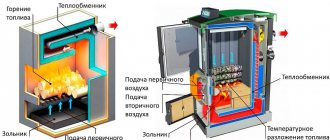

In heating private households or country cottages, combined boilers are often used to heat the house - they will provide a comfortable temperature in all rooms, regardless of the presence or absence of centralized gas supply or firewood.

A significant plus of such units is the adjustment of the cost estimate not only for heating the building, but also for supplying hot water. Besides, it's very convenient to be able to use different types of fuel, don't you agree?

The efficiency of combined boilers in the absence of access to the central supply system of energy resources is confirmed by numerous reviews of their owners. The main task is to choose the optimal type of heating unit.

We will help you make the right choice. The article describes the features of the work, operation and maintenance of different types of combined boilers. We have outlined the main criteria for evaluating equipment and provided practical recommendations for choosing a heating unit.

Requirements for the pipes used

The material of the pipeline must be suitable for the temperature loads and the pressure in the pipeline. At a minimum, it must maintain performance at 95 ° C. With regard to pressure, for autonomous heating, a standard level of 1.5 atmospheres is considered. In the installation of heating mains for heating with such requirements, the following pipes are usually used:

- Galvanized steel. There are practically no temperature restrictions, and the pressure limits are about 12 atmospheres. Mechanical strength and resistance to deforming loads can also be emphasized. However, steel can cause a lot of problems due to threaded connections, not to mention the fact that metal is, in principle, a rather laborious material from the point of view of physical handling during installation.

- Polypropylene pipes. There are temperature restrictions (up to 95 ° C), and the maximum pressure is 9 atmospheres. However, the combination of mechanical strength, joint tightness and modest weight compensates for these disadvantages.

- Reinforced-plastic pipes. The optimal solution that is durable, flexible and practical. Such pipes for heating mains are used both in industry and in private households.

How to insulate heating pipes

What material is taken for insulating heating pipes in order to achieve a high protective effect and minimal heat loss: mineral wool is popular because of its cheapness, high heat retention coefficient and ease of installation anywhere and on any surface. Mineral heaters for heating pipes are produced in several versions:

- Basalt wool is produced from rocks containing basalt mineral. The main quality of these thermal insulation materials is high fire safety (the NG group is a non-combustible material). It begins to melt (but not burn) only at a temperature of at least 650 0C. At the same time, no toxins are released into the atmosphere. The disadvantage of insulation with any material of mineral origin, produced in the form of cotton wool, is its tendency to quickly humidify, even with moisture from the atmospheric air, and this leads to a violation of the thermal insulation parameters. In order to properly and correctly wrap the heating pipe on the street with cotton wool, a waterproofing layer is first applied to the pipes. Waterproofing prevents the occurrence of contact between heat-insulating materials and moisture (including condensation on an air overpass), since mineral wool is a porous material and water quickly penetrates into air pores. Considering that moisture is an excellent conductor of heat, we get the maximum possible heat leakage, if you do not apply a layer of waterproofing. The simplest waterproofing material is roofing material, it is fastened by wrapping it around the pipe and securing it with soft steel wire.Also, any waterproof materials can be used as waterproofing layers, including liquid solidifying solutions - bitumen, mastics, sealants, tar, heat-insulating paint for pipes. The main thing is that the protective surface has a high resistance to mechanical stress. It is recommended to use a warm paint in a pair with some other insulation;

- Fiberglass insulation consists mainly of quartz sand, not necessarily refined. Glass wool is used for insulating pipes not only outside, but also for thermal insulation of buildings in indoor premises - in ceilings, in the inter-wall space, in the subfield. As a fire-fighting material, glass wool has proven itself perfectly (sand does not burn), and is successfully used in heating mains with a coolant temperature of up to 2000C;

- Ordinary construction foam is the last of the insulation materials that can be recommended for external insulation of heating mains. The material is flammable, it will not work to fit it tightly around the pipes - you will have to build a special foam box. In addition, the foam is brittle and brittle.

In addition to these, the most common materials, how and how to insulate heating pipes on the street with your own hands, so that the result is inexpensive and long-term:

- Insulation with polystyrene foam of a special form (shell): the form consists of two halves, repeating the shape of the pipe or the insulated section of the heating main. The halves of the groove are connected into the groove, and this lock serves as an additional barrier in the path of moisture;

- Extruded polystyrene foam is much denser than ordinary polystyrene, better retains moisture, better tolerates mechanical stress.

- Polyurethane foam - both individual elements are made from it, which are attached to insulated pipelines, and parts of a monolithic structure of a multilayer pipe. Polyurethane foam can also be applied in liquid form, which is very convenient when insulating complex or curved sections of the heating main. To work with liquid polyurethane foam, air compressors are used, and the insulation is sprayed under high pressure over the working surface. Spraying guarantees complete tightness of the layer;

Consider what else you can insulate a hot pipeline:

- Foam insulation for the heating main in the house, which looks like a kind of cover. Rubber, polyurethane and / or expanded polystyrene are used as materials for insulating covers in a private house. The inner diameter of the boot must ideally match the dimensions of the heating circuit. The cover is simply put on: it has a longitudinal cut, which, after the pipe is wrapped, is glued with tape or special glue that does not dissolve the material;

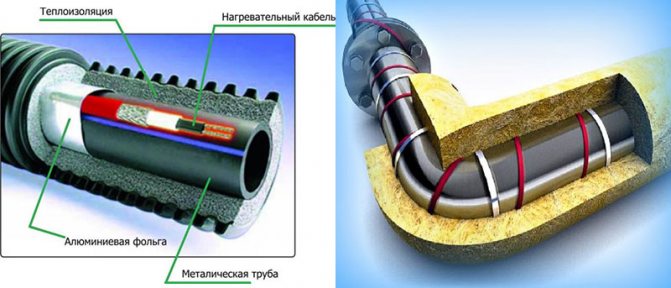

- Foil heat insulators for heating mains with a reflective effect.

Next comes penofol - this is a reflective synthetic material that directs heat flows back, since it has a mirror surface, most often made of aluminum. Insulate the track with penofol, winding it on top of the main layer of thermal insulation, after which the double-insulated pipes are wrapped with tape or soft steel wire, the insulation is fastened with clamps or glue.

Foil insulation works in several directions at once:

- Reflection of heat flows back towards the pipe;

- Retention of outdoor lower temperatures;

- Protection of the heating main from cold, wind and moisture.

Also, foil insulation is often used in tandem with foamed polyurethane or NPE (foamed polyethylene) to enhance thermal protection.

Heat insulating paint - an innovative heat insulator, was invented for spacecraft, and is now successfully used in the national economy, since its production has become significantly cheaper. 1-2 mm of thermal paint is enough to replace any of the heat insulators listed above.Thermal insulating paint is used both in the private sector and on an industrial scale.

Insulation for heating mains

Even correctly selected pipes do not guarantee heat savings during transportation. This property depends on the coverage of the circuit - a heat insulator. Today, the following materials are used for such purposes:

- Glass wool. It goes well with metal-plastic, has a low density and is cheap. But effective heat saving of glass wool can be provided only in combination with roofing felt or fiberglass. Accordingly, both costs and time for installation work increase.

- Basalt insulator. It has a cylindrical shape, is characterized by ease of installation and high thermal insulation performance. The only negative is that it is expensive in itself.

- Polyurethane foam (PPU). A type of plastic that demonstrates resistance to temperature extremes. But the main advantage of this material is different. There are practically no restrictions for the installation of PPU heating mains in terms of the complexity of the pipeline. The insulator can even be used in liquid form, which allows them to spot treatment of hard-to-reach local areas.

- Crosslinked polyethylene. Polymer-based structural insulator, among the main advantages of which are strength, resistance to thermophysical stress, chemical and mechanical stress.

About thermal insulation of the pipeline

Most high quality and durable heat insulators for municipal and industrial systems are made from rubber or mineral wool. The most demanded brands for thermal insulation of heating pipes are Paroc, Isover, Rockwool, Linerock, etc. These manufacturers produce high-quality and durable products.

Types of heat insulators

PPU shells of various diameters.

Regardless of the material, the following types of heaters for the pipeline are distinguished:

- Shells... Perhaps the easiest insulator to install, which is available in the form of cylinders of various densities and diameters. Shells are in great demand as insulation for cold pipelines.

- Slabs... Heat-insulating mineral wool plate is a universal heat insulator. Mineral wool slabs are used to insulate the loggia, floors, ceilings, interior partitions and roofs. They are also used to insulate cold water pipes.

- Mats... The main difference between mats and slabs is the presence of stitching, which protects the material from delamination. Mats are softer than slabs, they are more flexible and are available in three versions from different manufacturers:

- No covering material.

- With lining material presented as a foil side.

- With lining material represented by fiberglass on one side.

Thermal insulation mat with a foil layer.

Advice! Mineral wool is known for its moisture intolerance. Therefore, it is advisable to purchase a material with a foil side, or provide it with additional protection by laying a waterproofer.

Characteristics of heat insulators

Modern manufacturers do their best to keep their material competitive in the market.

In this regard, heat insulators for heating mains have the following properties:

- Do-it-yourself ease of installation.

- Acceptable price.

- The ability to tolerate both positive and negative temperatures well.

- Prevention of corrosive processes in pipes.

- Maintaining the temperature of the medium in isolated areas.

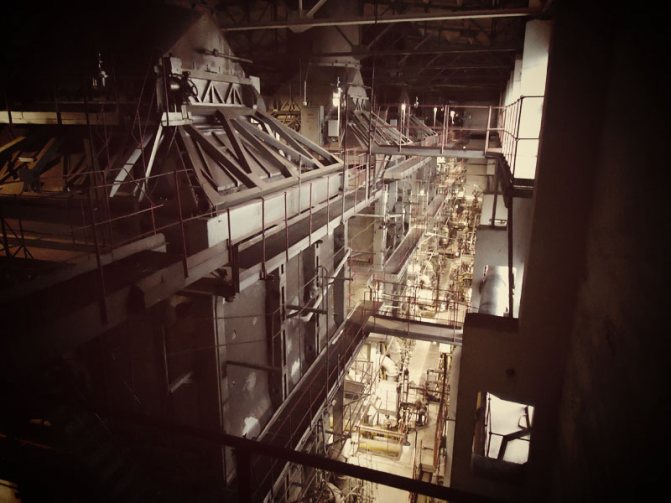

Heating main installation technology

The organization of the main heat supply system is carried out in several stages:

- Design.Based on the results of a comprehensive survey of the direction of the line laying, taking into account the requirements for the transportation of the coolant, a list of materials, their performance characteristics, and the installation configuration are determined.

- Preparation for laying. Technical conditions are being created for the future installation of pipes. The area of the gasket is cleared and, if necessary, trays (channels) are installed for the rear protection of the circuit.

- Installation of pipes. The direct installation of the heating main is carried out, in which the substrate and the insulation material are attached to the prepared trays. For this, clamps, anodized protection means and fixing hardware can be used.

- Testing and commissioning are in progress.

Heating line laying configurations

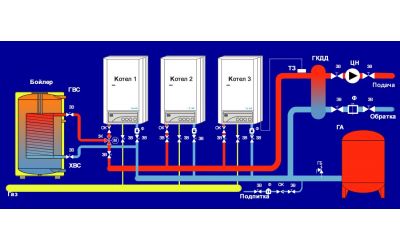

Several pipelines can be laid in one line. In this regard, a distinction is made between one- and two-pipe, as well as a beam method of laying. In the first case, only one circuit is used, in the second, respectively, two channels. With radial installation of a heating main, several circuits are connected to a collector, from which flows are directed to separate points of consumption. This system is beneficial in that it allows you to regulate the work of streams, alternately loading and distributing them depending on the current needs.

disadvantages

Let's talk about the disadvantages of such systems.

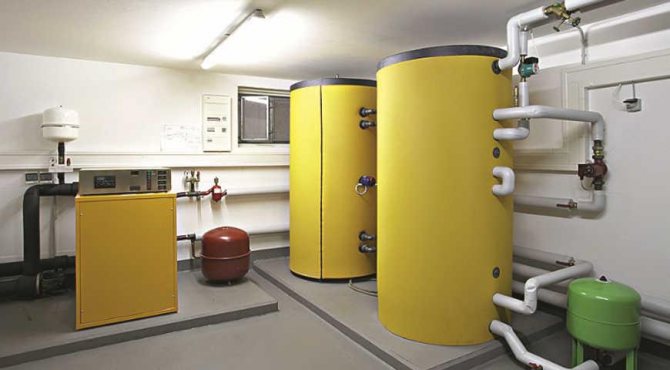

- An autonomous mini-boiler room must be placed in a separate room: it is located in the immediate vicinity of the object, sometimes in the form of a stationary building, sometimes in the form of an extension.

- It is necessary to think over purification systems. Any boiler house pollutes the environment in one way or another, which is unacceptable for the courtyards of residential buildings. Therefore, it must be equipped with cleaning systems in accordance with the rules and regulations. This increases the cost of construction.

- High prime cost associated with the low prevalence of autonomous boiler houses - they have not yet been put on stream. Therefore, not all developers can afford them.

However, modern engineering solutions make it possible to eliminate some of the shortcomings. For example, an autonomous boiler room can be installed on the roof if the building complies with the standards prescribed in SNiP. It is good if the roof boiler room is included in the project at the construction stage.

Do you need a reliable project of an autonomous mini-boiler room for an apartment building? Fill out the questionnaire at AllianceTeplo - we will help with the design and construction of any type of boiler house.

To calculate the cost of the boiler room, please fill out the questionnaire for the boiler room. The questionnaire can be completed online or downloaded. For any questions you may have: multichannel telephone e-mail

Fill out the questionnaire online

Calculate the cost of the boiler room

You may also be interested in

Unjustified costs of a boiler house and ways to reduce them Most of the costs of a boiler house are, as you know, for fuel. However, it is not possible to reduce the purchase and consumption of fuel in modern economical conditions, including due to the appearance of unjustified costs.

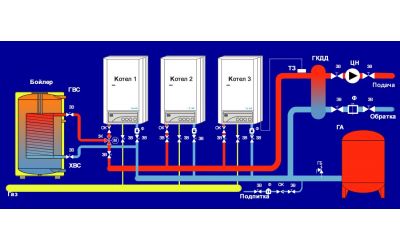

Cascade boiler houses The overwhelming majority of boiler houses do not use their thermal energy 100%. So, in the heating season, power is consumed by only 50%, and in the inter-heating season - by approximately 25%, which falls on the provision of facilities with hot water.

Firewood Firewood is timber that is burned to generate heat and light. Burning can take place in a stove, cauldron and even over a fire. According to GOST 3243-88, firewood up to 1 meter long is called logs.

Boiler house reliability Boiler house reliability is the ability of the system to produce and distribute heat carrier among its consumers under normal operating conditions.The main criterion for reliability is the failure-free operation of the entire boiler house as a whole and each of its elements in particular.

Features of the manufacture of modular boiler rooms Modular boiler rooms are boiler equipment located in a special module (or several modules). Design features allow you to easily transport the finished unit to any place, quickly install and carry out commissioning, as well as guarantee high efficiency of the unit due to assembly at the manufacturer.

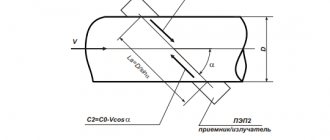

Features of channelless laying

The main difference between this method of organizing heating networks is the rejection of load-bearing gaskets. That is, the installation of trays for a heating main of this type is not necessary - the installation is carried out directly on the ground. The lack of additional protection and support of the pipeline is compensated by the use of special fittings in polyurethane foam insulation with a polyethylene sheath. Also, for such networks, an on-line remote monitoring system is provided, which continuously monitors the state of insulation.

Heating mains for heating a private house

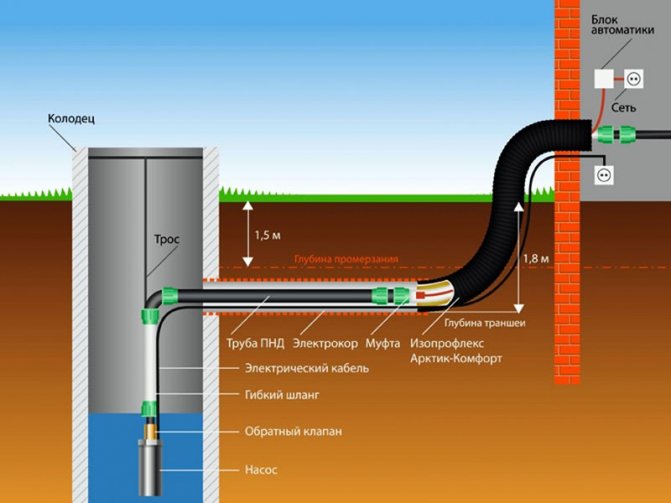

In private homes, the heat resource is often outside the home. To ensure a highly efficient heating system, it is necessary to deliver the heat carrier to the room, then the heat loss will be minimal. Regardless of the place where the heating main is laid - on the ground or under the soil, you need to take care of choosing a pipeline from the optimal material. You will also need to provide high-quality thermal insulation.

LLC "Heating Water" offers modern flexible pipes flexalen various markings. Our company is a direct dealer of pipelines from the Thermaflex manufacturer. You can not only buy Flexalen from us, but also order fast and high-quality installation. Our specialists carry out surface and underground laying of heating mains practically in any territory.

Heating mains repair

Maintenance with diagnostics and repair procedures can be carried out both in a planned manner according to the schedule, and on a signal from the monitoring equipment. Repair and restoration operations are performed in the following order:

- Localization of damage using special equipment.

- Dismantling of tray ceilings.

- Dismantling the faulty section.

- Replacing, fixing or supplementing the problem area with a necessary element. Often, an electric welding installation of a heating main is performed at a point with damage to a pipe in a gas environment.

- Cleaning the circuit from dirt and foreign objects.

- Pressing works aimed at checking the tightness after repair.

- Assembling the structure.