Many in their lives have faced construction and the search for information about a particular product. This article will focus on the review and comparison of the world famous Rockwool products.

After reading this article, you will find out:

- What is ROCKWOOL

- You can watch the video: The history of the manufacturer ROCKWOOL

- Learn what types of ROCKWOOL insulation are available and where they can be used

- You can familiarize yourself with the summary table of technical characteristics and the price of Rockwool products

- Decide on the choice of insulation to insulate the surface you need.

For those who do not know what ROCKWOOL is

ROCKWOOL Is a group of companies that is a leader in the production of stone wool insulation under the world famous brand "ROCKWOOL", not only in Russia, but also in Europe, Asia and other continents of the world. Since 1909, it has constantly developed and improved its technologies, thanks to which the manufacturer has launched on the market a diverse line of stone wool heaters, which are designed for insulation, sound insulation and fire protection of residential, office, industrial and engineering buildings and structures.

TodayIn addition to stone wool insulation, the ROCKWOOL brand also produces acoustic suspended ceilings, road noise barriers, decorative façade panels and soil substrates for the horticultural industry.

Overview of the qualities of wall insulation

Basalt insulation in the form of mats is considered the best option for arranging a wall cake of frame walls... The material combines the main properties: heat capacity, vapor permeability, resistance to deformation and fire.

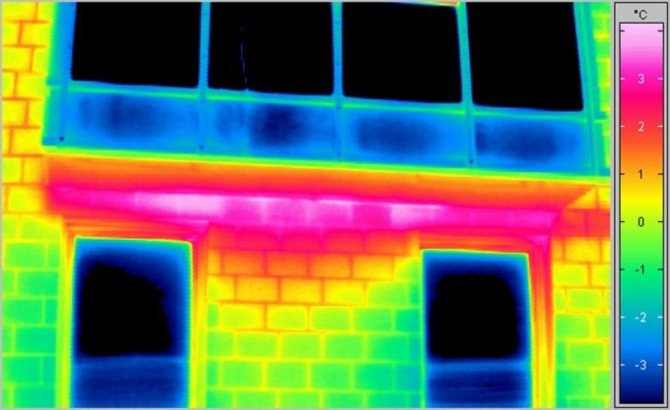

Heat saving effect and steam permeability

The main advantage of "stone" mats, which determines their scope of application, is their high heat-insulating ability. Rockwool basalt wool does an excellent job of regulating the temperature inside the house. In winter, the insulation protects the room from frosty air, and in the summer it keeps it cool and does not allow the heat to penetrate inside. Insulating mats fit tightly together. This technology prevents the appearance of cracks - cold bridges.

Elastic stone wool canvases are easy to mount, no additional fasteners are needed - the layers are installed in a previously prepared frame.

An indisputable plus of basalt insulation is its "breathing" ability. Unlike foam insulators, natural wool is breathable... In the frame, the effect of a thermos is not created, and the excess of accumulated moisture is removed through the micropores of the insulation.

Moisture resistance and sound insulation

As testimonials show, stone wool used for walls or floors, delays the propagation of shock and airborne noise... By choosing the optimal insulation layer, you can achieve a decrease in the sound effect in the range of 43-62 dB.

An indisputable plus of basalt insulation is its hydrophobicity. Rock does not get wet - drops do not linger on the surface, but roll down. The material does not absorb water, which means it retains its thermal insulation qualities. This property of the insulation is very important for outdoor installation, the use of cotton wool for the arrangement of "wet" areas: saunas, baths.

The inability to accumulate water and the mineral base of the heat insulator exclude the appearance of a favorable environment for the development of parasitic microflora, the appearance of rodents and insects. For stony composition processes of decay, decomposition, mold formation are not characteristic... Rockwool basalt mats can be reused - their characteristics and qualities are practically unchanged over time.

Fire safety and environmental friendliness

The key factor in the use of insulation in residential buildings is operational safety. In this regard, stone wool has succeeded.

Basalt withstands high temperatures and does not ignite, the heat insulator begins to melt when heated from + 1000 ° C. Rockwool insulation complies with the following safety classes:

- KM0 - completely safe;

- NG - non-combustible materials.

Due to its fire resistance, stone wool insulation often used as effective fire barriers.

The Rockwool heat insulator is considered an environmentally friendly product. In its production, no harmful components are involved - only a natural mineral and a water repellent that provides moisture resistance. Stone wool, regardless of operating conditions, does not emit hazardous substances into the environment. In terms of environmental friendliness, Rockwool basalt insulation is ahead of most alternative polymer-based insulation. Its use is permissible inside the house..

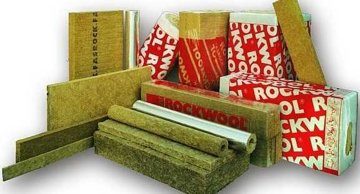

ROCKWOOL range of insulation

Thanks to modern equipment and the latest production technologies, in the range of ROCKWOOL insulation there are a dozen types of insulation that the manufacturer produces in different thicknesses, which allows you to insulate almost various objects and surfaces.

Among them are:

LIGHT BATTS

LIGHT BATTS SCANDIC XL 100mm

ACOUSTIC BATTS

FLOR BATTS

FIRE BATTS

SAUNA BATTS

ROCK FACADE (BATTS FACADE)

WIRED MAT

TECH BATTS

RUF BATTS

LIGHT BATTS is the best basalt insulation for private housing construction, which is produced in the form of plates 1000x600x50mm and 1000x600x100mm in size.

They insulate them: attics, balconies, loggias, frame walls, partitions, floors, roofing and ceilings between floors.

LIGHT BATTS SCANDIC XL 100mm is a new, most popular and convenient insulation for private housing construction, with an increased size of slabs. The size of one slab is 1200x600x100mm.

They insulate them: attics, balconies, loggias, partitions, floors, ceilings between floors and walls.

ACOUSTIC BATTS is a specially developed technology for the production of stone slabs, in which the fibers of stone wool are arranged in a random order, which maximizes the effect of sound insulation and helps to provide a sound barrier against ambient noise and very loud human speech.

They insulate them: middle layers inside the room (partitions in living quarters, overlappings along the lags).

FLOR BATTS are rigid slabs specially designed for thermal insulation of floors, with a load of up to 3 kPa.

They are insulated: ceilings between floors, as well as for laying under a cement screed, underfloor heating and a screed made of gypsum fiber board and particle board.

FIRE BATTS are high temperature stone slabs that are covered with aluminum foil to create a reflective heat effect and avoid heating up adjacent structures.

They are insulated: fireplaces and stoves in private houses, as well as piping systems.

SAUNA BATTS are light heat-resistant plates with foil, on the one hand, which are produced specifically for rooms with high humidity and temperature, where it is important to reduce electricity costs, as well as keep the room warm.

They insulate them: walls in steam rooms, saunas and baths. Can be used without vapor barrier.

ROCK FACADE (BATTS FACADE) are moderately rigid heat-insulating plates that are resistant to deformation and perfectly retain heat.

They insulate them: building facades, for subsequent plastering and finishing with siding panels.

WIRED MAT is a technical insulation with stainless wire, which is produced in rolls with or without foil.

They are insulated: air ducts, high temperature equipment and piping for heat preservation and fire protection.

TECH BATTS is a line of flat heaters produced by the manufacturer with different densities for insulating flat surfaces.

They are insulated: technological equipment, vertical and horizontal surfaces, stoves, fireplaces and other flat surfaces.

RUF BATTS are basalt slabs with increased rigidity, which are resistant to mechanical stress and are produced in the following stiffness options:

- RUF BATTS - 160 kg / m3.

- RUF BATTS V - 190 kg / m3.

- Roof Butts N - 115 kg / m3.

- Roof Butts S - 135 kg / m3.

- Roof Butts EXTRA - the layers differ in density and are glued together: the outer layer is 210 kg / m3, the inner layer is 135 kg / m3. There are markings on each side of the mat.

- Ruff Butts OPTIMA - the layers differ in density and are glued together: the outer layer is 200 kg / m3, the inner layer is 115 kg / m3. There are markings on each side of the mat.

They are insulated: roofs, when arranging attic floors.

LIGHT BATTS

Rockwool light butts are heat-insulating hydrophobized light slabs made on the basis of mineral wool and basalt rocks. This product is the benchmark for lightweight mineral boards in the Russian construction market.

- Environmental friendliness. Natural materials guarantee safety for the atmosphere and humans.

- Practicality. Rockwool light butts slabs are easy to install during construction. Easy to transport. Reliable in operation.

- Moisture resistance. Their use in the installation of walls guarantees a comfortable microclimate in the middle of the room.

- Excellent heat insulator. Your room will always be warm and cozy.

- Fire resistance. Rockwool mineral slabs prevent combustion, which ensures the reliability and safety of the wiring in particular and the home in general.

- Compactness. They have a special packaging technology - Fullpack (complete sealing of plastic film). This allows the plates to be stored for a long time, as well as to be transported without problems. You can find out about the advantages of rockwool light butts in a new package from the managers of our company.

The multidirectional fiber structure in the rockwool light butts mineral wool base provides excellent strength characteristics at moments of compression.

This guarantees the absence of material shrinkage and a change in its geometric size, throughout the entire service life (50 years - manufacturer's guarantee).

In addition, such a structure provides an exceptionally low coefficient of thermal conductivity, and the excellent vapor permeability of rockwool light butts insulation guarantees effective protection - moisture does not condense in the material and does not reduce its properties.

Hydrophobic impregnation makes it possible to maximize the water-repellent properties of the material.

Rockwool Light Specifications

- The dimensions of the slabs are: thickness - from 5 cm to 20 cm, length - 100 cm, width - 60 cm.

- The maximum water absorption is 1.5%.

- The density of thermal insulation is on average 37 kg / m3.

- Fusion of fibers at temperatures above 1000 ° С

- Water vapor permeability is = 0.30.

- Compressibility - 30%

- Thermal conductivity - 0.036.

- All declared characteristics correspond to GOSTs and certificates of conformity.

As you can see, the light rockwool insulation is very practical and useful. Its choice will be an excellent solution for thermal insulation and noise reduction in the room you are building. In addition, you can use it in case of redevelopment or insulation of an already rebuilt building. A detailed description of Rockwool Light mineral slabs can be found on our website in the corresponding section.

Accordingly, you can buy light butts both for installing walls and ceilings, and for sealing cracks. In the latter case, material trims are used.

A distinctive feature that favorably distinguishes Rockwool Light from the entire line of thermal insulation materials is the latest technology in production - Flexy.

The ability of one edge of the material to change the size, springing, compressing and unclenching, makes it possible to significantly facilitate the installation work on installing thermal insulation, ensuring 100% tightness at the joints.

Today, the rockwool light butts minelite is in demand as a universal heat and sound insulation material, and is widely used in low-rise and cottage construction.

Table of technical characteristics and prices for Rockwool insulation (prices are valid as of 01.02.16)

| LIGHT BATTS SCANDIC * | LIGHT BATTS * | ACOUSTIC BATTS * | FLOR BATTS * | FIRE BATTS * | SAUNA BATTS * | FACADE BATTS * | WIRED MAT * | TECH BATTS * | RUF BATTS * | |

| Density (types, separated by commas), kg / m3 | 30 | 35-37 | 45 | 125 | 100 | 40 | 145 | 50, 80, 105 | 90, 110 | 115, 135, 160, 190 |

| Thermal conductivity, W / (m K), λ10 | 0,036 | |||||||||

| Thermal conductivity, W / (m K), λA | 0,042 | |||||||||

| Thermal conductivity, W / (m K), λB | 0,045 | |||||||||

| Peel strength of layers, KPa | from 4 to 15 depending on the type of insulation * | |||||||||

| Compressive strength at 10% deformation, KPa | from 20 to 65 depending on the type of insulation * | |||||||||

| Water vapor permeability, mg / m h Pa | 0,3 | |||||||||

| Water absorption, no more than kg / m² | 1 | |||||||||

| Service life, more than 50 years | Yes | |||||||||

| Flammability | NG | |||||||||

| Insulate construction types: | ||||||||||

| attic | + | + | ||||||||

| balconies | + | + | ||||||||

| loggias | + | + | ||||||||

| frame walls | + | + | ||||||||

| partitions | + | + | + | |||||||

| floors | + | + | ||||||||

| roof | + | + | ||||||||

| floors between floors | + | + | ||||||||

| overlap on lags | + | |||||||||

| floors between floors, under a cement screed | + | |||||||||

| fireplaces, stoves, high temperature equipment | + | + | + | |||||||

| piping systems, air ducts | + | + | ||||||||

| walls in steam rooms, saunas, baths | + | |||||||||

| building facades | + | |||||||||

| vertical and horizontal surfaces | + | |||||||||

| roof | + | |||||||||

| Price per package, rub (thickness 50 mm) | 475 | 598 | 733 | 761 | 2781 (30mm) | 682 | 796 | 1230 | 925 | 955 |

* — you can always find out detailed information and current prices in Rockwool product catalog.

Material in package

| Material size, mm | Quantity, pcs. | Area, m2 | Volume, m3 |

| 1000 x 600 x 50 | 10 | 6,00 | 0,300 |

| 1000 x 600 x 60 | 8 | 4,80 | 0,288 |

| 1000 x 600 x 70 | 8 | 4,80 | 0,336 |

| 1000 x 600 x 80 | 6 | 3,60 | 0,288 |

| 1000 x 600 x 90 | 6 | 3,60 | 0,324 |

| 1000 x 600 x 100 | 5 | 3,00 | 0,300 |

| 1000 x 600 x 110 | 5 | 3,00 | 0,330 |

| 1000 x 600 x 120 | 4 | 2,40 | 0,288 |

| 1000 x 600 x 130 | 4 | 2,40 | 0,312 |

| 1000 x 600 x 140 | 3 | 1,80 | 0,252 |

| 1000 x 600 x 150 | 3 | 1,80 | 0,270 |

| 1000 x 600 x 160 | 3 | 1,80 | 0,288 |

| 1000 x 600 x 170 | 3 | 1,80 | 0,306 |

| 1000 x 600 x 180 | 3 | 1,80 | 0,324 |

| 1000 x 600 x 190 | 3 | 1,80 | 0,342 |

| 1000 x 600 x 200 | 2 | 1,20 | 0,240 |

Specifications