Home / Gas boilers

Back to

Published: 22.06.2019

Reading time: 4 minutes

0

807

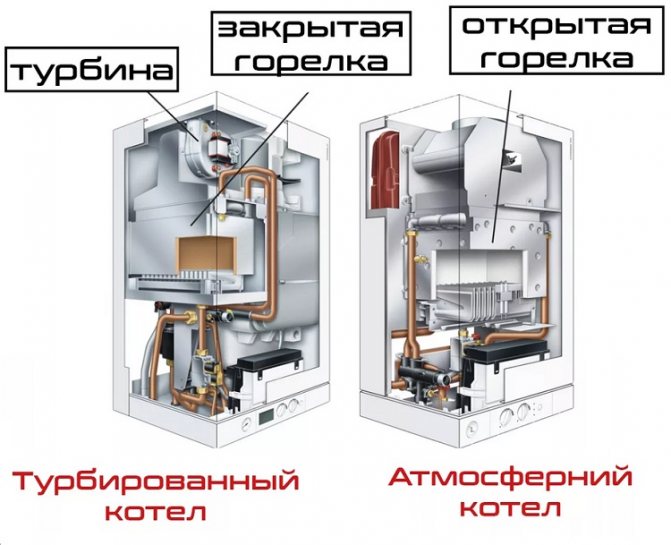

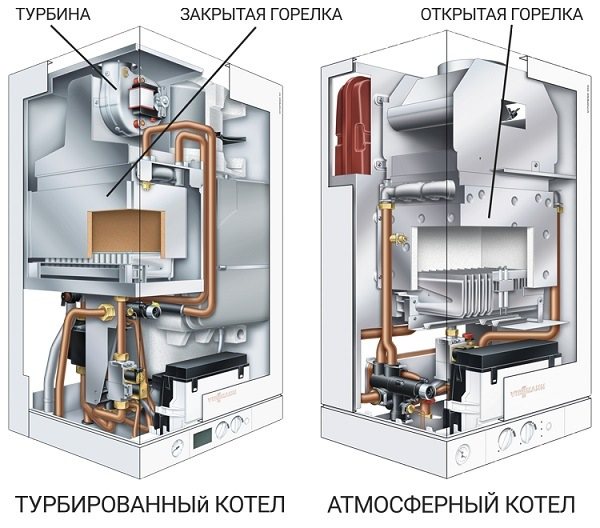

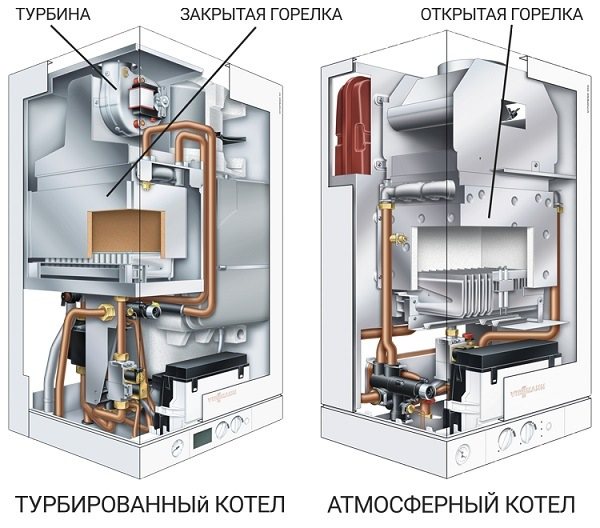

A turbocharged boiler by its design differs from the atmospheric one in the way that air is supplied to the burner and the combustion products are removed. They can be placed on the floor and on the wall, there are single and double-circuit gas turbine boilers.

- 1 The principle of operation of a turbocharged boiler

- 2 Advantages of turbo boilers

- 3 Disadvantages

- 4 Turbocharged or naturally aspirated?

- 5 Floor standing turbocharged boilers

- 6 Wall mounted turbo boilers

- 7 Best manufacturers of turbocharged boilers

- 8 Installation rules

The principle of operation of a turbocharged boiler

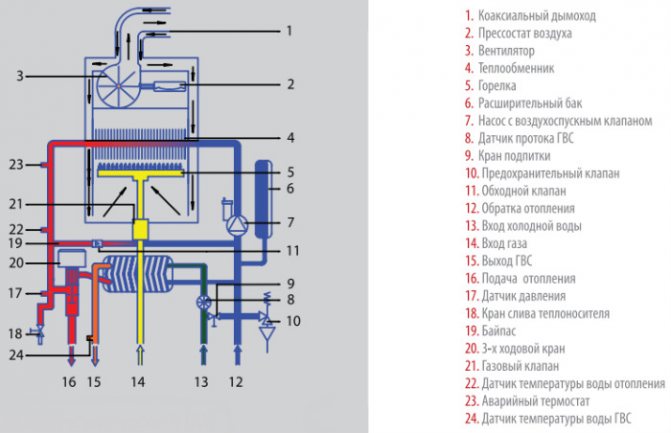

The name "turbocharged" means that the boiler has a turbine, that is, a fan that supplies air, maintains combustion and removes combustion products. The design assumes a closed type of combustion and a smoke exhaust system with several turns.

When the fuel burns, a certain amount of heated gases is released. To increase efficiency through increased heat transfer, the design provides for the passage of these gases through the channels where they give off their heat, increasing the efficiency. Thus, it is possible to reduce the temperature of the exhaust gases to 100-120 ° C. To understand how a turbocharged gas boiler works, you need to understand how equipment with a closed combustion type works.

Such units are connected to a coaxial chimney or to a pipe-in-pipe system: the inner pipe is used to remove gases, and the annular space is used to supply outdoor air. In equipment of this type, air circulation and smoke removal is carried out using a fan, the intensity of which depends on the gas pressure. It is connected to automation.

When the gas pressure changes in the system, the automation sends a signal to change the rotation speed. However, it should be understood that the system is characterized by noise and in order to reduce its level, at the beginning of the boiler operation, you need to set the minimum mode. The control of the turbine operating mode makes it possible to regulate the degree of heating.

Overview of turbocharged gas boilers

For heating small apartments and offices, a turbocharged gas boiler will be the best choice. It is safe, easy to operate, and reliable. Stably provides consumers with heated water in the volume they need.

Its advantages over atmospheric:

- if the power is up to 60 kW, the place of installation does not matter;

- no air is taken from the premises for combustion;

- combustion products are removed by means of a fan to the street through a chimney;

- high efficiency allows you to use less fuel.

Turbine boilers are completely safe and can be installed in any room.

A closed gas boiler burner is much safer than an open version. During its operation, the products of processing of gaseous fuels do not enter the premises. Oxygen is not burned out

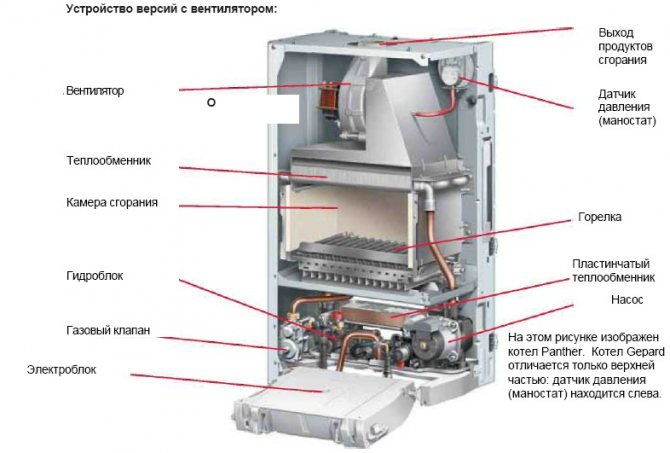

Design and features of operation

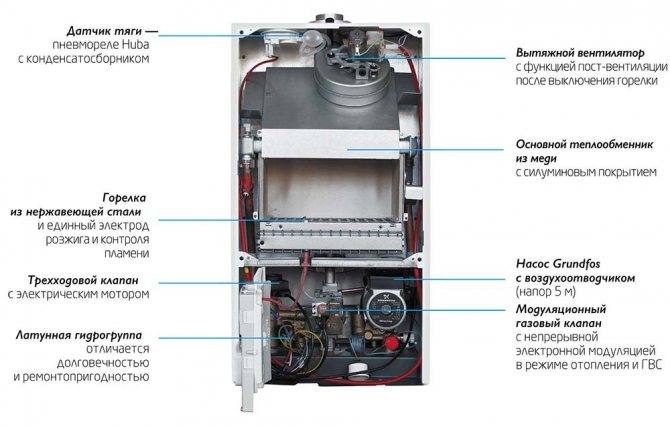

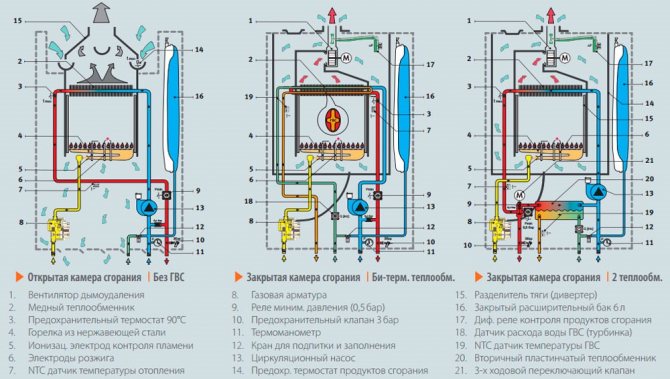

The main structural components of a boiler with a closed burner version:

- gas-burner;

- fan;

- DHW heat exchanger;

- built-in expansion tank;

- heating heat exchanger;

- circulation pump;

- temperature sensors;

- gas valve;

- security systems;

- coaxial chimney;

- electronic control unit.

The installation of such a boiler should be carried out on the outer wall of the house or near the ventilation shaft. Despite the fact that the cost of the turbocharged model is higher than the atmospheric one, you can save on the equipment of the boiler room and the device of the traditional chimney.

Most double-circuit units stop heating the room when hot water is supplied. Contrary to the opinion of the majority, the coolant does not have time to cool down and the temperature in the apartment remains.

The turbocharged boilers are equipped with the "Summer" mode. In this case, hot water is supplied independently from the heating system - this is a strong argument in favor of purchasing a model with a closed burner.

The advantages of turbocharged boilers:

- air intake for heating is made not from the room, but from the street:

- sealed combustion chamber;

- no need to install a chimney;

- there is no need to build a boiler room (installation can be carried out in any room);

- compact size;

- high efficiency and low energy consumption;

- high productivity (on average, 10 liters of water are heated per minute);

- automated work and electronic control system;

- high security;

- ease of use.

Disadvantages include the high cost of equipment and parts for repairs and dependence on electricity supplies.

Closed burner models

A single-circuit boiler is used to supply heated water to the heating radiators. In dual-circuit models, a second heating circuit is provided for the preparation of hot water. A boiler with a capacity of over 20 kW will allow you to heat the room and heat the water.

However, a floor-standing unit of low power, then it should not be "overloaded". It is better to heat water with a gas water heater. According to the standards, it is allowed to install two separate boilers in one boiler room: wall-mounted and floor-standing. One of them will supply sanitary water, and the second will supply heat carrier.

Double-circuit models are divided into boilers with a bithermic heat exchanger and a separate one. The first is used for heating and hot water supply. Its disadvantage is sensitivity to bad water. Scale builds up on it quickly and performance decreases.

It is recommended to use limescale powder during operation. A separate heat exchanger performs the same functions as a bithermal one, but is less sensitive to water.

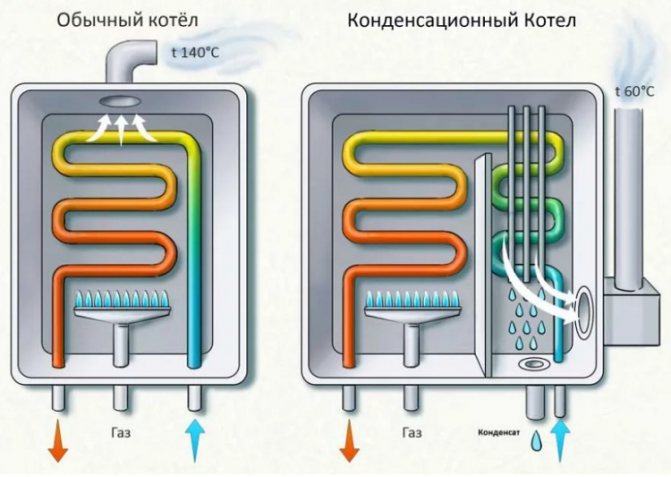

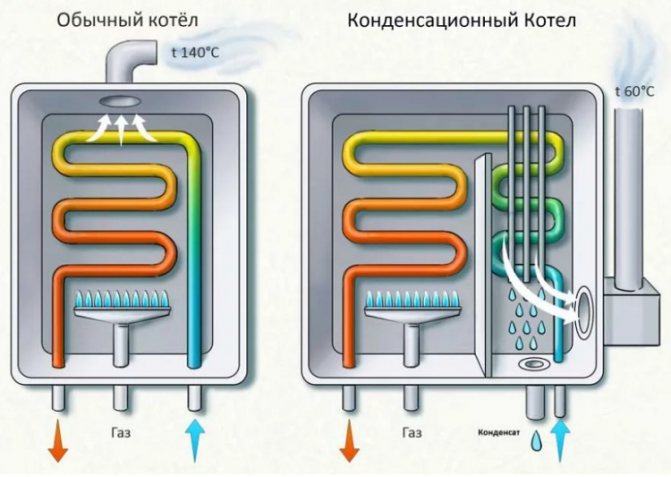

The high efficiency of condensing boilers is due to the reasonable use of condensate, the heat of which is transferred to the heating circuit

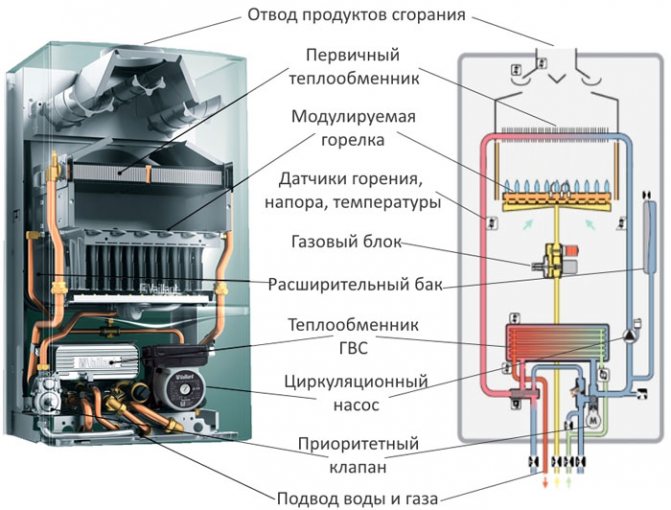

Condensing boilers, in addition to the usual heat generation, additionally use the energy released during the operation of the equipment during condensation of water vapor. In fact, these models collect condensate in order to give its heat to heating devices. Such boilers can save up to 17% of gas, and their efficiency reaches 108%.

You will say that the efficiency of any type of heating equipment cannot exceed 100%? Maybe this is confirmed by condensation models. They partially use the energy released during the combustion of one portion of fuel twice.

Condensing boilers have two heat exchangers. One of them heats water or coolant, the second collects and prepares condensate for subsequent use

Overview of atmospheric gas boilers

Main characteristics of atmospheric gas boilers:

- power - from 20 to 60 kW;

- large dimensions and weight;

- productivity - up to 30 l / min;

- the average efficiency factor is 79-92%;

- electronic control panel.

This model is equipped with an open combustion chamber. Oxygen is taken from the room where the equipment is located, and the combustion products are removed through the chimney. A leak in the combustion chamber leads to the fact that some of the gases enter the environment and can cause poisoning.

Gas boiler equipment with an open burner is categorically not suitable for installation in residential premises. Even with a flawlessly functioning chimney system, the risk of toxins entering the air mass cannot be ruled out.

Therefore, a special room with good ventilation is equipped for atmospheric boilers.

Choosing a place for installation:

- the structure is installed in a technical building;

- for powerful and dimensional models, a building with a foundation is required;

- to ensure sufficient draft, a close location of the chimney with a minimum bend is necessary;

- it is important to provide communications for the output of the coaxial chimney.

The operation of an atmospheric boiler is based on heating the material of the heat exchanger with a gas burner, which then transfers the received energy to the heat carrier or water prepared for use.

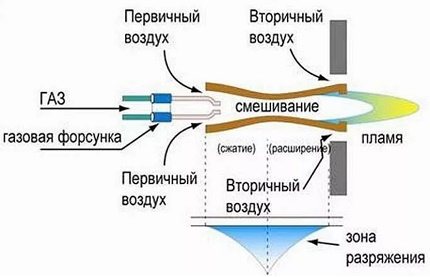

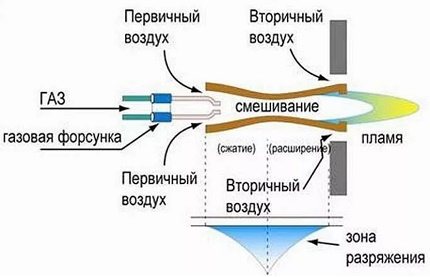

Burner design:

- nozzle;

- head;

- air regulator;

- ejection tube.

With a partial part of the gas comes directly, and the other part with air. At full - before entering the combustion chamber, the gas is completely mixed with air. There are no fully mixed models in the CIS countries.

Gas boiler burner and the principle of its operation. Before the air hits the nozzles, it mixes with the gas. Mixing can be complete or partial

The burners are available in one and two stages, with smooth switching of the fuel feed rate and modulating. The savings in consumption depend on the complexity of the design. Some models allow the use of diesel fuel. But the price for such boilers is much higher.

The burners are supplied with CO2 and flame sensors. If the draft is insufficient, the flame can go out, which will lead to gas contamination of the room. A similar problem is observed with home-made structures that are converted from solid fuel boilers.

Advantages of atmospheric gas boilers:

- stable operation even with an insignificant gas pressure (fate follows that in this case the fuel supply elements fail faster);

- for efficient combustion of the mixture, additional air supply is not required;

- silent work;

- ease of use.

There are also significant disadvantages. The most important is the possibility of carbon monoxide leakage and fire. Therefore, boiler equipment with an open type of gas burner requires a separate room (it is impossible to install it in apartments).

Types of atmospheric gas boilers

Heating equipment differs among themselves:

- dimensions plus weight directly related to dimensions;

- power;

- Efficiency.

The maximum power of wall-mounted models of atmospheric boilers is 36 kW. This indicator is due to the design features.

To select the optimal power, you should take into account the area of the room and the factors of possible heat loss (windows, cold floors and walls). It is recommended to choose a boiler that is capable of heating the area 25% more than the actual one.

The power of the boiler is selected so that for every 100 square meters there is at least 10 kW plus 25% of the result obtained

In addition to power, when choosing a boiler, you should pay attention to efficiency. This indicator shows how much energy is required to heat water, and how much burns out. Average rates for atmospheric boilers are 80-90%. More expensive models provide the maximum effect - up to 97%.

In condensing boilers, the efficiency is 100%. The fact is that the exhaust gas heats up to 110 ° C. In turbocharged units, this figure is at 55 ° C. In condensation rooms - 30 ° С.

Advantages of turbo boilers

The use of turbocharged gas boilers is associated with both positive and negative aspects.

The advantages of the equipment include:

- easy installation in any convenient place;

- air intake from the street, which does not affect the violation of the indoor climate;

- the presence of a modulation burner device adapted to operate at low fuel pressure;

- transition to liquefied gas is possible;

- the presence of automation that regulates the combustion mode depending on the weather;

- smoke exhaust without the likelihood of harmful gases entering the home.

In general, turbocharged gas installations have no analogues in terms of economy and efficiency.

How to choose?

Today, there are many manufacturers of double-circuit turbocharged gas boilers on the heating equipment market. To select a specific model, you need to decide on the power of the boiler. The average figure is 1 kW for every 10 m² (with a ceiling height of up to 3 m). Based on this indicator, you can select a boiler of the required power.

Connection to the gas pipeline and commissioning must be carried out by gas service specialists.

Floor devices

Floor standing turbo boilers have high performance and are suitable for heating a large private house. The high power (up to 100 kW) of such equipment allows you to heat private houses with "old" heating systems with cast iron radiators, in which a large volume of coolant circulates.

Wall mounted turbocharged gas boilers

Double-circuit wall-mounted gas turbo boilers are more compact in size, which allows them to be installed directly in the kitchen or dining room. They do not have such a high power (up to 50 kW) as their floor-standing assemblies, however, under certain circumstances, they can be more economical.

Savings are possible provided that a wall-mounted gas boiler with a closed combustion chamber is installed in modern facilities with good insulation (when the heat loss of the building is minimized), and a small volume of coolant circulates in the heating circuit (the smaller the volume of the coolant, the less fuel is required to heat it).

disadvantages

Among the disadvantages of turbocharged gas boilers are:

- use of electricity. Boiler automation and turbine depend on electricity;

- with regular power surges in the network, the automation may fail;

- condensation is present. Since the temperature of the flue gases does not exceed 120 ° C, condensation forms in coaxial chimneys, which can block the duct when freezing.

To solve the latter problem, the chimney is usually insulated and a condensate collector is installed.

TOP 5 leading brands

Wolf

Wolf is a leading German manufacturer offering customers the best gas-fired heating boilers. The products of this brand are equipped with control systems that allow you to choose the optimal operating modes. Gas fired boilers are tested and certified in accordance with common European directives. Wolf CGB boilers are in stable demand. They operate on natural / liquefied gas and are used for efficient heating and hot water supply of large country houses, buildings for several families.

Wolf CGB condensing boilers are equipped with a closed combustion chamber. During the operation of the units, air is supplied from the room or from the atmosphere

Baxi

Baxi is an Italian company that produces units that combine excellent performance and functionality. For example, "Baxi MAIN Four" is the fourth generation of wall-mounted units with display, electronic ignition, bithermal heat exchanger. "Baxi Nuvola Duo-tec" - wall-mounted single-circuit boilers with a modulating burner and stainless steel heat exchanger. They are equipped with an energy-saving circulation pump and an automatic air vent. The manufacturer has implemented an innovative control system, thanks to which the consumer can adjust the boiler operation to the type and quality of gas.

Gas boilers "Baxi MAIN Four" are installed in limited space and have an elegant design

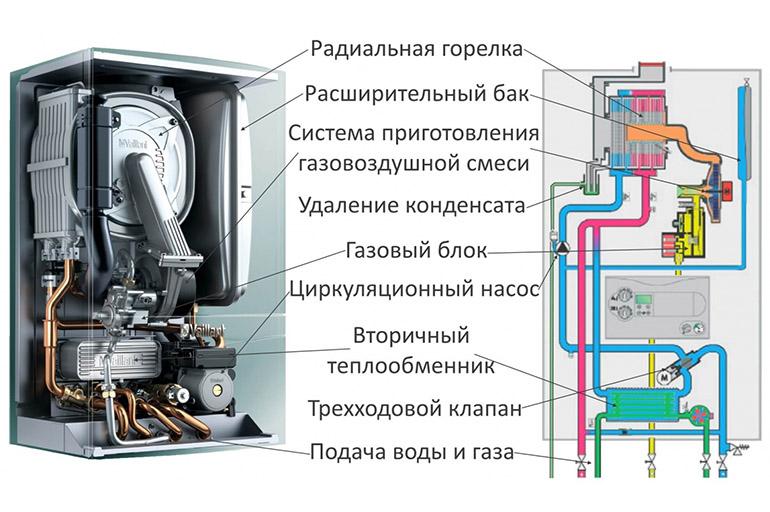

Vaillant

"Vaillant" - a model line from a German brand includes conventional, condensing, single-circuit units and gas heating boilers with a hot water heater. The equipment from a well-known company has a high efficiency and is equipped with built-in circulation pumps. Vaillant turboTEC PLUS VU boilers are prominent representatives of the model line.They are equipped with a closed expansion vessel, an automatic air vent, a safety valve, a copper primary heat exchanger and a chrome-nickel steel burner.

The wall-mounted boiler "Vaillant turboTEC PLUS VU" is equipped with an LCD display with large buttons and backlight

Dakon

"Dakon" - with the help of gas boilers for heating from a Czech manufacturer, you can economically solve problems with heating a house and providing hot water. For example, the DAKON GL Eko cast iron gas heating boilers equipped with an atmospheric ejection burner, Honeywell electronics, and a draft interrupter are in good demand. They are equipped with control units, to the outputs of which additional elements are connected: room thermostats, anti-freezing devices, external sensors.

Wall-mounted DAKON gas boilers are equipped with a bithermic heat exchanger and an anti-limestone system

Navien

"Navien" - Korean-made units with excellent technical performance. They have been in operation for a long period, work stably at low pressure, and have minimal dimensions. Double-circuit wall-mounted boilers "Navien Ace ATMO" with a natural system for removing combustion products are in great demand. Such units are equipped with automation, which turns on the pump when the temperature drops below 10 degrees. The developers took into account the possibility of the device functioning under conditions of frequent voltage drops. Therefore, the boilers are equipped with a special chip that is triggered when the voltage in the network changes.

"Navien Ace ATMO" - demanded heating equipment equipped with separate heat exchangers

Each buyer can independently select a unit that meets individual needs and financial capabilities. But the installation of gas heating boilers must be trusted by professionals, because the safety of using the device depends on the literacy of actions.

Turbocharged or naturally aspirated?

When the buyer is faced with the choice of which boiler is better to choose: turbocharged or atmospheric, all the features of their design and operation should be considered. The main difference is that in an atmospheric boiler, the process of fuel combustion occurs in an open manner with natural air exchange, therefore such equipment is often called convection. Such boilers are connected to a standard chimney, and air for the combustion process is taken from the boiler room.

When using atmospheric boilers, there is an increased gas consumption and strict installation requirements, regulated by SNiP. Also, atmospheric equipment must not be used in multi-storey buildings and during installation, the cabinet must not be covered with decor. In a turbocharged boiler, the combustion chamber is closed. Forced air exchange and flue gas removal by means of a turbine are applied. During operation, the air from the furnace is not used for fuel combustion.

Therefore, the norms are allowed to install such equipment in small rooms, decorating the case, near the counter. Turbocharged gas boilers are connected to a coaxial chimney, which serves both for the intake of outside air and for the removal of combustion products.

Therefore, the main difference in comparison with atmospheric boilers is forced air exchange and smoke removal.

Features of choosing an installation site for a gas atmospheric boiler and its operation

To understand which boiler is better atmospheric or turbocharged, to use for a specific heating system, you need to understand some of the design features and the principle of operation of the devices.

An atmospheric gas boiler by its type can be wall-mounted or floor-standing, as well as single-circuit, intended only for working with a home heating system, or double-circuit (with an additional coil) - for heating water.

In such a boiler, an open-type combustion chamber is installed, that is, air is drawn in directly, in a natural way. It is because of this feature that atmospheric installations are located in special rooms-boiler rooms, which, as a rule, do not present a particular problem to equip in a private country house. But in the event that a gas boiler is planned to be installed in an apartment, then this factor becomes not only a disadvantage, but also an obstacle.

In addition, for the removal of combustion products, a traditional chimney with access to the roof of the building is required, which, again, is quite feasible in a private house, but difficult in an apartment building. Exceptions can be apartments of an old building with already existing chimneys, which nevertheless need to be modernized over the years, but the percentage of such houses is small. In the event that it is planned to install an atmospheric boiler in a country house, then in addition to the boiler room equipment, it will be necessary at the initial stage of construction to design and arrange a chimney taking into account all the rules and regulations. It is imperative that an effective ventilation system should be equipped in the combustion room, which will ensure the flow of oxygen necessary for the combustion process.

Floor standing turbo boilers

Floor standing turbo boilers generally have high power and are reliable in operation.

When choosing a floor-standing option, the following characteristics should be analyzed:

- heat exchanger material (cast iron or steel). Cast iron is more reliable and durable (up to 35 years), but steel is cheaper;

- number of circuits: can be single-circuit and double-circuit. Some models have a built-in container for preparing hot water. If there is no need for DHW, then a single-circuit floor boiler can be used, which copes well with heating large rooms, since there is no energy consumption for DHW.

The disadvantage of floor-standing turbocharged boilers is the size. This is important when placing it in a small area. The advantage is reliability, all units and parts of the boiler are made of durable materials due to the absence of weight restrictions. Such boilers are used for about 5 years longer than wall-mounted ones.

Rating of the best models

The highest mark, due to the optimal combination of cost and quality, was given to 7 turbocharged boilers of domestic and foreign manufacture.

BaltGaz Turbo E 14

Specifications:

- power: 14 kW;

- Efficiency: 92.5%;

- hot water capacity: 11.5 l / min. At dt = 25 ° C;

- fuel consumption at maximum power: 1.2 cu. m / h;

- functionality: 2-circuit;

- installation method: wall-mounted;

- burner type: modulated;

- heat exchanger material: copper;

- manufacturer: Russia.

The complete set of the device is complete. There is a circulation pump, there is a possibility of programming with a period of 1 week, work with reduced fuel consumption, frost protection, “warm floor” mode. Additionally, you can order a remote control.

Neva Lux 8224-1 Turbo

Specifications:

- power: 24 kW;

- Efficiency: 92.5%;

- fuel consumption when operating with nominal heat transfer: 2.62 cu. m / h;

- functionality: 1-circuit;

- modulated burner;

- heat exchanger material: copper;

- installation method: wall-mounted;

- manufacturer: Russia.

The boiler has a long service life thanks to the liquid cooling of the combustion chamber. The manufacturer periodically organizes skype conferences called "Quality Day". The user can online ask questions to the engineers of the plant that produced the equipment.

Baxi Eco-4S 24F

Specifications:

- power: 24 kW;

- functionality: 2-circuit;

- Efficiency: 92.9%;

- energy consumption in nominal mode: 2.54 cubic meters m / h;

- hot water capacity: 13.7 l / min .;

- primary heat exchanger material: copper;

- manufacturer: Italy.

The boiler is focused on Russian conditions: it remains operational at low pressure of the energy carrier, the electronics are resistant to voltage drops.

Vaillant TurboTEC Pro VUW 242 / 5-3

Specifications:

- power: 24 kW;

- functionality: 2-circuit;

- Efficiency: 91%;

- gas consumption during operation in nominal mode: 2.8 cu. m / h;

- hot water capacity: 11.5 l / min;

- primary heat exchanger material: copper;

- burner type: modulated;

- manufacturer: Germany.

In addition to good performance and high quality, the attractive design of this model is noted.

Viessmann Vitopend 100-W A1HB001

Specifications:

- power: 24 kW;

- functionality: 1-circuit;

- Efficiency: 91%;

- gas consumption when working with nominal heat transfer: 2.77 cubic meters m / h;

- manufacturer: Germany.

As with all previous models, a programming function is provided.

A drawback is noticed: when the frost is below -17 ° C, the chimney freezes and the device turns off. Insulation required.

Buderus Logamax U072-24

Specifications:

- power: 24 kW;

- Efficiency: 92%;

- gas consumption when working with nominal heat transfer: 2.8 cu. m / h;

- primary heat exchanger material: copper;

- burner type: modulated;

- manufacturer: Germany.

The boiler is from a well-established brand and is relatively cheap. This is due to the Russian assembly. Adaptation to domestic conditions also plays a significant role.

Navien GA 23KN

Specifications:

- power: 23 kW;

- installation method: floor;

- functionality: 2-circuit;

- Efficiency: 91.5%;

- gas consumption during operation with nominal heat transfer: 2.24 cu. m / h;

- hot water productivity: 13 l / min .;

- burner type: modulated;

- primary heat exchanger material: steel;

- manufacturer: South Korea.

The equipment is completed with a remote control and a remote room thermostat. The disadvantage is the relatively high noise level.

Wall mounted turbo boilers

Photo: idroclimaterm.it

Wall-mounted turbo boilers are very common, as they are compact, have a beautiful design and are easy to install.

Wall-hung boilers have the following features:

- simple installation and connection;

- fast heating. Despite the fact that water heating is carried out in a flowing manner, it occurs instantly;

- weather-dependent automation, modulating burner.

The most popular are double-circuit turbocharged boilers, since single-circuit boilers are convenient for use only for heating non-residential buildings.

Calculation of the power of the heating boiler

When choosing a gas boiler, one should not forget about the power. The efficiency of the autonomous heating system depends on this parameter. It is not difficult to carry out the necessary calculations, because heating 10 m2 requires 1 kW of power. An illustrative example: for a dwelling with an area of 120 m2, a 12 kW boiler is suitable. Such a simple calculation has a significant drawback, because modern construction technologies and climatic features of the region are not taken into account.

The calculation according to this formula is suitable for small insulated houses (attic, walls, double glazed windows) with low ceilings. We have few such dwellings, so you need to take into account the quality of the house insulation, heat loss in winter, and the climate. Also, do not forget about unforeseen situations: a decrease in the pressure of natural gas and a strong cold snap. Therefore, when calculating the power, 20% must be added to the resulting figure.

When calculating the power, it is necessary to take into account the fact that a lot of heat comes out through non-insulated windows, walls, the attic.

The best manufacturers of turbocharged boilers

The most popular and high-quality equipment is produced by German firms. Italian and French companies follow. A number of Russian enterprises have mastered the production of turbocharged boilers, and their quality is approaching the level of world brands.

The first in the quality rating is the products of the companies: Buderus, Bosch Gas, Protherm, Vaillant... Slightly inferior to them: Baxi, Neva Lux, Arderia.

Next are the slightly inferior Korean brands: Navien, Daewoo, Kiturami, Hydrosta.

How to choose the right place for installing atmospheric and turbo boilers

The location for installing the boiler is selected based on the following parameters.

- Floor-standing or wall-mounted construction (floor-standing, as a rule, are placed in separate technical rooms).

- Boiler power and weight (larger models may require separate foundation preparation).

- For atmospheric models, the close location of the chimney is important, the finished structure can have a minimum bending angle in order to provide sufficient draft.

- Turbocharged boilers require communications to bring out the coaxial chimney.

| It's important to know! Due to the tightness of the combustion chamber, turbocharged boilers do not require installation in a separate room. |