Natural gas heating equipment is very popular today - it can be used to heat rooms of any size. In residential buildings connected to a centralized gas network, boilers equipped with electric ignition are usually installed. Such a device greatly simplifies the use of the unit - you no longer need to use matches to “turn it on”. It is enough to press the electric ignition button and the gas boiler will start producing heat energy. A special device instantly generates sparks, causing a flame to appear.

The principle of ignition

Electric igniters, which are equipped with most modern models of gas boilers, include the following elements: diode, resistor, capacitor, transformer, candle, switch. This convenient and practical invention facilitates the operation of the unit, speeding up its start-up and set-up. With the help of a compact device, you can kindle a flame in a burner not only quickly, but also safely, without the use of matches and lighters, which tend to run out and deteriorate. The flame appears immediately after pressing a button or turning a lever.

It is customary to distinguish between several types of electric ignition for gas boilers - mechanical, automatic and semi-automatic. If the unit is equipped with a mechanical ignition, to turn it on, you must not only activate the burner by turning the switch, but also press a special button. The device will generate a spark and ignite a flame. If the electric ignition is automatic, then the equipment turns on when you turn the knob - you do not need to use additional devices. To be able to use auto-ignition, the heat-generating device must be connected to the mains (an earthed socket must be nearby). If the electric ignition of the gas boiler is out of order, it is worth calling a repairman for heating equipment at home, this can be done on the website https://24master.com.ua/.

Piezo ignition of a gas boiler

Acts like a piezoelectric element in lighters. In such boilers, a special button on the boiler body is used to start. Pressing the button generates a spark and ignites the gas. In fact, the ignition method is semi-automatic. It's not an automatic machine yet, but you don't have to bring a match to the burner either. Why is this method good?

The first is simplicity. It is quite possible to repair a broken unit yourself, or to replace the gas boiler ignition unit with a new one, which is not expensive.

Second, piezo ignition is a mechanical element that does not require electricity to operate. Plus, boiler equipment with piezo ignition is cheaper.

Why Ignition May Not Work

Electric ignition is considered one of the most vulnerable elements of a gas boiler, since it is he who breaks down more often than other components. The reasons for the breakdown can be mistakes made during the operation of the device, wear of parts or mechanical damage. Having found that the ignition does not work, the first thing to do is to make sure that it is connected to the mains, and there is voltage in it. If everything is in order with the power supply, and the device is still not functioning, the reason may be a malfunction of the power supply or a button, damage to the wire. To diagnose a breakdown, you will need a tester, it allows you to check the presence of conductivity.

What is electric ignition

This is a convenient additional function when the gas is ignited by the actuation of a piezoelectric element or an electric candle.Electric ignition allows the gas to be ignited safely and protects users from the possibility of burns, since lighters and matches are not needed.

In some publications, the name piezo ignition or piezo ignition is found, there is no difference in design, they simply call it as convenient, and the basis is that the spark is given by a piezoelectric element. This scheme is used on budget models, the user has to use both hands to ignite the burner.

How to fix the ignition yourself

Self-repair of household appliances or their components is a rather risky undertaking, since the likelihood of aggravating the problem is quite high. It is very difficult to fix the electric ignition of a gas boiler without special knowledge and skills. The device may fail due to water or grease, power surge, or carelessness. The main symptom of a device malfunction is the absence of a spark. If there is a spark, but it is not possible to ignite the flame, it is necessary to clean the contact areas of the burner and candles. If the electric ignition unit is broken, the current-carrying paths and the resistance of the windings should be checked. When repairing the ignition, new parts may be required.

Why do you need automation for gas heating boilers?

A type of thermostat is a programmer. From such a programmer, commands are transmitted to the gas boiler during the day, in accordance with which the mode of its operation is carried out.

The cycle of work is repeated every day. The main functions of the automation of a gas heating boiler are the following functions: Top of the week. Description of the video. Do-it-yourself electrician, construction and repair is a channel for those who make repairs in their private house or apartment with their own hands.

Content

You will learn how to build a house, garage with your own hands. You will learn how to make heating, plumbing, and electrical wiring with your own hands. How to do it efficiently, quickly and not expensive. However, do not rush to change it. Let's check it first.

Structurally, the piezoelectric element is a piezoceramic with applied electrodes. Piezoelectric elements can be of various shapes: in the form of disks, rings, tubes, plates, spheres, etc. For vibrators and generators, piezoelectric elements are combined into piezoelectric glasses to achieve the best characteristics. Piezoelectric substances of piezoelectric materials, in particular piezoelectric ceramics, have the property that electric charges arise on their surface under deformation under the action of external mechanical pressure. This effect is called the direct piezoelectric effect and was discovered in St.

It is not necessary to do this for verification. We examine the sensor.

Preparation for work

Its contacts must be firmly attached to the case. They should not be oxidized. We check the thrust sensor with a tester, measuring its resistance. We are trying to fire up.

Diagnostics at the service center

Repair of electric ignition of a gas boiler is included in the list of services of many service centers specializing in maintenance of household appliances and heating equipment. Turning to qualified specialists, you can count on the fact that the device malfunctions will be eliminated as quickly as possible. Reliable service centers that value their own reputation provide customers with a long-term warranty for equipment repairs.

To determine the cause of a malfunction in the electric ignition of a gas boiler, the foremen use modern diagnostic devices. During the repair, specialists use exclusively high-quality original components. In addition, the SC offers to call the master at home. This service eliminates the need to deliver the overall unit to the workshop yourself. Repair of a gas boiler may involve replacing the ignition unit, restoring the control unit, eliminating the leak, installing a new valve.An experienced specialist will be happy to answer all the client's questions regarding the rules for operating the equipment, and also tell you how to avoid breakdowns in the future. Service centers offer advice or order this or that service at any time of the day. This can be done by phone or through the website.

Features of installation and operation

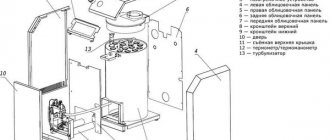

Floor standing models must be installed in a separate room

Non-volatile gas-fired heating equipment is installed in the system so that the coolant circulates naturally without using a pump. For this, the following conditions are met:

- the calculated slope of the line with the coolant is maintained;

- pipes of larger diameter are used to reduce the resistance in the path of the liquid;

- an expansion tank is built into the system, where excess hot water is located.

When installing, adhere to the rules for installing gas boilers. The norms also apply to the ventilation and exhaust system. Installation of equipment is allowed to persons who have access to such work and have been accredited.

The principle of operation of a gas burner

There are several different types of gas burners, but the principle of operation is the same.

The burner is a metal hollow tube with several holes (nozzles). It is supplied with gas, which is burned in air, which is forced into the combustion chamber.

As a result, a mixture of combustion products is formed (carbon monoxide, carbon dioxide, water vapor, soot - pure carbon), which is removed to the outside. The gas is evenly distributed thanks to the nozzle system, and the air is forced by natural draft (forced draft in industrial furnaces).

It can be schematically represented as follows.

The principle of operation of a gas burner (diagram)

And in a real gas boiler, the burner looks like this.

Thus, if the gas boiler does not ignite, this means that any of the combustion conditions are not met:

- Gas is not supplied.

- There is no draft (no air is supplied).

- Combustion products are not removed (as a result, they accumulate and do not allow the flame to ignite, which is why it goes out immediately after ignition).

Gas boiler from a gas fireplace for a workshop.

Greetings to all members of the forum!

I decided to make myself a small gas boiler for heating the container. Of course, you can say, they say, winter ends and he designs boilers: fool:. Maybe you are right. But on the other hand, there is a small amount of free time, which is sorely lacking during the working season. And the palms are itching to adjust.

The batteries are already standing, since before that there was a wood-burning boiler made of bubafoni. Drovyanoy was very comfortable due to the cheapness of fuel, but it had to be periodically monitored, although it was long-lasting (it burned even up to 9-10 hours from one tab). But that's not the point.

For more than 3 years now I have been using a gas fireplace like this:

Last year, a neighbor at the base gave me another fireplace of the same kind on the cheap. Then I had the idea to make a boiler out of one fireplace.

At first I began to make a heat exchanger, but then my father-in-law gave me his own, also homemade, with which he heated the dacha for 2 winters. His house is small there, about 5x5 m, and it also has 2 batteries, like mine. Therefore, I think it will do:

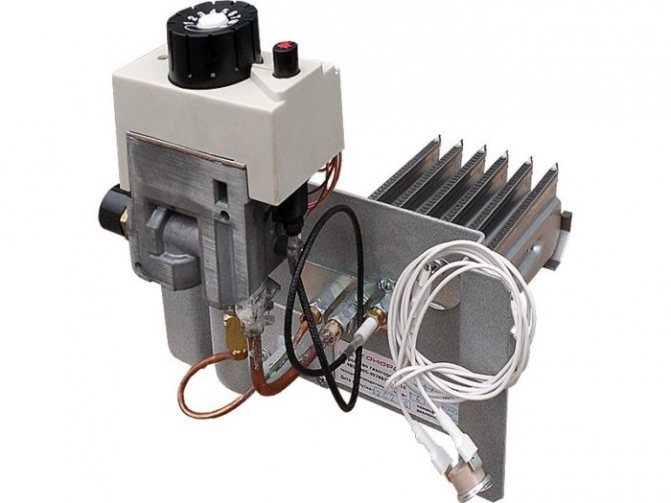

He had a ceramic burner set in there, similar to the ones on my fireplace. Only I want to put my own, and + move all the automation from the fireplace. There will be the possibility of stepwise temperature control and protection, which, as shown by three years of operation, is very good.

In general, he unrolled the fireplace, tried on the burners. The father-in-law's boiler stand came up with minimal modifications:

I decided to cut the pipes for the sake of compactness, there is not enough space in the container:

I welded a socket in the front, for attaching a position switch valve and a piezo ignition button (they are combined into one block):

The piezoelectric element itself is turned upwards, how it should stand:

The principle of protection (as far as I could figure it out):

During operation, a small tongue of flame constantly heats one contact of the piezoelectric element. While it is heating up, the tap is working to supply gas. As soon as the flame, for example, is blown out by the wind, the valve cuts off the gas supply after a few seconds.

A couple more photos:

Collected this miracle today. Let me think I'll try it dry.

I will briefly tell you about the launch for those who are not familiar with such fireplaces. To start, you need to drown the tap button and click the piezo. Then hold it a little so that the flame tongue heats the piezoelectric element (then the tap will not turn off), and then release it. After that, you can already turn on the second and third burners.

So I press the tap, set the tongue on fire, and the burner started, waited for the piezoelectric element to heat up. Then I release the tap, and he safely cuts off the gas: diablo :. I prokanezhilis with him until late at night, disassembled and assembled three times. I did not understand how he, the bastard, blocks the gas. Rather, how it blocks it is clear, but due to what keeps the channel open I can't catch up: cray:. There is one non-separable element, such as a valve, I don't understand the principle of its operation in any way. I already poked him with a magnet, the result was zero. There are no electrical elements, such as batteries.

Kind people! If anyone is familiar with this system, please enlighten! Otherwise, I can't even understand from which end to look for a malfunction. The wires rang, the contact is not broken anywhere, the crane itself does not wedge. What else to check?

The main causes of problems with a gas boiler

You can start repairing equipment only after the cause of the malfunction has been precisely determined. Then you can determine whether it is possible to fix it yourself or you will have to call the wizard.

External causes of boiler malfunction

The reasons for the fading of the boiler burner can be caused by external factors:

- deterioration of the natural draft of the chimney or its overturning;

- lowering the gas pressure in the pipeline;

- gas meter malfunctions;

- clogged gas filter;

- power outages;

- lack of supply air;

- a draft in the house, creating a short-term excess of supply air;

- heating system malfunctions.

Very rarely, sharp gusts of wind can overturn the draft in vertical external chimneys or exhaust shafts arranged in the thickness of the wall, due to which the gas boiler can go out.

Malfunctions inside the boiler

Modern gas boilers are equipped with a minimum set of safety automatics that shut off the gas supply according to the following features:

- Drop in gas pressure in the line.

- Insufficient chimney draft.

- Attenuation of the burner from external influences.

An extended set of automation allows you to control the temperature of the coolant, adjust the intensity of combustion, and so on. The more complex the device, the more elements that are prone to malfunctions in it. Because of them, the fuel supply is blocked and you should look for the reason why the gas boiler does not light up.

Here is a list of possible malfunctions:

- The burner ignites but goes out after a few seconds. This could be due to soot contamination of the photocell of the flame monitor. It is necessary to clean the element and try to ignite again.

- Failure of the draft sensor blocks the flow of gas into the burner. You can try to clean the sensor, if this does not help, then replace it.

- A failed thermocouple that controls the safety valve will prevent the burner from operating when the control wheel is released during ignition. The defective element must be replaced.

- The gas supply is also blocked if the coolant pressure sensor is faulty. As a temporary solution, its contacts can be included directly, but subsequently a new item can be installed.

- A "dead" display may indicate that the controller fuse has blown, replacing it will help. The same effect happens when the phasing of the electrical network is incorrect, it can be treated simply: you need to pull the plug out of the socket and insert it back, turning it over.

Varieties

There are two options for SABK automation, the principle of their operation is different. Non-volatile systems use mechanical sensors that open and close the gas supply valve when triggered by a thermostat.

Volatile systems make it possible to regulate the operation of the boiler more efficiently. Volatile devices include room thermostats, which can be:

- Simple. This option regulates the operation of the burner depending on the temperature in the room, maintains a stable temperature set by the owners.

- Programmable. These are sophisticated devices that allow you to change the temperature in rooms depending on the time of day or day of the week. For example, you can set a mode in which the temperature in the premises will automatically decrease at night or during the working day, while no one is at home.

What you can do yourself

The sequence of the first steps is the same in all cases:

- The boiler is disconnected from the power supply and the gas valve is closed completely.

- A visual inspection is carried out - for possible clogging, mechanical damage.

- If the combustion chamber is open, you can simply light a match or lighter and hold the flame near the holes through which air is supplied to the burner. If the draft is not clogged, the tongue will immediately deflect towards the holes, and the flame will burn evenly. If the flame deflects slightly, then there is a large blockage.

- You can also draw conclusions about the operation of the boiler. If it hums quite strongly, and the color of the flame is closer to colorless, then the thrust is too strong - it must be reduced.

Similar problems can arise at the very beginning of the boiler operation - in case of incorrect installation, with deviations from the diagram below.

Design features

Units are divided into devices with natural and forced draft. In the first version, an atmospheric burner and an open-type combustion chamber are provided. Air comes from the room where the boiler is installed, smoke is removed due to the natural movement of air. The equipment is installed indoors in compliance with safety standards.

In forced-action units, air is taken from the street or from an adjacent room (less often). The streams are moved by a fan along coaxial or separate small diameter air ducts. There is a possibility of organizing the removal of combustion products in a horizontal plane through the wall. Forced feed equipment is installed in any suitable room.

If the boiler does not start at all

It may also be that the boiler does not turn on - i.e. there is no flame initially.

The reasons for this may be:

- The simplest is low voltage or other power problems. What to do: you should again check the connection, the integrity of the electrical wiring, the serviceability of the outlet.

- The electronic control system does not work. Then it is necessary to call a service technician, since it is almost impossible to eliminate such faults on your own.

- Burner nozzles are clogged - they can be cleaned neatly at home. The cause of the blockage is incomplete combustion of the gas and soot deposits. The flame normally burns blue, and clogging can be identified by the abundance of red, orange and yellow tints in the flame. How to eliminate the cause is shown here.

- Weak pressure in the gas pipeline network, drops. You should clarify the data on a possible accident or temporary failure by calling the service company.

This is important to remember

Gas devices are classified as hazardous equipment. Therefore, the main thing to do in case of a problem:

- turn off the boiler;

- check for gas contamination of the room;

- ventilate the room.

Only after that you can figure out what to do if the gas boiler does not light up.

After that, the main thing is to check the traction, and then to study the error code on the display. This will help you understand if you are able to fix the problem yourself or if you have to call the wizard.

So, if the boiler does not ignite, or if its flame is very weak and dies out after a while, then this can mainly be due to mechanical reasons (clogging). And such malfunctions can be eliminated by yourself.

If the reason is different (or it cannot be determined reliably enough), it is preferable to contact a gas equipment service company to call a master.

Hello dear readers. What to do if the piezoelectric element in the gas column does not work? In what situations can you solve the dilemma with your own efforts? And when is it necessary to contact specialists? And how to fix the problem in Amina, Zanussi and other brands?

This material examines the reasons for the failure of the piezoelectric element in the gas apparatus. Cases with models of different brands are reflected. Methods for solving this problem are provided.

Electric ignition of a gas boiler

Unlike piezo ignition, electric ignition is part of an automatic gas equipment control system. The user does not need to press any button. The boiler starts up automatically. Agree, it's very convenient. Another advantage of this type of ignition is real energy savings.

Gas boiler CELTIC (Korea) with a smooth electric ignition system and a flame control function.

In other systems, the igniter must maintain the flame continuously. In automatic systems with electric ignition, this is not necessary. But there are also disadvantages. If piezo ignition is absolutely autonomous, then electric ignition, in accordance with its name, requires connection to electricity. And if there are problems with electricity at the installation site of the gas boiler and there is no uninterruptible power supply system, it will not be possible to start the boiler equipment in another way. We'll have to wait for the light to come on. However, you shouldn't worry about safety. If you turn off the electricity, protection is triggered, blocking the access of the energy carrier. When electricity appears, the electric ignition is triggered automatically, restarting the heating system.

Methods for troubleshooting geysers

Gas water heaters "Vector" are among the most demanded in Russia. This is evidenced by sales statistics.

When the piezoelectric element does not work in the "Vector" gas column, a spark does not appear and the burner does not ignite. The reasons for the problems are as follows:

- Lack of draft in the chimney. It could just get clogged and need to be cleaned. The column contains a special sensor that monitors the presence of traction. If it is not there, it will not start working. If you cannot do this on your own, it is better to call a special service.

- No water pressure. If the water pressure is very good, then it affects the membrane, which presses on the valve. A very low head may indicate a problem with the membrane or that the filter is clogged.

Solution: You need to disassemble the filter and rinse it under water, and the membrane is best replaced as it gets damaged over time. You can do it yourself.

- Nutrient is not working. The ignition is done with the help of batteries, without which there will be no current, for the appearance of a spark. It is necessary to remove the panel, then take out the block with batteries, pull them out and insert new ones.

The principle of operation of a non-volatile gas boiler

Non-volatile boilers do not need to be connected to the mains

When fuel is supplied, the piezo ignition is turned on, the igniter ignites from the spark, which will burn constantly. If the ignition device does not work, gas must not be supplied, as an explosion may occur. The pilot burner ignites from the pilot and heats the water to the desired temperature in the heat exchanger. Automation turns off the gas after reaching the desired result. The temperature sensor regulates the supply of a new portion of fuel when the temperature drops, and the main burner ignites again.

If there is poor draft in the chimney or the air flow is improperly organized, some of the carbon monoxide remains in the room. It is dangerous and causes toxic carbon monoxide poisoning. A non-volatile gas boiler requires a chimney device with a ratio of the volume of incoming air to the amount of exhaust combustion products of 10: 1. Non-volatile units operate without electricity due to the presence of two burners in the structure.

There is a spark, but no ignition

When this dilemma arises, the following factors appear:

- The gas supply valve is closed. Measure - turn it all the way.

- Low water pressure. It can be not only in the main, but also at the entrance to the boiler, where the filter can become clogged.

- The water heats up slightly. Solution: cleaning the heat exchanger (TO). Fastenings, on which plaque has accumulated, can be cleaned with VD-40, and the radiator can be placed in a basin with a composition based on citric acid. Then heat on the stove for half an hour, until the scale disappears completely.

- The burner clogged. Sometimes there is a lot of soot and soot in the jets. You can get rid of it with a thin copper wire.

If the piezo does not work in the "Electrolux" gas column or in another similar technique, then you should periodically check it for gas leaks using a soap emulsion. If there are no bubbles, then everything is fine.

Features of ignition of different models of gas boilers

For regulation in volatile automation, solenoid valves are used. The work of these valves is carried out according to the commands generated in the processor.

Using a special display, the operator can select one of the possible modes. And the correct implementation of this mode will be ensured by automation. From the point of view of the functions performed, automation for gas heating boilers can be of two main types:

In the first case, the main indicator for controlling the operation of a gas boiler is the temperature in the room. Depending on this temperature, the boiler operating mode is selected. When the temperature in the room drops, the boiler starts to work, and when the temperature exceeds a preset level, it will turn off.

Thermostat designs vary. At a certain temperature, the sensor closes and a turn-on command is sent to the gas boiler.

Lights up and goes out immediately

The reasons for this problem are as follows:

- Weak cravings. The chimney needs cleaning. If there is poor ventilation in the kitchen, then you need to open the vents or make a ventilation valve on the window frame.

- The ignition button is not pressed well. It needs to be held for 20 to 30 seconds.

- The sensor does not work, which removes the combustion products. This can be found out with a multimeter. If the sensor is working, there will be an infinity sign on the screen.

- Mixing streams. Set the controller to a constant normal temperature.

- High pressure in models with low power. Set the water parameters as indicated in the instructions.

- Systematic shutdown of the overheating sensor. Solution: replace it.

- Adjust the igniter. Disconnect the electrode from the igniter so that the spark is in the center of the burner. Inspect and test the tubing connections for leaks.

If the ignition is delayed, clean the burner. It is highly likely that soot and soot has accumulated in it. Also, the problem may lie in the microswitch.

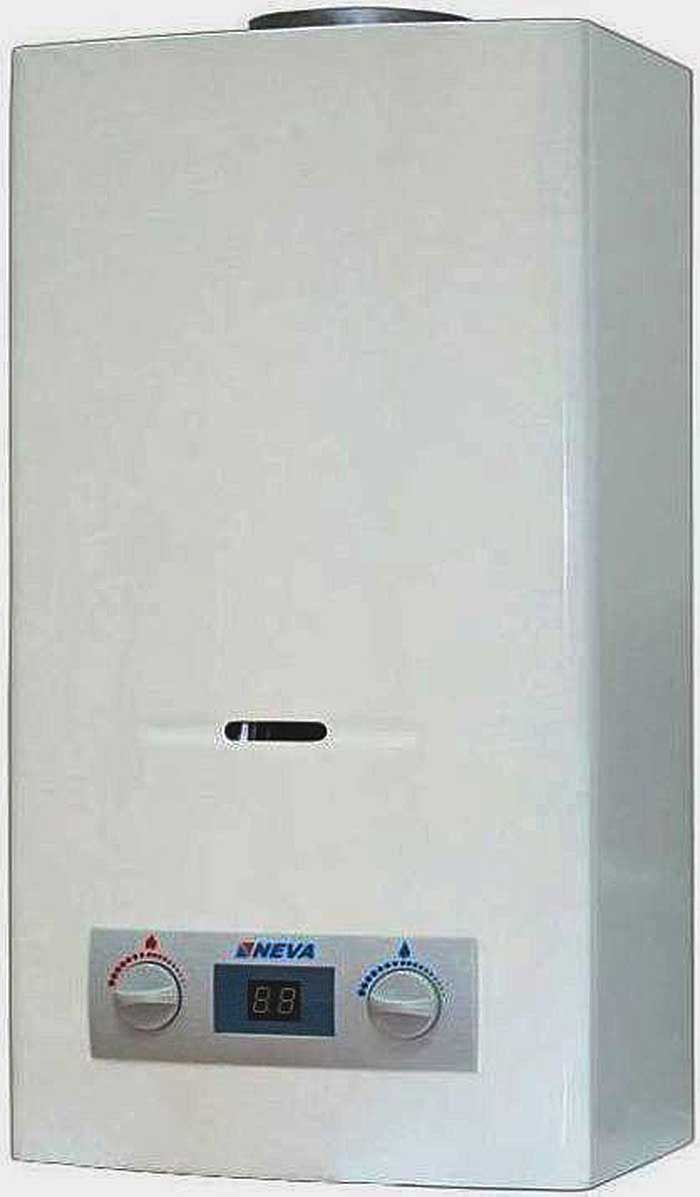

The advantage of domestic speakers

There are many types of malfunctions, so it is easier to find locally made parts. Therefore, speakers made in Russia, such as "Neva", are in great demand.

And the newer model "Neva 4511" consumes even less gas and is completely silent.

A gas water heater called "Oasis" is in demand, which can operate at low pressure and is protected from scale.

It is also equipped with a security system that blocks operation in case of overheating of the column.