Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Irina. and what is the coefficient for dismantling (to TEP18-03-001-02) radiators

it would be more correct to take, 0.4 or 0.7, if the same

radiator

dismantled and then put on another place I know that there is a direct price TERr65-19-1 for dismantling

radiators

, but something like that happened.

... pipelines ". According to clause 6. Appendix 3 to FSSTS-01-2001 (Appendix), the estimated price for radiators

cast iron does not take into account the cost of preparation

radiators

to install: “6. In estimated prices for

radiators

cast iron preparation cost is not included

radiators

to installation (grouping, regrouping, installing or replacing gaskets.

... cost of steel radiators

? Answer: In the monthly magazine "Estimated prices in construction" (SSC), the unit of measure for estimated prices for

radiators

steel installed in pieces, but at the same time in the name

radiators

their power is indicated in kW, so that you can determine the cost

radiators

and in kW. We believe that any of these meters can.

... heating. This indicator changes in kW of heat that a separate section can emit (for sectional aluminum or bimetallic radiators

) or all

radiator

(for solid steel or bimetallic

radiators

heating). Accordingly, when selecting specific models

radiators

.

... suits him, he needs this work (change of 7 seconds to reach 2,500 rubles) they decide to make their own calculation: dismantling radiator

- 900 rubles, installation

radiator

- 1300 rubles. and so that I would make an estimate taking into account their calculations, but without applying prices from the collections for dismantling and installation

radiators

... How to be in this case, I can't just score such an amount, but what about payroll, HP, joint venture.

Author: Irina. Good afternoon, colleagues. Tell me the most correct price for dismantling the brackets radiators

since the customer writes in the comments that he was not taken into account (in the estimate, dismantling

radiators

by TERr 65-19-1)

Author: Tatiana Polubarieva. Good day! Please tell me what is the price for the regrouping of cast iron radiators

... Thank.

... which collections should take into account these works? Answer: Radiators

cast iron MS (code 300 - 0555) are produced in 4 and 7 sections. If the contractor completes

radiators

at the facility, or at its base, then these additional works are paid according to the Collection TERr-2001 No. 65, tab. 65-02-020 "Rearrangement of old sections

radiators

»

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day. There is a question: how to take into account the bypass device during installation radiators

?

a source

What is measured and how is the heat transfer of radiators calculated?

Heat dissipation of the radiator - an indicator that indicates the amount of heat transferred by the radiator to the room per unit of time. It is measured in Watts (W). You can also find other names for this indicator on the Internet: heat power, power, heat flow

... Cal / h can also be found as a unit for measuring heat transfer, they can be converted to Watts and vice versa according to the dependence: 1 W = 859.8452279 cal / h.

Heat is transferred to a room by two processes: radiation and convection. Design

modern heating devices are designed so that, by combining both processes, to achieve maximum heat transfer.

The thermal power of radiators depends, in addition to its design, on three values: the temperature of the coolant at the radiator inlet, at the outlet and the air temperature in the room. Temperature head (Δt, K) represents the temperature difference between the radiator and the room. The heatsink temperature is taken as the average between the temperatures at the inlet and outlet of the heatsink. Thus, simple temperature head formula next:

Where

Δt - temperature head, K;

tpod. - coolant temperature at the radiator inlet, K;

torev. - coolant outlet temperature, K;

troom - room air temperature, K.

This formula is widely used both for calculations and in reference literature. However, calculating the heatsink temperature as an arithmetic mean does not reflect the actual heatsink temperature. A more accurate value can be obtained using the logarithmic dependence, then logarithmic formula for temperature head will look like this:

In the technical documentation of radiator manufacturers, you can find the heat transfer values obtained according to three main test methods: according to the standards EN-442, DIN 4704 and NIIST. EN 442 is a pan-European standard that all manufacturers of heating devices are guided by. The tests are carried out at a temperature of 75/65/20 in the cabin, where the ceiling, floor and walls are cooled except for the one opposite to the radiator. In accordance with DIN 4704, the heater is tested in 90/70/20 mode and all enclosing structures are cooled. According to NIIST, the temperature head is 70oC, the wall opposite the radiator and the floor are not cooled, the radiator is separated from the wall by a heat-insulating screen. Heat dissipation obtained according to different standards may vary by 1-8%.

If a different temperature regime is used in the heating system, then the heat transfer of the heating devices must be recalculated. This can be done by heat transfer conversion formula:

where Ф - heat transfer at the selected temperature regime;

ФSL - standard heat transfer (according to EN-442: heat transfer in 75/65/20 mode);

Δtln is the actual temperature head, calculated in the logarithmic way (for simplicity, you can use the arithmetic mean method);

Δtnorm - standard temperature head, i.e. initial: EN 442 - 50o, DIN 4704 - 60o, NIIST - 70o (calculation by arithmetic mean, recalculate for accuracy);

n - exponent (specified by the manufacturer).

The index n characterizes the design of the radiator. The higher this indicator, the more significantly the heat transfer decreases at low-temperature heating modes, and, conversely, increases faster at high temperatures of the coolant.

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

... pipelines ". According to clause 6. Appendix 3 to FSSTS-01-2001 (Appendix), the estimated price for radiators

cast iron does not take into account the cost of preparation

radiators

to

installation

: “6. In estimated prices for

radiators

cast iron preparation cost is not included

radiators

to

installation

(grouping, regrouping,

installation

or replacement of gaskets.

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

... please tell me what price can be applied when making horizontal holes in drywall about 5-7mm wide in places installations

radiators

? Drywall goes like a screen

radiator

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thank you in advance.

Author: Natalya. Hello, tell me what price you can apply for installations

control valves on

radiator

heating.Air cock comes with

radiator

.

Author: katya. Hello. Help me please. How can I change one steel radiator

in kW. Thank you in advance.

Author: Galina. We work on municipal orders. I cannot understand how the amount of work for installation

radiator

... I multiply the kW of 1 section by the number of sections and divide by unit. measurements (100 kW). it turns out more than CMX offers. You are welcome.

Author: ProSlave. Judging by your investment, you should have: if 8 sections of 127W = 1016 W / h or 1.016 kW / h. If you have 8 radiators

you get 8.128 kW / h. Accordingly, the price should be: 0.08128. Well, look what you have there.

Factors affecting the efficiency of heat transfer from a heating radiator

One of the key elements of the heating system is the radiator.

The radiator transfers heat energy from the heat source to the air in the room. Heat from a radiator is transferred by convection, radiation and heat conduction.

The heat transfer efficiency of an appliance depends on many factors, such as:

- Radiator installation method;

- Method of connecting the heater to the system;

- The presence of dust on the heater - microparticles significantly reduce heat transfer;

- Heater color and coating composition;

- The surface of the building structure behind the radiator;

- Indoor air speed, air flow direction;

- Atmospheric pressure - the coefficient of thermal conductivity decreases with decreasing air density.

Consider two main factors that have a significant impact on heat transfer:

1. Radiator installation method

The most optimal location of the heater, from the point of view of heating technology, is the installation under the window. Since the resistance to heat transfer of the window is several times less than the resistance to heat transfer of the outer wall, one of the largest heat losses occurs through the window. The radiator under the window creates a thermal curtain that reduces heat leakage from the room. The heater also heats the outside air that passes through leaks and cracks in the window frame (infiltration).

It is possible to install heating devices near the inner wall away from the outer walls, outer doors and windows, as well as under the ceiling - in this case, the heat transfer efficiency of the device is reduced by about 10%.

The ideal option would be to locate the radiator under a window without a window sill -100% heat transfer. Due to the window sill, the trajectory of air movement changes, and heat transfer decreases by 3-4%.

When the radiator is located in a niche, the heat transfer decreases by about 7%.

In the case of installing a heating device behind a decorative screen, which has a space for air at the bottom, the heat transfer of the radiator is reduced by 5-7%.

Radiators completely closed with a decorative screen reduce heat transfer by 20-25%.

2. Method of connecting the heater to the system

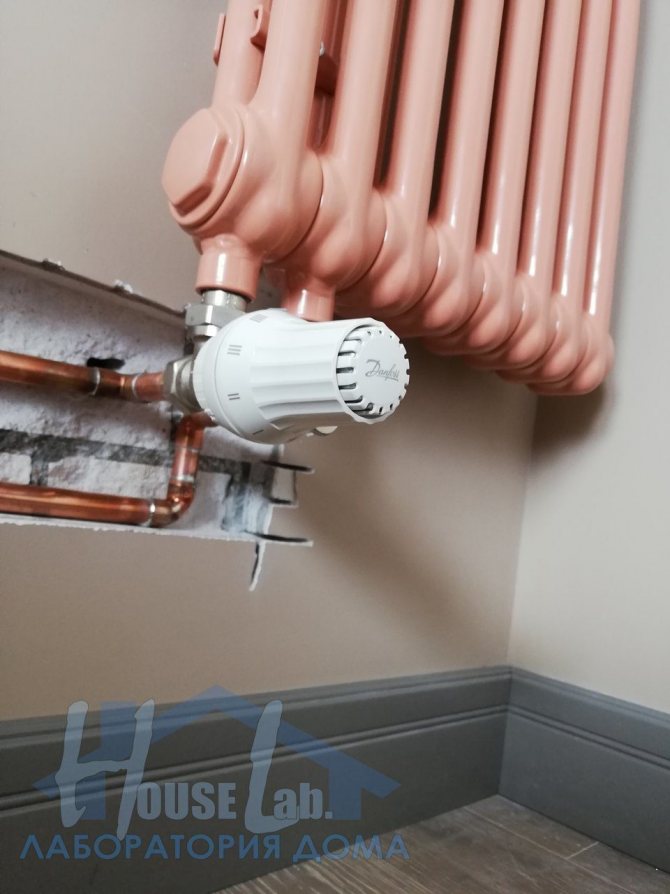

The way the radiator is connected to the heating system depends on the type of radiator. Bottom connection of radiators It is used with VK type radiators with a built-in thermostatic valve and bottom connection of the supply and return pipelines. Center distance 50 mm. The axis of the supply line is always further from the side edge of the radiator. Reverse connection will cause a drop in the heating output of the heater by more than 30%.

The pipe to the VK type radiator can come out of the floor (Fig. 1) or from the wall (Fig. 2). The heating appliance can be connected to the heating system via the radiator valve or directly.

There are many variations of connections, which depend on the type of fittings used, on the individual preferences of the customer, on the budget allocated for the heating system.

The pictures show the most common options for connecting heating devices in the KAN-therm Push and KAN-therm Press systems..

fig. 1

fig. 2

For radiators with side connection, the following types of connections are available:

- Lateral versatile (diagonal)

The pipe to the radiator can also come out of the floor (fig. 3) or from the wall (fig. 4). This connection is optimal in terms of heat dissipation. Recommended for radiators longer than 2 meters, as well as for those whose length is four times the height. The supply pipe connects to the left or right upper nipple and the return pipe to the opposite lower nipple. The opposite connection (bottom to top) will reduce heat transfer from the radiator by more than 20%

| Fig. 3

| Fig. four

|

- One-way side connection

The supply pipe is connected to the upper connection of the radiator, and the return pipe is connected to the lower one on the same side (Fig. 5). The opposite connection will reduce the heat dissipation of the radiator by about 20%.

fig. 5

|

|

Saddle connection

The supply and return pipes are connected to the lower fittings (fig. 6). With this type of connection, the heat transfer of the radiator will be approximately 10% lower than the nominal.

Systems KAN—therm offer a wide range of elements that allow for various schemes for connecting heating devices in a wide price range. In the offer of the company KAN special elements for connecting heating devices are presented, such as bends and tees with copper nickel-plated pipes Ø15 mm, various fittings for copper pipes, plastic masking nozzles and other elements that allow to implement all existing methods of connecting heating devices.

A correctly chosen method of connecting a heating device will allow you to effectively use the heating system, ensure the system's operability for many years and will bring aesthetic pleasure.

Material taken from www.ru.kan-therm.com

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day! Tell me rate

on

installation

oil

radiator

?

Author: Anna Vorontsova. I did not quite understand you, for example 1 radiator

consists of 12 sections, as in this

rates

then put the quantity? )) Our head is already going with these

radiators

)

Author: Tanya Bazhenova. “Natalya writes: Hello, tell me what rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

. "If you are not only installing

radiators

, but also install the pipeline itself.

According to clause 1.18.7. GESN 81-02-017-2001 norm 18-03-001-01 "Installation

radiators

cast iron "does not take into account the work before. ... Appendix 3 to FSSTs-01-2001 (Appendices) estimated price for

radiators

cast iron does not include preparation costs. ... the current estimate and normative base of the FSNB - 2001 norms and

rates

for crimping, grouping, replacement of gaskets.

Author: Alena. Good day! please tell me which one rate

can be used when making horizontal holes in drywall with a width of about 5-7 mm in places

installationsradiators

? Drywall goes like a screen

radiator

Author: Anna Vorontsova. Good day. Please tell me which or which rates

apply to assembly

radiators

bimetallic? Those. separate sections come to the object, we need to collect them in

radiators

(different in the number of sections) and then install.

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thank you in advance.

Author: Natalya. Hello, tell me which one rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

.

Author: katya. Hello. Help me please. How can I change one steel radiator

in kW.Thank you in advance.

a source

Thermal calculation

Table 4.1 The volume of the room heated by 1 kW of device power, depending on the thermal insulation of the house, is given in the table:

The thickness of the walls is 1.5-2 bricks with thermal insulation, or the same from a bar or a log house, the area of windows and doors is no more than 15% (a well-insulated house for winter living)

| 20-25 m 3 | |

| The street is bordered by 2 or 3 walls with a thickness of at least one brick with thermal insulation or from a bar, the area of windows and doors is not more than 25% (averagely insulated house) | 14-18 m 3 |

| Panel walls with internal cladding, insulated roof, no drafts (insulated summer house) | 8-12 m 3 |

| Thin walls made of timber, corrugated panels, etc. (trailer, guardhouse) | 5-7 m 3 |

The refined thermal calculation is carried out according to the existing methods using the main calculated dependencies set forth in the special reference and information literature [8], [9], taking into account the data given in these recommendations.

When the total water consumption in the heating system is found, its consumption, determined based on the total heat loss of the building, increases in proportion to the correction factors. The first one? 1 depends on the nomenclature step of the radiator and is taken, depending on the height of the radiator, equal to 1.01 at N m = 300 mm and 1.02 at N m = 500 mm, and the second -? 2 - from the share of increase in heat loss through the radiator section and is taken equal to 1.02 when the device is placed at the outer wall and 1.07 at the outer glazing.

Heat flux of radiators Q, W, under conditions other than normal (normalized), is determined by the formula

Where Q well - the nominal heat flux of the radiator under normal conditions, equal to the product of the nominal heat flux per section q n y (see Table 1.1), by the number of sections in the device N, W;

Θ Is the actual temperature head, ° С, determined by the formula

Θ = (t n + t k) - t n = t n - Δ t pr / 2 - t n (4.2)

Here t n and t k - respectively, the initial and final temperatures of the coolant (at the inlet and outlet) in the heating device, ° С; t n Is the design temperature of the room, taken equal to the design temperature of the air in the heated room, t in, ° C; Δt np - temperature difference of the coolant between the inlet and outlet of the heating device, ° С; 70 - normalized temperature head, ° С; from - a correction factor, which takes into account the effect of the flow pattern of the coolant on the heat flow and the heat transfer coefficient of the device at the normalized temperature head, flow rate of the coolant and atmospheric pressure (taken according to Table 4.2); n and m - empirical exponents, respectively, at relative temperature head and coolant flow rate (taken according to Table 4.2); M pr Is the actual mass flow rate of the coolant through the heating device, kg / s; 0,1 - normalized mass flow rate of the coolant through the heating device, kg / s; b - dimensionless correction factor for the calculated atmospheric pressure (taken according to Table 4.3); β 3 - dimensionless correction factor characterizing the dependence of the heat transfer of the radiator on the number of sections in it for any flow patterns of the coolant (taken according to Table 4.4); R - dimensionless correction factor, which takes into account the specificity of the dependence of the heat flux and heat transfer coefficient of the radiator on the number of columns in it when the coolant moves "from bottom to top" (taken from Table 4.5); φ1 = (Θ / 70) 1+ n - dimensionless correction factor, with the help of which the change in the heat flow of heating devices is taken into account when the calculated temperature head differs from the normal one (taken according to Table 4.6); φ2 = c (M pr / 0.1) m Is a dimensionless correction factor, with the help of which the change in the heat flow of the heater is taken into account when the actual mass flow rate of the coolant through the device differs from normal (taken according to table.4.7); with the flow diagram of the coolant "top-down" for all standard sizes of radiators? 2 = 1; when the coolant moves "from bottom to bottom" -? 2 = 0.95;

To well Is the heat transfer coefficient of the device under normal conditions, determined by the formula

Where F - the area of the external heat-transfer surface of the radiator, equal to the product of the area of the heating surface of one section f (taken from Table 1.1) by the number of sections in the device N, m 2.

The heat transfer coefficient of the radiator K, W / (m 2o C) under conditions other than normal, is determined by the formula

According to the results of thermal tests of various samples of ChM2 radiators with an installation height of 300 and 500 mm, the values of the exponents n and m of the coefficient c depend not only on the studied ranges of variation Θ and M pr, but also on the height and even the length of the device. To simplify engineering calculations without introducing a noticeable error, the values of these indicators were, if possible, averaged.

Table 4.2 Average values of exponents

n and m and coefficient c for different patterns of coolant movement in radiators of the ChM series

| Coolant flow diagram | Indicator values for radiators | |||||

| ChM1-70-300, ChM2-100-300, ChM3-120-300 | ChM1-70-500, ChM2-100-500, ChM3-120-500 | |||||

| P | t | from | P | t | from | |

| Top down | 0,3 | 0 | 1 | 0,3 | 0 | 1 |

| Upwards | 0,33 | 0,05 | 0,9 | 0,33 | 0,05 | 0,91 |

| From bottom to bottom | 0.3 | 0 | 0,95 | 0,3 | 0 | 0,95 |

Table 4.3 Average values of the correction factor b

| Atmosphere pressure | GPa | 920 | 933 | 947 | 960 | 973 | 987 | 1000 | 1013,3 | 1040 |

| mmHg st | 690 | 700 | 710 | 720 | 730 | 740 | 750 | 760 | 780 | |

| B | 0,959 | 0,965 | 0,970 | 0,976 | 0,982 | 0,988 | 0,994 | 1 | 1,011 | |

Table 4.4 Average coefficient values β3 taking into account the effect of the number of sections in the radiator on its heat flux

| Radiator type | Β3 values with the number of sections in the radiator | ||||||

| 3 | 4 | 5-6 | 7-8 | 9-12 | 13-18 | 19-22 | |

| ChM1-70-300 ChM2-100-300 ChM3-120-300 | 1,03 | 1,02 | 1,015 | 1,01 | 1 | 0,99 | 0,97 |

| ChM1-70-500 ChM2-100-500 ChM3-120-500 | 1,035 | 1,025 | 1,015 | 1 | 0,99 | 0,98 | 0,96 |

Table 4.5 Average values of the correction coefficient p when the coolant moves according to the "bottom-up" scheme

| Radiator type | P values with the number of sections in the radiator | |||

| 3 | 4 | 5 | 6 and more | |

| ChM1-70-300 ChM2-100-300 ChM3-120-300 | 1,03 | 1,015 | 1,01 | 1 |

| ChM1-70-500 ChM2-100-500 ChM3-120-500 | 1,02 | 1,01 | 1,005 | 1 |

Table 4.6 Values of the correction factor

| Θ, ° C | φ1 with the flow pattern of the coolant | Θ, ° C | φ1 with the flow pattern of the coolant | |||

| top-down and bottom-down | upwards | top-down and bottom-down | upwards | |||

| 44 | 0,547 | 0,539 | 78 | 1,151 | 1,155 | |

| 46 | 0,579 | 0,572 | 80 | 1,19 | 1,194 | |

| 48 | 0,612 | 0,605 | 82 | 1,228 | 1,234 | |

| 50 | 0.545 | 0,639 | 84 | 1,267 | 1,274 | |

| 52 | 0,679 | 0,673 | 86 | 1,307 | 1,315 | |

| 54 | 0,714 | 0,703 | 88 | 1,346 | 1,356 | |

| 56 | 0,748 | 0,743 | 90 | 1,386 | 1,397 | |

| 53 | 0,783 | 0,779 | 92 | 1,427 | 1,438 | |

| 60 | 0,818 | 0,815 | 94 | 1,467 | 1,48 | |

| 62 | 0,854 | 0,851 | 96 | 1,508 | 1,522 | |

| 64 | 0,89 | 0,888 | 98 | 1,549 | 1,564 | |

| 66 | 0,926 | 0,925 | 100 | 1,59 | 1,607 | |

| 68 | 0,963 | 0,962 | 102 | 1,631 | 1,65 | |

| 70 | 1 | 1 | 104 | 1,673 | 1,693 | |

| 72 | 1,037 | 1,038 | 106 | 1,715 | 1,737 | |

| 74 | 1,075 | 1,077 | 108 | 1,757 | 1,78 | |

| 74 | 1,113 | 1,116 | 110 | 1,8 | 1,824 | |

Table 4.7 Values of the correction factor φ2 with the flow pattern of the coolant "bottom-up"

| M pr | The values φ2 for FM radiators with mounting height, mm | ||

| kg / s | kg / h | 300 | 500 |

| 0,015 | 54 | 0,819 | 0,828 |

| 0,02 | 72 | 0,83 | 0,84 |

| 0,025 | 90 | 0,84 | 0,849 |

| 0,03 | 108 | 0,847 | 0,857 |

| 0,035 | 126 | 0,854 | 0.863 |

| 0,04 | 144 | 0,86 | 0,869 |

| 0,05 | 180 | 0,869 | 0,879 |

| 0,06 | 216 | 0,877 | 0,887 |

| 0,07 | 252 | 0,884 | 0,894 |

| 0,08 | 233 | 0,89 | 0,9 |

| 0,09 | 324 | 0,895 | 0,905 |

| 0,1 | 360 | 0,9 | 0,91 |

| 0,125 | 450 | 0,91 | 0,92 |

| 0,15 | 540 | 0,918 | 0,929 |

Below is an example of the calculation.

Conditions for calculation

It is required to perform a thermal calculation of the floor stand of a vertical single-pipe water heating system with a cast-iron radiator ChM2. The radiator is installed under a window (1200 mm long) on an outer wall without a niche on the first floor of a 9-storey residential building, connected to a riser with an offset closing section and an RTD-G thermostat on the piping to the device. The flow diagram of the heat carrier "from bottom to top".

The heat loss of the room is 1400 W. The temperature of the hot heat carrier at the inlet to the riser tn is conventionally assumed equal to 95 ° C (excluding heat losses in the pipeline), the calculated temperature difference along the riser? t st = 25 ° C, air temperature in the heated room t b = 20 s C, atmospheric air pressure 1013.3 GPa, i.e. b = 1. Average water consumption in the riser M st = 235 kg / h (0.065 kg / s). The diameters of the riser pipes and connections are determined as a result of hydraulic calculations and are equal to 20 mm, the diameter of the closing section is 15 mm. The total length of vertically and horizontally placed pipes in the room is 3.8 m:

L mp. In = 2.3 m (d y = 20 mm), L mp. In = 0.4 m (d y = 15 mm), L mp. G = 1.1 m (d y = 20 mm).

Thermal calculation sequence

The heat flux of the device under design conditions Q, W, is determined by the formula

Q = Q pot - Q mp .p, (4.5)

where Q sweat is the heat loss of the room under design conditions, W;

Q mp .п - useful heat flux from heat pipes (pipes), W.

The useful heat flux of heat pipes is taken equal to 50-90% of the total heat transfer of pipes when they are laid near the outer walls, and reaches 100% when the risers are located at vertical partitions,

In our example, we take Q mp .п = 0.9 Q mp,

Where Q mp = q mp. В L mp. В + q mp. Г · L mp. Г (4.6)

q mp .w and q mp .g - heat fluxes of 1 m of open-laid vertical and horizontal pipes, respectively, determined according to Appendix 2, W / m;

L mp. In and · L mp.g - total length of vertical and horizontal heat pipelines, m.

The useful heat flux from the pipes Q mp.p when the coolant moves "up-down" is determined at a temperature head Θ with r.tr = t n - t w = 95-20 = 75 ° С (excluding water cooling in the radiator), where t n is the temperature of the coolant at the entrance to the stowage floor, ° С.

Q mp. n = 0.9 (78.5· 2,3+62,8· 0,4+1,28· 78, 5· 1.1) = 285 W.

Q = Q sweat - Q mp .p = 1400-285 = 1115 W.

According to the table. 3.1 we take the value of the leakage coefficient a pr equal to 0.265. The water flow through the device is equal to M pr = a pr· M st = 0.265 · 0.065 = 0.0172 kg / s.

The temperature difference of the coolant between the inlet to the heater and the outlet from it Δt np is determined by the formula

where C is the specific heat capacity of water, equal to 4186.8 J / (kg ° C).

Temperature head Θ with an acceptable approximation (without taking into account the cooling of water in the riser of a one-pipe heating system) is determined by formula (4.2).

Θ = t n - Δt pr / 2 - t n = 95-7.75-20 = 67.25 ° С

We accept the radiator ChM2-100-500-0.9 in advance for installation. Taking into account the analysis of the data in tables 4.5 and 4.6, we preliminarily assume that the values β3 and p are equal to 1, then the required heat flux of the device under normal conditions is determined by the formula

, (4 .7 )

Where φ1, φ2 - dimensionless coefficients taken according to table. 4.6 and 4.7.

Based on the obtained value, we determine the number of sections in the radiator N by the formula

. (4.8)

In the future, taking the table. 4.4 β3 , and according to table. 4.5 r, we determine the number of sections previously accepted for installation according to the formula

According to the standards, N = 10 sections should be accepted for installation.

Recall that, taking into account the recommendations [6], the discrepancy between the heat fluxes from the required and installed areas of the heating surface of the heating device is allowed within: downward to 5%, but no more than 60 W (under normal conditions).

In the general case, the discrepancy in the selection of the device is determined by the formula

The length of the radiator accepted for installation is 825 mm, which is 69% of the space under the window sill. According to a similar calculation for the selection of the ChM2-100-300-1.2 radiator, N = 14 sections were obtained and, accordingly, the device length was 1165 mm, which by 97% overlaps the length of the space under the window (1200 mm). When choosing a radiator ChM3-120-500-0.9, 9 sections are required, the length of the radiator is 925 mm - overlap of the window-sill space by 77%, the radiator ChM3-120-300-0.9 is 13 sections (exceeds the length of the window-sill space by 7%).

In order to improve the comfort conditions in the heated room and increase the heating effect of the radiator, the standard size ChM2-100-500-0.9 with 11 sections can be adopted for the installation. At the same time, the heater covers 75% of the length of the window sill, which is practically in line with our recommendations. But in this case the residual will be + 11%. In this example, the best choice would be ChM3-120-500-1.2 radiators.

Thus, this example shows the effectiveness of the selection of heating devices with a nomenclature step, typical for radiators of the CHM series.

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day! Tell me rate

on

installation

oil

radiator

?

Author: Anna Vorontsova. I did not quite understand you, for example 1 radiator

consists of 12 sections, as in this

rates

then put the quantity? )) Our head is already going with these

radiators

)

Author: Tanya Bazhenova. “Natalya writes: Hello, tell me what rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

. "If you are not only installing

radiators

, but also install the pipeline itself.

According to clause 1.18.7. GESN 81-02-017-2001 norm 18-03-001-01 "Installation

radiators

cast iron "does not take into account the work before. ... Appendix 3 to FSSTs-01-2001 (Appendices) estimated price for

radiators

cast iron does not include preparation costs. ... the current estimate and normative base of the FSNB - 2001 norms and

rates

for crimping, grouping, replacement of gaskets.

Author: Alena. Good day! please tell me which one rate

can be used when making horizontal holes in drywall with a width of about 5-7 mm in places

installationsradiators

? Drywall goes like a screen

radiator

Author: Anna Vorontsova. Good day. Please tell me which or which rates

apply to assembly

radiators

bimetallic? Those. separate sections come to the object, we need to collect them in

radiators

(different in the number of sections) and then install.

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thank you in advance.

Author: Natalya. Hello, tell me which one rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

.

Machine for mechanical grouping of radiators

SANITATION AND AUTHORS Y. Shakhnovich ANOK FOR FUR Declared on the 29th, 1953. RADIATOR 81/452362 RADIATOR GROUP IN STATE STANDARD. the design of the machine provides the possibility of assembling a heating device from a model of groups of sections, grouping a number of radiators of different types, disconnecting a group of sections from a radiator, attaching it to a radiator and the possibility of replacing gaskets in connections. Fig. 1 shows a general view of the machine in plan; fng. 2 - side view of the machine. The electric motor 1 is connected on the same shaft with the inductor 2. At the end of the reduction axis, the flange is attached 3. From the reducer, the gearwheel U, mounted on the l, 5 gs; two podnnpk; x I. Flanep 3 ssed 4 en: f; yannom 7 n "and" thorns 8 are connected with conical bri to end. nr, ox., which n 4 springs 11, mot guliruOtspsiai, "; -: ng i todppn, ;., For dependencies; chivankya nipples in polkh; nsh; and sgg pom There are still found osh14 with solid kp, nyovy channels, with 1 res: ilnot ;:. kami 15. At the end of each mandrel there is a step; l fg;, 6. ; the radiator key is attached to the coupling 17. Inside,; ,: imo. I have a slot, a pin and two springs. At kgpp and: appearances I:, Xia sound signaling device 1. On a shovel of another mandrel 14 krpnntl,: n and "," indicating nya divides a ruler "on; and section, in which you can see the lash., th. l. The dial ruler and the stock fnksyato 1 b, and. . and ","; Depending on the size of the section and the type of radiator. On the rod of the retainer, rings are made 1 s: pnOo gcn between which corresponds to the width of the section. 103305 For the longitudinal movement of the mandrels, a device is made in the form of two gears 15, a roller 22 and a handle 23. : lifting table 24 and abzhepny with four adjusting screws for lifting it when grouping heating devices of different types; cassettes 25 for centering the radiator in a horizontal position; clamp 2 b to hold the radiator in a horizontal position; two hinged cassettes 27, in which the radiator is tested for assembly tightness. The assembly of radiators from single sections on a seal from gaskets is carried out as follows. On the table, in cassette 25 for centering the radiator to the end stop, one section is inserted with one side screwed by hand. nuts with nipples and gaskets. The section is clamped with a vertical clamp 2 b. This section is joined by a second section with nipples wrapped on the other side. Radiator keys 17 are started in the nipple of the first sktsin, after which the electric motor is turned on and the sections are connected closely. When the nipples are fully and tightly screwed in, the clutches begin to slip and the keys stop rotating. Further, the radiator keys 17 are wound in the nipples of the second section, to which the third section is connected. These sections are connected in the same way as before. blowing So groups: »I up to 10 sections.If there is a need to have a radiator with a large number of sections, the radiator 1 out of 10 sections is removed, and a new group of sections is assembled in the centering cassette. The assembled sections are connected together. After assembling the radiator, the plugs and the radiator are screwed into it. It is placed on the hinged cassette 27 to test it for tightness. The radiator is hydraulically tested in an open cassette, and in the pneumatic method, in a closed cassette covered with a mesh. The first section of the radiator is inserted into the cassette 25 of the table, clamped with the vertical clamp 26, the plugs are turned out and with the help of the radiator keys inserted into the nipples, the connections of the sections are loosened. When rearranging radiators for steam heating systems, the joints of the radiator sections are cleaned of cardboard gaskets and replaced with asbestos strand The assembly of the sections is carried out in the sequence described above. Machine for mechanical grouping of radiators of central heating systems, equipped with hollow spindles for the passage of mandrels of nipple socket wrenches, driven in rotation through a gear clutch, so that, in order to be able to disassemble and assemble radiators of different types from separate sections or groups of sections, movable mandrels with devices are used to ensure that the radiator keys can easily get into any radiator nipple, 2. In the machine according to claim 1, the use of a device for the longitudinal movement of the mandrels, made in the form of two gears, a roller and a handle, and a sound signaling device informing about the ingress of a radiator key blade into the nipple.

Watch

Installation of bimetallic radiators

Sorted by relevance

| Sort by date

Author: Vlad Svetlov. I am new to budgeting. I am making an estimate for replacing 10 cast iron radiators

7 sections MS-140. Heat flow of one section 0.160 kW 10

radiators

this is 11.2 kW, units of measurement in the estimate of 100 kW, I put 11.2 it turns out to be beyond the block.

Author: Olga. Good day! Tell me rate

on

installation

oil

radiator

?

Author: Anna Vorontsova. I did not quite understand you, for example 1 radiator

consists of 12 sections, as in this

rates

then put the quantity? )) Our head is already going with these

radiators

)

Author: Tanya Bazhenova. “Natalya writes: Hello, tell me what rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

. "If you are not only installing

radiators

, but also install the pipeline itself.

According to clause 1.18.7. GESN 81-02-017-2001 norm 18-03-001-01 "Installation

radiators

cast iron "does not take into account the work before. ... Appendix 3 to FSSTs-01-2001 (Appendices) estimated price for

radiators

cast iron does not include preparation costs. ... the current estimate and normative base of the FSNB - 2001 norms and

rates

for crimping, grouping, replacement of gaskets.

Author: Alena. Good day! please tell me which one rate

can be used when making horizontal holes in drywall with a width of about 5-7 mm in places

installationsradiators

? Drywall goes like a screen

radiator

Author: Anna Vorontsova. Good day. Please tell me which or which rates

apply to assembly

radiators

bimetallic? Those. separate sections come to the object, we need to collect them in

radiators

(different in the number of sections) and then install.

Author: katya. Hello. Please tell me how you can translate one steel radiator

in kW. Thank you in advance.

Author: Natalya. Hello, tell me which one rate

can be applied for

installations

control valves on

radiator

heating. Air cock comes with

radiator

.

Author: katya. Hello. Help me please. How can I change one steel radiator

in kW. Thank you in advance.

a source

Estimates for the replacement and repair of heating batteries

If the replacement of communication networks is carried out in an apartment of a residential building, then for any changes in the arrangement of electrical and plumbing equipment, appropriate amendments must be made to those. passport of the entire residential building. But this does not apply to heating devices, so their independent replacement is prohibited. But in a private house, the owner can easily replace the batteries on his own.

You need to figure out which radiators are best to choose.

- Cast iron - they are not subject to corrosion and are very durable, but they are distinguished by a large mass.

- Steel - very durable, have an attractive appearance, but they are made of thin (1.5 mm thick) steel sheet, therefore they are sensitive to mechanical damage.

- Aluminum - have a rather low weight, look good, but do not imply contact of the coolant with other metals, an air outlet is also required.

- Bimetallic - have a steel core and aluminum fins, have a high efficiency, at the same time they are quite strong and presentable.

Having decided on the type and brand of the radiator, you should calculate the number of required radiator sections. It is calculated according to a simple formula - 1 section per 2 sq. m. area of the room. You can install spare ones, the number of which does not exceed 20% of the total, and each battery can be equipped with a separate choke or thermostatic head.

It is also advisable to equip each radiator with a valve, with which you can completely disconnect the battery from the general circuit, and a valve that will direct the water flow through the shunt (bypass).

Replacement of radiators is carried out in the absence of water in the heating system. The new batteries are attached to brackets and connected to the common system using ball valves. The joints are sealed with fiber or fum tape. The air from the radiators is vented through the Mayevsky cock. It is necessary to check the tightness of all connections.

Prices for the installation of radiators, convectors, pipes, registers, mud collectors, air collectors and air taps should be found in the collections for the internal devices of heating systems GESN-18, FER-18, TER-18.

Installation of bimetallic radiators and basic requirements for their operation

General information on the installation of bimetallic radiators

Installation of devices is carried out in individual packaging (plastic wrap), which is removed after finishing work.

Bimetallic radiators are completed for a fee with steel blind and through plugs (adapters), covered with a special hot-dip galvanizing method, and brackets with screws.

At the request of the customer, they can also be equipped with an air release valve (similar to the Mayevsky valve), valves and steel elongated nipples for a fee.

Steel pass-through plugs of devices (adapters) are equipped with pipe threads G 1/2 or G 3/4 for connection to heat pipes or to control valves of the heating system (in accordance with the customer's order).

When rearranging and reassembling, special care should be taken to avoid stripping the threads in the aluminum section headers. The regrouping should be carried out with two keys in order to avoid skewing the radiator sections and the possible destruction of their heads, taking into account the ultimate efforts. The plug thread must engage with the radiator head thread by at least 4 threads. Shear head sections are not repairable and must be replaced with new ones. In order to avoid leakage when rearranging sections, we note once again that it is recommended to use factory-assembled radiators.When installing devices, special care must be taken in order to avoid mechanical damage to thin-walled ribs, especially in the outer sections.

Installation is carried out only on prepared (plastered and painted) wall surfaces.

It is recommended to install the devices at a distance of 30-50 mm from the wall surface, 70-100 mm from the floor, with a gap of 80-120 mm between the top of the radiator and the bottom of the window sill.

Installation procedure for bimetallic radiators

Installation of radiators must be done in the following order:

- mark the installation locations of the brackets;

- fix the brackets on the wall with dowels or fixing the fasteners with cement mortar (it is not allowed to shoot the brackets to the wall on which heating devices and heat pipes of heating systems are attached);

- install the device on the brackets so that the horizontal radiator headers (between the sections) lie on the bracket hooks;

- connect the radiator to the heating system supply lines, equipped with a tap, valve or thermostat on the lower or upper supply line;

- after finishing the finishing work, remove the packing foil.

Incorrect installation of the radiator should be avoided during installation:

- its placement is too low, because when the gap between the floor and the bottom of the radiator is less than 70 mm, the efficiency of heat transfer decreases and cleaning under the radiator becomes more difficult;

- too high an installation, since when the gap between the floor and the bottom of the radiator is greater than 120 mm, the air temperature gradient increases along the height of the room, especially in its lower part;

- too small a gap between the top of the radiator and the bottom of the window sill (less than 75% of the depth of the radiator in the installation), since this reduces the heat flux of the radiator;

- non-vertical position of the sections, since this impairs the heating equipment and the appearance of the radiator.

Replacing the heating riser

When replacing heating pipes, you should also choose the right building materials, that is, pipes.

If you bet on the choice of pipes made of metal-plastic or reinforced polypropylene, you can get:

- ease of assembly and installation;

- light weight of products;

- the ability to bend well, which is very useful when assembling on site.

But, at the same time, plastics wear out easily and may not withstand pressure surges up to 20 atm., Which occur during a water hammer.

Therefore, many builders now prefer the installation of galvanized steel pipes when installing risers and connections to radiator valves.

First, water is drained from the system, and this must be done by a locksmith from the housing department. If work on replacing risers is carried out in emergency mode, then everything is done completely free of charge.

Only after a complete descent can you begin to dismantle the old risers with the help of a grinder. Then threading is done to screw on the new riser, or it is welded using welding. After that, the new pipes are connected to the threads on the riser using couplings and sealed with silicone sealant or sanitary flax.

At the next stage, tees are installed on the threads, and valves are attached to them, and the shut-off valves are attached to branch pipes with a thread that is long at one end and short at the other. Jumpers are mounted, and the last is the connection of the radiator itself.

At the end, the air is vented and a test run of the riser is performed.

All prices for the replacement of heating pipelines made of galvanized steel pipes for pipelines made of multilayer metal polymers, with a riser heating system, can be found in the collections GESNr-65-15- (05-07), FERr-65-15- (05-07), TERr -65-15- (05-07).

And the replacement for similar pipelines, but already made of galvanized steel, should be better noted at the prices of GESNr-65-15- (01-04), FERr-65-15- (01-04), TERr-65-15- (01-04 ). But some estimators recommend using the prices for laying pipelines of galvanized pipes with a diameter of 15 to 150 mm according to the collections of prices GESN -16-02-002- (01-12), FER -16-02-002- (01-12), TER -16 -02-002- (01-12).

Recommendations for choosing a heating radiator

Another important aspect when choosing a radiator heating, if you are the owner of an apartment with centralized heating, then bimetallic (3), steel (1) or cast iron radiators (2) are suitable for you, and aluminum (4) radiators are prohibited for installation, becausethey are designed for pressures up to 6 atmospheres, which with our housing and communal services, which can supply any pressure to the system, you understand, is a nuisance. And if you are the owner of a private house, then you can install radiators from any of the above material *.

* But I would still like to mention: if you decide to save money and buy aluminum radiators,

The whole truth about aluminum radiators. Everyone should know this!

1. What are the types of aluminum radiators. 2. Pros and cons of design features. 3. Where can aluminum radiators be used and where not. 4. Influence of the coolant pH on the durability of aluminum radiators. 5. What happens when someone threw a mass onto a central heating riser. 6. Hydrogen in the system. And a lot of useful information, both for professionals and for end users.

MORE IN THIS VIDEO

1 2 3 4

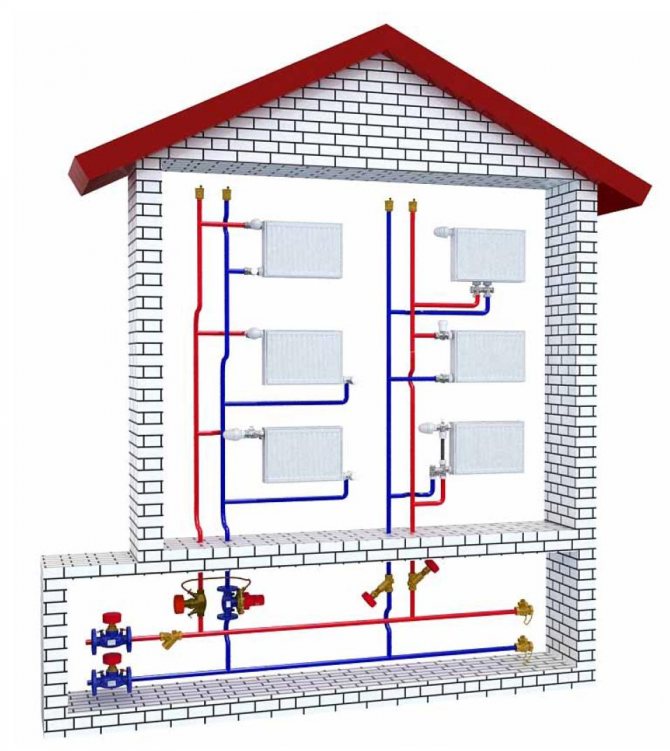

The choice of installation schemes for heating radiators

There are many schematic diagrams for the installation of heating systems, each of which is calculated based on the individual characteristics of the house and your wishes. Still, I would like to mention a few of them.

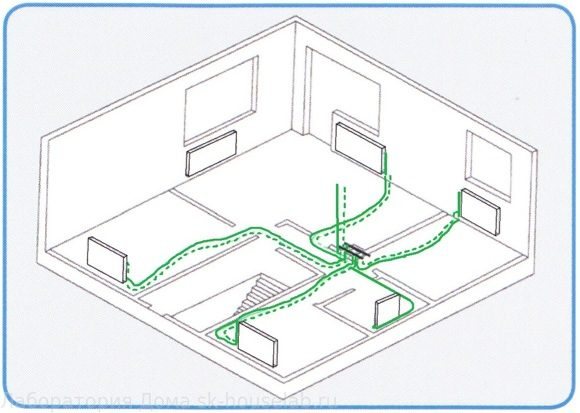

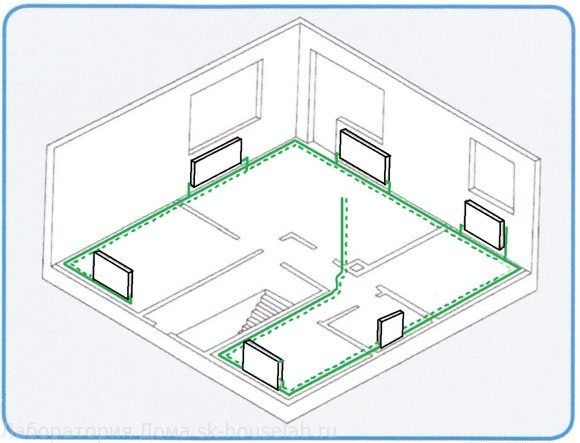

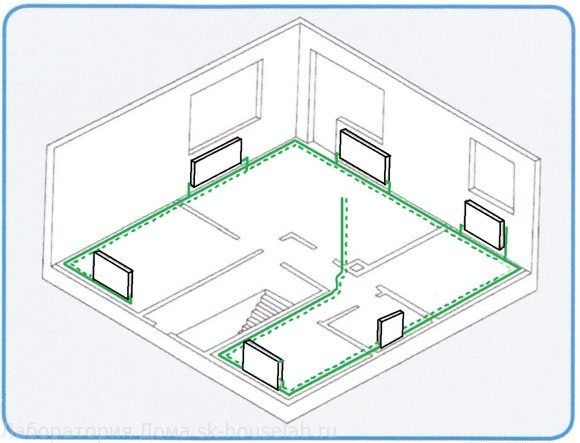

Collector wiring

A separate connection is made from the collector to each device.

Advantages:

Separate connections for each device. No joints in the floor and walls. Minimum connections. Only one pipe diameter (typically 16 mm).

Disadvantages:

The presence of collectors increases the cost of the system.

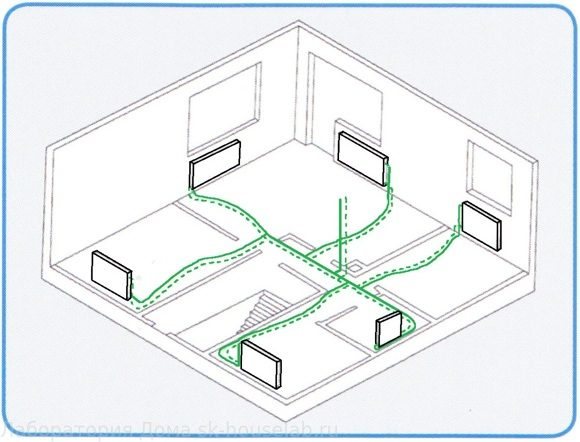

Bypass tee system

Trunk pipes are located along the perimeter of the heated area. The connections to the devices are made using tees.

Advantages:

Allows to realize both open and hidden pipe laying. Suitable for new buildings and reconstructions.

Disadvantages:

The presence of a large number of connections (tees). Large assortment of pipes and fittings of various diameters.

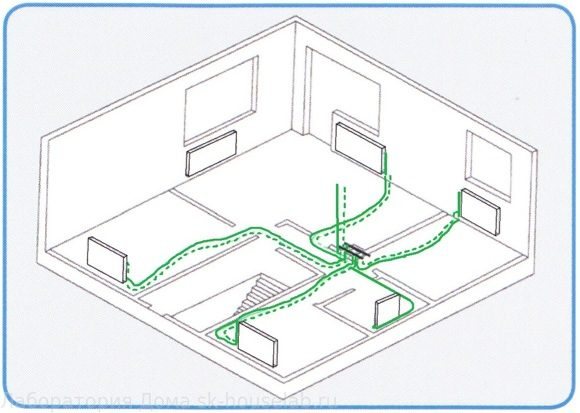

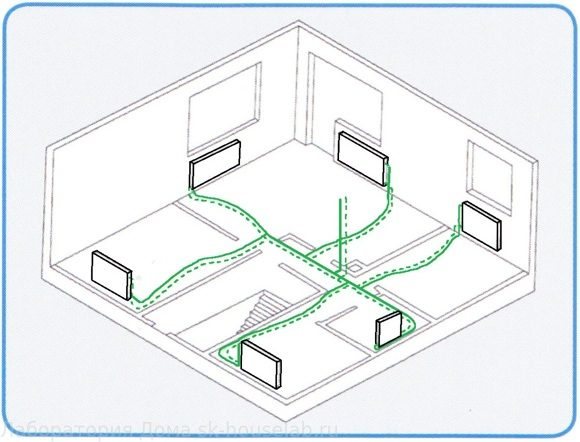

Beam tee wiring

Trunk pipelines are located in the floor of the central part of the heated area. Branches to the devices are made using tees.

Advantages:

The minimum cost of the system.

Disadvantages:

The presence of a large number of connections (tees). Large assortment of pipes and fittings of various diameters.