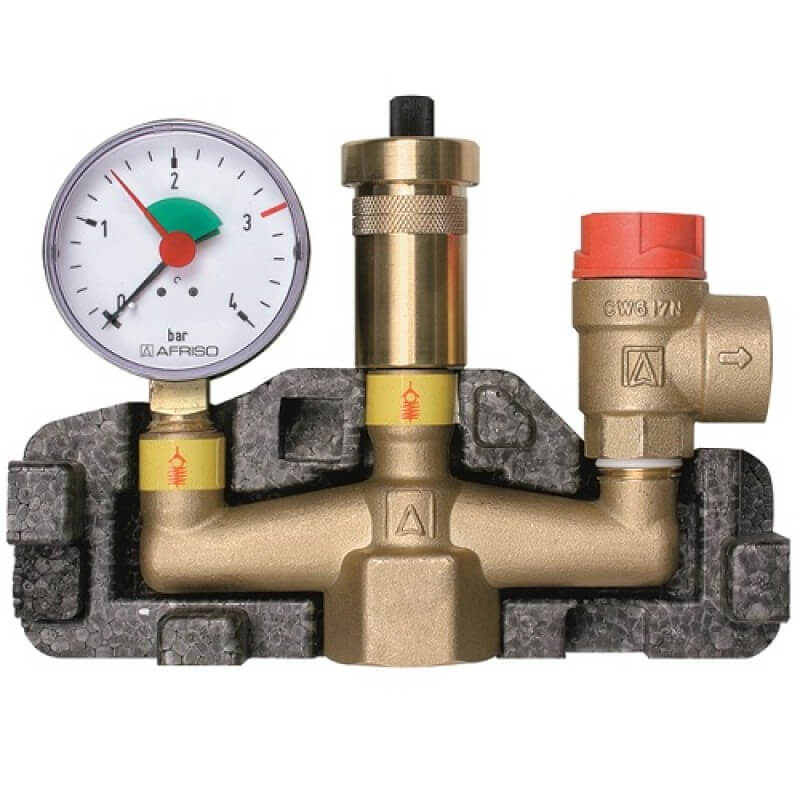

Boiler safety group - a set of safety elements designed to protect heating systems from exceeding the maximum permissible operating pressure and venting air from them.

It is a compact device consisting of a steel console on which are placed: a pressure gauge, an automatic air vent and a safety valve.

The pressure gauge allows you to monitor the operating pressure in the system, the air vent removes air plugs, the safety valve releases the coolant in the event of overpressure.

Principle of operation

If an open expansion tank is installed in the boiler equipment system, then the installation of a safety group is not required - the pressure in the pipes is equal to atmospheric, and an excessive amount of air leaves the system through the tank.

The safety group for the heating boiler works according to a very simple scheme, when each unit is responsible for maintaining the norms of the given indicators:

- The main job of an air vent is to release air that enters the pipes during operation.

- The safety valve prevents significant pressure readings in the heat generator.

- Thanks to the pressure gauge, the owner of a private house will be able to regulate the pressure level while filling the pipeline with a coolant, as well as later during the operation of the boiler.

All modules are a single link and are located in a special case - a collector.

Safety engineering

It is important to follow simple precautions when installing and operating the unit. They will not only help maintain health, but also reduce the risk of injuries of varying severity.

Among the basic rules, the following should be highlighted:

- It is necessary to install the security system in such a place so that you can freely approach it and eliminate minor breakdowns.

- The components of the safety unit must not interfere with the operation of the heating system. Otherwise, there is a high probability of breakdowns.

- Structural parts can become very hot during operation. Because of this, you need to be extremely careful not to touch hot elements. If you neglect this rule, you can get a fairly severe burn.

- In the event of an emergency, the device must be turned off immediately. This will protect it from even more damage and help reduce the risk of injury.

- Any repair work can only be carried out with disconnected and cooled equipment.

Installing a safety block for a heating system is a rather complicated undertaking that requires significant time and financial costs. With the right approach to business and following all the recommendations of professionals, you can simplify the work and complete it as soon as possible.

In the past few years, a closed heating system has become more and more popular. Heating equipment is becoming more and more expensive, and we want it to last longer. In closed systems, the possibility of free oxygen getting inside is practically excluded, which prolongs the life of the equipment.

Varieties

Let's consider the types of security groups. They differ:

Outward appearance: classic - in the photo above, compact - in the photo below:

The presence of thermal insulation: there are models with and without insulation:

Installation method: to the pipeline (all of the above models) or to the wall:

Boiler safety group WATTS GAG / KAV with wall console.By the way, on the left side of this boiler safety group, fittings are preinstalled for connecting an expansion tank (models up to 33 liters are well suited)

Boiler maximum power: most often the following sizes are found up to 50 kW, up to 100 kW, up to 200 kW:

Boiler safety group WATTS KSG 30 / 25M-ISO insulated for boilers up to 200 kW

Device device

As a rule, the grounds for disrupting the normal functioning of a closed-type boiler are an increase in pressure or a significant overflow of the pipeline with a heat carrier, that is, water.

The heat exchanger is the first section in the boiler that reacts to these deviations, and therefore it quickly fails.

To avoid these malfunctions in the heating system, a safety group for boilers is used.

With the help of this block, the required pressure of the coolant in the pipes and radiator batteries is achieved.

During excessive pressure readings, the excess heated water is discharged.

Various abnormal situations occurring, for example, excessive heating of the heating boiler, increase the pressure in the pipeline.

During strong heating, the water begins to expand, the closed water heating system is not designed for this - there is no additional reserve here.

The result of increased pressure is a breakdown of boiler equipment or a rupture of the pipeline. In order to regulate the pressure and, during a potential threat, reduce it to the required value, it will be necessary to install a boiler safety group.

The design consists of the following elements: safety valve, pressure gauge and automatic air vent. All of these devices are housed in a metal housing with threaded connections.

Air vent

Most often, the automatic air vent for boiler safety systems is made of brass.

Air bubbles in the heating system are formed for the following reasons:

- poor quality seals or failure of old ones;

- initial filling of the heating line with water with air bubbles;

- incorrect installation or incorrect commissioning of the heating system;

- water make-up;

- blockage or deposits on the pipes.

The water entering the heating circuit contains a large amount of air, which, when heated, expands and creates plugs.

Due to their formation, the pressure increases, and the speed of movement of the heat carrier decreases.

Therefore, it is advisable to install an automatic valve for air discharge, which is characterized by ease of use - it does not require human participation in the adjustment.

The principle of operation of this device will completely depend on its design.

Typically an automatic valve includes a valve and a duct. The first element controls the discharge of an excessive amount of air. If there is no significant liquid head in the pipes, the float is in the raised position and the valve is in the “closed” position.

During the formation of a plug, the float is lowered, and the rocker arm opens the outlet valve - this is how air is released from the heating pipes. After releasing excess air, the float returns to its original position and the valve closes.

Air vent

Its function is to discharge air from pipes. The air vent is equipped with a bucket with a float.

If enough air accumulates in the vessel, then it opens the valve and releases excess air. Also, when overheated, part of the steam is discharged through it.

Due to the design features of the air vent, the entire safety unit is installed on top of the boiler. This is necessary so that the air accumulates in it and when the air is released, the release of the coolant is not allowed.

Heating cable for pipes - tips for choosing, nuances of application and features of operation (140 photos)

A water gun for heating - what is it, the principle of operation and features of the use of the device (110 photos and videos)

Heat accumulator for heating - description of the system and features of its use in a private house (120 photos)

How to choose?

Choosing the right model is not difficult, you need to look at:

- Maximum allowable system power (kW) for which the node is designed. Usually it is 44, 50 or 55 kW. If the system has less power - great, if more - you need to look for a more durable option.

- Pressure relief valve. As a rule, valves with a fixed value of 1.5 bar, 3 bar, 4 or 6 bar are installed in ready-made assemblies. The response pressure should correspond to the maximum permissible operating pressure of the most vulnerable element of heating systems - usually a steel boiler heat exchanger, rated at 2 or 3 bar. Safety valves for 2 bar, despite sufficient demand, are difficult to find on sale, a way out of the situation is to assemble the assembly with your own hands by purchasing a safety valve and other elements separately (see below for more on this).

- Working temperature - this is the permissible temperature of the coolant, in almost all modern models it is in the range of -10 ° C - 110 ° C, which is more than enough.

- Coolant compatibility - if antifreeze is used as a heat carrier instead of water.

- Threaded connection diameter - it can be 1 ", 1/2" or 1.4 "in diameter. You can pick up a knot that does not match the thread diameter, but then you have to take care of the selection of the adapter, which is not always easy.

It is important to pay attention to the material of manufacture, galvanized steel or stainless steel is a good, but not the best option.

Brass products are more expensive, but more durable, wear-resistant and even more resistant to corrosion.

The material of manufacture is not always indicated in the characteristics, in addition, the collector can be made of steel, and the rest of the elements - of brass.

Brass can be distinguished by its characteristic monochromatic, matt color (bronze-gold or silver, depending on the alloy).

The best known manufacturers and models: characteristics and prices

TIM JH-1024-1.5

One of the most inexpensive, but proven models. Despite the low cost, it has a brass collector. Maximum CO power - 50 kW, safety valve response threshold - 1.5 bar, connection diameter - 1 ″ BP. Country of origin - China.

Price: RUB 990-1200

VALTEC VT.460.0

One of the best ready-made safety groups for the boiler and heating system of the renowned Italian manufacturer VALTEC. The assembly is entirely made of nickel-plated brass, with an additional threaded outlet for connecting an expansion tank. Differs in high reliability and quality of all connections and technical elements. The permissible CO power is up to 44 kW, the response threshold is 3 bar, the diameter of the connection to the network is 1 B.

Cost: RUB 1,650-1,800

Watts KSG 30

The security group is another well-known German company with production in Italy. There is a whole range of models on the market, where there are models designed for power up to 100 and even up to 200 kW. The collector body is made of galvanized steel, which, given the cost, is a disadvantage. However, the technical elements are brass, there is a thermal insulation casing. Maximum CO power - 50 kW, response pressure - 3 bar, connection diameter - 1 ″ (female thread).

Cost: RUB 2,600-3,400

Caleffi 302631

Another reliable and high-quality (in terms of materials and assembly) model of Italian production, completely made of brass, with a polystyrene heat-insulating casing included.The maximum CO power is 50 kW, the response pressure is 3 bar, the diameter of the threaded connection is 1 ″ BP.

Cost: RUB 4,500-4,750

Self assembly

A correctly assembled safety group should be in the shape of a trident so that the air vent is in the middle, directly above the connection for the safety group.

So the air will flow into it guaranteed, without any obstacles.

A homemade security team includes the following elements:

- pressure gauge, automatic air vent and safety valve;

- 2 steel or brass elbows at 90 ° with external and internal threads (the diameter is matched to the thread diameter of the modules and the cross);

- 1 steel or brass crosspiece;

- 1 coupling / nipple for connecting the assembly of the finished unit with the tee of the heating system;

- tow or silicone for sealing joints (FUM tape is not recommended, as it deforms at temperatures above 70-80 ° C).

We connect the elements in accordance with the photo below, connect to the heating system and check the operability:

Conclusions and useful video on the topic

Video # 1. How to assemble a safety group for heating with your own hands:

Video # 2. Installation rules for the security module:

Video # 3. Connecting the safety assembly to a polypropylene supply pipe:

Many are sure that the protective assembly belongs to ordinary devices and its installation is optional. However, a negligent attitude towards this issue will not be able to protect the heating unit and the heating system itself from rupture as a result of a sharp jump in pressure, which is quite common in a closed circuit.

Please write comments, ask questions, post a photo on the topic of the article in the block below. Tell us how you equipped the heating circuit with a safety group. share useful information that may be useful to site visitors.

Source: sovet-ingenera.com

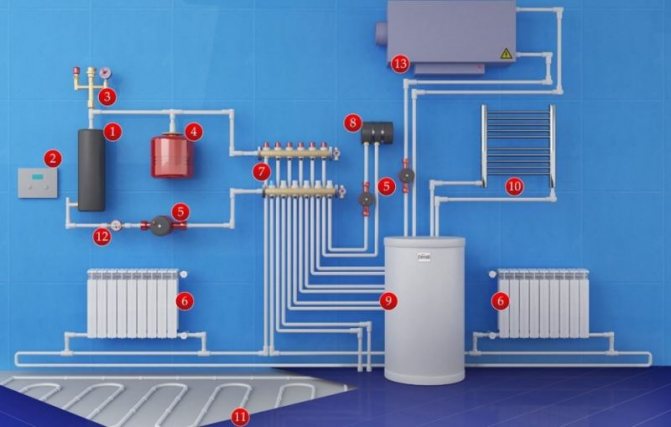

Heating connection

The whole process of connecting the safety group to the heating system consists in a threaded connection to the vertical branch pipe previously allocated for it (diameter of the thread of the branch pipe = diameter of the thread of the safety group) and in checking the functionality of its modules.

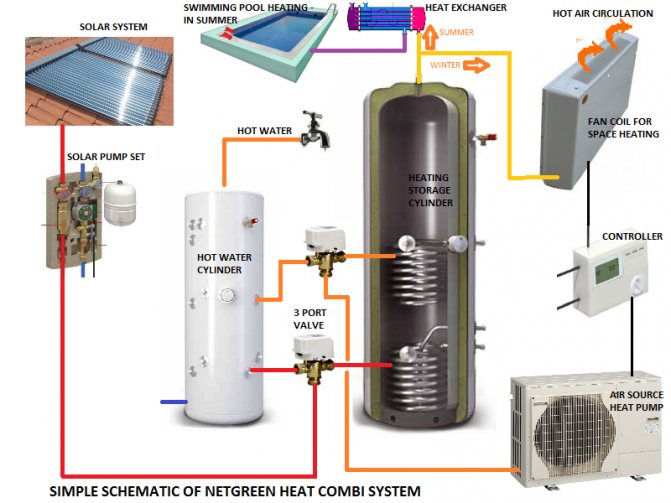

An example of installing a safety group is shown in the diagram below:

After a tight connection, you need to check the operation of the air vent by forcibly opening it: turning the valve handle (upper cap) until it clicks. We leave the air vent open.

For the period of filling the system with coolant, it is better to close the automatic air vent. It is necessary to put a drain pipe on the relief valve, leading either to the floor (into a prepared container) or to the sewer.

In the first case, the consequences of the accident will be visible; when you drain into the sewer, you may not know about what happened.

Connection diagram

In a floor-standing boiler, unlike a wall-mounted one, there is no built-in circular pump, expansomat and safety group. All this needs to be installed outside of it. The supply pipe is connected to the top of the boiler and the safety group is mounted there.

There should be no shut-off valves, filters or other elements between the boiler and the safety group. For example, if the tap is closed, then an accident will happen.

The security group can be presented in a proprietary form. The main element in it is an emergency valve that relieves pressure. In some cases, it is possible to install only one safety valve on the tee instead of the entire safety group.

Very often, a safety group is placed immediately above the boiler, and at the moment the pressure is released by the valve, the liquid enters the boiler, which is unacceptable if it is electric. Therefore, if the safety group is installed above the boiler, then a tube is connected to the emergency valve, and it is taken to the side. A container for liquid is placed under it.

Connection diagram of a safety group in a heating system with an expansion tank

The return flow diagram is performed as follows (in the direction from the boiler) - a shut-off valve, a circulation pump, a mud filter, a second shut-off valve, a tee with a valve for connecting an expansomat and a valve for filling the network. Systems with such a simple design do not require the installation of a check valve. The mud filter is mounted with an oblique outlet downward. The pump rotor must be horizontal and the terminal box in the upper position.

The expansomat compensates for pressure fluctuations in the heating system. As the water heats up, it expands. To prevent pressure release through the emergency valve, the expansion tank lowers it. The volume of the expansomat must be at least 1/10 of the entire system.

For example, if the volume of the boiler is 80 liters, and the heating system is 140 liters, then the total volume is 220 liters. Therefore, a 22 L expansion tank is required for stable operation. Experts recommend taking a larger expansomat - 1 / 7-1 / 8 of the volume of the entire system.

Expansion vessel in a closed heating system

It is recommended to use FUM tape, flax, pastes or other sealing agents as a seal for threaded connections, which will ensure a tight connection of all elements even during heavy loads.

Maintenance

- It is advisable to check the status of all modules of the security group every 2-3 months.

- The safety valve must be cleaned every 6 months to prevent leaks and contamination. To do this, open it by turning the valve cap in the direction of the arrow.

- After 5-7 operations, it is recommended to replace the safety valve due to wear of the spring, which can lead to leakage and operation at lower pressure values in the system.

Installation features

Many factory models of heating boilers are already equipped with a safety block. As a rule, these are wall-mounted boilers. But as for floor-standing boilers, a protective mechanism is not provided in them. Therefore, you need to install it additionally.

The installation of the protective mechanism can be carried out separately.

In this case, the safety valve must be placed above the boiler. Although most often the heating safety group is mounted in one place: it is more convenient, more reliable and cheaper in cost. It should be noted that the safety group for heating, the price for which depends on the manufacturer and model, is set quite simply. The main thing is to follow a number of rules.

Before installing the security system, you should think about how it will be repaired and checked, which must be carried out regularly. It is advisable to create the ability to disconnect each of the elements of the heating system during installation so that you do not have to reset the entire heating system in the future. It is best to carry out the installation on the supply pipe, at a distance of about 1.5 meters from the heat boiler. Ball valves need to be embedded behind the safety block. This will ensure long-term, high-quality and reliable operation.