Recently, manufacturers of gas-fired heaters are busy with the fact that they are constantly developing new products and modernizing their products. But since the cost of gas is growing all the time, and in many villages and villages this type of fuel is not available at all, one has to look for alternative heating methods. And one of these heating options include diesel boilers, among which the diesel boiler by kitura is especially popular. This type of boiler appeared on the market for a long time, and still enjoys great confidence among the population of our country.

Features of Kiturami boilers

Kiturami is a South Korean company with more than half a century of experience in the design and manufacture of heating boilers and related equipment.

During this time, the company has become one of the leaders in the domestic Korean market, and also found an extensive sales market in North America and the neighboring countries of Asia. In our country, Kiturami boilers have been officially distributed for at least ten years and have already shown themselves on the good side.

The main emphasis in the promotion of boilers is made on the introduction of innovative technologies and, in particular, their own developments, which have no analogues in other manufacturers or determine the narrow specifics of the equipment operation.

Diesel boilers, by definition, are not considered as a basic model range for a wide range of applications. In terms of economic feasibility, they are inferior to gas, electric and even solid-state boilers. However, they are still in demand among consumers in view of a number of reasons why liquid fuels are becoming preferable.

In remote areas of residence, where there is no stable connection to power grids, no gasification, the issue of fuel availability is acute. At the same time, the heating of the house must, by definition, work without interruption throughout the season. If for many countries such situations are rather an exception to the rule, then for us, on the contrary, it is routine, the cause of which is the vast expanses separating settlements.

Diesel fuel, unlike gas, is easier to transport and easier to store with minimal risks to life and the environment. Unlike solid fuel boilers, diesel fuel during combustion gives uniform heating and a greater degree of control over the waste of resources. And finally, the design of the diesel boiler and in particular the burner does not limit the use of other heat sources.

With minimal changes, the diesel burner can be replaced for the use of blue fuel, and boilers equipped with an extensive combustion chamber and grate, can quickly switch to using coal, wood or pellets.

Diesel boilers Kiturami are highly technological and perfectly balanced equipment for using diesel fuel as a heat source, and at the same time, they are excellent for the listed types of conversions to work with gas or solid fuel. Thus, constructive and functional flexibility is the first significant advantage.

Kiturami boilers often use their own designs and unique layout. On the one hand, this reduces the maintainability of heating equipment, but on the other hand, it provides the highest boiler efficiency and balanced operation, while observing simple and transparent operating rules.This is the second good reason to turn your attention to diesel boilers from South Korea.

The final advantage is the cost of boiler equipment. Even taking into account the high performance and proven quality of the boilers, their cost does not exceed the market average among similar offers.

So it turns out that Kiturami boilers have three features: a balanced design, high efficiency and an affordable price.

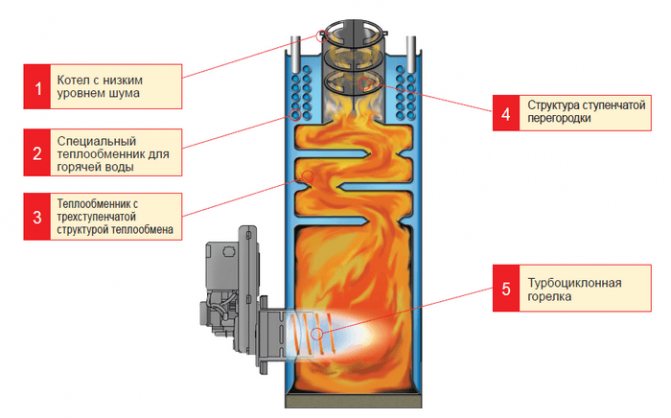

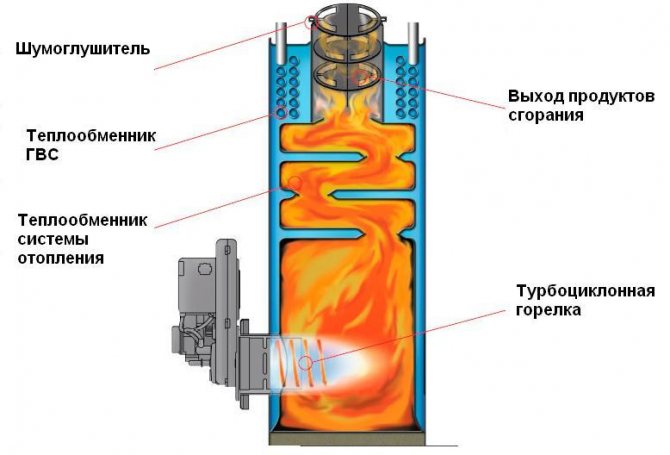

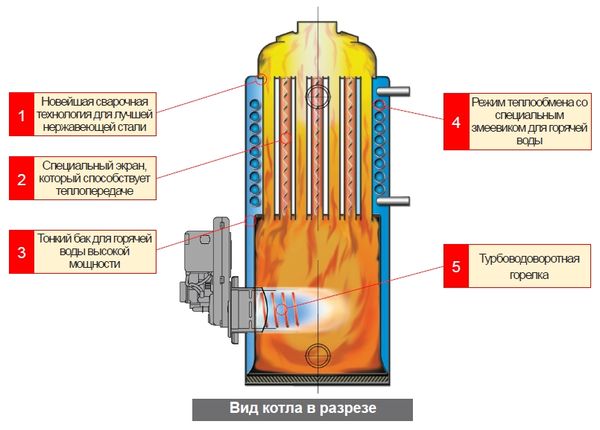

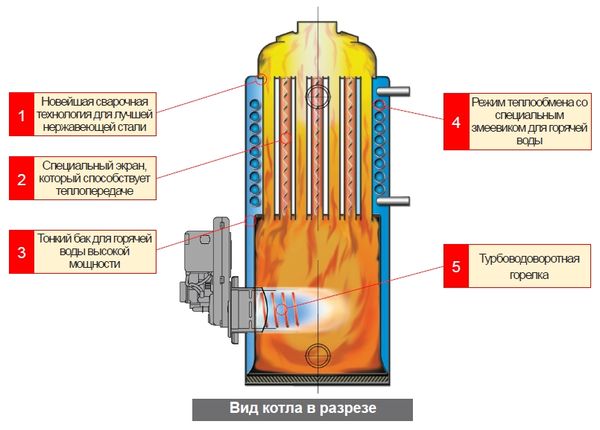

Boiler device Kiturami

Installation and maintenance of devices

So, we found out that Kiturami heat generators have excellent characteristics, but it is worth remembering that during their operation you must adhere to the relevant requirements, otherwise the most reliable device in the world will require major overhaul.

The very first thing many boiler users face is to install an already purchased model. During installation, it is necessary to adhere to all the manufacturer's requirements, for this reason it is much better if qualified specialists are engaged in the work - in this case, there will be no risk of the need to repair the device immediately after the installation work. Indeed, in most cases, the reason for the imminent breakdown of the device is just its incorrect installation. And to avoid all this, you will have to pay a little extra.

Due to the fact that the diesel heat generator is equipped with a fuel tank, certain operational requirements are also imposed on it. So, extremely clean fuel can be poured into the tank, in addition, it should be regularly cleaned, as well as the boiler itself. For this reason, when buying, you should pay attention to whether the tank is equipped with a precipitation outlet and a fix-package.

Note! Before turning on the boiler itself, fuel should be poured there and allowed to stand for at least twenty minutes. Only then can you start setting up the device.

If voltage drops often occur in your area, then take the money and also buy a stabilizer that can save the functionality of the control unit and various sensors present in the device. But correct installation and competent operation is not everything, because Kiturami diesel boilers need periodic preventive measures. Such events consist of:

- mechanical cleaning;

- checking all nodes is not a subject of operability and the presence of leaks.

Some of these works can be done by hand - for example, to connect the device itself - but it is advisable to entrust the rest to professionals. And all the time remember about the need to care for the heat generator, so carry out all these activities in advance. So you will be able to avoid a number of minor problems, as well as prevent more serious ones.

Specifications

The operational characteristics, dimensions and parameters of the Turbo series boilers are presented in the table below. It is clearly seen that the series of floor-standing diesel boilers covers a power range from 10 to 35 kW, which is quite enough for heating houses up to 250-275 square meters. Part of the heat will be spent on preparing hot water, which must be taken into account in the calculations.

All Kuturami boilers are double-circuit and heat exchangers, by the way, are ideally designed specifically for these tasks.

| Boiler model | Unit rev | TURBO-9R | TURBO-13R | TURBO-17R | TURBO-21R | TURBO-30R | |||

| Power | kcal / hour | 9000 | 13000 | 17000 | 21000 | 30000 | |||

| Power | kw | 10,5 | 15,1 | 19,8 | 24,4 | 34,9 | |||

| Fuel consumption | liter / hour | 1,13÷1,5 | 1,6÷1,97 | 1,87÷2,15 | 2,28÷2,80 | 3,75÷4,30 | |||

| Efficiency | % | 92 | 92 | 92.2 | 92.4 | 91.8 | |||

| DHW consumption | Δt = 25ºC | 6,0 | 9,7 | 11,3 | 14,0 | 23,3 | |||

| Δt = 40ºC | 3,8 | 6,1 | 7,1 | 8,7 | 14,6 | ||||

| Heating supply and return | mm | 25 | 25 | 25 | 25 | 25 | |||

| Hot water in / out | mm | 15 | 15 | 15 | 15 | 15 | |||

| Chimney diameter | mm | 80 | |||||||

| Power supply | V / Hz | 220/50(60) | |||||||

| Power Consumption | W | 80 | 160 | ||||||

| External dimension | w × d × h | 325×600×835 | 365×650×930 | ||||||

| The weight | Kg | 60 | 79 | 85 | 85 | 85 | |||

Fuel consumption

Fuel consumption is indicated in the table with technical requirements. However, remember that the actual flow rate depends on the individual settings.For the actual power required to heat the house, an appropriate nozzle is selected from the set proposed by the manufacturer.

The thermal power, fuel consumption and fuel combustion mode are set. The parameter indicated in the table displays factory presets sufficient to ensure proper performance, provided only high-quality fuel is used, more often it means diesel fuel already with winter additives that do not allow it to thicken or stand out paraffin in excess of the norm.

In a real situation, for a boiler model with a capacity of up to 15 kW, you can expect fuel consumption at the level of 8 liters per day taking into account the frequency of operation of the burner and the optimal temperature regime in the house. However, this is not the limit.

The correct approach to the choice of the heating mode, as well as the installation of a controller with a variable temperature regime, for example, depending on the time of day and day of the week, can reduce the consumption even more.

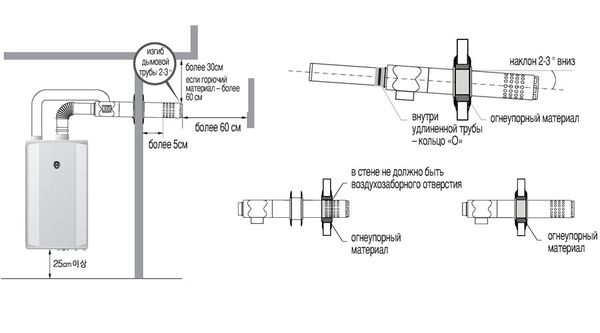

Chimney

Kuturami boilers, gas, diesel, floor-standing or wall-mounted, are mostly equipped with a closed combustion chamber and, accordingly, a forced exhaust system. The Turbo series, which we are currently considering, is no exception.

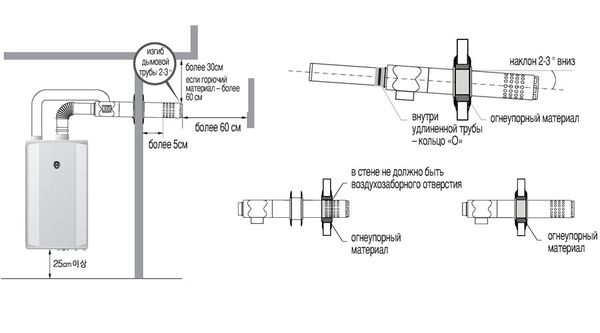

Chimney installation diagram

The chimney for boilers is used coaxial for the simultaneous supply of fresh air from the street and the removal of exhaust gases. Since the exhaust temperature after passing through the heat exchangers is no longer high, the requirements for the heat resistance of the chimney are reduced, and the list of acceptable materials is expanded.

In the best case, a steel coaxial chimney is still used, however, a ceramic vertical chimney with a group of internal separate channels for supplying air, removing gases from the combustion chamber and ventilation of the boiler room can be effectively used in the same capacity.

The chimney size is strictly specified in the boiler specification and operating instructions. For the entire Turbo series, this is 80 mm.

It is possible, if desired, to make a chimney with a slightly larger diameter, but not more than 50% above the specified value, that is, up to 120 mm.

In no case should you reduce the size and section. Even though the removal of combustion products is forced, the resistance of the chimney will greatly affect the combustion mode and the quality of fuel combustion.

turbo 13r

The model number of the boiler corresponds to the amount of heat generated per hour - 13000 kcal / hour. In terms of the usual kilowatts, the value is 15.1 kW.

The declared capacity is sufficient to heat a house with an area of up to 150 m2. Naturally, one should take into account the heat consumption for the preparation of DHW. If a significant consumption of hot water is predicted, moreover, regularly, then the heat output for the heating circuit will naturally be lower.

Reliability and balanced operation, combined with the affordable cost of the boiler, gives a clear advantage in the case of using several boilers at the same time in one building, for example, when dividing the heating circuit for each floor separately or when covering a large area in two more wings, directions.

Diesel boiler Kiturami Turbo / Kiturami Turbo pros and cons

Summing up, we can say that the main advantage of Kiturami Turbo boilers is their price and their unpretentiousness. This is especially true of the Kiturami Turbo 21R model, the pump of which allows diesel fuel to be lifted out of the tank.

The main disadvantage of Kiturami Trubo boilers is their low reliability and the almost complete absence of spare parts warehouses in Russian regions. In the event of a breakdown, you have to wait weeks for spare parts.

More on this topic on our website:

- Kiturami diesel heating boilers with DHW preparation We have already published reviews from users on our website about the Kiturami Korean diesel heating boiler. Then the case concerned specific models.

Wall-mounted gas boilers Buderus Logamax - a review and feedback from the owners About what the German company Buderus is, I already wrote on the pages of the site when I talked about the boilers produced by this one.

Pellet boiler Kiturami KRP 20 - review and feedback from the owners Well, Kiturami could not stay away from the general trend. When all companies specializing in boiler equipment produce.

Drazice boilers - a review and feedback from the owners To have constantly hot water in the house, you can use the second heating boiler circuit, which will be in the flow through a heat exchanger.

«>

turbo 17

Kiturami turbo boiler

The thermal power already reaches 19.8 kW, which is enough to cover the heating of a house with an area of up to 180 m2. It is possible to reasonably increase the upper performance threshold by selecting the appropriate nozzle on the burner, however, this will affect fuel consumption.

This approach allows you to solve the problem of increased DHW consumption so that you do not restrain yourself in using hot water without unnecessary costs even in the most severe frosts.

turbo 30 r

The most powerful model in the Kiturami range of oil boilers. Productivity at the level of 34.9 kW makes it possible to heat a room up to 350 m2, but at the same time the cost of the boiler in retail is approximately 45-46 thousand rubles., which is undoubtedly an attractive option.

As in the entire range of boilers, burners with a unique torch shape and optimal fuel combustion are used.

The minimum amount of nitrogen oxides is registered in the exhaust, which indicates the high environmental friendliness of the equipment.

KSO series

If the Kiturami boiler is planned to be used for heating large premises, you should choose and buy a suitable model from the Kiturami KSO series. It includes high-performance samples from 58 to 464 kW. All models are equipped with robust stainless steel heat exchangers and closed combustion chambers. The equipment not only heats the premises, but also provides hot water. The maximum productivity of the DHW circuits is 100 l / min - a significant indicator.

Diesel boilers Kiturami can be used to heat large buildings up to 4640 sq. m. The series is distinguished by high reliability and efficiency - the fuel burns with almost complete heat absorption. The equipment is controlled by computer control units.

Customization

It is better to entrust the initial start-up and adjustment of Kiturami boilers to a specialist who can correctly determine the optimal operating mode, select the desired type of nozzle and adjust the fuel consumption depending on its characteristics and even the method of connecting and positioning the fuel tank.

Diesel boiler nozzle

For self-installation, complete with the boiler, detailed instructions are attached, according to which you can determine the operating mode closest to the design value.

The main thing is to adhere to the sequence of actions defined in the technical documentation and a visual aid for putting the equipment into operation.

It is necessary to adjust and adjust the boiler settings not only at the first start, but also during maintenance before each new season and to switch to summer mode, in which only the DHW circuit will be used.

Operating rules

The user controls the Kiturami boiler through a thermostat. The settings are made using the knobs and buttons. Information about the current state of the unit is displayed by indicators on the board and light bulbs.

Main functions:

- Premises. The main mode used when people are in the house. To activate, press the "Presence" button and set the desired temperature using the regulator.

- Sleep. Helps save fuel while on holiday. For the transition press the button "Sleep", set the required temperature.The settings will be in effect for five and a half hours. Then the "Room" mode will be restored.

- Bath. Allows you to use a lot of hot water for two and a half hours. After the expiration of the period, the device switches to the previously activated mode.

- Lack of in room. Used to prevent the heating system from freezing when the user is away. Provides fuel savings by lowering the temperature to the minimum allowable.

- Timer. Allows to program the boiler operation time and its shutdown.

For a long and trouble-free operation of the equipment, you must strictly follow the rules for its use.

Operating rules:

- do not store flammable and flammable objects and substances near the device;

- have a fire extinguisher in the boiler room;

- do not repair or disassemble the unit yourself;

- prevent water freezing in the heating system;

- carry out maintenance 1-2 times a year;

- clean the chimney and chimney from soot several times a year;

- as it gets dirty, drain the sediment from the fuel tank and change the filter.

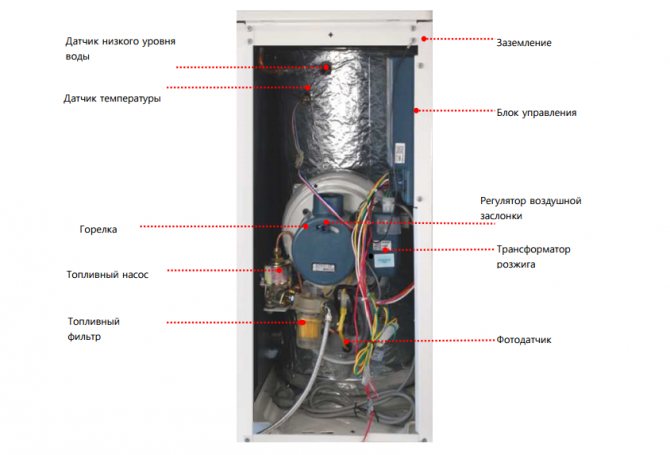

Malfunctions

Kuturami boiler equipment is equipped with a complete self-diagnosis system based on the operation of a number of sensors. The controller is able to assess the condition of the equipment as well as the current operating mode and respond to any deviations or problems that arise during operation.

In any emergency situation, the main action assigned to the boiler controller is to shutdown the burner to prevent significant consequences.

A well-developed self-diagnosis algorithm allows you to identify the problem and indicate the error code on the display so that the user can take all the necessary actions to repair and restore performance as quickly as possible.

Among the frequent breakdowns of Kiturami diesel boilers:

- No ignition (error code 01);

- Does not start, there are no messages on the display .;

- Coolant leakage (depressurization of the heat exchanger or one of the pipeline connections);

- The flame is periodically extinguished with an emergency stop of the boiler;

- There is no draft, the operation of the boiler is accompanied by the ingress of smoke and exhaust into the room.

Error 01 and solution

If error code 01 appears on the boiler display screen, it means that the fuel for some reason did not ignite, there is no flame, the controller forcibly stops the fuel supply, issues an error message, signals the problem to the user.

Solving the problem requires an accurate implementation of the order of actions that can identify the source of the problem and eliminate the obstacle in the operation of the boiler as efficiently as possible.

In short, the procedure looks like this:

- Check the voltage in the power supply;

- Check the fuel line for integrity or its capacity;

- Check the condition of the fuel filter, if the scheduled replacement is close, then it is better to immediately change the consumable;

- Especially for boilers 21R and 30R, check that the fuel does not flow by gravity;

- Change the fuel for the sample to another, as high quality as possible. Alternatively, it is possible, acting on the air damper, to facilitate the supply of a rich fuel mixture to the combustion chamber;

- Check or replace the fire control photosensor;

- Check and clean the injector and ignition electrode;

- Check the transformer that sparks the electrodes.

Quite often, the fuel-air mixture is supplied under too much pressure into the chamber and therefore does not have time to ignite from the electrode. The problem is solved at the 5th step of the algorithm by adjusting the air damper, which is why a mixture with a changed concentration enters the chamber.

Doesn't start

The most unpleasant situation is when the boiler simply does not turn on. There are no signals on the display, and accordingly there is no error code by which the malfunction could be determined.

In such a situation, it would be adequate to call a service center specialist who can understand the situation and issue the correct verdict, as well as determine the repair procedure. On your own, you can only check the presence of voltage in the network, as well as the fuses in the boiler.

Leakage

Most often, a leak means that the gasket seal has been damaged in some connection of the pipeline inside the boiler. It is enough to inspect the equipment and determine the place of leakage, replace the gasket.

The heat exchanger in Kiturami boilers is made of alloy steel and copper, so it does not leak without obvious errors in the selection of the coolant or mechanical damage.

The burner goes out periodically

The most common cause is a malfunctioning burner setting. It is important to adjust its power and use a gas analyzer to determine the optimal air / fuel ratio for full combustion. Such work cannot be done on your own, so it is better to contact the service src = "https://udobnovdome.ru/wp-content/uploads/2016/08/nastroyka-gorelki.jpg" class = "aligncenter" width = "600 ″ height = "495" [/ img]