and works normally. Previously, it was 1-2 times a day and only when hot water was turned on, but now it is constantly. Tell me what could be the problem? Clean the flame control electrode with a zero, it must have become covered with soot. Do not know who is responsible for the control - it will not hurt to clean everything that is in the combustion chamber above the burner. Well, if it doesn't help, then the fee. What is the reason for the blocking of the Ariston UNO 24 MFFI boiler when the heating is turned on? Moreover, the blocking occurs approximately after half an hour of operation - when the batteries are fully warmed up. I thought maybe the temperature sensor, but the indicator "says" the ignition. It is necessary to pay for the repair, it is not necessary to change it. The boiler Ariston Uno 24 MFFI EE is faulty - the yellow lamp turns off and lights up. How to fix? Check the operation of the turbine. Check the pressure switch. Check the functionality of the email. boards. The Ariston Uno 24 boiler operates in heating mode and periodically turns off. with extinction of all diodes. When incl. its on a button incl. it starts, for a while it can work for an hour or half an hour and off. It seems to me that the fee. Recently carried out repairs. Did the following. 1- cleaned the air vent valve. Didn't work completely. From this, in the heat exchanger, due to the presence of air, the scale turned into some kind of black flakes. (local overheating affected). 2- flushed both heat exchangers. The secondary was 90 percent clogged. I did the second operation twice. But I think I'll have to repeat it in the spring. 3-flushed the filter on the return line. It looks like the secondary heat exchanger is clogged with scale, overheats and turns off. Need to rinse! The gas boiler Egis Plus 24 FF is in operation. The pressure in the heating circuit dropped by 0.5 atm for two weeks. I checked the expansion tank, it was zero. Pumped up to 1 atm. Now it began to fall more slowly, the pressure in the expansion tank is normal. For what reason can there be such a pressure drop in RB? Outwardly, he is whole, the air does not poison. Basically, the pressure in the heating circuit drops after using hot water. When pumping, I closed the supply and return valves. I drained the water from the boiler, it spilled out a little when I pumped it up. Before that, the season worked fine. If you are sure that the heating circuit is falling, then look for a leak in it. Installed and connected Ariston Egis Plus 24 with an open combustion chamber. There is a problem, advice is needed: 1. The temperature in the DHW circuit does not depend on the set parameters and is always maximum. Regulated in the heating circuit. 2. Feeling that the boiler does not change the intensity of the flame (in both modes). It lights up at maximum and works like this until it turns off when the maximum temperature is reached. Is it customizable in some way or something more serious? First you need to look at the gas valve settings. The boiler in heating operation generates error 104. The pressure in the expansion vessel is 1 bar. the pressure in the 1.4 bar apparatus does not drop, the bypass is normal, the turbine and everything else is also normal. Everything is clean along the contour. What can the third digit mean in the error? Boiler Ariston Chimney class. And if we have a pressure sensor? I didn't find it. If the error is only when working for heating, most likely, the malfunction needs to be looked for in the heating system, I would start by checking the CO filters. Most often not, but there were instances with a pressure sensor.For correctness, check the menu parameter 247 and, if necessary, set 0. We installed and started up the Ariston Clas System 15 FF wall-mounted boiler. During operation, it gives an error 104. Pressure in the expansion tank 1. The pressure in the boiler 1.5 does not drop. The filter is clean. There is no air in the CO. The heat exchanger is flushed clean. What could be the malfunction? It stops 3-4 times a day. I noticed that when an error occurs, some hiss and a pressure surge from 1.5 to 1 and again to 1.5 becomes error 104. Options: board, pump, NTC. Tell me, must the coolant be drained before air injection? We drain (bleed through the vent) the coolant until the pressure gauge shows 0. Before that, shut off the CO cocks under the boiler. Then we pump the pressure into the air part of the expansion tank with a pump, checking the pressure with a third-party pressure gauge. We pump up 1.0-1.2 bars. We open the taps. Then we pump it with pressure in CO, control the pressure with a boiler pressure gauge. We pump it either through the make-up tap or with a third-party pump at the CO filling point. We pump up to 1.3 -1.5 bar. We check if the air vent is open. We turn on the boiler, and if there is a mode for removing air from CO, then we drive the device in this mode. We also warm up the CO to the maximum. Air is removed from CO. We go through the heating devices and bleed the air out of them through the Mayevsky tap. The pressure will drop slightly. We feed up to the values indicated above. Everything. If everything is correct, then when heated to the maximum temperature, the pressure in a closed system will not rise more than 0.3 bar. Malfunction in the operation of the double-circuit boiler ariston egis 24 ff - when hot water is turned on for 20 seconds of operation, the flame goes out and error 109 lights up the plausibility test failure. What is it and how to fix it? First, the burner goes out, and then 109 comes on. DHW temperature is the temperature of the water in the tap? Can I make repairs myself? Choose one of the options: 1. Error 109 lights up and then the burner goes out; 2. The burner goes out and then error 109 lights up; Set the DHW temperature to 50 degrees or less and see if there are any changes. Tell me, where is the expansion tank on the Egis 24FF gas boiler, and more specifically the pumping valve? And how to properly drain the water from the boiler? In order to properly pump the pressure into the expansion tank. Located at the back, above the boiler. - Close the tap of the cold water inlet to the device. - Open a hot water tap on the mixer at any point of the tap. - Open the make-up tap. - Wait until the pointer of the pressure gauge reaches zero. The problem in the operation of the double-circuit boiler Ariston BS II 24 CF. When the heating is turned on, the burner starts up and turns off after a short time, the system does not warm up completely, and the device is already turned off. They called the foreman, he said that the pump was out of order, although when the boiler was turned on, a slight vibration was felt and the supply pipe heats up and the first three radiators too (the remaining three were not possible to check). But the return line is a little warm. The boiler does not give out errors. Tell me how you can check the pump's performance? Switch off the boiler using the button and from the socket; turn off all the taps, drain the water from the device through the drain fitting, cover the board with some kind of waterproof oilcloth on top to prevent water from getting in, remove the pump and try to turn it by hand - how easily it turns. 1. the return filter is clogged. 2 the filter in the boiler is clogged (the pipe where the pressure gauge comes in). 3 the heat exchanger is clogged. 4. the pump does not reach the operating parameters. Aegis plus 24 FF boiler is in operation. When I turn on the hot water supply, the device turns off after 30 seconds and gives error 303. Tell me, what could be the damage? Most likely, you will need to change the board. The boiler Ariston BS 24 FF was installed, it worked for 4 years without breakdowns. Now there is a problem: You set the temperature, for example, 70, the boiler does not heat up the entire system, although everything was normal before.Only the first 3 batteries are heated, respectively, the return flow cools down, the device turns on for a short time (the sensor on the dial shows a maximum of 40) and the heating is turned off, although the return flow is slightly warm. I don't know what the problem is, maybe you need to install an additional pump? (The stabilizer is worth it, the filter is only from mechanical impurities.). The filter in the boiler is clogged. We are going to connect a 15 kW single-circuit wall-mounted gas boiler Ariston. Does it need an expansion tank? How to check the boiler after starting up? This model already has a standard expansion tank, but its volume is not always enough for work. We need to inspect the heating system. If it is large enough, then it will be necessary to embed an additional tank outside the boiler. Before starting commissioning, fill the heating system with water, including underfloor heating and radiators, and ensure that the chimney is ready. The Ariston boiler is in operation, which works from a cylinder with liquefied gas. Recently, it became scary to turn it on: the volume of the flame soars high up. How can you fix and repair? It is necessary to see why there is no flame control, and what is out of order - a reducer or a flame regulator, or there is another reason for this phenomenon. Boiler malfunction Evo class. Suddenly stopped turning on, only the fan works without stopping. Shows errors 201 and 607. Can this be fixed? Error 201 means a short or open circuit in the hot water circuit temperature sensor circuit. Error 607 is the pressure switch contacts are closed before the fan turns on. In Egis Plus 24, the heating mode was turned off, only hot water was left. It became impossible to start it: writes "Board failure". How to make repairs yourself? Measure the potential between zero and ground, there should be nothing. If the voltage is at least 2-3 V, then the boiler will write an error and the potential must be removed. Then you should find out the voltage in the network: at 180-190 V, the board will also fail. If everything is in order, then the problem is in the board itself. Ariston Genus 24 is connected, the error "flame separation" began to appear. How is this eliminated? The gas pressure in the boiler is clearly too high. The gas valve should be adjusted. There may also be a problem with the air supply to the boiler. The Class 24 double-circuit boiler has stopped giving hot water, error 103 is displayed. What can you do yourself? This error code indicates insufficient circulation of the coolant. The water pressure in the DHW circuit should be checked, if it is low, then there may be a leak. If the make-up gives nothing, or gives a short-term effect, you should call a specialist. When you open the hot water tap, the wall-mounted gas double-circuit boiler Ariston Class 24 turns on, d38 is displayed on the display, and after 2-3 seconds. 5P3 appears and immediately again d38, after 2-3 seconds again 5P3 and immediately again d38. And so the information on the board changes during the first 20-25 seconds. heating water. Then the water heats up without problems and d38 is constantly on the screen. It began after they stopped heating the house, that is, the boiler only works to heat the water. This is the first question. And the second: After closing the hot water tap, error 104 lights up on the display. The boiler starts up only after pressing RESET. What could be the cause of these problems? There was the same malfunction. We decided to flush the secondary DHW heat exchanger. But you have to flush every six months. The symptoms were one to one. Yet. There is a special device for flushing, it is connected to the input / output of the DHW circuit. If you use it every six months, then such a rinse is sufficient. If the heat exchanger is heavily contaminated with deposits, then it is necessary to remove the heat exchanger and "soak" it in a solution with citric acid (vinegar). We installed and started up the clas evo 24 ff boiler. A malfunction has occurred. The boiler does not pump the heating system, the first two radiators are warming up. Heating polypropylene. At the same time, it does not give any errors.What could be the problem? I also want to add that the temperature quickly builds up for about one and a half minutes and the boiler goes out. There is no circulation of the heating system, there may be a blockage or the transport plugs from the radiators may not be removed, there may be air both in the pump and in the system. The gas boiler Ariston clas system 24 ff was put into operation. When starting up, the boiler does not always ignite, it is clear that there is a spark, a certain amount of gas flows (I noticed the meter readings), but the flame does not ignite. After 8 seconds, as expected, error 501 is displayed. Sometimes, at the moment of ignition, you can see how a small flame flares up and goes out, sometimes it ignites without problems with a normal flame. I also noticed that the flame on the burner can be of different strengths. I thought that this was due to the temperature of the coolant, but with several switching on and off of the boiler, the flame is different at the same temperature. The boiler was installed what is called "as is", i.e. no parameter settings have been made. The only parameter that tried to change this parameter 220 "Smooth ignition" - the factory setting is 47, tried to increase it to 80 - did not give a result, returned it back. I didn't change any other parameters. I also noticed that when the temperature setting is increased to 61 degrees, the device does not turn off, i.e. it gradually reduces the flame as it approaches the temperature and continues to burn in this mode. When the temperature was set to 53 degrees, it heated up and turned off, but then it could not start due to the above problem. It is impossible to find a specialist for such boilers in our outback, and the nearest center is 200 km away. Maybe someone faced a similar problem? Please advise what test operations need to be done to identify the malfunction. It is necessary to slightly increase the minimum gas pressure on the gas. valve. Warming up to the set temperature takes place for min. pressure. DHW control (knob) - to the maximum. The flow must correspond to the maximum (12 l / min). The first measurement (by gas) at the inlet, in static, then at start-up. If the pressure drops below 14 mbar, do not touch the valve, otherwise you will lose all factory settings. Tell me, I have a wall-mounted gas by-pass boiler Ariston Class 28 CF installed. When DHW is turned on, the water temperature does not correspond to the temperature set on the screen. At first I didn’t pay attention to it, but lately the readings are very different, I put 45, but it flows, about 38. How to fix it? Can I carry out repairs myself? Need inspection and maintenance with complete cleaning done. After switching on the boiler (in heating and hot water mode), the green LEDs 50/60/70 and the yellow LED house light up, the boiler does not ignite. What to do? This error is the presence of a flame when the gas valve is closed (false flame). The board needs to be repaired. I have a wall-mounted boiler EGIS II 24 FF connected for three years of operation. During the year, the fan relay failed several times, what is the reason? The fan runs constantly! Sticky contacts. Perhaps the propeller rotates hard, because of this, the current through the contacts is too high. Try to put a relay with a high current. (More than it was) the current is indicated on the relay case. Also check the contacts of the fan connector on the board and the contacts on the fan itself - perhaps somewhere the contact is not very good, because of this, the relays do not work for a long time. In boilers of this series, reconfiguration of this parameter (protection against water hammer) is not provided for any of the three modifications of the control board. The boiler is new. For some reason, the DHW circuit does not work. The heating is working properly. On an attempt to turn on hot water, the boiler only shows the temperature, and is not even going to heat it, it waited about 5 minutes. The problem is in the 3-way valve. The caliper let the water in - ruined the mechanics of the servomotor. You need to change both. Installed wall gas boiler BS II 24 CF NG. When DHW is switched on, the yellow lamp (t-40) first comes on, and then it starts to flash.The water heats up normally, the heating works, in general, everything works. Should the light be blinking or some kind of system malfunction. When heating and DHW are on, it is on, not blinking. I was told that it should not be so, it should just burn. The boiler has just been installed, we are afraid of failures in the winter. The boiler was installed this spring, there were no problems. Now a rather strange breakdown has occurred - an error 5p3 (flame separation) appears. Moreover, the error appears only if the temperature of the heating circuit is set below 60 degrees (the device tries to start, ignition is heard, the burner icon appears on the panel for a second, then it disappears and an error pops up). If I set it to 60 degrees or more, the problem goes away. What could it be? This 5P3 error on these boilers may occur due to the pulse power supply installed there. The potential that the ionization electrode sees arises as a result of combustion meets the potential of the boiler itself (which will be more than 5V) if it is not grounded, this error may occur. The technician can check this by disconnecting the ground wire from the main control board and restarting the boiler at your desired temperature. the error should be gone. If this does not happen or your boiler is grounded. Then you need to look at the settings of the gas valve. The gas boiler Ariston Egis plus 24 FF is in operation. When the hot water tap is opened, cold water starts to flow almost immediately after opening, then hot for 20 seconds, and again cold, again hot for the same approximately 20 seconds, and again cold, and this continues indefinitely. The display of the gas boiler shows err 109, judging by the instructions this is some kind of "plausibility text failure". Can you tell us what kind of test it is, what could cause the error, and how to fix this problem? The boiler needs maintenance. Tell me about connecting a room thermostat to the boiler. He did everything according to the scheme that came with him. To begin with, I threw off the jumper, the boiler did not start - this is normal! I connected a room thermostat, the device did not start, but when I turned the knob, somewhere more than 23 degrees, there was a click in the thermostat, the boiler started to work, but it turns off and on without responding to the thermostat. I tried to flip the terminals on the thermostat, on the contrary, the device turns on up to 23 degrees, when you turn the thermostat knob, a click and the boiler turns off, but in this position it does not respond to the thermostat. Who knows, tell me, maybe I'm doing something wrong! Probably turns off due to overheating of the coolant above the ordered temperature. Add the boiler temperature.