At the end of the 20th century, mankind was faced with the acute question of finding new, alternative sources of energy. The reason for this was the impending fuel and energy crisis and the ever-increasing pollution of the environment. It was necessary to find new sources of thermal energy that could replace oil and gas. Along with the development of solar energy, another more promising and, most importantly, more budgetary direction has appeared - the use of biofuels.

Biofuels are fuels obtained from the processing of biomass by thermochemical or biological means - with the help of bacteria. Both plant and animal raw materials can be used as biomass, as well as organic residues of production and waste of livestock of farm animals. The most commonly used sources are plants and wood waste.

Depending on the state of aggregation, the following types of biofuels are distinguished:

- Solid (wood, wood chips, fuel briquettes, fuel pellets, fuel peat);

- Liquid (bioethanol, biobutanol, biomethanol, biodiesel);

- Gaseous (biogas, biohydrogen).

Solid biofuels

Firewood, like centuries ago, continues to be used to generate heat and electricity. An example of the largest biomass power plant in Europe is the Austrian CHP. Its capacity is 66 MW.

Despite the fact that the world is actively developing and financing projects for the creation of energy forests where woody biomass is grown, the use of various products of the woodworking industry for obtaining biofuel is attracting more and more attention. Such enterprises are already quite well developed and actively supply their products to the market. These include fuel briquettes and fuel pellets - pellets.

To obtain fuel briquettes, various bio-waste, such as bird droppings and manure, are dried and pressed. The resulting briquettes are used for heating residential and industrial premises.

Fuel granules - pellets are used in a similar way. They are produced from sawdust, wood chips, bark, substandard wood, straw, agricultural waste (sunflower husks, nutshells). To obtain pellets, the biomass is first crushed into flour, then enters the dryer, and from it to a special press, where, under the influence of pressure and high temperature, the lignin contained in wood waste becomes sticky. It makes it possible to obtain ready-made cylinders of biofuel at the output. A distinctive quality of fuel pellets is their low ash content - about 3%.

The technology for obtaining fuel peat used for heating residential buildings is also simple. Raw materials are delivered directly from the extraction site to the peat processing plant, where the peat is cleaned of impurities (sieved), dried and pressed into briquettes.

Another type of biofuel - wood chips - is used in Europe at large CHP plants with a capacity of one to several megawatts. The production of wood chips is carried out directly at logging or in production using special chippers - shredders. As a raw material, small-sized wood and logging residues are usually used - branches, bark, stumps, etc.

Production technology

As with the organization of any technological process, at the very beginning, the incoming control of the incoming raw material is carried out. In this case, a random check of the grains is carried out.The quality of the seeds is used to judge the quality of the entire consignment.

The next step is getting the oil. Why the raw materials are sent to the churn. The cakes obtained after the oils are squeezed out are not thrown away, they are used for the production of feed for livestock.

The oils are further processed (the so-called esterification). It consists in enriching the oil with methyl esters. The total content of these substances throughout the volume must be at least 96%.

The essence of the technology is quite simple: it is necessary to add methanol and an activator of chemical processes (any alkali). The source of methanol is usually sawdust. However, it is possible to simplify the task. Instead of separating methanol, you can dilute the oil with the required amount of isopropyl alcohol or ethanol.

For the esterification processes to take place, it is necessary to heat the oil to high temperatures. It usually takes up to two hours in time. In this case, it is necessary to constantly monitor the process and not be distracted: even a slight increase in temperature can lead to the ignition of the oil.

The completion of the chemical reaction is evidenced by the receipt of a glycerol sediment at the bottom and the formation of two layers in the container. Therefore, it is advisable that a transparent container is used for these processes: in this case, it is possible to visually accurately determine when the process is completed, which will eliminate the need for subsequent modifications and prevent rejects.

Liquid biofuels

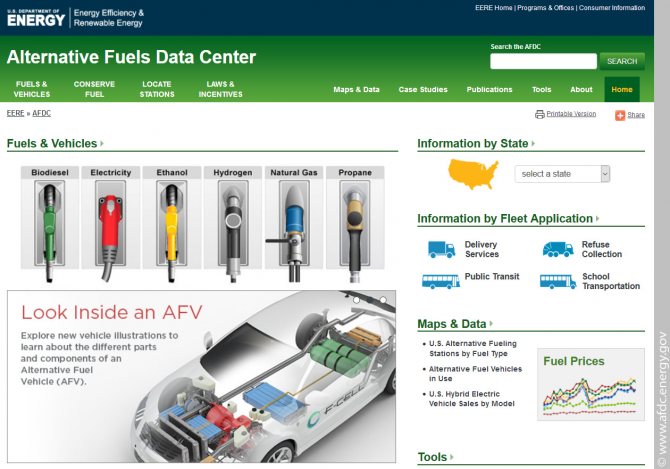

Liquid biofuels are becoming more and more popular due to their environmental friendliness and safety. It is mainly used in internal combustion engines. This type of fuel is obtained by processing various plant materials.

There are main types of liquid biofuels:

- Bioethanol

- Biobutanol

- Biomethanol

- Biodiesel

Bioethanol

Takes a leading position in the list of liquid biofuels. Its scope is in ordinary cars, and in recent years it has also been used as biofuel for home fireplaces. Bioethanol mixed with gasoline as a fuel has a number of advantages over conventional gasoline: it improves the performance of the car engine, increases its power, does not overheat the engine, does not form soot, carbon deposits and smoke.

Bioethanol is a great alternative for fireplace lovers. Since it does not form smoke, soot and emits a small amount of carbon dioxide during combustion. Can be used to heat fireplaces even in apartment buildings. At the same time, there is no heat loss at all, as is usually the case when operating conventional fireplaces with a chimney.

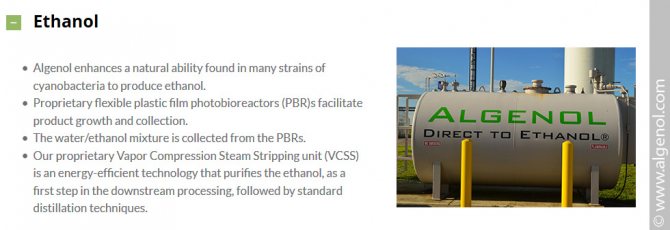

It is produced according to the technology of alcoholic fermentation from raw materials containing starch or sugar: corn, cereals, sugar cane, sugar beets. It is economically justified to obtain ethanol from raw materials containing cellulose.

Biobutanol

As a fuel for engines, it is more preferable than bioethanol: it mixes better with gasoline, and can be used as a separate fuel. To obtain it, traditional crops are used: sugar cane, corn, wheat, sugar beets. While less popular than bioethanol.

Biomethanol

Its production technology is still imperfect and requires the introduction of many more innovative developments. It is supposed to be obtained by biochemical transformation of marine phytoplankton cultivated in special reservoirs. But so far it has not been possible to establish production on an industrial scale. The applications for biomethanol are the same as for conventional methanol. This is the production of a number of substances (formaldehyde, methyl methacrylate, methylamines, acetic acid, etc.), as a solvent and antifreeze.

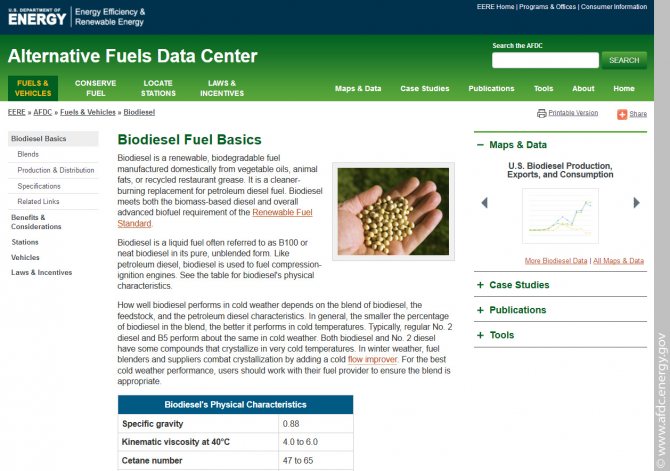

Biodiesel

It is used in automobile engines both separately and in a mixture with conventional diesel fuel.In addition to the absence of the negative impact of biodiesel on the environment, numerous studies have highlighted another advantage. Due to the low sulfur content, the lubricating properties of biodiesel are better, which helps to extend the life of series engines. Raw materials for biodiesel production can be both plants (cotton, soybeans, rapeseed) and fatty oils (palm, rapeseed, coconut), algae.

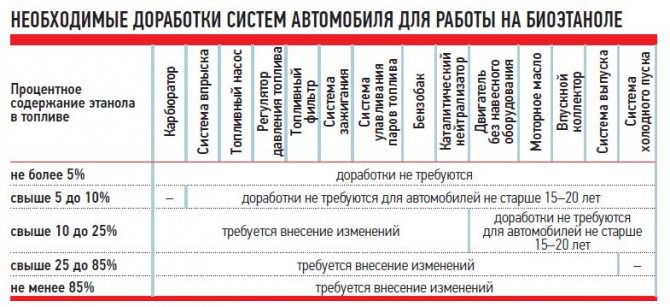

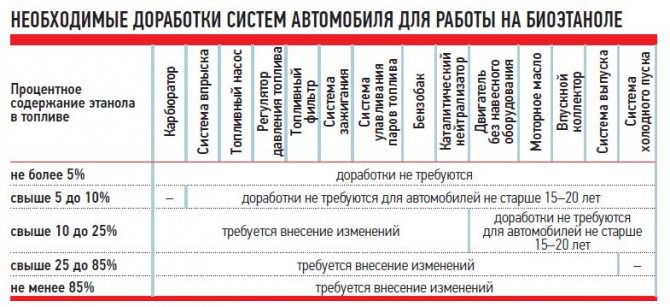

NECESSARY ADJUSTMENTS OF VEHICLE SYSTEMS FOR OPERATION ON BIOETHANOL

There is also a purely Russian problem. According to a long tradition, our state considers alcohol to be an antisocial substance and protects citizens from it with taxes and restrictions. In this situation, the cost of alcohol fuel is unlikely to be more attractive than the usual gasoline. And will they be allowed to sell ethanol around the clock? ..

There are also global obstacles. One of them is the lack of uniform standards and requirements for biofuels. Where are the guarantees that, for example, the multi-fuel Opel traveling around Germany will like bio gasoline made from other raw materials in neighboring France? Therefore, modern models that run on biofuels usually do not disdain gasoline or diesel fuel.

Gaseous biofuels

There are two main types of gaseous fuels:

- Biogas

- Biohydrogen

Biogas

Fermentation product of organic waste, which can be used as fecal residues, sewage, household waste, slaughterhouse waste, manure, dung, as well as silage and algae. It is a mixture of methane and carbon dioxide. Organic fertilizers are another product of household waste processing in biogas production. The production technology is associated with the transformation of complex organic substances under the influence of bacteria carrying out methane fermentation.

At the beginning of the technological process, the waste mass is homogenized, then the prepared raw material is fed using a loader into a heated and insulated reactor, where the methane fermentation process takes place directly at a temperature of about 35-38 ° C. The mass of waste is constantly mixed. The resulting biogas is fed into a gas tank (used for storing gas), and then fed to an electric generator. The resulting biogas replaces conventional natural gas. Can be used as biofuel or generate electricity from it.

Biohydrogen

It can be obtained from biomass by thermochemical, biochemical or biotechnological methods. The first method of obtaining is associated with heating wood waste to a temperature of 500-800 ° C, as a result of which a mixture of gases - hydrogen, carbon monoxide and methane - begins to evolve. In the biochemical method, enzymes of the bacteria Rodobacter speriodes, Enterobacter cloacae are used, which cause the production of hydrogen during the splitting of plant residues containing cellulose and starch. The process takes place at normal pressure and low temperature. Biohydrogen is used in the production of hydrogen fuel cells in transport and power engineering. It is not widely used yet.

The advantages of energy

Biological and scientific interest in natural energy resources arises from the following positive qualities of the product:

- Economic availability of material... Many countries spend a lot of money to buy oil or natural gas. The economy of the state is suffering losses. Biofuel can be obtained in almost any country. Local fuel production will reduce the cost of importing foreign energy resources.

- Mobility... Wind or solar installations are intended exclusively for stationary use. Cannot be transported. Biological materials, if necessary, can be transported from one region to another.

- Biofuel is renewable resource... Plant and animal waste will never disappear.

- Natural resource reduces greenhouse gas emissions in atmosphere. Prevents the likelihood of global warming.

- The use of biofuels for car engines reduces maintenance costs.

In the not too distant future, operating a combustible fuel will be cheaper than using gasoline.

Emissions of harmful substances into the atmosphere

The reduced amount of carbon dioxide emissions during combustion is a big plus for biodiesel. According to the assurances of scientists who deal with these issues, the volume of CO2 emissions from the combustion of biodiesel does not exceed the volume of carbon dioxide processing by those plants that served as a source of raw materials for the production of fuel throughout the entire life cycle.

However, emissions from fuel combustion do occur. That is why it is not entirely correct to call biodiesel an environmentally friendly fuel. However, some believe that the amount of carbon dioxide produced is so small that they can be neglected. This statement is highly controversial.