What is a single-circuit boiler

Single-circuit gas boilers are used to heat the coolant with which the heating system is filled. The single-circuit boiler does not produce water for hot water supply. In premises where the heated area sometimes exceeds three hundred square meters, floor-standing boilers are used. These heating devices are much more powerful than wall-mounted ones.

Wall-mounted single-circuit heating devices are most often used in high-rise apartments, and can heat an area of up to three hundred square meters. These boilers are much more compact than floor-standing ones, and weigh a little more than 40 kilograms. Wall-mounted single-circuit boiler organically fits into the interior. Also, these wall-mounted devices are more functional than their floor-standing counterparts. The power of the most advanced models of wall-mounted single-circuit boilers is no more than 35 kilowatts.

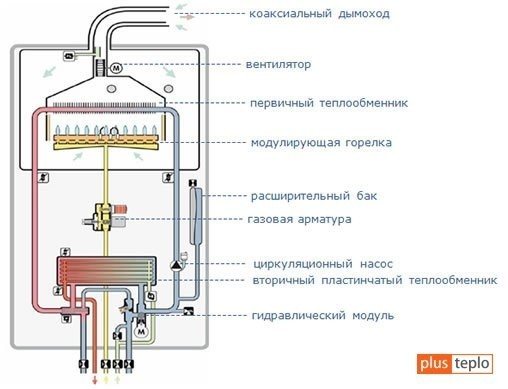

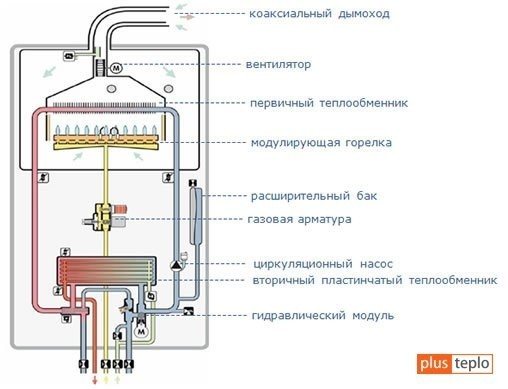

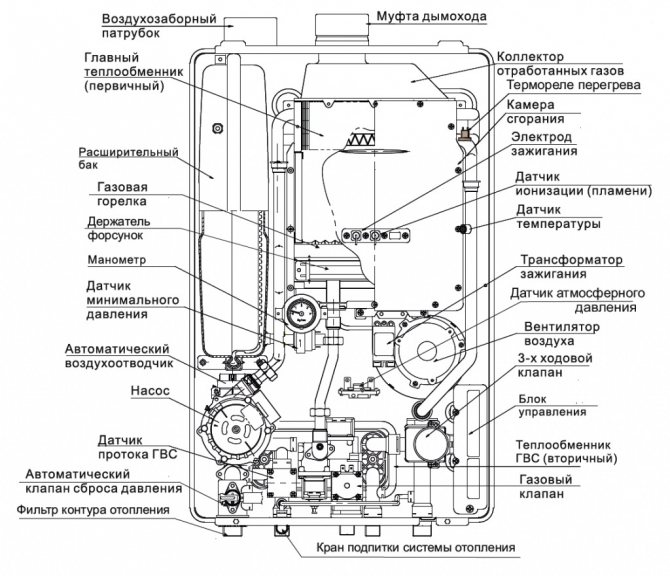

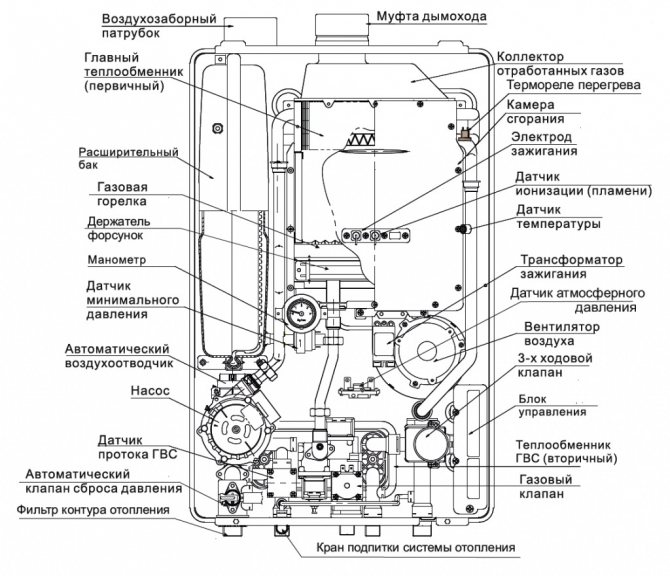

A single-circuit gas boiler does not have any complex elements and mechanisms in its design. This boiler consists of:

- burners;

- heat exchanger;

- control unit;

- water pump;

- turbine electric motor (if the boiler is with a closed combustion chamber);

- pressure gauge;

- sensors;

- shut-off valves.

Wall-mounted single-circuit boilers can be equipped with an expansion tank, which is hidden under the boiler casing. Also, the expansion tank can be part of the floor heating device, which has a low power.

How is a double-circuit gas heating boiler arranged?

On the heat engineering market, Italian double-circuit gas heating boilers are represented by a wide range of models. They are similar to each other, similar in design to boilers from other manufacturers, but ...

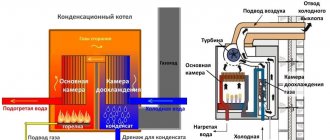

Diagram of a double-circuit gas heating boiler

Despite the "similarity" of the name and the schematic arrangement, such double-circuit boilers cannot be called the same. For all the similarities, there are differences. One of the key differences in the design of the boiler heat exchanger, which is designed to transfer the heat obtained during the combustion of fuel to the coolant. The heat exchanger is usually located in the upper part of the boiler and the gas burner is located below it. The heat generated during the combustion of gas, rising upward, is transferred to a metal heat exchanger, inside which a heat carrier flows. The role of the heat carrier is the transfer of thermal energy from the heat exchanger to the heating radiators located throughout the house or apartment.

Depending on the design of the heat exchanger, a distinction is made between:

- Boilers with two heat exchangers (primary and secondary);

- Boilers with bithermic heat exchanger.

Primary heat exchanger made of copper pipes with copper plates soldered onto them. The main function of such a primary heat exchanger is the transfer of heat from the gas combusted in the burner to the coolant of the heating system.

Primary heat exchanger of a double-circuit boiler

In the secondary heat exchanger, heat is exchanged between the coolant and running water from the hot water supply (DHW) line. Due to the fact that heat transfer occurs through thin plate partitions, the secondary heat exchanger is also called plate.

Schematic - secondary plate heat exchanger

Secondary plate heat exchanger. Side view

Secondary plate heat exchanger. View from above

Boilers with one bithermal heat exchanger are also used. In fact, in such a heat exchanger there is a tube in a tube.Heated water for hot water flows through the inner pipe, and the outer circuit is used to warm up the heating medium of the heating system.

Bithermal heat exchanger of a double-circuit boiler

By the type of removal of gas combustion products from the boiler, two-circuit, turbocharged gas heating boilers and with an open combustion chamber are distinguished. Turbocharged boilers (with a closed combustion chamber) do not require a separate chimney for their operation.

What is a double-circuit boiler

This heating device not only heats up the heating medium, but is also intended for preparing hot water. A double-circuit boiler has a more complex device than its single-circuit counterpart. The most complex device has a two-circuit heating device, which is equipped with a three-way valve.

There are two-circuit heating devices that are equipped with a pair of heat exchangers. One heat exchanger is responsible for heating the water in the heating system, and the second heats the water for water supply. The most rational design is provided by double-circuit heating devices, which are equipped with a bithermal heat exchanger. Such a heat exchanger is two in one. Inside the bithermal heat exchanger there is another heat exchanger, which is designed to heat water for domestic purposes. But the more popular models are boilers with separate heat exchangers.

Double-circuit gas boilers are good because they solve all the problems associated with the preparation of hot water by heating the room. Such heating devices are quite compact and fit organically into any interior. The design of a double-circuit heating device resembles the design of its single-circuit counterpart, which is also supplemented by:

- the second heat exchanger (if the boiler design provides it);

- 3-way valve (if the heat exchanger is not bithermal);

- inlet and outlet for the DHW pipeline.

How to extend the service life of double-circuit boilers?

The greatest harm to a double-circuit heating boiler is brought about by the provision of hot water supply, since in this case, "new" water with its salts and other impurities constantly circulates through the secondary or bithermal heat exchanger, which clog (scale) the heat exchanger. For a more gentle operating mode, it is recommended:

- Use a mechanical filter at the cold water inlet to the boiler.

Mechanical filter - Set the maximum heating temperature for "hot" water within 40-50 ° C.

- Carry out regular cleaning of the boiler heat exchangers at least once every 2-7 years. The term of the "inter-purification" operation of the heat exchanger depends on the water hardness and the amount of its consumption.

Dirty secondary heat exchanger

Pros and cons of a double-circuit boiler

A double-circuit heating device has many advantages. The main advantage of this device is that thanks to such a boiler, you can simultaneously heat the room and use hot water. Using a double-circuit boiler will save you from additional costs that may be associated with the purchase of a boiler. Also, the external attractiveness of double-circuit heating devices should be attributed to the indisputable advantages. These boilers look aesthetically pleasing not only in the boiler room, but also in any other room.

Modern double-circuit heating devices have high efficiency, which can significantly reduce the cost of utilities. Double-circuit boilers allow you to perfectly adjust the temperature inside the room, as well as adjust the temperature of the water in the DHW pipe.

These heating devices are not without several drawbacks, the list of which includes:

- turning off heating at the time of parsing hot water;

- relatively low productivity in the preparation of hot water.

Advantages and disadvantages of double-circuit boilers with an open chamber

The purchase of a double-circuit gas boiler with an open chamber in a private house gives the following advantages:

- due to the absence of a forced air fan in the burner area, the operation of the boiler is practically inaudible;

- heating of sanitary water and heating medium is carried out in one building;

- compact dimensions to save free space;

- full automation of the work process.

The disadvantages of this type of boilers include:

- the inability to simultaneously obtain good pressure and optimum temperature with the parallel use of several points of water intake;

- high likelihood of scale formation inside heat exchangers;

- dependence of automation on the availability of electricity.

If the purchase of an uninterruptible power supply (UPS) helps to cope with the last point, then only the installation of a single-circuit boiler + an indirect heating boiler can solve the first two drawbacks. In this case, the boiler does not heat tap water, but the prepared heat carrier, which excludes the appearance of scale inside the heat exchanger. At the same time, there are no restrictions on the connection of water intake points. And thanks to the implementation of the recirculation mode, there is no need to wait until the hot water from the double-circuit boiler reaches the tap.

What is an indirect heating boiler

Today more and more people are using indirect heating boilers. This useful device allows you to more efficiently use the heat of a gas boiler. In winter, when the heating system is turned on, the indirect heating boiler works from this system, and in the summer, when the boiler does not work for heating, such a boiler works from an electric heating element or the boiler is switched to summer mode (if the settings allow).

The heating of water in an indirect heating boiler does not occur in a direct way, but as if in an accompanying way. Inside such a boiler there is a rather large coil, inside which the coolant circulates from the heating system. Thus, the gas boiler heats the water in the indirect coil, which circulates through the pump in the heating system, and the heat exchanger heats the water in the boiler. Such heating of water for the hot water main is recognized as the most cost-effective.

The casing of this boiler is mainly made of steel sheet, and the inside of it is made of stainless steel. Between the outer and inner parts of the indirect heating boiler there is a special material that hardly conducts heat. The design of such a boiler is very similar to that of a thermos.

As a rule, an indirect heating boiler is installed near the heating boiler. The heated coolant must pass through the boiler first. The water in such a boiler will always be hot, and several hot water extraction points can be connected to this boiler at once. Hot water is heated in an indirect heating boiler without affecting the operation of the heating system.

In most cases, such a boiler is equipped with a highly efficient heat exchanger made of special steel. More expensive indirect heating boilers are equipped with heat exchangers made of brass. The heat exchanger of the boiler has the shape of a long spiral, which allows you to very quickly heat the water to the temperature that the water in the heating system currently has.

The device and features of the operation of boilers

Modern gas boilers, depending on the number of circuits, can be single-circuit and double-circuit. They are similar in appearance and design, but are designed to solve different problems, and in different conditions.

As a result, it can be argued that both types of equipment are equally useful and effective, so there is no better one among them. So it all depends on the right choice. Next, we will figure out in detail how the single-circuit type of a gas boiler still differs from its two-circuit counterpart.

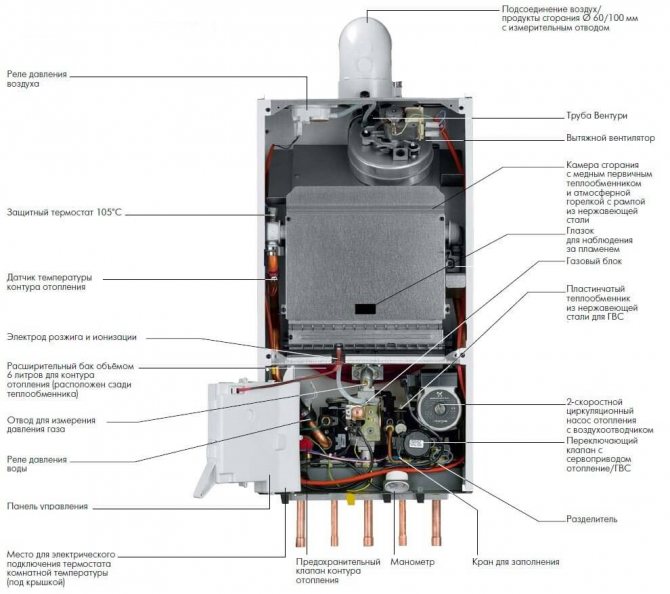

Differences in the design of single and double-circuit units

Products that belong to both types of equipment for the most part consist of the same components.

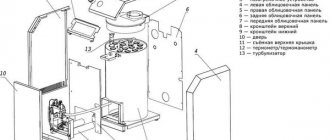

A detailed device of a modern single-circuit wall-mounted boiler and a diagram of the device of its double-circuit "brother" are shown in the following figures:

Any single-circuit boiler is structurally simple. Which makes them more reliable and affordable. But the listed advantages are leveled by the need to buy a boiler.

The presence of a complex heat exchanger and a three-way valve in a two-circuit unit makes it fundamentally different from any single-circuit analogue

The main units of the two types of boilers are similar - both the name and the purpose.

So, similar elements of single and double-circuit equipment:

- cold water supply pipelines;

- gas-burner;

- membrane tank;

- chimney.

Even a structural element designed for heating water is called the same for them - a heat exchanger.

But, if you look at it, it turns out: the name is the only thing that is similar to the specified unit for boilers of different types - the heat exchanger of a single-circuit unit is a pipe that serves to efficiently transfer the heat released during the combustion of gas to water.

An important difference between double-circuit boilers is that they are equipped with everything necessary for space heating and hot water supply. Therefore, there will be no additional costs for the purchase of equipment, and they also save space.

And in the case of its dual-circuit counterpart, everything is not so simple, since its heat exchanger is structurally more complicated. Moreover, such products are divided into separate subspecies and are bithermic and doubled.

In the first case, the structure is a pipe placed in a similar product with a larger diameter. This feature allows you to create 2 circuits, one of which is designed to transfer heat to the liquid used for heating, and the second for the hot water supply system.

The double heat exchanger consists of:

- pipeswhich provide heating water for heating;

- platestransferring heat to liquid for water supply.

That is, the design complexity of the heat exchangers of double-circuit boilers differ solely because of the need to solve 2 problems.

But still, the most significant difference between single-circuit and double-circuit products is the presence in the design of the latter three-way valve... The task of which is to change the direction of hot water.

So in the standard position, the valve is in a position in which the coolant is supplied only to the radiators. Everything changes when the hot water tap opens. Since the three-way valve, having received the corresponding signal, moves to a different position. Namely, in providing hot water supply.

In this case, the supply of the coolant to the radiators is stopped, and in full - the premises will not be heated throughout the entire period of using hot water for domestic purposes.

That is, the design of a double-circuit boiler allows it to supply hot water only in one of two modes. But still, such a feature should not be considered a weak point of the equipment.

Comparative overview of gas boilers

Both of the presented types of equipment are used to heat the coolant for the purpose of heating rooms and buildings. And on this, the functionality of single-circuit boilers is limited.

A single-circuit gas boiler serves exclusively for heating the coolant entering the radiators of the heating system. But if you add an indirect heating boiler to it, then it, like its two-circuit counterpart, will be able to provide hot water supply

Their double-circuit counterparts are additionally used to provide hot water supply in order to solve any domestic problems. That is, they make it possible to take a shower, perform any other hygiene procedures, wash dishes, etc.

Next, we will conduct a comparative review of single and double-circuit boilers according to a number of criteria.

| Comparison criteria | Single-circuit boiler | Double-circuit boiler |

| type of instalation | floor; wall | floor; wall |

| Additional investment | absent if there is no demand for hot water supply; if DHW is required, then you need to purchase a storage boiler | absent if there are no more than 2 tapping points and they are located next to the boiler |

| Profitability | turns on when the water temperature in the boiler is cooled below the permissible level | the heating circuit turns on when the coolant cools below the permissible level; the DHW circuit is switched on every time after the start of water withdrawal |

| Compactness | when used in conjunction with a boiler, the footprint actually doubles | more compact than single-circuit; wall models are suitable for use in confined spaces |

| The convenience of use | when used in conjunction with a boiler, hot water will be of the same temperature at all points of extraction; the coolant is supplied to the heating system evenly | when the boiler power is insufficient and there are many points of water intake, changes in the temperature of the water and the coolant are possible, and sharp; no water is supplied to the heating system when the taps are open |

As you can see, for the organization of hot water supply in the presence of a single-circuit boiler, you will have to buy additional equipment. For example, an indirect heating boiler. And these are additional expenses.

Moreover, after purchasing a boiler, it must be correctly installed and connected. And how to do this correctly and what to take into account when operating such devices, we described in detail in this article.

Pros and cons of a single-circuit boiler and BKN

A boiler that prepares hot water by indirect heating is often used in conjunction with a single-circuit heating device. This tandem has both advantages and disadvantages. The main advantage of such a boiler is that this device practically does not require any maintenance and financial costs throughout the entire period of operation. The indirect heating boiler does not overload the power grid with excessive load, which is very important for those regions where voltage sags are observed.

An indirect heating boiler that works in conjunction with a single-circuit gas boiler is very convenient to use. Such a boiler rationally consumes water, since it does not require draining a large amount of water until the moment when hot water flows. Such a boiler heats water very quickly, and several mixers can be connected to this device, which can be located in different places of the house or apartment.

The heat exchanger of the indirect heating boiler operates under conditions that completely eliminate the formation of scale. Also, the design prevents the formation of harmful microorganisms inside the device. The indirect heating boiler does not require periodic cleaning and can operate for more than ten years without any maintenance.

The heat exchanger of the indirectly heated boiler is specially protected against corrosion. This protection very effectively protects these elements of the boiler from stray currents that occur in the water mains.

Indirect heating boilers have several minor drawbacks, the list of which includes:

- higher cost than their electric counterparts;

- indirect heating boilers are larger than conventional boilers;

Double-circuit boilers with an open combustion chamber

Wall-mounted double-circuit gas boilers differ from single-circuit boilers in that they have an additional heat exchanger. It is installed in order to specially prepare sanitary hot water in it. Owners of such a boiler will not need to install auxiliary devices for obtaining hot water. All the necessary elements are in one case.

It should be borne in mind that double-circuit boilers are designed exclusively for operation in systems where there are only 1-2 draw-off points, for example, hot water is supplied to the shower and kitchen sink. Whereas the sets of single-circuit boiler + indirect heating boiler will allow you to simultaneously comfortably use the bathroom, shower and sink in the kitchen without loss of pressure.

Using a single-circuit boiler and a conventional boiler

Along with indirect heating boilers with single-circuit gas boilers, conventional boilers are also used. Conventional electric boilers are slightly cheaper than indirect heating boilers, but they are significantly inferior to them in many parameters. A conventional electric boiler heats water much longer and this device needs regular maintenance.

It is advisable to clean the electric boiler from scale once a year, and also periodically change the anode, which protects the electric heater. An electric boiler also needs a reliable power supply, and an independent electrical line must be laid to this device. Also, this water heater seriously loads the power grid - in general. Therefore, it is better to use an electric boiler in those rooms where the electrical wiring has a margin of safety.

What is a gas double-circuit wall-mounted boiler?

Such boilers are gas-fired heating devices. The gaseous fuel is burned in such a boiler, as a result of which a certain amount of heat energy is generated. This energy can be used for space heating, water heating, etc. Most often, natural gas - propane-butane and methane - is used as a starting fuel for gas boilers. And there are several reasons to choose just such a gas:

- Ease of use;

- The ability to quickly automate the operation of gas-powered devices;

- Economical gas consumption;

- Fuel availability;

A high level of gas combustion efficiency, and, as a result, a sufficient amount of heat to heat residential and industrial premises.

Gas burners as part of a double-circuit boiler

The burner of a gas boiler is responsible for obtaining the required amount of heat, which can ensure the correct operation of the heating system in each room of the heated object. Also, the water is heated to the required temperature and is supplied hot in the proper volume. Thermal energy can be obtained by burning appropriate volumes of fuel. For this, the burner is placed in the combustion chamber, where, in addition to gas, air is also injected, which helps to maintain the flame.

Depending on the selected mode, the burners can be conditionally divided into single-level, multi-level and simulated. In the first version, the equipment operates only in two modes - "start" and "stop", is highly economical, inexpensive and has a simple design. Double-deck burners can operate at full or partial power. Its advantages can be fully appreciated, starting in spring, when there is no need for heating, and therefore it makes no sense to operate the device at full strength.The modulating burner is considered the most expensive, with its help you can adjust and regulate the power of the boiler. The latter is economical and lasts quite a long time.

Structurally, burners are open and closed. In the first case, the air, without which full combustion of fuel is impossible, is supplied from the room where the boiler is located. Such a system is equipped with a chimney, with its help natural draft is provided.

Atmospheric heating boilers are equipped with a conventional metal pipe, while turbocharged models are equipped with a coaxial chimney. They can be installed vertically, but often they are located at an angle - this option is connected to a common shaft, through which smoke and combustion products are fully removed.

Special attention should be paid to turbocharged models of gas boilers, in which closed-type combustion chambers are installed. Oxygen enters them forcibly, and therefore they are considered more reliable and do not pose any danger in the process of work, which makes them in demand in residential premises. In addition to the chimney, they need a special channel - it is through it that oxygen will be supplied to the chamber.

For turbo boilers, coaxial pipes are required in order to remove smoke and draw in fresh air from the street. In some models, there are two such elements, in addition they are equipped with a pipe for air supply.

All of the above models are necessarily equipped with fans that promote smoke, as well as automation and a multi-level protection system.