Heating is one of the privileges people need to live comfortably. To prevent each apartment from connecting separate heating, an entire system is installed in the house. Such systems differ among themselves depending on the type of house, its size and the number of apartments.

In the paragraphs of this article, we will try to answer in detail the questions regarding the heating network at home.

How is the process of heat supply of a high-rise building

Each apartment building has a central heating system, which consists of the following elements:

- a source;

- heating network;

- consumer.

Boiler houses and thermal power plants act as sources of heat energy.

From boiler rooms to houses, hot water is directed immediately and requires a decrease in temperature, otherwise the heating equipment of the house will be damaged. In a CHP plant, it is converted into steam to generate electricity, then this steam is used to heat the coolant entering the building's heating network.

What is an elevator?

In simple terms, the elevator is a special device related to heating equipment and performing the function of an injection or water-jet pump. No more, no less.

Its main task is to increase the pressure inside the heating system. That is, to increase the pumping of the coolant through the network, which will lead to an increase in its volume. To make it clearer, let's give a simple example. 5-6 cubic meters of water is taken from the supply water pipe as a heat carrier, and 12-13 cubic meters get into the system where the apartments of the house are located.

The original roof covering was removed and the lower structure was reinforced with significant additional structure to avoid any subsequent structural fall. Prior to retraining, tenants used electric ovens and gas boilers for both heating and hot water supply. Thus, the building was not in a real tech room. Due to the small space available under the building, it would have been impossible to place a technical compartment on the ground floor. In this regard, however, the lift was very useful: the structural reinforcement used to support it allowed for a new central heating and cooling system at roof level.

How is this possible? And due to what is the increase in the volume of the coolant? This phenomenon is based on some laws of physics. To begin with, if an elevator is installed in the heating system, it means that this system is connected to central heating networks, through which hot water flows under pressure from a large boiler house or CHP.

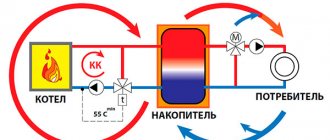

The installed system consists of a 20 kW reversible double-circuit heat pump: the first circuit is constantly in heating mode and connected to a heat storage element to supply hot water; The second circuit is installed in heating mode during winter and summer cooling periods. During the summer months, the heat pump can simultaneously cool and heat. If necessary, heating from cooling is recirculated to produce hot water instead of being discharged to the environment.

Figure 3 - Heat pump and solar thermal system on a south-facing parapet. For the storage of solar energy, it was also planned to accumulate a capacity of 800 liters with an integrated heat exchanger. Due to aesthetic and space constraints, eight collectors were installed on the railing and two on the wall of the technical compartment.For maintenance work directly from the roof, the collectors are mounted 200 mm apart and 200 mm from the ground connections and the roof surface.

So the temperature of the water inside the pipeline, especially in extreme cold, reaches +150 C. But how can this be? After all, the boiling point of water is +100 C. This is where one of the laws of physics comes into force. At this temperature, water boils if it is in an open container, where there is no pressure. But in the pipeline, water moves under pressure, which is created by the operation of the supply pumps. Therefore, it does not boil.

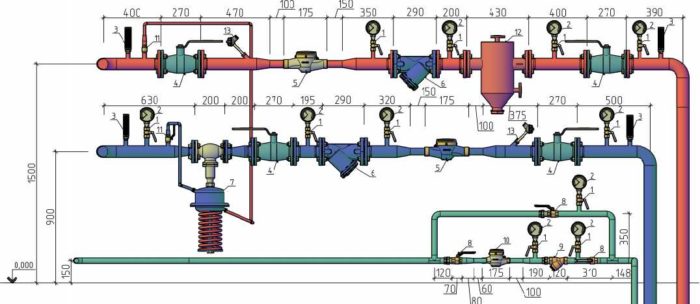

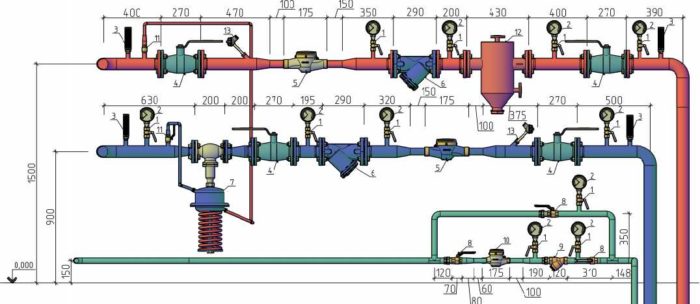

An anchoring structure of C profiles was used to support the weight of the manifolds and resist wind forces. The distribution system consists of four pipes: two are used for heating or cooling, and the other two are used for distributing hot water. The pipes are made of polypropylene to allow for a faster and more economical installation. Again, the supporting structure of the new elevator compartment is mechanically useful for anchoring the vertical pipes connecting the technical compartment to the individual apartments.

- Firstly, cast iron does not like large temperature differences. And if cast-iron radiators are installed in the apartments, they may fail. It's good if they just leak. But they can break, because under the influence of high temperatures, cast iron becomes brittle, like glass.

- Secondly, at such a temperature of metal heating elements, it will not be difficult to get a burn.

- Thirdly, plastic pipes are now often used for piping heating devices. And the maximum that they can withstand is a temperature of +90 C (besides, with such figures, manufacturers guarantee 1 year of operation). So they just melt.

Therefore, the coolant must be cooled. This is where you need an elevator.

As shown in Figure 4, pipes are ordered in two groups, each feeding a column of apartments on both sides of the staircase. Finally, various floors are heated and cooled by radiant ceiling panels during renovations. Designing a heating and cooling system with the ultimate goal of providing an optimal supply of renewable energy and the least loss of thermal energy is a recent challenge for many small energy advisory offices.

Thus, the installation becomes prohibitive for most plumbing operators due to the strong integration between the various elements put into play. To this end, the project partners collaborated to develop modular technology that aims to facilitate the installation of sophisticated cooling and heating systems in small and medium-sized residential buildings.

What is "heating network" and "heating unit"

The heating network of a house is a collection of pipelines that provide heat to each living space. This is a complex system that consists of two heat pipes: hot and cooled.

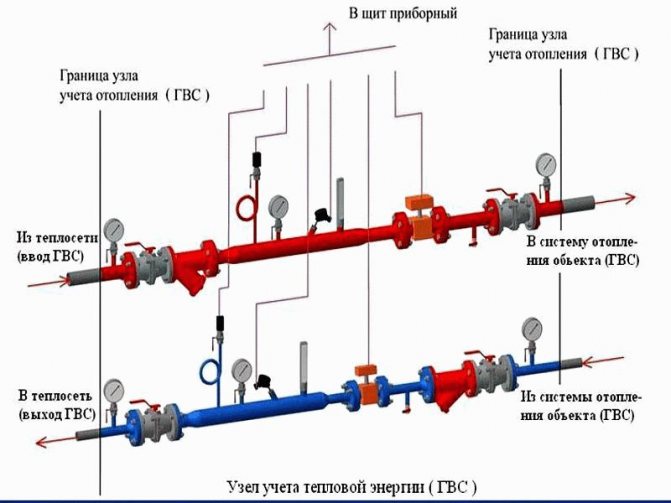

Heating unit - heating equipment system; the place where the hot water pipe merges with the building heating system. Distribution and metering of heat takes place here.

The list of performed tasks includes:

- control over the state of the heat source;

- monitoring the condition of water and heat pipelines;

- registration of data from metering devices.

Types of heating units

In multi-storey buildings, heating points of two types are used.

Single-circuit provides a direct connection to hot water pipes, that is, heat pipes are connected using an elevator. In high-rise buildings, the heating network is quite extensive, but most of the equipment is located in the basement.

Important! The scheme of a two-circuit heating unit is a system of two heat pipes in contact with each other through a heat exchanger.

Further, we will consider in more detail the principle of operation of a single-circuit heating unit. Due to its structure, namely the presence of an elevator, and its low cost, it is used most often. For companies that are engaged in the installation of heating equipment and heating units, it is more profitable to use outdated elevator units that do not require careful attention.

Device

A single-circuit heating unit is designed in the simplest way. As already mentioned, it consists of a pipe extending from a heat source and a "cold" pipe, which are connected by means of an elevator. Also on the pipes there are filters and measuring devices that control the flow, the temperature of the coolant and the pressure in the pipes.

The filtering equipment is installed, since the entire heating system reacts rather negatively to dirt and sediment in the coolant. Over time, it must be cleaned or changed.

Important! If the pressure is unstable, a lowering device is installed in the heating unit.

Installation of counters has some nuances:

- placed on a pipe with "return" heat;

- it must be located as close as possible to the heat source;

- setting of parameters (required amount of heat per hour, day).

Functioning principle

In this paragraph, we will tell you what processes take place inside the elevator heating unit.

According to the scheme, hot water supplied by utilities enters the house through a "hot" pipe. Having “bypassed” the entire building, it returns to the unit in a cooled state and is removed from the system. But in the elevator, hot and "cold" water is mixed, not allowing the temperature to go beyond the permissible limits. There are situations (suitable for areas with low temperatures) a heating mechanism is built into the elevator: if the temperature of the water during mixing is below the permissible level, the mechanism turns on.

The intra-building heating system can be disconnected from the city heating system using valves. Such actions are carried out during repair work and for general prevention. For such cases, there are special valves on the pipes designed to remove water from the system.

Important! All parts of the unit are connected to the heating system using flange connections.

The use of a single-circuit unit has both advantages and disadvantages.

The advantages of such a heating unit are:

- ease of use;

- the rarity of breakdowns;

- the relative cheapness of the components and their installation;

- fully mechanized and does not depend on extraneous energy sources.

The main negative sides:

- for each heat pipe, personal calculations of parameters are required for the selection of an elevator;

- the pressure in each pipe must be different;

- manual adjustment only;

- Who carries out the installation and maintenance of the heating unit.

Houses with a large number of apartments have a system for supplying heat and hot water from the city, which is located in the basement. Such a heating system needs preventive maintenance. The most "weak link" are filters, or mud collectors, which must be monitored and cleaned (they accumulate all the dirt from the coolant).

This work is done, or at least should be done, by the locksmiths from the housing and communal services bodies that serve the building. Since the heating center is complex and dangerous in operation, in no case is the intervention of unauthorized people allowed, and only specially trained personnel are allowed to carry out diagnostics and repairs.

Individual heating point

ITP in a block-container is used to connect heating, ventilation, hot water supply and technological heat-using installations of the whole building or part of it.

BTP - Block heat point - 2var. Manufactured at the factory and supplied for installation in the form of ready-made blocks. It can consist of one or several blocks. The equipment of the blocks is mounted very compactly, as a rule, on one frame. Usually used when it is necessary to save space, in confined spaces. By the nature and number of connected consumers, a BTP can refer to both an ITP and a central heating substation. Supply of ITP equipment according to specification - heat exchangers, pumps, automation, shut-off and control valves, pipelines, etc. - delivered in separate items.

+ BTP is a product of full factory readiness, which makes it possible to connect reconstructed or newly built objects to heating networks in the shortest possible time. The compactness of the BTP helps to minimize the area of equipment placement. An individual approach to the design and installation of block individual heating points allows us to take into account all the wishes of the client and translate them into a finished product. warranty for BTP and all equipment from one manufacturer, one service partner for the entire BTP. ease of installation of the BTP at the installation site. Manufacturing and testing of BTP at the factory - quality. It is also worth noting that in case of mass, quarterly development or volumetric reconstruction of heating points, the use of BTP is preferable to ITP. Since in this case it is necessary to mount a significant number of heating points in a short period of time. Such large-scale projects can be implemented in the shortest possible time using only standard factory-readiness BTPs.

+ ITP (assembly) - the possibility of installing a heat point in cramped conditions, there is no need to transport the heat point as an assembly. Transportation of individual components only. The delivery time of the equipment is much shorter than that of the BTP. The cost is lower. -BTP - the need to transport the BTP to the installation site (transportation costs), the dimensions of the openings for carrying the BTP impose restrictions on the overall dimensions of the BTP. Delivery times from 4 weeks. Price.

- ITP - a guarantee for different components of a substation from different manufacturers; several different service partners for various equipment that is part of the heat point; higher cost of installation work, terms of installation work, T. That is, when installing the ITP, the individual characteristics of a particular room and the "creative" decisions of a particular contractor are taken into account, which, on the one hand, simplifies the organization of the process, and on the other hand, can reduce the quality. After all, it is much more difficult to perform a welded seam, a pipeline bend, etc. in the "place" than in a factory.

Possible problems

The thermal system of a house is a complex mechanism. Any breakdowns and malfunctions are inevitable. But most often problems arise in the heating unit, namely, the breakdown of the elevator. Mechanical reasons: flaws in the locking equipment, clogged filters. This creates a temperature difference in the pipes before and after passing the elevator. If the difference is not big, then the problem is not serious: you just need to clean the elevator. Otherwise, repairs are needed.

Other problems of the heating unit include an increase in the permissible temperature of the measuring equipment, the occurrence of leaks in the pipes. When the filters become clogged, the pressure in the pipes increases.

Important! In the event of any malfunction, it is necessary to diagnose the entire heating system.

As mentioned in the article, elevator units are an obsolete technology. Gradually, in apartment buildings, they are replaced with automatic heating units, which do not require constant monitoring by a person and regulate all indicators themselves.

The disadvantage of such heating systems is the high cost and, like any automated device, it runs on electricity.

However, devices are built into the scheme of single-circuit units that make it possible to regulate the temperature and pressure in the incoming coolant. Thus, it allows people to save money when paying for communal services.

Features of the installation of the elevator system

The elevator heating unit diagram is a two-level system. The top is a chain of nodes associated with adjusting input media from a centralized network. The lower part is responsible for the receipt and distribution of the "return". The connecting element is a branch for supplying chilled water to the mixing chamber.

The device of unregulated elevators is simpler, but the efficiency is much lower. Therefore, this type of equipment is rapidly being replaced by modern and automatic controlled units. Their undoubted advantage is the absence of the need to constantly monitor the operation of the equipment. In addition, process automation significantly increases the efficiency of the device, especially if the electronics are responsible for maintaining the required parameters.

Elevator unit controller and timer - an integral part of modern devices

As a rule, a heating elevator is built into an existing heating system. It is not uncommon for outdated or outdated equipment to be replaced with a new one. Therefore, before choosing a unit, they carefully examine the installation site, assess the possibility of expanding the space for the construction of a new unit.

A simple conclusion follows from this: all work should be entrusted to specialists with practical experience in the installation and improvement of heating systems of various types. Stable skills, knowledge of the principles of calculations, engineering solutions, the ability to understand drawings and diagrams are required.

The elevator heating unit assumes absolute tightness of installation - otherwise you will not get around problems. The expected optimization of heating costs will lead to increased costs and flood control. This is another argument why such work should be entrusted to competent craftsmen.

House-wide performance improvement initiatives are an effective way to improve networks and generate savings. However, do not forget that the miser pays twice. Use the services of professionals, and you will not have to regret that inadvertently relying on your own strength.

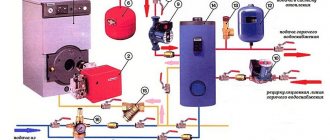

How it works?

Local boiler houses or heat and power plants are responsible for providing heat to apartment buildings. From them, through highways, heated water is supplied to the heating units of each house. This feeding system is called central. One properly operating heat and power plant is capable of providing a whole district with a heat source.

It is worth noting that the temperature of the water supplied from the CHP plant averages 130 0 C. Of course, this is unacceptable. Therefore, before getting into the apartments of citizens, the water must be cooled.

In order for heat to get inside the object, inlet valves must be installed.

In order to cleanse the oxidations, salts and heavy metals formed in the pipeline, the system is equipped with mud collectors.

Tips are installed on the supply and return pipelines. To ensure constant circulation, pressure must always be present in the system.To achieve this, a retaining washer is installed between the insets.

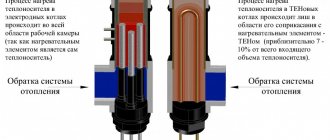

The heating unit of an apartment building is equipped with the main element - a heating elevator. The principle of operation of this unit can be compared to a pump. Under the influence of pressure, water from the CHP plant and water from the return flow enters the elevator chamber.

As we already know, the water produced by the CHPP has an exorbitant temperature. Thus, when mixed with water from the return, water of the required temperature is obtained. After that, she exits the nozzle at high speed and is ready to get into the apartments.

An elevator with an electronic sensor has been installed in modern homes. This allows you to monitor the temperature and make the water cooler or warmer, if necessary. This adjustment helps to reduce the cost of heating bills.

The usual water supply scheme is a pair of supply and return pipes. In this case, there are two options for the location of the pipes:

- Both supply and return are located in the basement of the house;

- The feed is in the attic or technical floor, and the return is in the basement.

The second option has begun to be used recently, but according to experts, it is not always better. After all, in the attic it is much more difficult to achieve constant temperature readings.

The Mayevsky crane is still in use. This device allows stagnant air to be released from the radiators. Opens with a screwdriver and a key. It is still considered the most convenient and reliable for connecting heating.

Individual heating in residential buildings

In addition to the central one, you can find autonomous heating of an apartment in an apartment building, usually such a heat supply is rare and has been installed in new buildings in recent years. Also, local heating systems are used in the private residential sector. It is customary for a boiler room to be located either in the building itself in a separate room or near the house, since it needs to be regulated.

In addition, dependent heating systems are used in apartment buildings. In this case, the coolant is transported to the apartment batteries without additional distribution directly from the CHP. In this case, the water temperature is regardless of whether it is supplied through a distribution point or directly to consumers.

Types of heating systems in an apartment building are open or closed (in more detail: "").

In the latter version, the heat carrier from the CHP or the central boiler house, after entering the distribution point, is supplied separately to heating radiators and to hot water supply. In open systems, such a separation is not provided for by the design, and heated water for the needs of residents is supplied from the main pipe, therefore, outside the heating season, consumers are left without hot water supply, which causes a lot of complaints about utilities.

Radiators for heating systems of high-rise buildings

Cast-iron radiators, which have been used for more than a dozen years, are familiar to many residents of multi-storey buildings. If it is necessary to replace such a heating battery, it is dismantled and a similar one is installed, which is required by the heating system in an apartment building. Such radiators for centralized heating systems are considered the best solution, since they can withstand a sufficiently high pressure without problems. In the passport to the cast-iron battery, two numbers are indicated: the first of them indicates the operating pressure, and the second indicates the test (pressure) load. Usually these values are 6/15 or 8/15.

The higher the residential building, the higher the working pressure. In nine-storey buildings, it reaches 6 atmospheres, so cast iron radiators are suitable for them. But when it is a 22-storey building, then 15 atmospheres will be required for the working functioning of centralized heating systems.In this case, steel or bimetallic heating devices are needed.

Experts do not recommend using aluminum radiators for centralized heating - they are not able to withstand the working state of the water circuit. Also, professionals advise property owners when carrying out major repairs in apartments, in case of replacing batteries, to change the pipes for the distribution of coolants by ½ or ¾ inch. Usually they are in poor condition and it is advisable to install ecoplast products instead.

Some types of radiators (steel and bimetallic) have narrower watercourses than cast iron products, so they become clogged and subsequently lose power. Therefore, at the point where the coolant is supplied to the battery, a filter should be installed, which is usually mounted in front of the water meter.

One of the key parts of the heating main is the heating unit. The scheme of the heating unit, the device and the principle of operation may seem incomprehensible to a beginner, but with minimal knowledge, you can fully understand these intricacies, which will help to equip a highly efficient heating main in the future. First of all, you should consider the basic points.

- Show all

Hot water supply in heating systems

DHW in multi-storey buildings is usually centralized, while the water is heated in boiler rooms. Hot water supply is connected from heating circuits, both from one-pipe and two-pipe. The temperature in the hot water tap in the morning is warm or cold, depending on the number of main pipes. If there is a one-pipe heat supply to an apartment building with a height of 5 floors, then when you open the hot tap, cold water will first go out of it for half a minute.

The reason lies in the fact that at night, rarely any of the tenants turn on the tap with hot water supply, and the coolant in the pipes cools down. As a result, there is an overexpenditure of unnecessary cooled water, since it is drained directly into the sewer.

Unlike a one-pipe system, in a two-pipe version, hot water circulates continuously, so the above problem with DHW does not arise there. True, in some houses, through the hot water supply system, a riser with pipes - heated towel rails, which are hot even in the summer heat, are looped.

Many consumers are interested in the problem with hot water supply after the heating season has ended. Sometimes the hot water disappears for a long time. The fact is that utilities are obliged to comply with the rules for heating apartment buildings, according to which it is necessary to carry out post-heating tests of heat supply systems (about

Major problems

Unfortunately, even such a simple device as an elevator unit is subject to various failures and malfunctions. To determine the malfunction, it is necessary to analyze the readings of the pressure gauges at the control points.

One of the key causes of damage to the elevator assembly is a large accumulation of debris in the pipelines. Often this debris is dirt and solid particles in the water. In case of a sharp drop in pressure in the heating system, a little further than the sump it is necessary to clean this reservoir. Dirt is dumped using drain channels, after which the nets and internal surfaces of the structure are serviced.

In case of pressure surges, check the system for corrosive processes or debris. The problem can also be caused by the destruction of the nozzle, as a result of which the pressure level becomes too high.

Even in the operation of elevator units, there are such phenomena in which the pressure begins to rise at an incredible rate, and the manometers before and after the sump display the same value. If so, it is necessary to carry out a comprehensive cleaning of the return circuit sump. To do this, open the taps, clean the mesh and get rid of all the dirt inside.

If the dimensions of the nozzle have changed due to corrosive processes, it is possible that a vertical misalignment of the heating circuit has occurred. In this case, the lower radiators will warm up quite well, while the upper ones will remain cold. To eliminate the malfunction, you need to replace the nozzle.

Experienced engineers and heating technicians recommend using one of the three operating modes of the boiler plant. Such recommendations were created taking into account theoretical data and mathematical calculations, and were also confirmed by many years of practical experience. Each of the selected modes guarantees highly efficient heat transfer with low losses. At the same time, even the long length of the highway does not affect the efficiency indicators.

These modes differ from each other in different temperature ratios on the supply circuit and the return one:

- 1.150/70 degrees Celsius.

- 2.130/70 degrees Celsius.

- 3.95/70 degrees Celsius.

When choosing the optimal ratio, it is important to take into account several factors, including regional characteristics and the average winter air temperature. If we are talking about heating a private house, it is better to abandon the use of the first two modes, which imply heating the coolant to 150 and 130 degrees Celsius. At such temperatures, there is a possibility of getting dangerous burns and other consequences from depressurization.

As you know, the liquid in the pipeline is heated to temperatures that exceed the boiling point. However, it never boils, which is due to the corresponding pressure. If it is necessary to choose the optimal mode for a private building, you need to reduce the pressure and temperature, for which the elevator unit is used. The element itself is a special heating equipment, which is located in the distribution point.

general information

The heating point is located at the entrance of the heating main into the premises. Its main task is to change the operating parameters of the heat-transfer fluid, and to be more precise, to reduce the temperature and pressure of the water before it enters the radiator or convector. Such a process is necessary not only to increase the safety of residents and prevent possible scalding on contact with the battery, but also to increase the operating life of all equipment. The function is indispensable in cases where the building has polypropylene or metal-plastic pipes.

The relevant documentation indicates the regulated modes of operation of such units. They indicate the upper and lower temperature thresholds to which the coolant can be heated. Also, according to modern standards, each unit must have one that determines the current indicators of the liquid with which the heating unit operates.

The scheme, principle of operation and design of thermal equipment may depend on several features, including a project that was created taking into account the individual requirements of customers. Among the existing types of heating units, a special models based on an elevator are in demand

... Such a scheme is characterized by particular simplicity and availability, but with its help it is impossible to change the temperature of the liquid in the pipes, which gives the consumer a lot of inconvenience. The main problem is the excessive consumption of heat resources during temporary thaws during heating.

In the system of heating units based on an elevator, a reduced pressure reducer may be present, which is located directly in front of the elevator. The elevator itself mixes the cooled liquid from the return pipe to the heated coolant that has reached the supply circuit.

The principle of operation of the unit is based on creating a vacuum at the outlet, which significantly reduces the water pressure and starts the mixing process.