Gas boiler piping in the heating system

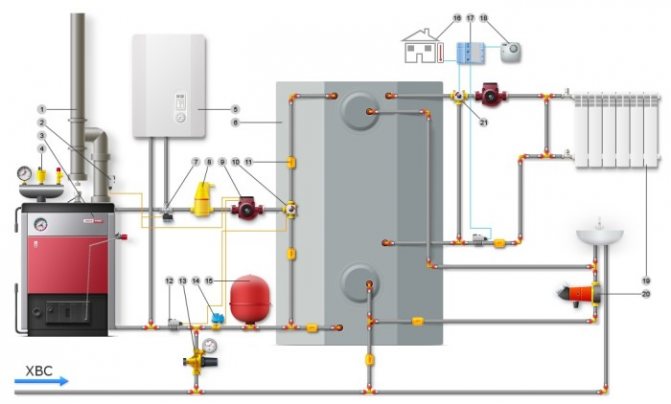

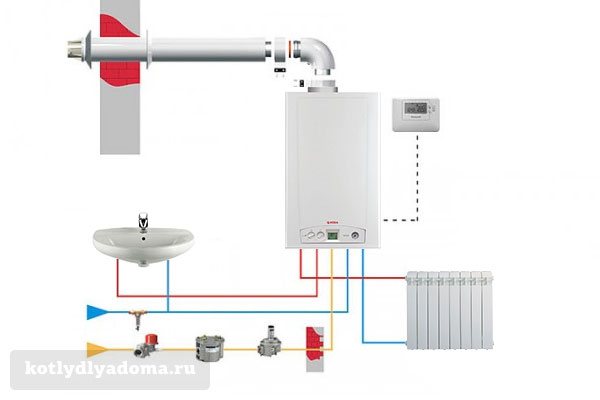

After the wall-mounted gas boiler has been installed and the heater is placed on the wall, the first step is to connect it to the heating system. Depending on which model is installed single-circuit or double-circuit, there are different strapping schemes. We will consider the connection process using the example of a wall-mounted double-circuit gas boiler.

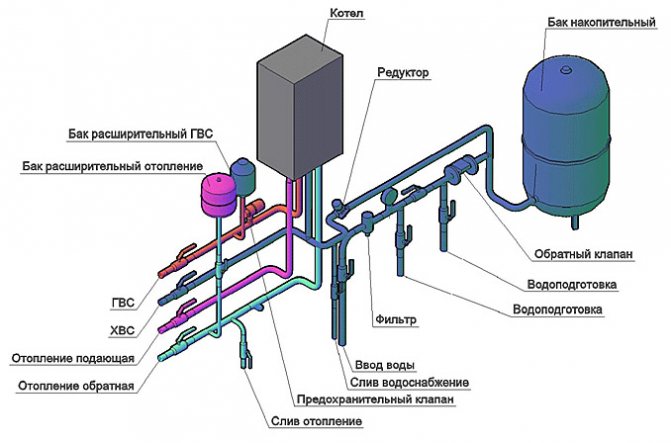

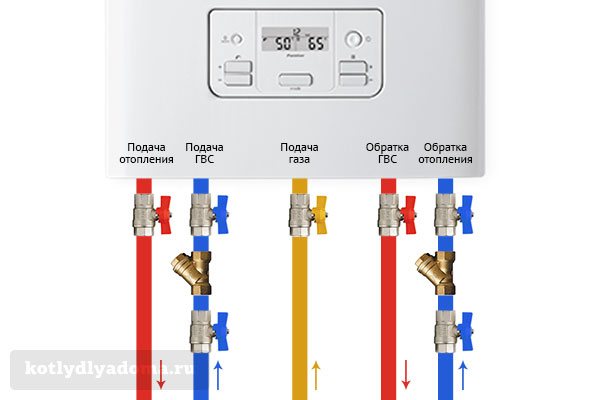

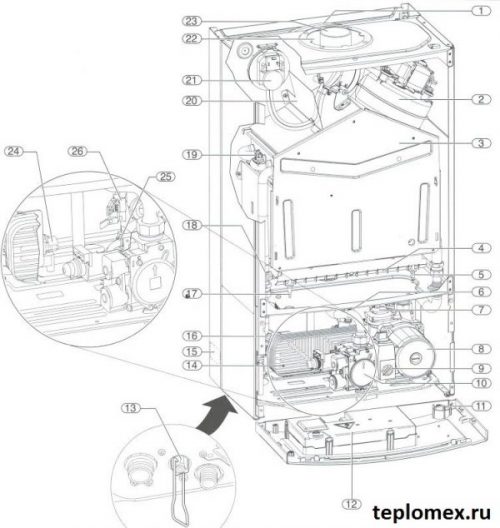

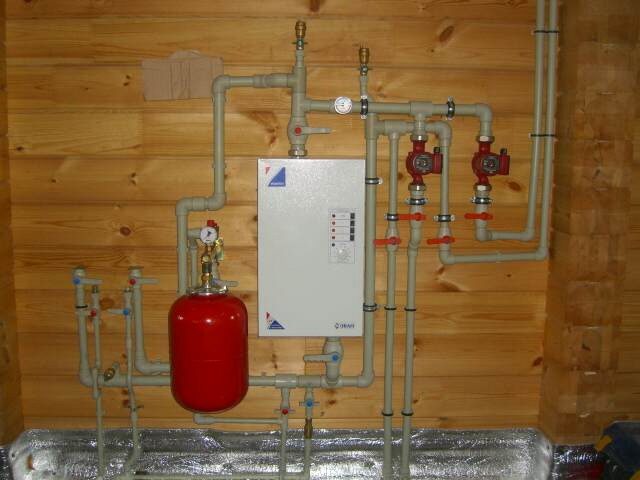

Photo 1: Connection diagram of a wall-mounted double-circuit gas boiler

As you know, a double-circuit boiler, in addition to heating, is capable of producing hot water for household needs. Structurally, this is realized by installing one bithermal or two separate heat exchangers. A double-circuit boiler does not produce very much hot water, but it is quite enough for 1-2 points of distribution (for example, a kitchen faucet and a shower).

A modern hinged gas boiler is very compact and already contains inside itself the main elements necessary for the functioning of a forced circulation heating system, such as: a circulation pump, an expansion tank, a safety group. In the heating systems of small private country houses, this is more than enough, but if necessary, you can install an additional expansion tank or another pump.

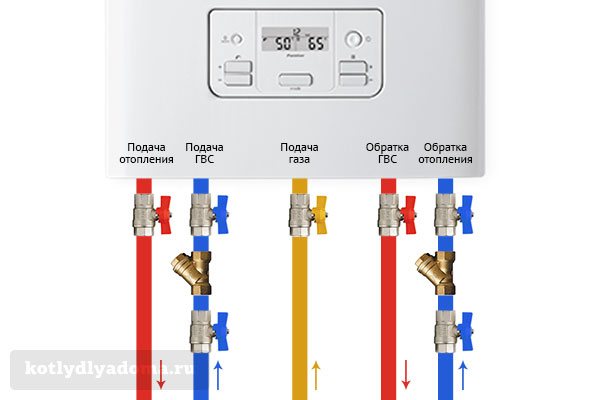

At the bottom of any hinged double-circuit boiler there are 5 nozzles. They are connected to: supply and return lines of the heating system, supply and return of hot water supply, main gas. The gas inlet is usually centered and colored yellow. All other lines can be arranged in any order, depending on the model of the gas boiler. Therefore, before starting the strapping, it is required to clarify the purpose of each of them in the operating instructions.

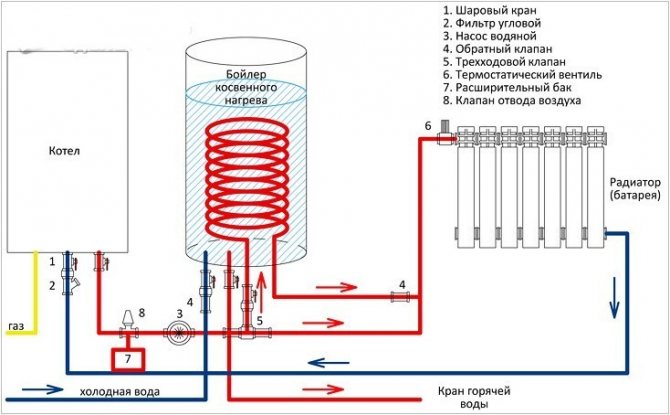

Photo 2: Scheme of piping a wall-mounted double-circuit gas boiler

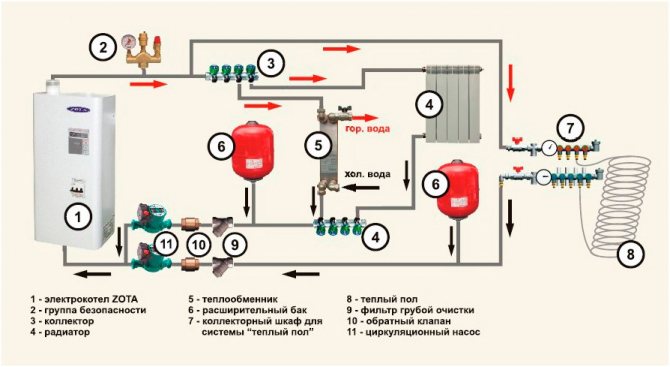

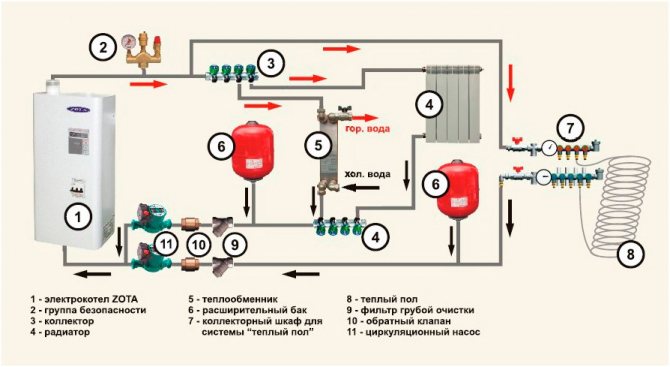

The piping of a wall-mounted gas boiler is carried out with polypropylene or metal pipes. The cross-section of the heating pipes is usually larger than the DHW pipes 3/4 and 1/2 inches, respectively. The heating system is connected to the boiler through the "American" nuts. Ball valves are installed on each line, for the convenience of dismantling the gas boiler without draining the coolant and to isolate the boiler from the heating system, if necessary. To ensure tightness, all connections must be made using plumbing FUM tape or flax.

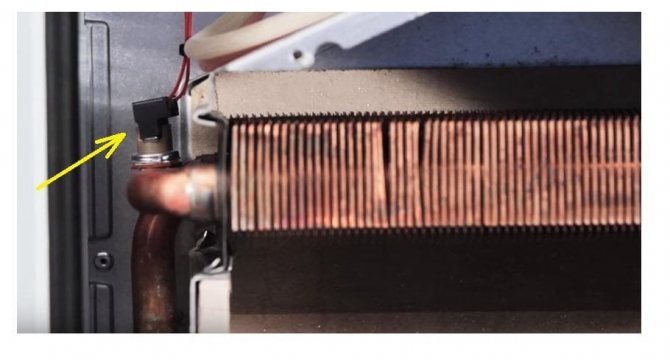

Coarse filters must be installed in the heating return line and in the DHW supply line. For the convenience of flushing and cleaning, they are also cut off by shut-off valves. Often, in order to increase the service life of the secondary heat exchanger of a double-circuit boiler, a magnetic fine filter is additionally installed on the hot water supply.

teplomex.ru

A brand such as "Buderus" is one of the most famous heating equipment in the world. At the turn of the century, this German company gained fame mainly for its reliable Buderus solid fuel boilers. Good reviews from buyers, specialists, German build quality have done their job, and now the Buderus brand is associated, first of all, with reliability and quality.

The only significant drawback was the rather high cost of such equipment. Several years ago, the company merged into a holding with an equally well-known German manufacturer - Bosch, for the production of gas equipment, including in Russia (wall-mounted gas boilers are assembled in the city of Engels, Saratov Region).

This allowed them to significantly reduce the price of their gas boilers and water heaters, as well as shorten the delivery time of equipment to retail outlets. In recent years, the holding has also been actively developing a new direction - these are wall gas boilers Buderus: double-circuit, single-circuit 12, 18, 24, 28, 35 kW.

In order to get an idea about them and decide whether it is worth buying a Buderus gas boiler or not, you need to familiarize yourself not only with customer reviews and prices for them, but also with the technical characteristics and device of the device, consider the features and range of mounted boilers.

Having compiled for ourselves some kind of instruction manual, we will determine both the advantages and disadvantages of single-circuit and double-circuit gas boilers of the Buderus brand.

Gas boiler "Buderus Logamax U072"

Model range of gas boilers Buderus Logamax.

The company supplies the Russian market with wall-mounted (hinged) boilers of the Logamax series in a double-circuit and single-circuit design, among which there are several modifications.

1. Buderus Logamax U042 / U044

These are Buderus double-circuit gas boilers with a copper bithermic heat exchanger. They come with a closed combustion chamber U042 K, and with an open one - U044 K. They are produced with a power of 24 kW.

2. Buderus Logamax U052 / U054 K

Both double-circuit and single-circuit boilers with a rated power of 24 and 28 kW are produced. Domestic hot water productivity for dual-circuit models is 11 and 13 l / min, respectively. They have one bithermal heat exchanger made of high quality copper.

They are marked as follows: U054 - boilers with an open combustion chamber, with a chimney diameter of 131 mm, U052 - with a closed chamber, i.e. turbocharged boilers. If the article "K" is added to the designation, this is a double-circuit boiler or a combined one, if it is absent - a single-circuit boiler, only for heating.

3. Buderus Logamax U052 T / U054 T

The main distinguishing feature of these models is the presence in them of a storage boiler with a volume of 48 liters. It is used in houses with increased demand for hot water. They are produced with open and closed combustion chambers and with a power of 24 kW.

4. Boilers model Buderus Logamax U072 the most popular and budget. We will dwell on them in more detail.

Unlike the models described above, this series has a wide power range: 12 kW, 18 kW, as well as 24 kW and 35 kW. They are produced in two-circuit and single-circuit versions, and only turbocharged ones - with a closed combustion chamber.

Forced draft boilers can be used both for a coaxial chimney 60/100 mm and for a system of separate smoke exhaust and air intake 80/80 mm.

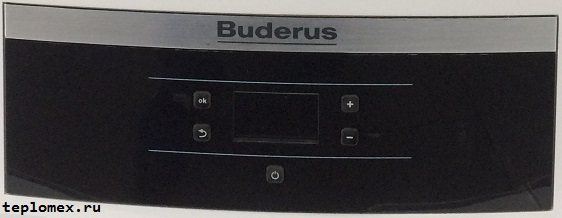

Boiler control panel "Logamax U072"

Double-circuit gas boilers Buderus Logamax U072K with a capacity of 24 kW will produce hot water of 11-12 l / min, with a capacity of 35 kW - up to 16 l / min. If this indicator is important to you, then you should buy a gas boiler with a minimum capacity of 24 kW. Boilers "Logamax U072-18" are intended more for heating a private house with a small area of up to 130-150 m2.

The main distinguishing feature is the presence of two separate heat exchangers in gas boilers of the U072K series:

- the main copper for heating the coolant in the heating system;

- secondary stainless steel for heating running water.

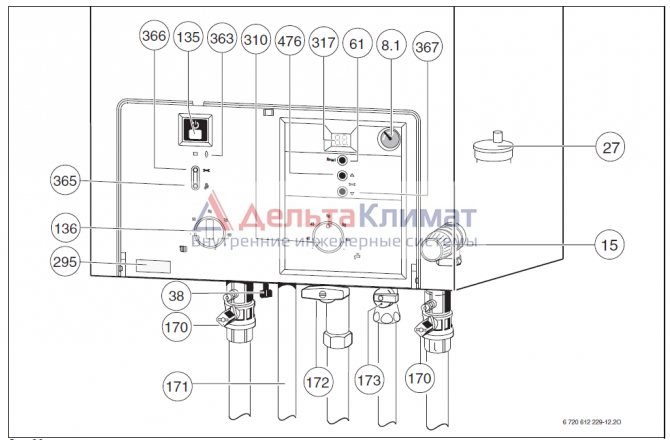

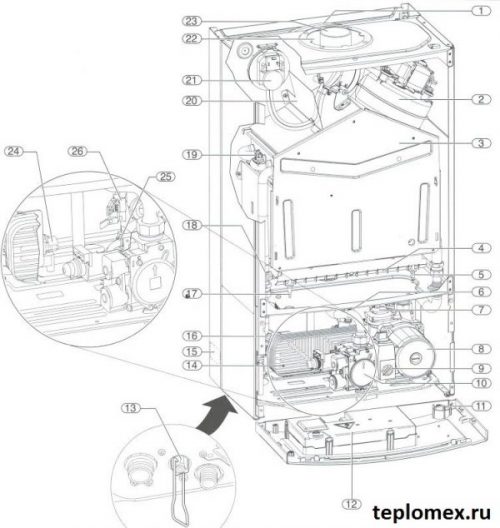

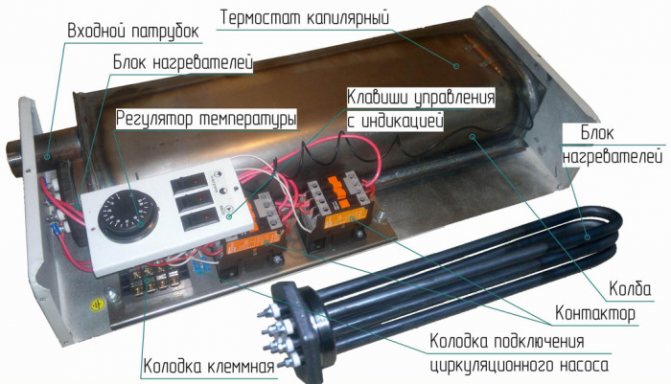

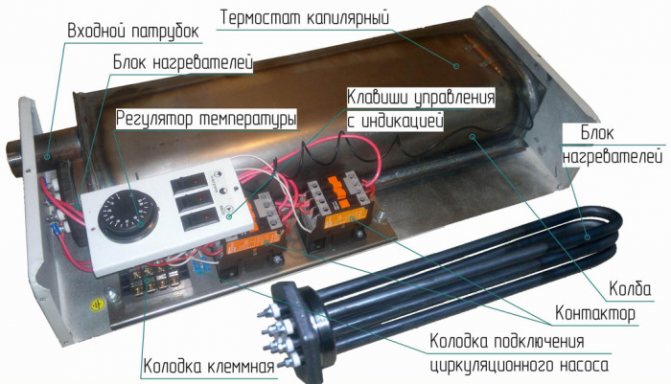

The device of a double-circuit gas boiler Buderus

The device of the gas boiler "Buderus Logamax U072-24K"

1 - expansion tank 2 - turbine 3 - bunker for combustion of exhaust gases 4 - atmospheric burner 5 - ignition electrode of a gas burner 6 - overpressure relief valve 7,8 - pump with automatic air vent 9 - pump speed switch 10 - gas supply 11 - pressure gauge 12 - boiler operation control panel 13 - boiler feed 14 - secondary heat exchanger 15 - serial number sticker 16 - pressure switch 17 - flame control sensor 18 - flow temperature sensor 19 - emergency heating circuit temperature sensor 20 - air baffle 21 - differential pressure switch 22 - air flow into the boiler 23 - exhaust gas emission 24 - hot water temperature sensor 25 - pressure relief valve in the hot water circuit 26 - hot water circuit flow meter

As in the Bosch gas boilers, they are equipped with: a circulation pump "Wilo», Expansion tank 8 l. (10 liter in a 35 kW boiler), boiler safety group. There is a system of "gas control" and self-diagnostics of the boiler, protection against overheating of the apparatus and freezing of the coolant, as well as protection against blocking of the pump.

The boiler burner ignition is electronic, operation is controlled using a multifunctional LCD display, which also displays errors under certain codes in case of malfunctions in the boiler.

For even more correct operation of the gas boiler, the company recommends buying a room thermostat "Buderus Open Therm», Which already has an integrated ambient temperature sensor. You can also connect a thermostat from other manufacturers.

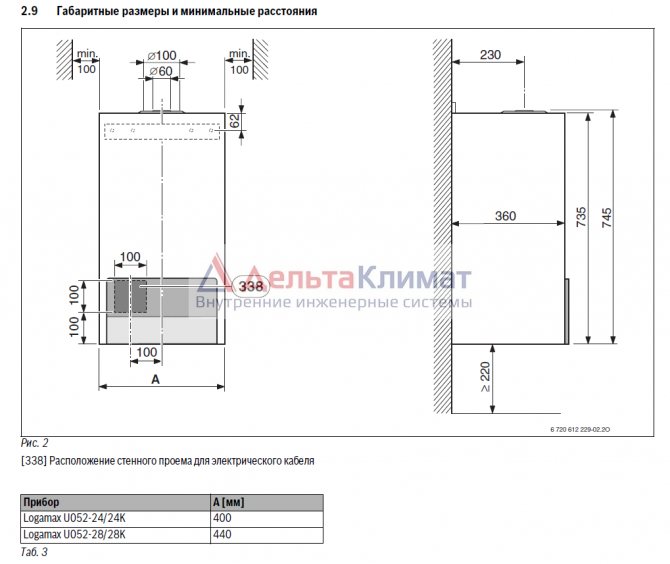

Buderus gas boilers are adapted to Russian frosts and are capable of operating on natural and liquefied gas, the diameter of the connection fittings: heating - 3/4, water - 1/2, gas - 3/4 inches. Thanks to their compact dimensions (700 x 400 x 300 mm), these boilers can fit well even in cramped kitchens.

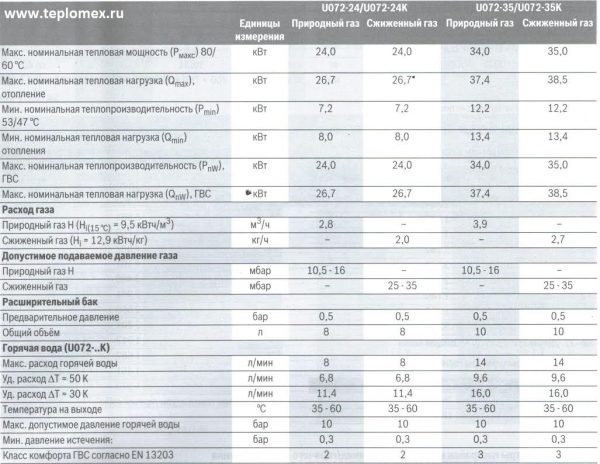

Technical characteristics of gas boilers Buderus

Technical characteristics of boilers Buderus Logamax U072

Advantages of Buderus wall-mounted gas boilers

- German brand; - low noise; - price from 30,000 rubles; - inexpensive spare parts.

Disadvantages of gas boilers Buderus

- not native components; - a small number of service centers; - Russian assembly.

Buderus gas boilers will undoubtedly find their buyer, mainly due to the promoted brand and low prices. Just imagine, a German boiler of the Logamax U072K series can be bought at a ridiculous price of 30-35 thousand rubles. But do not flatter yourself, because this equipment is not assembled in Germany and from components not of the highest quality.

Therefore, before you buy gas boiler Buderus, find out: what reviews these boilers have from specialist gas workers, is it easy to find spare parts in your city, and is there a service center that serves gas equipment of this brand. Watching video reviews.

Setting up the regulation of Buderus boilers

All heating units need regular balancing and regulation of parameters. In most cases, a full range of such works is performed during the maintenance of boilers. However, there are situations where unscheduled adjustments are required. For example, after an emergency stop, with a decrease in performance, with repeated errors issued by automation or after a system upgrade.

The specialists of our center are ready to carry out both a one-time adjustment of your heating unit and take it for long-term maintenance. We are authorized to work with the entire Buderus model range, and our craftsmen have all the necessary licenses and certificates.

Boiler regulation includes such measures as: warming up; chimney and safety automation; control and debugging of the ventilation system, fuel supply and power grid. We provide an official guarantee for all types of work.

For more information on all types of services provided by our center, you can call the 24-hour hotline or come to our office.

__________________________________________________________________________

Which boiler to install: selection criteria

In order not to be mistaken when selecting a unit for heating, experts recommend choosing a boiler according to the following parameters:

- The power of the device is the most important criterion. A weak boiler will not be able to effectively heat the house, and a too powerful boiler will work "idle" most of the time. Power is selected according to the heated area: for 10 m² - 1 kW of power.

- The next criterion is the type of fuel. The most accessible and cheapest energy carrier in the region should be chosen. Many models overcome this problem by running on most types of fuels.

- Heat exchanger material. Cast iron boilers have greater durability, are not subject to corrosion, retain temperature longer and are unpretentious in maintenance. Steel units have less weight and size, warm up faster, but are susceptible to condensation and, as a result, corrosion.

- The volume of the combustion chamber - the larger, the less often it is necessary to "look in" there, that is, to report fuel. Alternative - boilers with automatic fuel supply, which allows loading every 4–7 days.

Advice! Safety is also an important parameter. Therefore, you need to pay attention to the presence of automatic alarm and emergency shutdown in case of overheating.

Connecting the wall-mounted boiler to the mains

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which practically does not require the intervention of the owner. Obviously, the control unit and the various sensors require a mains connection.

Double-circuit wall-mounted boilers are available in two versions: with the usual socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then an individual outlet for a gas boiler should be located next to it, but not under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

Photo 3: Installing a voltage stabilizer for a wall-mounted boiler

A gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Boiler automation is very sensitive to the quality of the supply voltage. With an insufficient level or imperfect sinusoidal shape at the input, the devices quickly fail. To prevent frequent breakdowns and prolong the life of the unit, it is required to connect voltage stabilizers for gas boilers. To avoid stopping heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

Start-up and operating instructions

Before starting the boiler for the first time, it is necessary to install it on a wall or a ramp (supporting structure), connect all communications and power supply. These actions are performed only by specialists of the gas service or authorized technicians from the service center.

It is imperative to check the connections of gas pipes using soapy water.... The system is then filled with water based on the pressure reading on the display. It should not be brought to the limit values, it is enough to provide 0.8 bar.

When heated, the coolant will expand, due to which the pressure will rise and reach the optimal operating value.

The Buderus Logamax u072 24k boiler is started using the "Stand-by" button.

In this case, the display will show the current temperature of the coolant... At the first start, it is set to minimum, therefore, to start work, you must set the desired heating mode. The burner and circulation pump will start and the boiler will start operating.

The operation of the unit does not require any special action from the user.

The temperature is adjusted periodically according to weather or climatic conditions.

Once a year, it is necessary to call a master for maintenance, in the event of breakdowns, a specialist from the service center is also immediately invited.

Download instruction

Download instruction for gas boiler Buderus Logamax u072 24k.

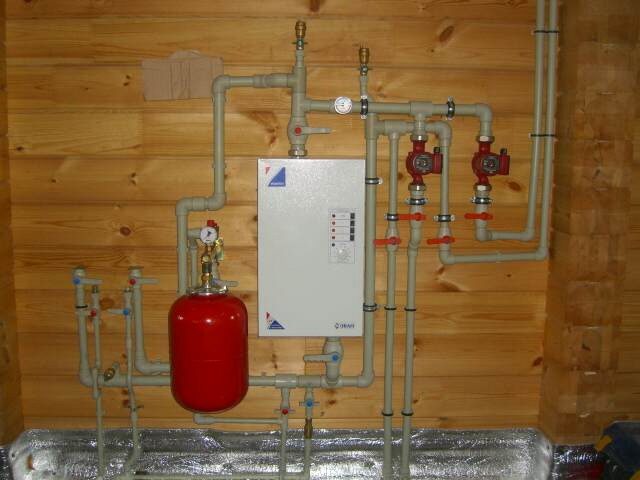

Choosing a chimney for a gas boiler

Any wall mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led out directly through the wall of the house.

Photo 4: Installing a coaxial chimney for a turbocharged boiler

In double-circuit boilers with an open combustion chamber, the combustion process takes place with the help of air from the room in which the heater is installed. Typically, such models are installed in specially equipped boiler rooms. For the removal of combustion products, they are connected to traditional ceramic or stainless steel flue gas boilers.

Wall mounted boilers with a closed combustion chamber (turbocharged) use outside air in their work. It is fed into the device through one of the channels of the coaxial chimney. The second channel is used to discharge flue gases into the atmosphere. The coaxial chimney is very easy to install and you can connect a gas boiler to it with your own hands.

Choice

Modern heating equipment can use natural gas, electricity or solid fuel for operation. Installation of heating boilers requires compliance with special requirements for installation and operation.

Gas boilers

Heating systems with gas units are popular for use in a private house. Natural gas is an inexpensive and efficient fuel. Of course, this is only possible for those regions where there are main gas pipelines and the supply of gas to the house does not cause any difficulties.

At the same time, we must not forget that gas is an environment of increased danger due to its explosiveness. When choosing gas installations, you need to remember the following differences:

- manufacturer and price segment;

- power consumption;

- number of contours - single-circuit and double-circuit models;

- type of installation (floor or wall);

- method of cleaning exhaust gases.

Wall mounted gas installations are very popular - they are easy to install and small in size.

The complete set of such a unit includes a burner, an expansion tank, a circulation pump (one or more), a pressure gauge and a thermometer, a heat exchanger, an exhaust gas discharge circuit (natural or forced). For safety, the equipment is equipped with special sensors.

Electric boilers

Its main advantage of these compact boilers against units operating on a different type of fuel is the complete absence of waste during operation (including the absence of combustion products). It is considered to be the most environmentally friendly (and aesthetically pleasing) type of heating in a private house. But, along with this, perhaps the most expensive. Boilers can be installed on the floor or on the wall. Depending on the type of heating, such installations are:

The design of heating elements boilers is quite simple. Several heating elements are placed in a container with distilled water or an antifreeze liquid based on ethylene glycol. Depending on the set heating temperature, either all heating elements work, or only some of them. This design is very primitive and somewhat obsolete.

The principle of operation of an induction boiler is based on electromagnetic induction. Simply put, a core is placed in a dielectric pipe, the heating of which occurs from the action of the current of an electric coil around the pipe. At the same time, the core heats the water that flows through the pipe.

The design is simple, and thanks to this, even very powerful installations are small in size.

In the principle of operation of the electrode unit, the law of physics is used, based on the heating of water due to resistance when an electric current is passed through it. In this case, the water must have a special concentration of salts. These devices are safer than the previous two, since when water leaks from the heating tank, the unit automatically stops working.

Solid fuel boilers

Now this equipment is used for heating houses where there is no possibility of heating with natural gas. Such boilers run on various types of solid fuel, but the main type is traditionally firewood. Heating equipment of this type is very similar to a stove, but at the same time it meets all safety standards and modern quality requirements for similar installations.

Boilers are designed with a combustion chamber, heat exchanger, feed hopper, chimney, nozzles, control unit and hot gas removal chamber. Boilers are installed only on the foundation. They have a fairly large overall dimensions and weight.

The main stages of setting up Buderus boilers

- Checking and adjusting automation.

This includes not only diagnostics of the operation of the control system, but also of various sensors, including for weather-dependent operation. - Burner adjustment.

Our craftsmen will not only carry out all the necessary work, but also check the correct selection of the burner for your type of boiler. With the help of special equipment, specialists will adjust the air and fuel supply for optimal combustion. - Balancing hydraulics.

Correct operation of pressure transducers, pump, valves and auxiliary fittings will maximize efficient and safe operation.

Commissioning of boilers by qualified specialists will ensure the correct and safe operation of the entire heating system. The complex of works includes pressure testing during the delivery of the heating unit in separate sections; filling the heating system; tightness control; checking the position of the flue gas baffle plates (not on all models); switching on the burner and control system; flue gas temperature control; checking the flue gas discharge system; control of operation in all modes.

Major error codes

Consider the designation and interpretation of the most common errors:

| The code | Decoding | Ways to fix the problem |

| H11 | Problems with the DHW temperature sensor | Check the contacts and the sensor itself for operability, if necessary, replace |

| 2P | Overheating of the coolant | Check the contacts and the general performance of the circulation pump |

| 3A | Stopping the fan | Check contacts, replace the fan with a new one |

| 4C | Overheating of the heat exchanger | Stop the boiler, call the master |

| 4U, 4Y | Short circuit or breakage of the flow temperature sensor | Check the condition of the sensor and contacts, if necessary, replace it |

| 6A | There is no flame | Check the presence of gas in the system and in the boiler equipment, call specialists |

| 3C, 3L, 3P, 3Y | Fan failure | Check connection and functionality, replace |

| 6C | The system sees a flame on an inoperative burner | Moisture on pins or control board, poor grounding contact |

Connecting a wall-mounted boiler Buderus

The peculiarity of wall-mounted boilers is that it is, as they say, a miniature boiler room. The boiler itself and the DHW circuit, sometimes together with a small storage tank, and a circulation pump and, of course, control automation are enclosed inside one housing. Sometimes a small expansion tank is also placed inside. Naturally, all these units are combined and connected to each other already at the factory. But nevertheless, the boiler itself still needs to be correctly and reliably connected to the gas, chimney and nozzles of the heating and hot water circuits. All connection operations are described in the installation instructions, and theoretically can be performed independently with the necessary skill. But do not forget that during the initial connection and commissioning, you will still need to have a contract with a certified installer on hand.

When replacing a wall-mounted boiler, which at first glance is quite simple, it is also worth remembering that the boiler is equipment of increased danger, and its poor-quality connection can lead not only to failure, but also to much more sad consequences.

Any questions about connecting gas boilers are best left to professionals. There is an unimaginable number of subtleties, which, by the way, are well known to our specialists both theoretically and practically, and if you do not want to face unforeseen heating accidents, we recommend contacting.

The efficiency and safety of the gas boiler operation largely depends on its correct connection to the heating system. This process, also called strapping, consists of several stages. Due to the fact that gas is a very dangerous fuel, some work must be carried out by certified employees of gas services, but a lot can be done with your own hands.

Connecting a wall-mounted gas boiler is a set of works that includes: piping in the heating system, connecting to a gas and electrical network, installing a chimney. In this article we will try to cover each of the stages.

Diy wiring diagram - if you are confident in the strength

The installation of boilers is divided into several stages. First of all, you need to decide on the installation site. Next, you need to install the brackets for the boiler. It is different for each type. Installing a bracket for a boiler is not a difficult process in itself - at this stage, the main thing is to correctly mark and calculate the system for supplying and connecting pipes, as well as taking into account the dimensions of your boiler in the room. The next step is to connect the heating system of your home and loop the pipes with the boiler circuit according to the connection diagram.

The last stage, which is relevant only for the installation of gas and solid fuel boilers, is the supply to the chimney system. Well, and, of course, checking the heating system after all types of work. Now in more detail. After marking and fixing the boiler, we proceed to determining the location of the chimney. If you don't have a chimney system in your house, then you will have to punch a hole in the ceiling and install it. In houses with ready-made chimneys, you need to make a breakdown in the wall, such systems are usually called turbocharged. The most reliable chimney system is the so-called "pipe in pipe".

Particular attention should be paid to the angle of inclination of the pipe. If it is placed incorrectly, then condensation may form in it, which, if it enters the boiler, can lead to the failure of the entire unit. If your chimney system is in an overlap, then a special condensate drain must be provided for it. This process is laborious, but it will save you from possible breakdowns.

The heating boiler connection diagram is described in detail in the installation instructions, and in the process of operation it is necessary to follow all the points. Even if this is not indicated in the wiring diagram, it is imperative to install water filters in the boiler pipeline circuit. This is especially true for an electric boiler, since the presence of filters significantly prolongs the operation of the heating elements. The filters also prevent various materials from contaminating the pipes.

When connecting a gas boiler, it is imperative to install a shut-off valve, with which you can block gas access to the installation if you need to leave the house for a long time. After it there should be a gas filter, the installation of which is required by all authorities. All gas pipe connections must be carefully soldered. Regular tapes and other materials used for other pipe connections will not work.

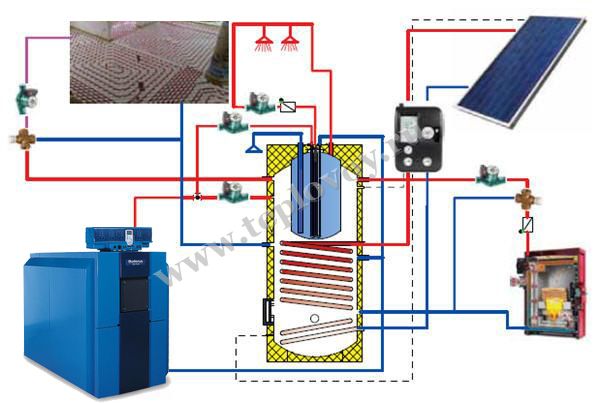

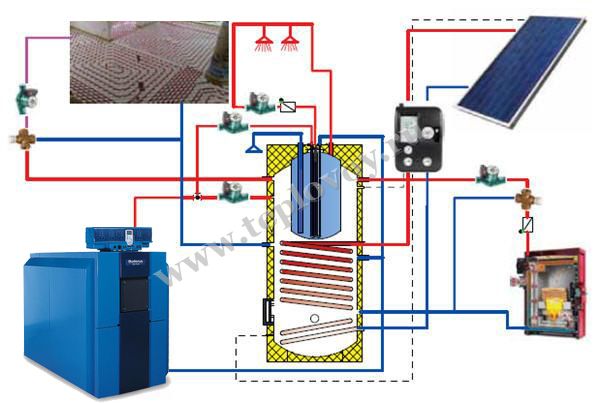

Boiler connection diagrams Buderus

There are standard classic schemes illustrated in the installation instructions for Buderus boilers of a particular series.However, in practice, almost always, the schemes undergo changes to optimize the wiring, fit the geometry of the furnace room and the relative position of individual units of the heating system.

The heating systems of country houses, although similar to each other, are only in general terms. In reality, however diverse the areas and layouts of buildings are, their heating systems are just as different. Departure from standard schemes can also be caused by:

- connecting the pool heating heat exchanger,

- placing a volumetric buffer tank to which you plan to connect alternative heat sources: solar collectors, a solid fuel boiler or a fireplace insert with a water circuit.

Complications of the circuit cannot be avoided also when implementing the connection diagram for Buderus cascade boilers, when the system is designed to use several gas boilers working together or alternately. A modern approach to the construction of such systems is the use of special units - hydraulic switches that ensure the equalization of temperatures and pressure of the coolant in several circuits connected to it.

How to set up correctly

The operating mode of the Buderus Logamax u072 24k boiler is configured using the control elements located on the control panel. The current values are indicated on the display, the user is only required to turn on the setting mode for one or another parameter and set the required DHW or heating medium temperature.

Also, in accordance with the external conditions, a transition is made to the summer or winter mode of the boiler operation (the heating circuit is turned off or activated). If an error occurs, you can reset it by pressing and holding the Reset button for 5 seconds.

IMPORTANT!

More complex settings related to gas or water pressure limits are performed by a service technician. Independent intervention in the operation of the system is fraught with the failure of important components of the boiler.

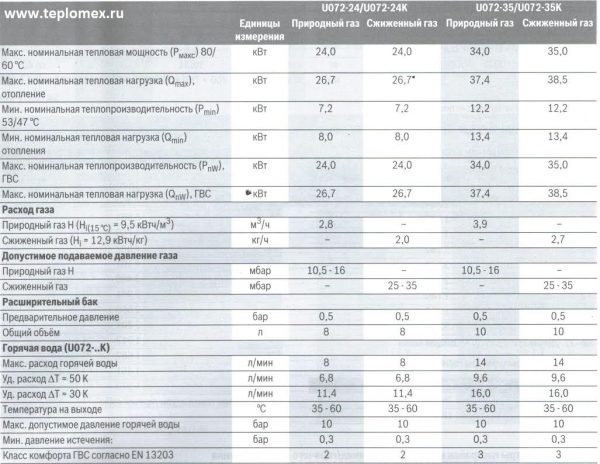

Electric boiler piping diagram

The piping system of an electric boiler almost completely coincides with the piping of a gas one. Electric boilers are not equipped with five pipes, as the fifth is usually a gas pipe.

The minus of an electric boiler is completely dependent on the stability of the electricity supply. If the lights are turned off, the room will become very cold. Interruptions in voltage can affect malfunctions of the boiler itself. Even if it has overvoltage protection, even the strongest protection can give unexpected failures.

Major malfunctions

The design of Buderus boilers has been created on the basis of the most advanced technical developments.

They are stable in operation, but insurance has not yet been invented against the occurrence of malfunctions.... Buderus boilers are equipped with a self-diagnosis system, which is a network of sensors connected to the most important and critical components or parts of the boiler.

The operation of all elements in a continuous mode is controlled by these sensors, if any inconsistencies or changes in the normal mode occur, an alphanumeric code of one or another error appears on the display. In addition, other malfunctions are possible.

Let's consider the most common:

- The burner does not ignite. The reasons for this may be disconnected starters of heating or control systems, failure of circuit breakers, failure of the regulator or boiler temperature limiter. The boiler may be blocked due to problems with the flue gas control equipment.

- The burner turns on, but immediately gives an error. Most often, the problem is a closed gas valve, or the presence of air in the gas pipeline. In both cases, open the valve and release the air.

- After the start of the burner, a signal appears that there is no ionisation current. Usually the problems are oxidation of the contacts or mixed connection of the "N" and "L" electrodes.It is also possible for the ionization electrode to close to the body or breakdown of the burner control unit.

- After ignition, the burner generates an error - the current is less than 1.5 mA. This may be due to oxidation or the formation of soot on the ionisation electrode, which should be cleaned.

- Boiling sounds are heard from the heat exchanger. This is a sign of a thick layer of limescale, or an insufficient amount of coolant in the system.