There are various ways to heat the sauna.

Today, more and more often you can find baths built by the owners of summer cottages with their own hands. After all bath - it is not only fashionable, but also very useful.

The heart of such a building is the stove, which determines whether the bathhouse will be functional, comfortable and warm. A well-equipped sauna guarantees the highest level of wellness treatments!

And today we will tell you how to make heating in a bath with your own hands.

Simplified bath heating systems

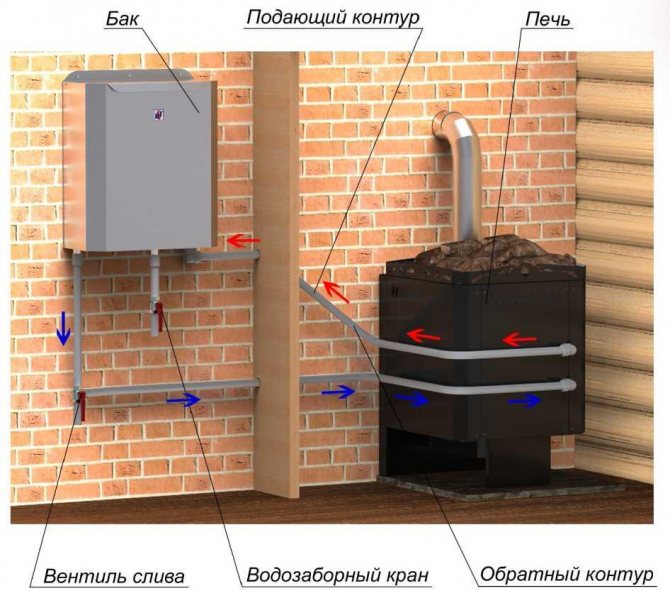

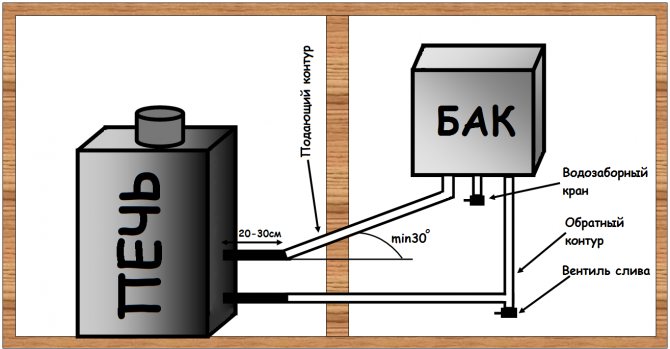

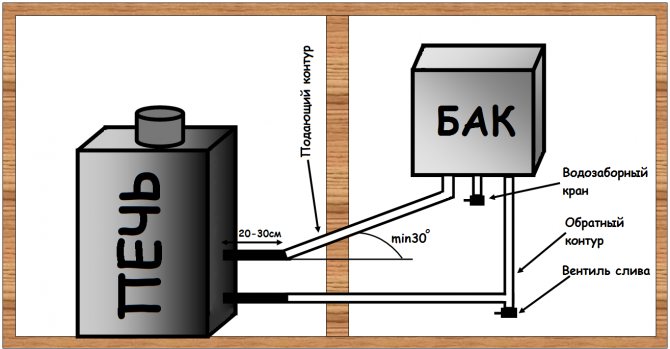

The most simple to manufacture, maintain and operate is the system in which the bath is heated from the oven to the steam room. That is, the stove-stove, which provides maximum heating of the ambient air and the production of heated steam, is located in the steam room, and its furnace part, through which the fuel is loaded, is carried out into the dressing room. At the same time, due to the implementation of such a design, the bath is heated from the sauna stove simultaneously both in the steam room and in the dressing room. In this case, the washing section of the bath is heated by placing a tank with hot water in it, and, if necessary, an additional heating battery.

The storage tank located in the washing section of the bath is connected by pipes to a heat exchanger heated by a bath stove. The water in the storage tank is heated using a circulation pump that pumps water through a heat exchanger located either directly in the fuel combustion area or on the chimney of the furnace.

A stove for a bath with a heat exchanger for heating and obtaining the required amount of hot water is the most effective and simple way to maintain the optimum temperature in all rooms of the bath. Such a combined design is quite economical in terms of fuel consumption, generates a large amount of heat and has a relatively short time to reach the operating mode.

https://youtu.be/ZMvVdPM7gwo

Electric heating

The use of electricity to heat bath apartments is considered to be the most unprofitable heating method. Despite the fact that the technical part of the question - the purchase and installation of two or three heaters costs mere pennies, the energy consumption for heating the dressing room and the rest room using electric convectors is quite expensive.

It is considered even more unprofitable and unsafe to heat the bath room with the help of infrared emitters. According to the owners, such a device can be hung in the vestibule of the bath above the front door; it is economically unprofitable to heat the entire room with it.

The only economically viable way to heat a room with electricity is to use an electrode electric boiler with aluminum radiators or equipment in the room with a warm floor. In this case, the cost of paying for consumed electricity is comparable to gas heating.

When deciding how to make heating in a bath, it must be borne in mind that the cleanest option for creating a heating system is the use of electricity. The use of modern equipment makes it possible to provide heat supply to the building in an autonomous mode in the required thermal mode.

Sauna stoves and their features

If necessary, a stove for a bath with a heating circuit can be quite versatile both in terms of operating mode and in terms of the fuel used in it.Such a furnace can be used either in the mode of continuous fuel combustion, or in a cyclic mode, with periodic loading of combustible material. Natural gas, wood, charcoal or fuel pellets can be used as fuel. In addition, electric ovens of appropriate power can be used to heat the bath and heat water.

For the manufacture of continuous combustion furnaces, steel is usually used. Such a furnace heats up quickly and cools down quickly when the fuel is stopped. Sometimes the surface of steel stoves is lined with decorative non-combustible material, which increases its safety and heat capacity.

Furnaces used in a cyclic room heating mode must have a high heat capacity and the ability to retain heat for a long time after the fuel supply stops. They are made of refractory bricks, which have a large mass and high heat capacity. Such an oven, after heating, can maintain a high temperature for a fairly long time. The disadvantages of such furnaces include a long time to reach the operating mode, that is, a long time for heating the furnace in a cold state.

To organize the supply of hot water to the bath, as well as to heat the premises, stoves equipped with forced circulation systems of hot water, as well as heat exchangers, are used.

How to make heating in a bath - choosing a method of heating a steam room

A visit to the Russian bath has become a family tradition for many. Many owners of private houses want to install a bath building on their personal plot, but often they are faced with the problem of arranging heating. There are several ways to heat a modern steam room and other rooms located in the bath.

The choice of the type of heating structure depends on the financial capabilities and wishes of the owners. Since the steam room is used from time to time, therefore, before heating the bath, it is necessary to decide how this building will be used.

If it is planned not only to bathe in it, but also to wash and take a bath, then using a regular oven for heating will not be very convenient.

Modern methods for providing heating in the bath all year round are varied, among them the most popular are:

- electric floors;

- installation of water heating;

- installation of the "warm floor" system and others.

Heat exchanger ovens

Furnaces equipped with heat exchangers can successfully solve all problems of space heating, water heating, steam generation. Heating a bath from a heat exchanger of a bath stove can include not only the main rooms of the bath, but also auxiliary ones, for example, a shower room, a recreation room, a pool, a billiard room, etc.

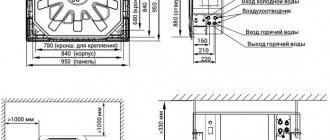

When designing a furnace equipped with heat exchangers, even at the stage of building a bath, one should take into account:

- the size of the bath and the area of the heated premises;

- dimensions and weight of the furnace;

- specific gravity of the heating device;

- the number of heat exchangers included in the furnace kit;

- total volume and composition of the circulating coolant;

- diameter and length of the chimney.

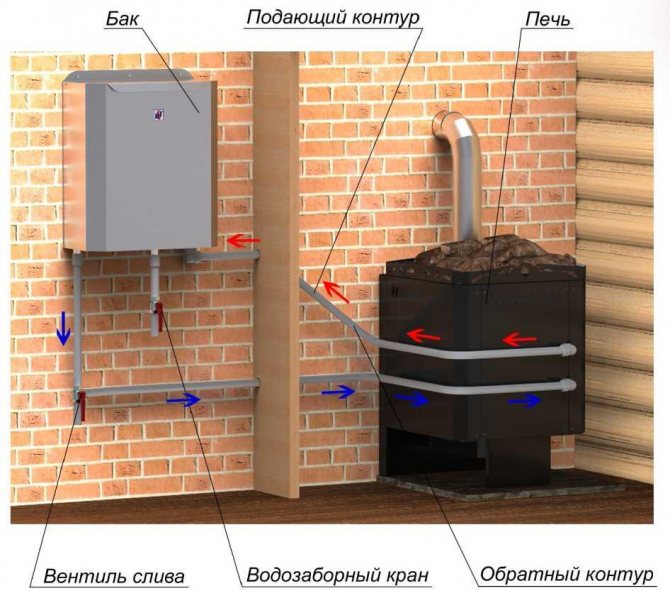

Sauna stoves with a heat exchanger can be connected using heat-insulated pipes:

- To a remote tank for heating water, used in the washing compartment of the bath.

- To the heating radiators located in the service rooms of the bath - the recreation room, billiard room, etc.

- To the hot water supply and water heating system, which includes not only the main and service rooms of the bath, but also the living quarters of the house.

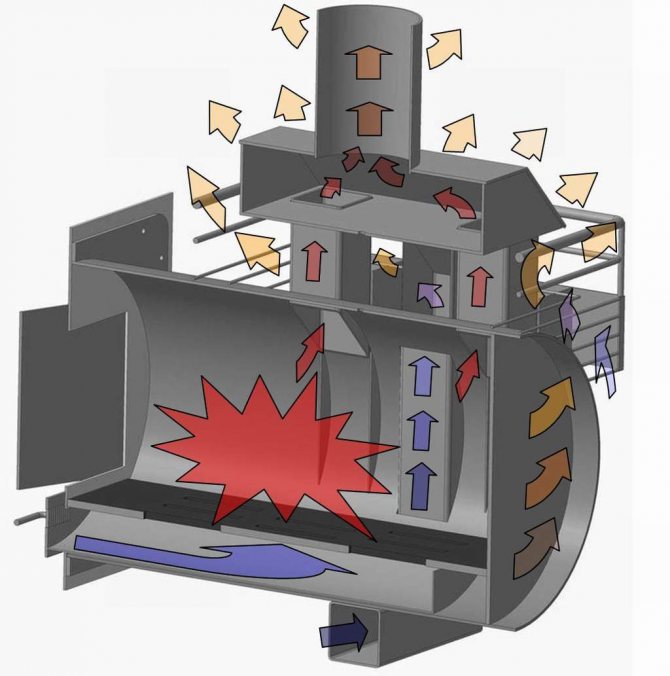

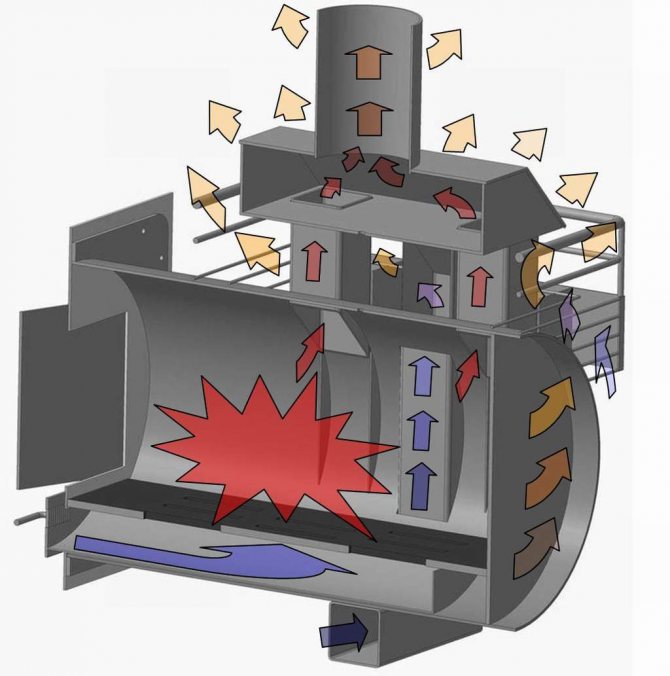

Stoves for heating a bath with wood come with an internal or external heat exchanger. The internal heat exchanger is located in the combustion chamber between the body and the casing.It uses the heat obtained directly from the combustion of fuel and heating the furnace.

An external heat exchanger is installed around the chimney. It uses the heat given off by heated gases when they are removed to the outside. The increased volume of the external heat exchanger increases the efficiency of its functioning. The use of heat from the gases escaping through the chimney saves fuel and increases the efficiency of the furnace by reducing the temperature of the flue gases.

In a cast iron stove, water is heated in a heat exchanger by flue gases and heat radiation. In this case, the heat exchanger body is located in the upper part of the furnace in the area of the chimney.

A brick stove for a bath involves the location of a heat exchanger inside a brickwork in the immediate vicinity of the firebox. This somewhat increases the thermal inertia of the heat exchanger, and also reduces the likelihood of its overheating or oxidation of its surface under the influence of an open fire.

The heat exchanger providing heating of the bath from the stove to the steam room must correspond to the technical parameters of the effective power of the water heating system, the operating pressure in the system, the volume and composition of the circulating heat carrier.

Fuel

The next very important point that you should pay attention to is this is fuel... For heating a bath, you can use not only firewood, as many people think. Of course, burning wood guarantees unique aroma of wood and the special warmth of the bath, but making a supply of firewood for the whole winter is not an easy task. Modern technology can provide us with more convenient energy sources.

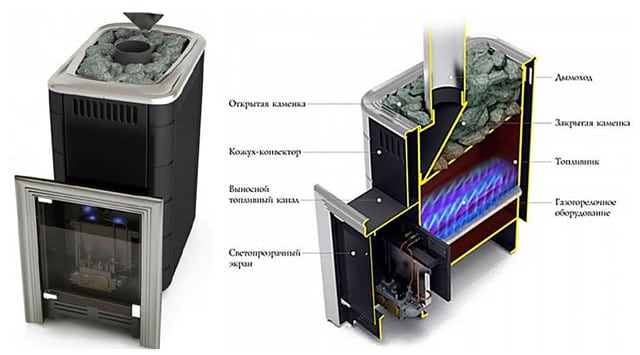

Today there are stone ovensrunning on gas, electricity, the same wood, and, of course, on liquid fuel. There are also models that combine the use of several types of fuel at once. You can of course make a similar oven and do it yourself, but this will require special skills and the necessary experience.

In the case of using electric heating for a bath, you can adjust the current strength in the heating elements yourself. It is also very important not to forget during installation about the installation of an automatic protection system, which will stop the further supply of electricity if the temperature in the oven rises above the permissible norm.

When choosing a fuel, you should pay attention to the price and availability, in that firewood is significantly inferior to, because they are very difficult to get, electricity is available to everyone, but it will come out more expensive. Liquid fuels are not only flammable, but they will also cost you a lot. Gas is cheap, easy to use, but not always available.

Features of a sauna stove with a heat exchanger

A sauna stove equipped with a heat exchanger has certain design features.

These include, in particular:

- tube supply system for coolant circulation;

- thickened body walls;

- increased volume of the heater;

- the presence of a mandatory air distributor;

- firebox door made of heat-resistant glass.

The heat exchanger functions due to the constant circulation of water through all the devices that make up the heating and heating system in the bath. For efficient use of the heat exchanger, the length of each of the connecting pipes should be a maximum of 3 m. Especially in the absence of external thermal insulation of the pipe.

Subject to the rules of fire safety, as well as in the presence of forced ventilation and thermoregulation systems, a heat exchanger can be equipped with a universal stove for a bath and home heating.The stove itself can be located in the bathhouse and connected to the living quarters of the house using a heat-insulated heating pipeline and hot water supply to the home.

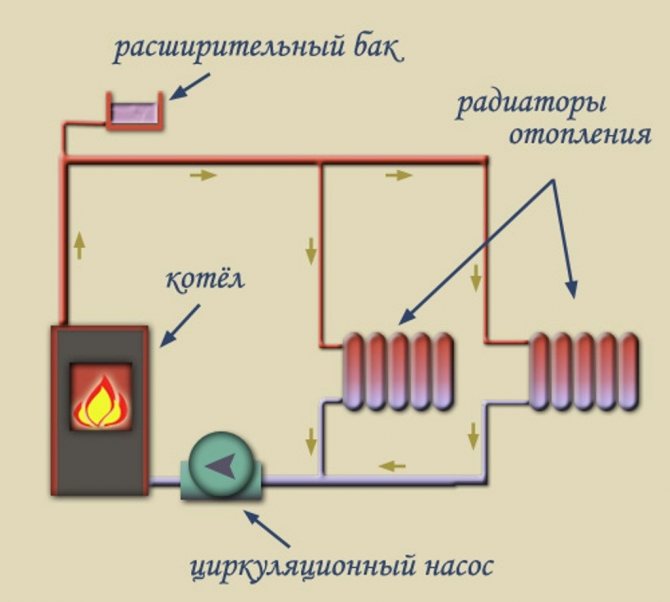

To organize the circulation of water in the centralized heating system, as well as to supply hot water to the premises of the house and to the washing section of the bath, an automated pumping station is used to maintain a constant pressure in the line.

The simplest design of a universal stove is an electric stove with separate electric heaters for the heat exchanger and heater sections.

Such a furnace can operate in several modes, namely:

- In the mode of heating the residential premises of the house and its hot water supply (DHW) with the maintenance of the minimum required temperature in the premises of the bath in the cold season.

- In the heating mode of the bath and the whole house with hot water supply during the cold season.

- Organization of heating a bath and a heater in the summer.

A similar stove for a bath and heating can simultaneously be created in the form of a continuous operation device on natural gas or fuel pellets. Using charcoal or wood as fuel is difficult in this case and has certain technical difficulties. Indeed, in wood or coal stoves, the possibility of automatic temperature control is not provided. This can lead to sudden temperature fluctuations in the heating main.

If it is possible to connect to a natural gas main or an electric cable of industrial voltage, it is possible to make a stove for a bath from a heating boiler operating, respectively, on gas or electricity. Such a stove can serve as a heating and water heating system. Together with the heating boiler in the sauna, you can also install a small steel wood-burning stove in the steam room.

Device

In fact, almost any wood stove, even an old brick stove, can be converted and supplied with a water circuit. Nevertheless, it is better to give preference to ready-made solutions with a well-arranged structure, where the heat exchanger is inscribed harmoniously and does not spoil the combustion process and traction.

The idea is to place a water heat exchanger directly in the combustion chamber or in front of the chimney. Depending on its design and location, it is possible to organize radiator heating throughout the building.

There are five main types of heat exchangers:

- coil;

- register of pipes inside the furnace;

- built-in boiler, storage tank;

- pipe register on the outer wall of the oven, convection;

- chimney heat exchanger.

Coil

+ Simple execution.

+ Maximum heat dissipation.

- Forced circulation only.

Inside the furnace, often at the entrance to the chimney, there is a plate heat exchanger, approximately the same as that installed in gas boilers. Due to the hot air and combustion products, the coolant is heated. Since there is no natural convection of liquid in this case, and for circulation in the heating system, it will be necessary to install a circulation pump. This already makes the heating dependent on the availability of electricity.

Register of pipes inside the furnace

+ Fast heating.

+ Simplicity of design.

- Weak heating regulation.

A tubular direct-fired heat exchanger is formed inside the combustion chamber. A number of "П" -shaped pipes installed parallel to each other and united by two collectors, respectively, inlet and outlet. The heat from the fire and smoldering wood heats the coolant in the pipes. A rather risky option, since in the absence of circulation, the coolant boils. If there is no additional volume for expansion and removal of vapors, a burst of the heat exchanger is possible. However, this is the simplest and most affordable option for self-execution and alteration of an existing wood-burning stove.In stoves originally equipped with such a register, a heat regulator is installed, which, depending on the heating of the water, adjusts the position of the damper, reducing the activity of burning wood.

Boiler

+ Heat reserve, high inertia.

- Strong influence on the combustion process.

The storage tank is formed directly on the sides of the firebox and additionally on top. It is a direct alternative to the pipe register, only the heat exchanger is formed from sheet steel. In fact, the structure forms the main walls of the furnace itself. Replacing, for example, brickwork. Disadvantages are similar to the previous version. The advantage is more active convection and the ability to organize a heating system with natural circulation of the coolant. It is only important to provide cold water supply at the lowest point of the heat exchanger and hot water intake at the highest point.

Butakov's furnace with a boiler and a water circuit

Register of pipes along the furnace body

+ Good heat transfer.

+ Smooth heating.

+ Ability to regulate the temperature of the coolant.

+ The water circuit has little effect on the combustion process.

The convection type is typical for most modern wood-fired ready-made stoves. A register of shaped pipes is formed along the perimeter of the furnace, and also partially along the chimney channel from the outside of the main body of the furnace. The best option for organizing heating with natural circulation and with minimal risk that the coolant will boil.

Chimney heat exchanger

+ Simplicity of design.

+ Compatible with any oven design.

- Has a negative effect on cravings.

A chimney heat exchanger is a special case for organizing water heating based on a stove that is not equipped with a built-in heat exchanger. It is more often a cylindrical tank, fixed to the chimney so as to grip it around the perimeter. The water is heated by the heat of the gases emanating from the firebox. There is also a variant with a coil wound around the pipe. The first option is suitable for natural circulation heating, in the second case a pump is required. Both options are bad in that they significantly lower the temperature of the walls of the chimney, causing condensation and rapid clogging of the chimney.

The difficulty in designing a water circuit in a furnace is a strong heat removal from the combustion chamber or chimney. Due to this, the combustion temperature and, most importantly, the heating of gases can be significantly reduced, which affects the magnitude of the thrust. This is especially true for long-burning furnaces with a water circuit. Not only do they create a weak draft by themselves, heat removal can stop the smoldering of wood and thereby cause a dangerous situation when the stove dies out or, even worse, the draft collapses, and carbon monoxide, along with unburned flammable gas, will begin to flow into the room.

The main disadvantage of furnaces with a water circuit is the inability to regulate the temperature of the coolant and turn off the heating during the operation of the furnace. If the wood is already burning, then circulation must be maintained in the heat exchanger, otherwise the water will boil, and the metal will break from the excess pressure, and the stove will deteriorate, as will the interior situation in the house.

The problem is partially solved for external registers and plate heat exchangers. External convectors are capable of working as an air convector even without being connected to the heating system or quickly enough to dump the heat coming from the firebox. In the case of a coil and plate radiator, it can be positioned so that it is possible to shut off the flow of flue gases through it.

Heating the bath from the heating system of the house

If the central heating system of the house has sufficient capacity, the auxiliary rooms of the bath can be heated with it.For this, heat-insulated pipes are laid from the home heating system to the bath, to which the heating radiators of the auxiliary rooms of the bath are connected. In this case, the stove-heater can only be used to heat the steam room or the washing section of the bath, if necessary.

If the distance from the water-heating boiler of a residential building to the bathhouse is small, then the heat loss with such a heating system can be minimal. In addition, the presence of an independent external heating system will allow you to maintain the optimum temperature in the sauna room in winter. This is required to prevent freezing of water supply and sewerage pipes, as well as the bathhouse itself. In this case, the combination of heating systems for a residential building and a bathhouse can be of an auxiliary, backup nature.

Mixed

In the case when you do not often use the bathhouse (especially in winter, rarely arriving at the dacha), then a mixed heating device would be the best option. For example, a stove is installed and electric heating is done. Decided to take a shower, relax or “stretch” - use electricity. We decided to take a steam bath "in an adult way" - heat the stove thoroughly.

Underfloor heating control unit

Water

A water heated floor is much safer than an electric one and will effectively cope with floor heating in a bath, although it will take more time for this. The source of hot water for heating a bath can be a stove with a built-in water circuit or a boiler for general heating of the house. The choice is often due to the location of the bath itself. Naturally, it makes no sense to lead a heat supply line from the house to the bathhouse, if it is a separate building or install an additional boiler. If the bathhouse is adjacent to the house or is located inside it, then the central boiler will do the job much better.

A water-heated floor can be installed both under a concrete screed and for heating a wooden floor with almost any type of floor covering suitable for use in a steam room.

If it is not possible to use a concrete screed, then heat-reflecting plates made of aluminum or galvanized steel are placed under the pipes of the underfloor heating, forming a groove for their laying and having a sufficiently large surface area for heat distribution.