With the onset of cold weather, many motorists are wondering how to provide a comfortable microclimate in the garage. To solve this kind of problem, only the installation of a small-sized furnace device is suitable. Since the heated area is not large, an economical option is suitable for many - a potbelly stove working on mining.

Photo 1 The classic version of the potbelly stove, however, in a new variation - more compact and cost-effective. Ideal for heating small spaces.

The small-sized device optionally does not have complex elements. It functions equally effectively on coals, wood chips, wood or any other type of fuel. However, all materials require a time-consuming purchase, investment of funds, as well as arrangement of a place for their storage. The situation is completely different with used oil, which is quite difficult to find an application for. Nevertheless, it is not necessary to dispose of it, because it is used for stoves that use recyclable materials.

Photo 2 The device is not complicated in execution and has a lot of positive characteristics: efficient heating and economical fuel consumption are the key ones.

The principle of the potbelly stove

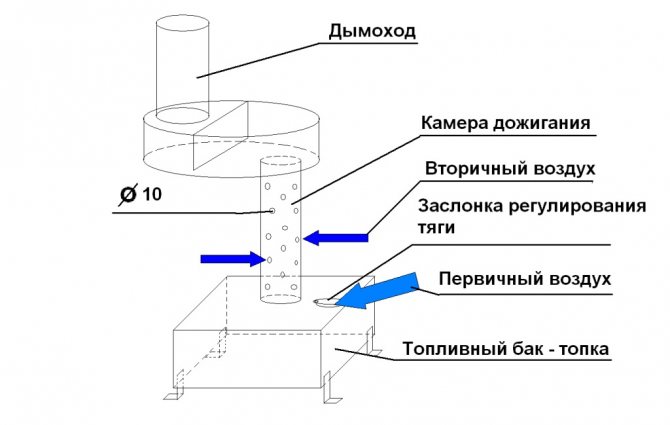

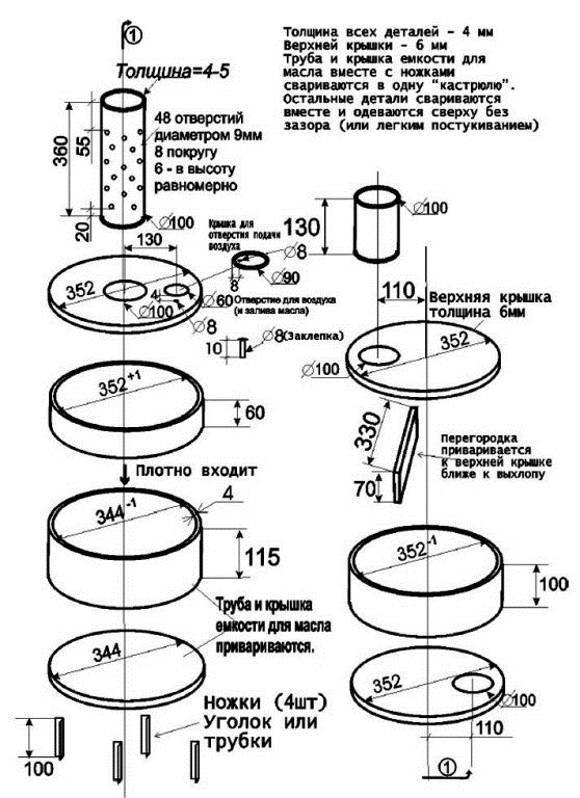

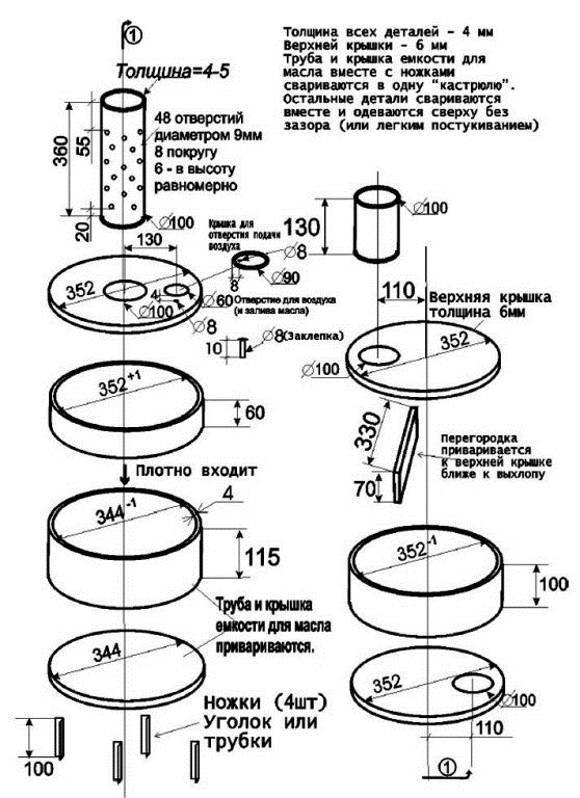

The work of a potbelly stove is based on the phenomenon of pyrolysis. In such a furnace, where the fuel is oil extraction, there are 2 main compartments: the tank and the combustion chamber, which are at different levels. The first is intended for pouring mining and its combustion.

In the other compartment, located above, the combustion products of the mining, mixed with air, are afterburned. At the first stage, the temperature is relatively moderate, and at the second stage it is much higher - up to 800⁰.

In the manufacture of such a furnace, the main task is to make sure that air flows into both compartments. It enters the first chamber through an opening for loading liquid fuel. The hole is equipped with a special damper, by means of which the volume of air supply is regulated.

Despite the fact that the design of the stove is very simple, increased requirements are imposed on the stove chimney. For efficient removal of combustion products, it is necessary to prepare a straight pipe with a diameter of more than 10 cm and a length of more than 400 cm. Bends and horizontal sections are extremely undesirable. In addition to its direct purpose, the pipe also acts as a residual heat exchanger

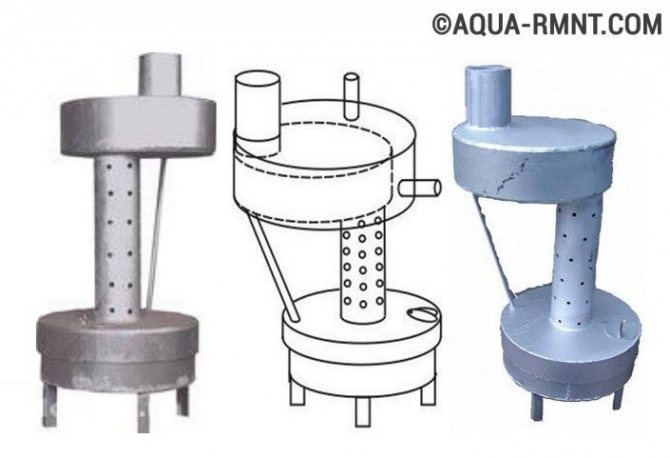

Air access to the second tank is provided by holes with a diameter of about 9 mm. The efficiency of a correctly assembled potbelly stove reaches 90%. Visually different potbelly stoves can differ from each other both in shape and size, but the principle of operation is the same.

The power of the stove-stove is proportional to the volume of the lower tank. The more voluminous it is, the less often you will have to add mining. Sometimes this container is made very massive, containing about 30 liters of used oil.

Improvement of the simple design of the stove for testing made it possible to invent a unit for arranging a garage, in which it would be pleasant to wash your hands with hot water, or a small private bathhouse:

Image gallery

Photo from

Enlarged afterburner chamber

Drawer bottom chamber

Convenient scheme for pouring mining

Practical hot water tank

Creating a stove-stove from a gas cylinder

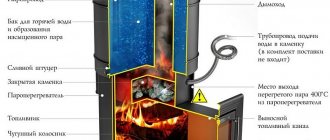

Another variant of the design of the furnace for development is a self-made stove-stove based on a 50-liter gas cylinder. In addition to this basic element, you need to prepare 2 steel pipes with a wall of about 4 mm and a diameter of 10 cm. One of them will remove the burning gases, and the second will act as a heat exchanger.

To this must be added a 4 mm steel sheet for the canopy over the heat exchanger and the baffle between the evaporator and the combustion chamber. For the vapor chamber itself, you need a brake disc from a car with such a diameter that it effortlessly enters the cylinder. A piece of 0.5-inch pipe is needed to transport oil to the combustion chamber.

An excellent potbelly stove is obtained from a used cylinder. Although there is no gas in it, it is better to play it safe - to hold the cylinder outside for a while with the valve open. Lather is applied around the outlet. When it stops bubbling, the valve is twisted, if it is removable, if not, the condensate is drained in another way.

In addition, you should keep in stock an equilateral steel angle with a shelf of 50 mm and a length of more than 1 m, a 0.5 inch valve, clamps for sealing - 2 pcs., A hose, any cylinder equipped with a needle valve.

The work on creating a potbelly stove is performed in a certain order. First, the balloon is turned upside down and a small hole is drilled in it. A measure such as wetting the drill and drilling with oil will prevent sparking.

The valve is dismantled with a gas or adjustable wrench. After freeing the vessel from all residues, it can be cut, welded

The container is freed from gas condensate. Drain it carefully away from the housing, because its unpleasant smell persists for a long time. Then the workpiece is filled with water, after which it is drained again, thus removing the remaining gas. Since the mixture is explosive, there should be no source of open flame nearby.

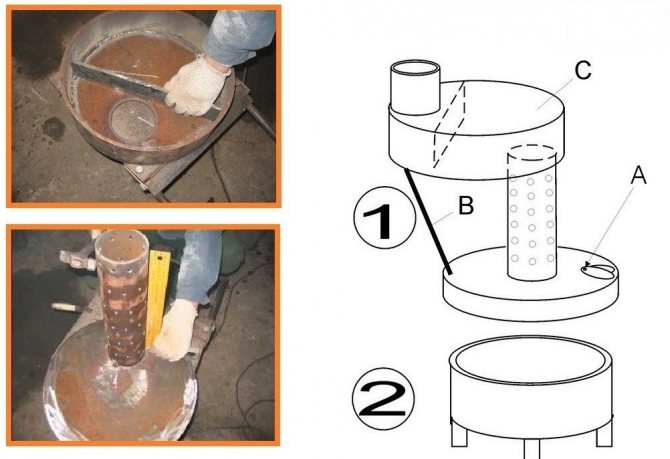

Cut out in the body of the cylinder 2 rectangles of the same width, equal to 1/3 of the diameter of the workpiece. The height of the lower rectangle is 20 cm, the second, located 5 cm higher than the first, 40 cm. To separate the chambers, a circle with a diameter equal to the inner diameter of the vessel is cut out of the sheet.

A hole is made in its middle for a pipe with a diameter of 10 cm. This part will separate the combustion chamber from the heat exchanger.

A burner is made from a pipe 20 cm long and 10 cm in diameter. The lower part of it is perforated, making holes with a diameter of about 2 cm. The inside is cleaned from burrs, otherwise they will collect soot on themselves, which will significantly narrow the hole later.

A previously cut circle is put on the burner, placing it exactly in the middle, and welded. The structure is placed inside the stove and a weld is made around the circumference of the cylinder.

Weld the bottom and cover onto the car brake disc. This will be a drip tray or evaporator bowl. To supply fuel, an opening is left in the lid through which air will enter the stove. The opening is made quite wide, otherwise the thrust will decrease, and the oil will not get into the bowl.

Weld the pipe onto the top of the lid. A sleeve is made from a pipe with a diameter of 10 cm, which connects the bowl to the burner.

A fuel supply system is assembled, for which:

- make a receiving hole in the pallet;

- insert a 0.5-inch piece of water pipe into it at an angle of about 40⁰;

- weld the pipe to the furnace body;

- an emergency reserve valve is screwed to the pipe, the role of which is played by an ordinary water tap.

A heat exchanger is made from a pipe with a cross section of 10 cm. It is cut horizontally into the stove body, and a reflector is mounted at the end. Inflation is arranged by installing a duct fan at the end of the heat exchanger. The air driven through the heat exchanger with its help has a high speed.

In order to make the system more controllable, it is automated by connecting a thermostat to a duct fan. This solution allows you to set the required temperature

An air swirler is placed inside the heat exchanger, consisting of triangular teeth connected by welding.A chimney is made from a pipe with a cross section of 10 cm.

It is welded into the hole in the upper part of the furnace body and led out through the wall to the roof of the building.

The section of the pipe passing through the enclosing structure is best placed in a refractory glass, and a metal sheet must be attached at the entry point

Next, they are engaged in the manufacture of an oil tank. If there is a freon-free cylinder with a serviceable needle valve, then it is quite suitable for this purpose. The vessel and the stove are connected by a hose connected to the valve. To fill the used oil, a hole is made in the tank body.

To provide air access to the burner and the evaporator bowl, a groove is selected in the lower compartment door. Thrust plates are attached to the upper chamber door opening, which ensures reliable sealing of the combustion chamber. For the same purpose, the door is additionally equipped with a lock.

Now, even if the stove body is deformed as a result of strong heating, the tightness of the combustion chamber will not be broken.

It remains to weld the legs from the corner pieces to the body and put the oven vertically. In addition to vertical stoves, horizontally located stoves are also made from a cylinder. Their structure is similar.

Do-it-yourself waste oil garage oven: principle of operation

As a fuel, as the name implies, such furnaces use waste engine oil - a mixture of heavy hydrocarbons. Development is cheap, its stocks are regularly replenished when the car is serviced, and owners of small garage services almost always have it.

At the same time, it ignites quite difficult, and practically does not form flammable vapors. Therefore, the most common designs of waste oil furnaces use the principle of pyrolysis, that is, the decomposition of oil into lighter fractions when heated, which makes them direct descendants of gas generators popular in the first half of the 20th century.

The basis of such a furnace is a metal container with oil, above which a combustion chamber is installed - a perforated pipe with holes for air flow into the combustion zone.

The oil tank has a filler hole with a cover that allows you to adjust the degree of its opening to control the combustion process (the so-called choke). On low-power furnaces, the combustion chamber goes directly into the chimney; in more advanced designs, an expansion chamber with an internal partition is used for complete afterburning of gases.

How does a DIY garage oil oven work? During ignition, the torch introduced into the tank through a fully open throttle begins to evaporate the waste. When entering the combustion chamber, oil vapors mix with air and ignite.

Since the walls of the combustion chamber are firmly connected to the oil tank, the heat from the combustion of vapors is transferred to its walls, and the oil begins to actively evaporate without the aid of a torch. A chain reaction of decomposition develops: the more the tank heats up, the more actively the mining evaporates and decomposes, and the hotter the fire flares up in the combustion chamber.

To be able to control this process, a choke is needed - by closing it, you can reduce the combustion activity and thereby limit the temperature of the furnace.

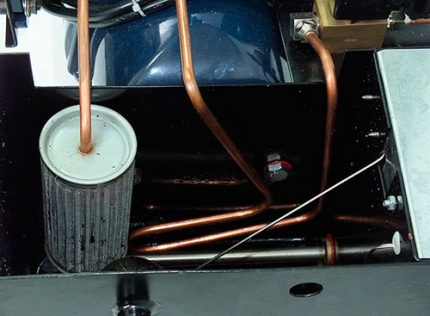

In the photo below, the oil stove in the garage:

Advantages and disadvantages

A properly assembled pyrolysis stove is capable of heating to a high temperature with low fuel consumption, in contrast to a voracious and ineffective potbelly stove.

The average consumption of homemade garage products is in the region of half a liter of oil per hour - thus, when changing the oil in an ordinary car, the crankcase volume of which is 3-4 liters, you can provide your garage with heat for at least 6 hours.

During operation, such a stove practically does not smoke and heats up quickly. Since under normal conditions engine oil is difficult to ignite, this type of fuel is practically safe in storage.

However, the pyrolysis stove also has an undoubted drawback: if the stove is almost omnivorous and it is possible to burn almost any combustible solid waste in it, then the furnace only needs oil for working out, moreover, purified from water: boiling in a heated tank can lead to a sharp splashing of burning oil, which can be compared to an explosion.

With frequent visits to the garage in winter, there will be a need to purchase mining, but basically this is just a question of its transportation: most car services do not contact the official delivery for processing and sell waste oil to those who wish at fairly low prices.

REFERENCE: There is an important nuance during the operation of self-burnt furnaces: it is quite difficult to extinguish them, since even with a fully closed throttle, there are enough holes in the combustion chamber to maintain the temperature at which the pyrolysis process is interrupted.

Blocking the chimney will lead to the fact that combustion will go with fatty fumes, which will go into the room through the ventilation holes in the combustion chamber. Therefore, it is necessary to pour oil into the oven in such a way that it will be enough just for the planned time of stay in the garage.

Pyrolysis of engine oil produces a large amount of non-combustible residue that heavily contaminates the oil tank. It has to be cleaned regularly, and this point should be provided for in the design of the furnace - having made the tank non-separable, you will quickly regret it.

Do-it-yourself stove in the garage for working off - drawings:

Potbelly stove plus water circuit

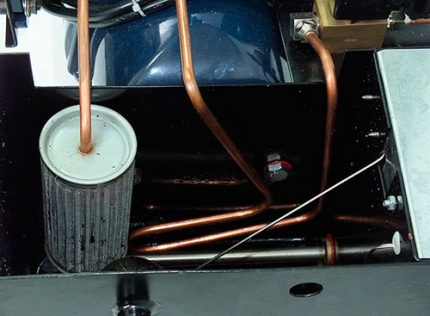

Any home can use an emergency heat source. An ordinary, but slightly modernized potbelly stove can play its role. There are two ways to improve the furnace - to put a water jacket on the burner tube or wrap its body with a coil of copper pipes.

The coil turns are placed at a distance of about 5 cm from the perforated potbelly casing and connected to the general heating system. A reflective screen is installed around the coil. For its manufacture, sheet aluminum, galvanized steel, and tin are used.

The water jacket is a tank on the upper chamber of the stove. In its body there should be 2 fittings - one for the supply, and the other for the drainage of water. In general, the design resembles a samovar. The volume of the water jacket depends on the length of the heating system and the way of circulation of the coolant.

In practice, the issue of the device of the water circuit is solved by installing the container directly on the stove. Hot water enters the heating system through the outlet to the heating system. Having passed in a circle, it gives off heat to the room and returns back to the container.

If a pump is installed in the system, the volume of the tank is small, and with natural circulation it has impressive dimensions. To control the parameters of the water, a pressure gauge and a thermometer are installed on the tank.

Drip potbelly stove for mining

You can also make an economical model of a drip stove on your own. A small metal barrel or another container available on the farm is suitable for the case. A hole is made in the body through which oil will flow.

Next, take a burner with a capacity of about 2 liters, connect a copper tube 1 m long to its hose, and then fold it in half.

Such a unit, operating on waste oil products, can smoke, so the room in which it is installed must have good ventilation.

A hole is made in the container along the diameter of the tube. The tube itself is given the shape of the letter "L", and the burner is suspended.

The process of self-manufacturing of a mini potbelly stove

The potbelly stove is that version of the stove device that can be easily assembled on your own, while the costs will be minimal, especially if there is a frame for the stove, which can be an empty gas cylinder.Having previously prepared all the necessary tools, you can get to work:

- bubble level;

- building centimeter;

- welding machine;

- angle grinder;

- chisel;

- Metal sheet;

- metal pipe for chimney;

- barrel (for a cylinder shape model).

On this topic, we advise you to familiarize yourself with the material on our website: "Self-production of a stove for a bath: the main options for a stove device."

The most current version of the boiler is wood-fired. Due to its high efficiency, such a device is able to quickly warm up the room. It is this option that we will consider. The following is a detailed instruction on how to assemble a wood stove yourself.

[Photo 2 A standard model of a potbelly stove based on an empty gas cylinder.]

Alteration of a solid fuel potbelly stove for mining

When the farm already has a potbelly stove, but is not satisfied with the fact that it runs on solid fuel, you can modernize it and it will become universal. For this, a prefix is made, resembling in its design a stove on processing in its lower part.

There is also a perforated pipe here, but not straight, but bent at a right angle. It is connected to the side wall of the furnace, which serves as the final combustion chamber. If the potbelly stove door is welded and a hole is made in it for the pipe to enter, then the furnace will only work on working off.

The modernization of this oven consists not only in complementing it with a special attachment, but also in the original solution to protect nearby objects from fire, using the principle of convection. For this, pipes were welded to the side wall of the furnace. Cold air entering them from below cools the structure

So that you can use not only technical oil for heating, but also firewood, two replaceable doors are made. The standard one is hung when it is planned to lay firewood, and the modernized one with a corresponding hole - when the stove will operate on waste oil.

We also offer you to read an article on how to collect a potbelly stove using waste oil from a pipe - to familiarize yourself with the material, follow the link.

How to convert a wood stove to run on liquid fuel

Often there is no need to make a new heating device, because a simple wood-burning stove is already installed in the room. In order to be able to burn mining in it from time to time, the unit should be slightly altered. In this case, proceed as follows:

- a thick-walled metal bowl is attached to the bottom of the fuel chamber - it will serve as an evaporator;

- a hole is made in the side wall through which a nozzle is brought into the firebox;

- at a short distance from the stove, a container for oil is attached. Its height from the level of the firebox must be at least 1 m;

- from the nozzle to the container with the working off, a hose is drawn on which a ball valve is mounted. It will regulate the supply of fuel to the combustion chamber.

As an evaporator of a potbelly stove, you can use a brake disc from a car, if you pre-weld the existing holes.

Wood stove, converted to work on used car oil

When starting the ignition, a rag soaked in kerosene is placed in the bowl. After that, the mining feed is opened and the bookmark is set on fire. The oil will flow by gravity to the nozzle and drip onto the surface of the metal disc, gradually warming it up to operating temperature. As soon as the bowl warms up to 400–450 ° C, the mining drops will instantly turn into gas, burning with the release of a large amount of heat.

Secrets of the successful operation of a potbelly stove

In order for a stove stove running on waste oil to work efficiently and safely, you need to adhere to a few tips. The oil must be allowed to stand before use. Pour it into the oil tank for 2/3 of the volume of the latter.

For safety reasons, all elements of the stove should be cleaned regularly. To simplify this task, its top module should be removable. This will provide access to the combustion chamber. To remove soot from the walls of the chimney, it should be tapped.

In order to extend the service life of the combustion chamber and the furnace as a whole, it must be painted using paints that are resistant to high temperatures. The stove should be installed on a non-flammable base. It should not be placed in a draft, under the influence of which the flame may escape.

Features of work

The principle of operation of a potbelly stove on mining is based on the pyrolysis reaction (thermal destruction of waste with limited oxygen and resulting in a carbonaceous residue and pyrolysis gas with high heat transfer).

This is much safer and more economical than traditional combustion (additional savings are also obtained because there is no need to specially purchase fuel, because residual engine oil is used in the stove).

Construction example

For 40-60 minutes in a drip-type stove, from 0.5 to 2.5 liters of waste oil is consumed (depending on the size of the tank). During fuel processing, an oil-air mixture of moderate temperature (less than 100 degrees) is formed in the lower chamber, and heat up to 800 degrees is created in the upper part.

The heat output of the stove is limited to 16 kW (ready-made modified models, such as the GeKKona drip furnace, have an increased power - up to 100 kW). The principle of operation of the stove on waste oil allows you to obtain a high efficiency factor - 75-80%. A small potbelly stove is suitable for heating rooms with an area of 60-100 square meters.