The main causes of the destruction of interpanel butt seams

The following reasons for the depressurization of the joints can be distinguished:

- non-compliance with technological standards during construction;

- gradual displacement of wall panels due to uneven settlement of the supporting elements of the structure;

- deformation of panels due to temperature fluctuations;

- influence on sealed joints of atmospheric factors, such as "acid precipitation", snow and rain.

Sealing materials

For sealing and insulating interpanel joints, special sealing mastics and self-adhesive tape are used. These sealants come in a variety of brands, constituents and applications.

The main accompanying material necessary for sealing the joints is a sealant, which will perform a heat-shielding function, and also serves as the basis for the laid mastic and self-adhesive tape.

The best sealants are considered to be compositions based on expandable polyurethane (PPU). Due to these factors, the destruction and deformation of interpanel joints occurs, which leads to rapid freezing of the outer walls in winter, as well as their flow during heavy rains. As a result of this, not only can the interior of the building deteriorate, but also the risk of morbidity among the people there is significantly increased.

Normative base:

All work on insulation and sealing of seams in panel-type buildings is carried out in accordance with the following list of regulatory documents:

• VSN 19-95 Instructions on the technology of sealing butt joints of panels of external walls of residential buildings

• VSN 40-96 Instructions when performing work on sealing joints of external walls and window blocks

• TR 94.10-99 Technical regulations for sealing the joints of external enclosing structures

• TR 94.07-99 Technical regulations for sealing the joints of external enclosing structures

• Technological map 3 Sealing of joints of external wall panels, carried out during repair

• Manual to SNiP II-22-81 Expansion joints in the walls of buildings, sealing expansion joints

• TR 196-08 Technical recommendations on the technology of sealing and sealing joints of external wall panels

• 44-03 TC Technological map. Sealing joints of external enclosing structures

• VSN-119-75 instructions for sealing joints when repairing prefabricated buildings

• VSN 42-96 Instructions on the technology of sealing windows using sealants

• TR 116-01 Technical recommendations on the technology of sealing the joints of external wall panels

• Typical technical solutions to improve the thermal protection of buildings of the I-335 series

• TR 95.07-99 Technological regulations for sealing joints of external enclosing structures

• VSN 170-80 "Instruction Sealing vertical and horizontal joints of panels of external walls of P44 / 16 series

• VSN 17-94 Instructions on mechanized technology of thermal insulation of joints of external wall panels of residential buildings with phenol-formaldehyde foam

• SN 420-71 Building norms and rules for sealing interpanel seams

Primary sealing

This type of sealing, as a rule, is performed in panel houses immediately after the completion of their construction.

Interpanel seams of new buildings are processed in 3 stages:

- Empty interpanel cavities are filled with heat-shielding polyurethane foam.

- The interpanel seam is processed with an innovative insulation "Vilatherm", which is a fine-mesh, fairly light white material.

- Additionally, the seam is sealed from the outside with a special mastic with good water-repellent properties.

The use of these three stages allows you to create a so-called "warm seam", which allows you to provide reliable heat and waterproofing in all weather conditions.

Materials used

The use of a certain technology and material in these types of work largely depends on how much the joint is destroyed, what is the general state of the structure, what is the complexity of the technological process, etc. Climbers-assemblers in their work use:

- Polyurethane foam - professional polyurethane foam "Profil 65",. The advantages of its use are obvious: the material has increased resistance to various physical and chemical influences, limited by moisture absorption, and fills the intra-seam space well. When solidified, the foam becomes an excellent heat insulator that does not allow cold or draft to pass through. Under the protection of insulation and sealant, the polyurethane foam does not deteriorate under the influence of the sun and the environment;

- Insulation "Vilaterm" (Isonel). The advantage of using "Vilaterma" is also well known: it is a moisture-proof sealing cord specially designed for interpanel joints, which is not subject to decay. It is elastic, flexible, due to its increased (for this type of material) density it withstands multiple stretching-compression cycles. The described properties allow the sealing cord to cope well with its tasks in deformation interpanel joints for a long time;

- Sealant - premium mastic "Gidromast 622" (acrylic, can be painted), "Gidromast 24" (polyurethane) or "AM 05" (thiokol - only gray or black). This material, intended for external insulation, also has good physical and chemical properties, providing reliable protection against ultraviolet radiation and leaks. Possesses increased plasticity, providing high resistance to various deformations.

The specialists of "Diamand" LLC carry out a comprehensive diagnostics of interpanel seams and immediately (in favorable weather conditions) proceed to their sealing.

Reviews:

Interpanel seams. Sealing: general rules

Depending on the state of the seam, secondary sealing is divided into two types.

If its condition is satisfactory, if the old heaters have not undergone significant destruction, secondary processing can be limited only by applying a new outer layer of waterproofing mastic. If, however, all signs of severe destruction of interpanel seams are clearly visible, then when they are re-sealed, certain work is required. These include: opening the seam, removing all old fillers that have become unusable, and carrying out the entire range of sealing works, as when performing primary sealing.

When performing repair work on panel joints, it is necessary to follow some rules:

- In the case of leaking panel joints in the end wall, the interpanel seams of the entire end facade of the building, as well as the joints between the panels of the end and the longitudinal wall, are sealed.

- If the vertical joint of the longitudinal facade leaks, all vertical joints are sealed along the entire height of the house. In addition, all horizontal joints adjacent to it are sealed.

- If a defect is found in a horizontal joint, all joints located on three to four vertical rows of panels must be sealed.

- When carrying out repair work on panel joints, it should be borne in mind that the sealants are subjected to tension and compression at the joints. This is influenced by temperature fluctuations, shrinkage and "creep" of concrete, as well as loads arising from the settlement of the entire building. Moreover, with an increase in the ratio of the thickness of the layer of the hermetic means to the width of the interpanel seam, such loads become stronger. For this reason, the sealant layer should be half the joint width.

The cost of sealing seams in Moscow and the Moscow region

When ordering high-rise works, prices for sealing interpanel seams in Moscow and the Moscow region depend on the complexity of the technology, the height of the building, and the number of operations. The prices for standard operations (primary sealing of joints, partial filling of cracks, joints of plates) are measured in running meters. The work on the secondary sealing of interpanel seams, requiring the opening of the joint, removal of the old sealant, is also considered.

Individual contractual prices are used for the repair of walls with a large area of cracks in concrete, requiring continuous surface treatment (except for sealing joints), for complex orders, including wall insulation, repairs of steep metal roofs. The total estimate of turnkey works includes the cost of materials that the customer chooses independently, according to the recommendations of the contractor.

| Prices for sealing seams | ||

| Types of jobs | Units | Price, rub |

| When ordering up to 3,000,000 rubles. | ||

| Primary sealing of joints (new building) | running. m. | from 310 rub. |

| Restoration of the seam geometry | running. m. | from 800 rubles |

| Sealing of seams and joints with opening (solid) under adhesive tape | running. m. | from 650 rubles |

| Sealing of seams and joints with opening (optional) under adhesive tape | running. m. | from 750 rub. |

| Sealing seams and joints without opening (solid) | pog. m. | from 440 rub. |

| Sealing seams and joints without opening (optional) under adhesive tape | running. m. | from 460 rubles. |

| Sealing of seams and joints with opening (solid) | pog. m. | from 550 rub. |

| Sealing of seams and joints with opening (optional) | running. m. | from 650 rubles |

| Sealing seams and joints without opening (solid) | running. m. | from 380 rubles. |

| Sealing seams without opening (optional) | running. m. | from 410 rub. |

| When ordering from 3,000,000 rubles. | ||

| Primary sealing (new building) | running. m. | from 250 rubles. |

| Restoration of the seam geometry | running. m. | from 700 rubles |

| Sealing of seams and joints with opening (solid) under adhesive tape | running. m. | from 580 rub. |

| Sealing of seams and joints with opening (optional) under adhesive tape | running. m. | from 680 rub. |

| Sealing seams and joints without opening (solid) | running. m. | from 410 rub. |

| Sealing seams without opening (optional) under adhesive tape | running. m. | from 420 rubles. |

| Sealing of seams with opening (solid) | running. m. | from 470 rubles. |

| Sealing of seams with opening (optional) | running. m. | from 550 rub. |

| Sealing of seams without opening (solid) | running. m. | from 330 rub. |

| Sealing seams without opening (optional) | pog. m. | from 390 rubles. |

Sealing of interpanel seams. Technology

Interpanel seams, the sealing of which should be as efficient as possible, are processed in several stages. For the most durable sealing of expansion joints, it is necessary to open them.

We propose to consider the step-by-step repair of panel joints with opening.

The following sealing of butt joints in panel houses is called a "warm joint". Its main difference is the application of a layer of special heat-protective foam to the base of the seams.

Such a repair of seams has passed a large number of tests and has been successfully used for a long time in many countries of the world.

Sealing without opening

Sealing without opening is used when the old layer of mastic has visible defects, the connection with the wall is broken, and cracks appear. In this case, we clean up the seams and reapply a new layer. It is important to carry out these works in dry weather, despite the fact that the manufacturers of mastics write in the annotations that the work can be carried out at subzero temperatures, it is advisable to perform them with a plus. Two-component mastics have excellent adhesion, weather resistance and are easy to apply. This allows us to give guarantees for such types of work from 2 years.

Materials for repairing seams

In the process of work, we use:

- Sealing mastic- elastic waterproofing compound based on rubber, polyurethane or acrylic.

It is necessary to protect joints and cracks from moisture penetration. We fill it with seams, grooves around window profiles and other vulnerable areas. There are many brands of mastics, and the choice of a specific sealant is determined either by the facade decoration project or by the result of discussion with the customer.

- Vilatherm- a seal made of expanded polyethylene and in the form of a hollow cylinder. We put it in the voids between the concrete panels.

We select the diameter of the material for the width and depth of the joint so that Vilatherm fills the seam, but does not flatten excessively when covering it with sealing mastic. - Mounting foam - sprayed polyurethane foam composition. Applied from a balloon, this material polymerizes and continues to fill the voids over the next day. In winter and in the off-season we use Norwegian construction foam for low temperatures, and in summer we use German foam.

We work with proven and high-quality consumables that provide high quality repair work.

What materials are suitable for your task?

Ask by phone +7 (495) 997-24-50

Request a call

Please tell me what kind of sealant is used to coat the seams in panel houses?

- The urethane sealant is a one-component, cold-cure, mortar-free formulation. It is used for waterproofing and corrosion protection of concrete and metal surfaces, as well as an adhesive for a Regupol coating and a component for producing PU elastomers.

Urethane sealant is recommended for use in the construction and repair of hydraulic structures, including for coating concrete tanks with water and coagulant at water treatment plants, underground tunnels, bridges, for waterproofing roofs and foundations of buildings.

The high wear resistance of the coating allows it to be used to protect structures operating under conditions of high wear, hydro-erosion, exposure to abrasive and aggressive agents.

- Mastic sealant butyl rubber Hermabutyl Application: for external sealing and protection from further destruction of joints (joints) of concrete, reinforced concrete, metal, prefabricated structures made of wood, ceramic tiles, glass of industrial and residential buildings and structures.

Purpose: a. sealing the external joints of wall panels. The applied layer of sealant protects the surface and filler of the joint from moisture penetration, destruction and cracking of the interpanel joint (cement screed), and also prevents the penetration of moisture into the interior of the room, increases the durability of building structures;

b. external sealing of window and balcony blocks in large-panel buildings, external walls, adjoining balcony slabs, roof drips, enclosing structures. Effectiveness of application: protection against penetration, water, dampness and drafts.

Mastic is a viscous mobile homogeneous vulcanizing mass made of butyl rubber and a number of additives. If necessary, diluted with nefras solvent or white spirit.

It is applied in a layer 3-5 mm thick on a dry, clean surface without traces of oil and grease with a rod or a brush at an air temperature from minus 20 C to plus 30 C and ensures stable long-term reliability of joints and abutments at an operating temperature range from minus 60 C to plus 80 C ...

- Thixoprol-AM is a two-component curing sealant based on liquid thiol and thiol-containing TPM-2 polymer. The sealant is intended for sealing and repairing open joints of elements of external walls of buildings under construction and in operation with a maximum deformation at the joint up to 25%, for repairing all types of roofs to protect structures from atmospheric corrosion,for creating gas and waterproofing coatings of concrete surfaces and metal structures. Thixoprol AM is applied without an underlayer and has high and durable adhesion to concrete, metals, brick, glass, etc. Mixing of the components is carried out in any available way immediately before use. Sealant application temperature from minus 20 ° to 35 ° С. Operating temperature from minus 60 ° С to 90 ° С. Service life: more than 15 years.

Which one to choose for sealing the external joints of the frame and walls, sealing ebbs, installing a roof on the balcony? It is done for ourselves, therefore, we choose the best (but within reasonable limits).

Tamper proof

Sealing with opening is used if the old seams have visually visible defects: detachment from the mastic wall, complete or partial loss of Vilaterma, and also if the joint freezes.

In this case, the seam is completely opened. The old mastic is cut off with a knife, “Vilatherm” is taken out, the edges of the seam are carefully cleaned from dust. If necessary, the seam is restored with a cement-sand mortar. Further, we make the seal in the same way as in the case of primary sealing. We select the required Vilaterma diameter, install it with a compression of 20-50% and cover it with mastic. The thickness of the layer depends on the width of the seam, and according to GOST should not be less than 4.5 mm. By agreement with the customer, we can carry out waterproofing of joints "under the tape". In this case, masking tape is glued at the borders of the seams and then mastic is applied. This allows you to achieve beautiful, even seams that are aesthetically pleasing.

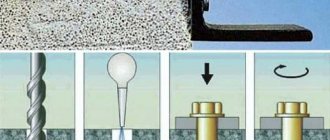

In some cases, it happens that the old seam is plastered with a cement-sand mortar, no visible damage is noticeable, but the seam freezes anyway. In this case, we drill holes in the seams with a perforator approximately every 30 cm and blow it out with polyurethane foam, then plug the holes with Vilatherm and make putty with mastic. This technology allows you to eliminate defects in insulation and eliminates freezing. And at the same time, it is cheaper than if we opened and sealed the seam completely.

You can order sealing of interpanel seams in winter and summer by phone or by leaving a request on the website.