Among the European leaders in the production of heating equipment,] Viessmann [/ anchor] stands out.

Founded over 100 years ago, it has accumulated significant theoretical and technological background.

This allows the creation of exemplary installations for heating and supplying hot water both to residential and public or industrial premises.

The quality and operational capabilities of Viessmann gas boilers are highly appreciated by both specialists and ordinary users.

For use in residential apartments or houses, two-circuit models are made that can not only heat rooms, but also prepare hot water for domestic needs.

Double-circuit gas boilers Viessmann

Double-circuit (combined) boilers have two functions performed simultaneously - heating the coolant for the heating system and preparing hot water for household needs.

As a rule, the power of double-circuit boilers is relatively small, up to 34 kW, which corresponds to the size of residential buildings, apartments or office premises of small and medium size.... This has its own calculation - the higher the power of the boiler, the greater the volume of hot water it must cook.

However, the heating of the DHW flow in the unit is produced by a plate secondary heat exchanger, whose capabilities are limited, and it is not able to provide high performance.

Therefore, powerful Viessmann boilers are single-circuit, but they have the ability to connect an external indirect heating boiler, whose performance is much higher and is able to meet large DHW needs.

Design options

There are different designs of boilers Viessmann Vitopend 100-W:

- Single-circuit. They are designated by the letters A1HB (for example A1HB001). They only heat the heating agent for the heating circuit.

- Double-circuit. These settings are referred to as A1JB (for example A1JB010, A1JB009). In parallel with heating the coolant, hot water is prepared for domestic needs.

All single-circuit boilers have the ability to connect an external boiler, which allows not only heating the coolant, but also supplying hot water... At the same time, the volumes of hot water are much larger than the standard plate heat exchanger of a double-circuit boiler can provide.

This is convenient if the size of the room is relatively small and the demand for hot water is high.

Advantages and disadvantages

The advantages of Viessmann double-circuit boilers include:

- Full functionality of the units, which makes it possible to heat housing and supply hot water.

- Compactness, attractive appearance. As a rule, double-circuit boilers are installed in the kitchen, where they do not interfere and do not take up much space.

- Full automation of work, only minimal adjustments to the operating mode are required from the user.

- The presence of a self-diagnostic system that detects and signals about the occurrence of malfunctions.

The disadvantages of Viessmann double-circuit boilers can be considered:

- The boiler performance on the DHW line is limited, with an active drawdown, the temperature drops both in the DHW system and in the heating circuit.

- The design of double-circuit boilers is more complex, which increases the risk of failure of individual elements.

- The volatility of the units makes it possible to stop heating and hot water supply in the event of a sudden power outage. In addition, it is necessary to use a voltage stabilizer, which excludes the failure of the control board in case of a sharp voltage surge.

The disadvantages of double-circuit boilers are the same for all units from any manufacturer, so they can to some extent be considered design features.

Connecting diesel boilers Viessmann

Viessmann diesel or oil-fired boilers are available only in floor-standing design.

Two types of boilers are used: only oil and gas-oil Viessmann Vitola.

There may be replaceable burners, which are rearranged when switching to another fuel or with two burners in the combustion chamber. In this case, the transition to another fuel is carried out only by switching the burners.

Installation of diesel boilers is exactly the same as for gas models. But with the use of quick-release couplings according to the Fastfix system, the labor intensity is reduced by half.

Elements are used that are easily inserted into each other without special tools.

Installation is facilitated by the fact that all branded burners must be tested before installation and their design is optimally matched to the boiler in terms of parameters.

High-power boilers are often assembled from three main types of blocks right in the future boiler room.

Views

All Viessmann double-circuit boilers are wall-mounted. Floor installations are single-circuit by default, although they have the ability to connect to an external storage or boiler.

They are equipped with an atmospheric type partial mixing burner, which is able to flexibly regulate the amount of gas by partially mixing air.

There are two design options:

- Convection boilers... They work according to the traditional method, heating the coolant and giving it to the heating system without additional procedures.

- Condensing units... They appeared relatively recently. The peculiarity of these installations consists in the preliminary heating of the coolant with the help of thermal energy obtained during the condensation of water vapor from the discharged gaseous combustion products. Designed to work in low-temperature systems - underfloor heating, etc.

NOTE!

The efficiency of condensing boilers, declared by manufacturers, is up to 108%, which is impossible in practice and is a common marketing ploy. It is determined by adding the boiler efficiency and the maximum efficiency of the condensing chamber, which is incorrect from a theoretical point of view.

What series and models belong to double-circuit

Viessmann double-circuit boiler models are designated A1JB.

Among the entire product range, there are two series:

- Viessmann Vitopend. They represent a model line of convection boilers with a capacity from 10.5 to 31 kW. The most popular models are boilers with a capacity of 24 and 31 kW, which is explained by the optimal match between their parameters and the needs of a medium-sized private house. Their efficiency reaches 90-93%, the feature of installation is the possibility of installation in a narrow compartment - there is no need to leave gaps on the sides, all maintenance is performed from the frontal plane of the boiler.

- Viessmann Vitodens. This is a series of condensing boilers. The Vitodens series is divided into three product ranges, 100 W - from 12 to 35 kW, 111 W - from 16 to 35 kW and 200 W - from 32 to 150 kW. Models with a capacity of 24 kW are in the highest demand, although condensing boilers have specific operating conditions and are not always able to demonstrate full efficiency.

IMPORTANT!

There is the Vitodens 222-F series, which are floor-standing models with a power of 13-35 kW, equipped with an integrated storage water heater, which allows them to be classified as a double-circuit boiler.

Specifications

Consider the technical characteristics of Viessmann double-circuit boilers:

| Parameter | Value |

| Boiler type | Gas convection or condensing |

| Fuel type | Natural or LPG |

| Efficiency | 90-93%, stated value for condensing models - 108% |

| Number of contours | Two - heating and hot water supply |

| Power | 10.5-150 kW |

| Coolant pressure | Up to 3 Bar |

| Heat carrier temperature | 35-70° |

| DHW temperature | 40-60° |

| Power supply | 220v 50hz |

Device

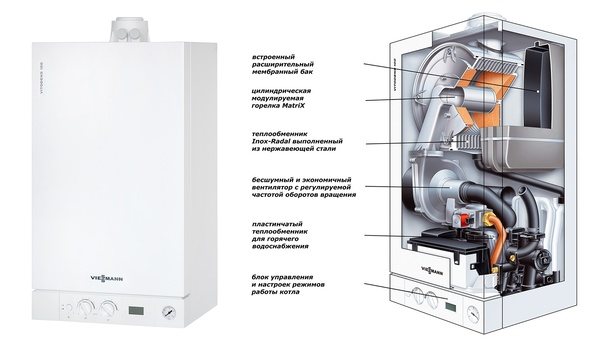

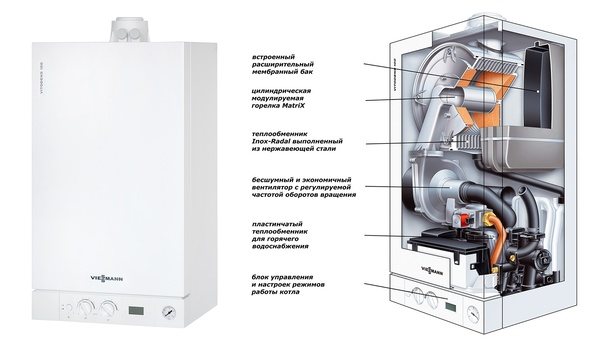

All double-circuit models are made of high-strength materials. The heat exchanger, gas burner and casing are made of high quality stainless steel that can withstand temperature and pressure changes. These are the main structural elements of boilers.

In addition to them, the assembly units include:

- Secondary stainless steel plate heat exchanger.

- Expansion tank.

- Circulation pump.

- Turbocharger fan (for models with a closed combustion chamber).

- Three-way valve.

- Gas valve.

- Control board with external panel and display.

- Self-diagnosis system (sensors installed on all parts and connected to the control board).

The coolant enters the primary heat exchanger and receives the maximum temperature there. At the outlet, it enters the secondary plate heat exchanger, where it partially gives off heat energy for heating the hot water supply.

Then, in a three-way valve, it mixes with a colder return flow and receives the required temperature for supply to the heating circuit.

In condensation models, everything works the same, only before entering the primary heat exchanger, the liquid is partially heated in the condensation chamber, which allows to reduce the heating level and reduce gas consumption.

Connection and setup instructions

After delivery of the boiler, it is necessary to install it in a pre-selected and prepared place. Do not hang the units on plasterboard or other weak partitions, the wall must have sufficient bearing capacity.

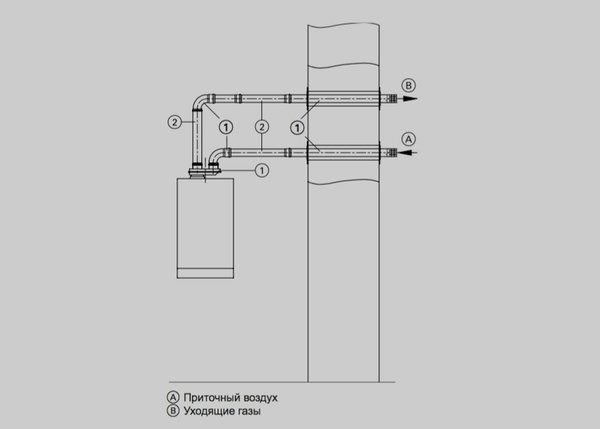

After hanging, the chimney is connected and the gas and water supply pipelines and the heating circuit are connected.

The Viessmann double-circuit boilers are set up after installation and a complete check of the quality and tightness of the connections.

Particular attention is paid to the connections of gas pipes, checking them with soapy water... The gas and water pressure limits are set, the operating mode, current temperature and other parameters are set.

It must be borne in mind that all units are initialized at the factory, therefore, in most cases, no specific actions are taken.

All work on connecting and setting up the boiler must be carried out by a qualified representative of the service center. Unauthorized intervention may cause damage to the unit.

Download instruction

Download the instruction for the Viessmann double-circuit gas boiler.

Features and benefits of Viessmann boilers

Installing a visman double-circuit boiler is an excellent solution for those who value comfort and prefer a reliable and trusted manufacturer. A large selection of economical and easy-to-manage heating equipment pleased the domestic consumer, which is confirmed by numerous reviews on the official website of the company.

Let's look at some of the advantages and design features of visman gas boilers:

- Modern automation and electronics allow you to connect a household heating appliance to the "smart home" system, set heating programs manually.

- Installing a remote thermostat allows you to program the heating mode with reference to the outdoor temperature.

- Unique modes "vacation" or "economical" allow you to leave the boiler unattended for a long time, minimizing the consumption of gas and electricity.

In addition, visman double-circuit boilers have:

- Modern stylish design.

- High efficiency.

- Low noise level.

- A high level of safety, both for the user and the environment.

Viessmann pays special attention to the quality of materials for the manufacture of its products. For example:

- High-alloy steel is used for the manufacture of the body and other important components.

- For the production of heat exchangers, a specially developed alloy of nickel and chromium is used. This patented technology ensures long-term trouble-free operation of gas equipment.

Advice! Sophisticated production technologies lead to the fact that the visman boiler has expensive diagnostics and repairs. The cost of component parts is also quite high.

Price range

The cost of Viessmann double-circuit boilers is in the range of 38-56 thousand rubles. The price depends on the power of the selected model... In regions located at a significant distance from densely populated areas, the cost of equipment will be significantly higher, since delivery will require significant costs.

In addition, you will need to purchase a chimney, a voltage stabilizer, filtration units for water, without which high-quality operation of boilers will be impossible.

It is recommended to clarify the composition and cost of all additional components in advance so as not to find yourself in a difficult situation when purchasing.

The lineup

Before buying, decide on the model. The assortment of the model range is huge, which will satisfy any client.

The production of not only floor-standing boilers, but also wall-mounted ones has been established. They have their own original models. The choice depends on the required power and personal preferences of the buyer.

For example, a good selection of capacities, high efficiency are more related to gas floor boilers. These include the following models: Vitola, Vitoplex, Vitogas, Vitocrossal and Vitorond.

Wall mounted appliances are quite compact, which is convenient for small spaces. They are supplied with installation elements. At a cost, they are cheaper than floor-standing boilers. Wall-mounted devices are represented by the following models:

- Viessmann Vitopend 100-W.

- Viessmann Vitodens 100 (200) -W. The power of the Visman gas boiler reaches 35 kW, the double-circuit device has higher efficiency characteristics than that of traditional devices.

In Europe, the second model is more often used - condensation. It costs more than conventional boilers, therefore it is not very popular in Russia, although it has a high efficiency factor - more than 100%, and is produced directly in Germany.

You will be interested >> Description of the double-circuit gas wall-mounted boiler Baxi

In the CIS countries and on the territory of Russia, the Viessmann Vitopend 100-W series is more popular. Wall-mounted models have a standard efficiency of 90%, an affordable cost - from 700 euros.

This series is produced in Eastern Europe and Turkey. There are a couple of species options:

- single-circuit (power 24, 30 kW);

- double-circuit 22-30 kW (for example, the average power of the wall-mounted gas boiler Viessmann is 24 kW).