Home / Gas boilers

Back to

Published: 26.07.2019

Reading time: 4 minutes

0

1080

Many boiler owners have no idea what a parapet boiler is, although they have been using them for a long time. This modern unit belongs to the class of energy efficient devices and removes flue gases using a coaxial chimney mounted in a through hole in the building wall.

Units equipped with a closed firebox, it is allowed to install them in small rooms. Since the oxygen required for combustion is not taken from the living area, it is not hazardous. The heating unit is so compact that it can easily fit even in the kitchen under the windowsill.

- 1 What is a parapet boiler

- 2 The principle of operation of parapet gas equipment

- 3 Types and prices

- 4 Installation of a parapet boiler

What is a parapet gas boiler?

Parapet gas boilers are heating units that combine the features of atmospheric and turbocharged models. They are completely non-volatile, but equipped with a closed combustion chamber.

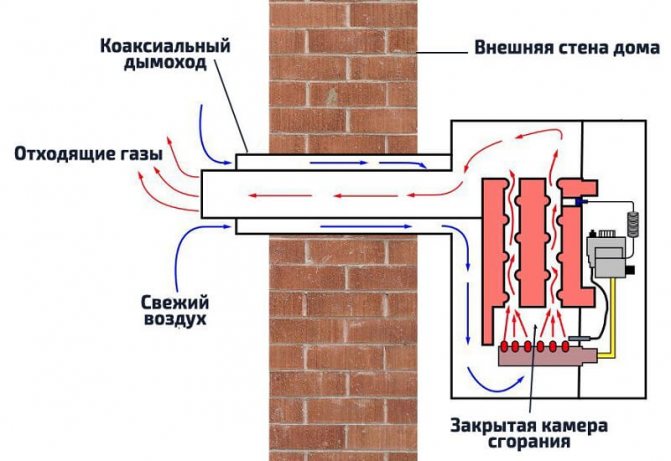

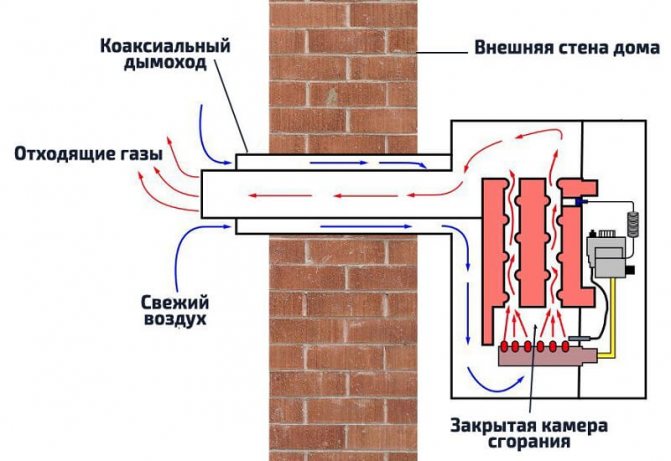

A special feature of this design is the use of a coaxial chimney that connects to the rear of the unit and leads out into the street. The extraction of smoke and the intake of fresh air occurs as a result of convection processes.

When starting the boiler into operation, there are no smells in the room, there are not even traces of soot and other combustion productsI.

In addition, oxygen does not burn out in the room, which allows maintaining the microclimate in a normal state.

Another feature of parapet boilers is the ability to use them as independent heating elements. In the lower part of the case there are special holes through which hot air comes out.

It circulates in the room and provides the set temperature in it.

Installation of a parapet boiler

Parapet gas boilers are fire hazardous equipment, and therefore, independent installation of equipment is prohibited.

Installation and assembly work of this type of equipment can be performed by certified craftsmen, and representatives of the gas company can connect to the gas network.

Violation of these rules creates a danger to human life and can damage the equipment.

Parapet boiler installation process:

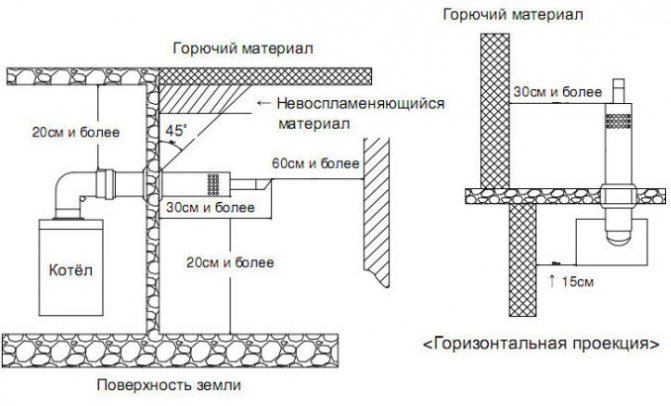

- The smoke exhaust system is brought out through the outer wall of the room into the environment.

- Protect the top of the pipe with a windshield to prevent strong wind from blowing the torch off the nozzle.

- Install the pipes of the water, gas supply network and hot water supply, it may be necessary to constantly maintain pressure, with the installation of a pump in the circuit.

- Carry out the processing of the wall intended for the installation of the unit with non-combustible materials for fire safety.

- The combustion room is equipped with a ventilation system.

- To comply with fire safety, it is forbidden to install the boiler closer than 0.5 m to furniture, wood and any other combustible objects.

- It is forbidden to remove the chimney in closed rooms, premises from SIP panels, entrances, attics.

- Equipment is selected according to a preliminary design of the thermal circuit.

- The sequence of installation work depends on the model of the device. Specific instructions for the intermediate stages of installation and commissioning are issued by the manufacturer.

- First, a channel is punched to discharge the chimney into the environment.The recommended place is next to the window to facilitate further maintenance of the chimney for the gas boiler and functional checks.

- Install the air pipe and fix it so that the part does not move.

- Carry out the installation of the boiler feed line.

- Install studs in the wall to secure the boiler unit.

- In a similar way, the chimney section is installed and fixed with maximum density between the assembly elements. It is necessary to fix the flue section at an angle to drain the condensate.

- Adjust the gaps so that the flame burns evenly without separation.

- Connect pipes, batteries and an expansion tank in an internal heating system.

- After the installation is completed, the water network is pressurized with a pressure of 1.5 from the working one.

- A representative of the gas service is invited to connect the unit to the gas network.

A distinctive feature of the parapet boiler is that when the gas burns, oxygen is not burned, which is important, especially in the autumn-winter period. To connect it with existing engineering networks, no complex communications are required, a wall with a hole for the exit of the coaxial pipe is enough. Users rightly believe that parapet boilers are versatile and promising for installing individual heat supply in a private house or apartments in a multi-storey building.

What is the difference from the usual one?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile structure and no impact on the internal atmosphere of living quarters.

If an ordinary atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then the parapet models are completely isolated and do not violate the air exchange mode.

Another difference is the ability to independently heat the air, which makes the parapet boiler similar to a stove.

Boiler start-up for the first time

Absolutely all modern imported and domestic boilers are equipped with an automated start-up system, fuel supply and an emergency shutdown system.

Emergency shutdown system: this system is triggered in the event of a sharp drop in fuel pressure, which is recorded on the electronic pressure gauges. A sharp drop in pressure indicates a gas leak, which is dangerous in itself and requires an emergency shutdown of the "receiver", that is, the consumer-boiler.

Automated start: this function allows you to set the boiler start-up on a timer, as well as set the frequency of supply. This greatly facilitates operation and saves fuel when the boiler operates in "sections" for 15-20 minutes and is turned off for an hour or two, while maintaining a constant temperature regime.

Automatic fuel supply allows you to constantly maintain a constant combustion mode.

For the first start-up of the boiler, it is necessary to observe all these parameters, using the setting data, which are given separately for each boiler in the instructions. The first start-up must be carried out with a minimum efficiency and increase it gradually at regular intervals, this will allow the boiler to "ignite" and check the main operating parameters.

Parapet boilers are an excellent combination of quality, relatively low cost and unsurpassed functionality. Parapet boilers are the choice of thousands upon thousands of homeowners.

Advantages and disadvantages

The advantages of parapet boilers include:

- lack of electricity consumption;

- internal air is not used, there is no additional load on the ventilation system;

- there is no need to connect to a common chimney;

- low fuel consumption;

- efficiency, practicality, resistance to external loads.

The disadvantages of the models can be considered:

- installation requires making a hole in the wall from 25 to 31 cm in diameter;

- installation is possible only near an outer wall;

- there is no way to provide full-function control and protection of units and parts of the unit (for non-volatile models).

Despite the shortcomings, parapet boilers are highly rated by users. The demand for them is constantly growing.

Do-it-yourself boiler installation

A protective cap is installed on the chimney so that the wind does not blow smoke back

The boiler must be installed by gas experts. A property owner can prepare a basement or wall spot for it, drill a chimney hole and make piping for heating and hot water. The fixing of the device and the connection of communications are performed by the wizard. Exceptions are cases when the boiler is connected to a gas cylinder.

To prevent the wind from blowing out the boiler, it is necessary at the installation stage at the end of the chimney to make a protective cap that will extinguish turbulence and strong air flows. From time to time, the inner pipe must be cleaned of soot, as internal deposits reduce draft.

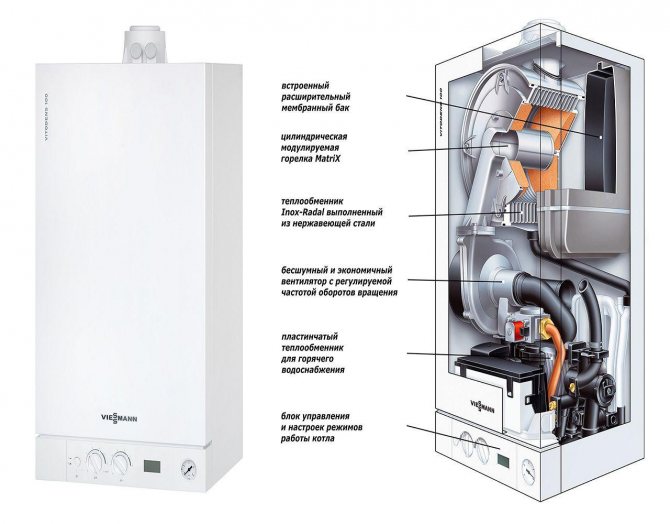

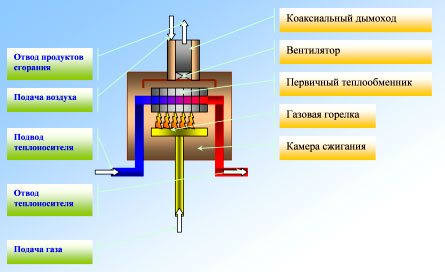

Device

The design of the parapet unit almost completely repeats the design of any non-volatile boiler.

The coolant enters the primary (main) heat exchanger, where it receives a high temperature and enters a three-way valve (mixing unit). In it, a colder "return" is added to the hot liquid, as a result of which the temperature of the heating system takes on the parameters set by the mode.

In double-circuit models, before entering the three-way valve, the coolant passes through a secondary heat exchanger, where DHW is prepared.

The difference lies in the structure of the combustion chamber and chimney, which are not typical for such devices.... To remove smoke, a coaxial double pipe is used, through the outer cavity of which fresh air enters, and the inner one is a chimney.

Air is sucked into a closed combustion chamber and enables the combustion process. It expands from heating and displaces smoke and other gases that occur during fuel combustion. Some models are equipped with two separate pipes, one of which supplies air and the other exits smoke.

This option allows you to enhance convection and stabilize the processes of gas movement.

Rating of the best manufacturers

Double-circuit parapet gas boiler, which manufacturer is better, what to focus on. It is necessary to analyze the rating of parapet gas boilers, read reviews.

Imported parapet gas boilers. Among them, it is worth highlighting equipment with cast iron heat exchangers, their advantage in reliability, with a capacity of 12 to 60 watts. They will be able to heat larger houses and apartments. A distinctive feature of this kind of heat exchangers is their resistance to temperature extremes and mechanical deformation. So, the Electrolux company produces equipment that can withstand critical temperatures above 90 degrees.

It should be noted the quality products of such companies: Italian - Fondital, Beretta; Slovak - Alphatherm Beta, Attack; Hungarian - Alphatherm Delta.

Russian parapet gas boilers. Domestic manufacturers often use components from the CIS and EU countries for the manufacture of equipment. These are cast iron heat exchangers, sensors, controllers. Thus, while maintaining quality characteristics, the final cost is reduced, by about 15%.

These types of products include: boilers "Titan N" (Ryazan); Lemax Leader GSU-ch (Taganrog); Siberia KChGO (Rostovgazoapparat CJSC). These models feature a wide range of equipment power. Manufacturers offer single-circuit, double-circuit boilers of various types.

It is worth noting the quality products of the Russian companies Helios, Danko, Conord.

It can be concluded that parapet gas boilers are universal equipment for heating a house, which combines high quality indicators (efficiency 93-95%) and optimal prices. They compare favorably with chimney models with an open gas chamber, in that they do not require a separate room for the boiler room. At the same time, in comparison with turbocharged models, it is easier to operate. The advantageous side of this type of equipment is its autonomy from the power supply system. This makes it possible to install the boiler in an area where there is a risk of power outages.

Views

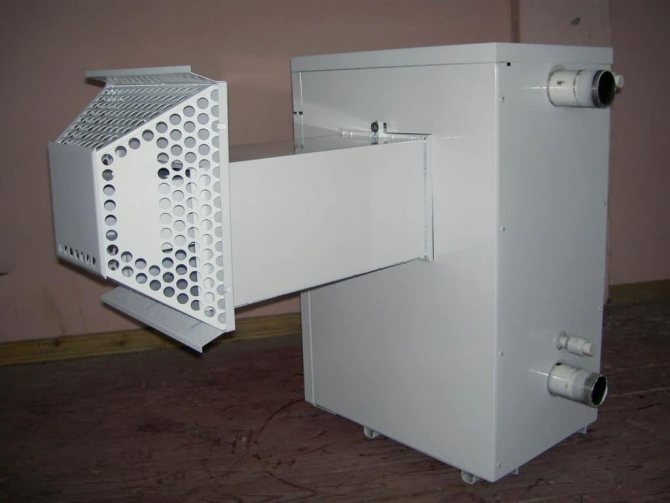

There are different options for the design of parapet boilers, which can be conditionally divided according to specific characteristics.

By installation method:

- wall. Installed in a hinged way on an external (load-bearing) wall. According to the installation conditions, they are limited in weight and power;

- floor. Floor-mounted. If it is wooden, a non-combustible stand is required. They have no restrictions on weight, dimensions and power.

By way of power supply:

- volatile. The design contains units that require the use of electricity - a circulation pump. electronic control board, etc .;

- non-volatile. They work only on mechanical control. A good choice for remote villages and areas with power outages.

By feature set:

- single-circuit. They are only able to provide heating of the coolant;

- double-circuit. In parallel with heating, heating agents are capable of preparing hot water for domestic needs.

NOTE!

Most users prefer the single-circuit floor standing models, which show the greatest efficiency.

Where to buy a parapet gas boiler for heating a private house or apartment

In Moscow and Moscow region

- MirCli (mircli.ru/search?keyword=parameter + gas + boiler + heating) - 80 Leningradsky avenue, building G, tel. +7 (863) 303–35–06, +7 (800) 775–29–90.

- ProComfort (pro-komfort.com/kotly-otopleniia/parapetnye-gazovye) - 1st Vyazovsky pr-d. 4, building 19, tel. +7 (800) 333–56–02, +7 (863) 333–26–06.

In St. Petersburg

- Thermomir (thermomir.ru/parapetnye_gazovye_kotly_rossijskogo_proizvodstva) - st. Lensovet building 62, building 1, tel. +7 (812) 615–80–19, +7 (800) 500–47–02.

- TeploDvor (ru / kotly-otoplenija / napolnye-gazovye-kotly / parapetnye) - avenue Vitebsk building 3 / B, office 25, tel. +7 (812) 628-13-33, +7 (800) 775-21-95.

And in conclusion, I would like to make it clear that such boilers are not yet a full-fledged replacement for either wall-mounted or floor-standing units. In fact, in the desire to “embrace the immense,” manufacturers take half-measures, cutting back on those and other parameters. Personally, we recommend taking a familiar, but more reliable and effective analogue.

Gas boilers

Principle of operation

The operation of a parapet boiler differs little from the normal operation of gas convection units.

The burner heats up the coolant, which gives part of the energy for the preparation of DHW or is led out to the heating circuit after preparation in a three-way valve.

There are no changes in this. A specific feature is the ability of the boiler to perform the function of a convector, which makes it possible not to install radiators in the room where the unit is located.

In addition, a special method of air supply and smoke extraction is used. When the burner is ignited, an overpressure of air arises in the upper part of the combustion chamber, forcing it to be discharged together with the smoke to the outside.

At the same time, a vacuum is formed in the lower part, which creates a suction of fresh flow through the outer part of the coaxial pipe. This creates a pressure difference similar to that used in conventional furnaces.

This allows a closed combustion chamber to be used without a turbo fan.

IMPORTANT!

In some designs, the chimney and the air intake branch pipe are made separately, but this does not change the principle of operation.

How does it work?

The unit has the following structural elements:

- sealed combustion chamber;

- a gas burner and a valve making up the gas burner device;

- heat exchanger;

- steel body;

- a branch pipe for air intake and removal of combustion products.

Advice! Often, the delivery set includes elements for assembling a coaxial chimney: pipes, fittings for connection, an adapter for installation in the wall in the meta of the pipe outlet.

Principle of operation

The boiler operating cycle consists of the following stages:

- if it is necessary to start, the consumer activates the pilot burner using piezo ignition;

- after that, gas is automatically supplied to the main burner, and it starts to function;

- high-temperature exhaust gases enter the heat exchanger, heating the coolant;

- when using boilers without connecting to a water heating system, hot air enters through convection holes on the body, covered with decorative grilles;

- the coolant in the heat exchanger heats up to a maximum of 90 degrees, when the maximum temperature is reached, the sensor is triggered, the gas valve shuts off the fuel supply;

- when the heat exchanger cools down, the sensor is reversed, the fuel supply valve opens and the main burner starts functioning.

Advice! If the gas supply is cut off, the pilot burner stops working and the boiler stops working automatically. To resume it, you must use a piezo ignition.

Rating of TOP-5 parapet gas boilers

Parapet boilers are devoid of many disadvantages of wall-mounted models, so their range is constantly increasing.

Let's consider the most popular models:

Lemax Patriot-12.5

Floor standing non-volatile parapet boiler of domestic production. The power of the unit is 12.5 kW... It is suitable for rooms up to 125 sq. m.

Main characteristics of the unit:

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to 2 bar;

- gas consumption - 0.75 m3 / hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

The boiler is single-circuit, but it is possible to connect an external boiler. This will allow you to get a full-fledged DHW line.

Lemax Patriot-20

Floor-standing parapet boiler produced by the Taganrog plant. The power of the unit is 20 kW, so the size of the room should not exceed 200 sq. m.

Only the basic task is performed - heating the coolant. If you need to expand the functionality, you should purchase and connect an external storage boiler.

Boiler parameters:

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to 2 bar;

- gas consumption - 1.2 m3 / hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Users and specialists note the low fuel consumption, which increases the efficiency of the unit and allows for significant savings.

Lemax Patriot-16

Another example of domestic heating technology. Floor-standing parapet boiler 16 kWdesigned for use in rooms up to 160 sq. m.

Like other models in the Patriot series, this is a single-circuit unit with a steel heat exchanger.

Its characteristics:

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to 2 bar;

- gas consumption - 0.95 m3 / h;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Units of the Patriot series with a capacity of 16 and 20 kW represent the same design, only one of the models has an artificially reduced performance.

Lemax Patriot-10

A product of engineers from Taganrog. A parapet boiler with a capacity of 10 kW is suitable for a country or private house with an area of up to 100 sq. m.

- Efficiency - 87%;

- coolant temperature - 80 °;

- system pressure - up to Bar;

- gas consumption - 0.6 m3 / hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

NOTE!

Reliability and low fuel consumption make Lemax Patriot parapet boilers the most successful choice for all users.

ATON Compact 12.5E

Ukrainian-made gas parapet boiler. The power of the model is 12.5 kW, and the service area is up to 160 sq. m. Non-volatile unit designed for floor mounting.

The main parameters of the boiler:

- Efficiency - 90%;

- coolant temperature - 90 °;

- system pressure - up to 1.5 bar;

- gas consumption - 1.39 m3 / hour;

- dimensions - 630x700x275 mm;

- weight - 50 kg.

The unit is equipped with a stainless steel heat exchanger and a safety gas valve.

How to choose a boiler?

The first thing you need to pay attention to when choosing is the power of the installation. This parameter depends on the area of the premises that need to be heated. The next important point is the material used by the manufacturer for the manufacture of the heat exchanger.

The best option is a 3 mm steel sheet. If thicker sheets are used, the efficiency of the unit decreases, if too thin sheets are used, reliability suffers.

The manufacturer does not always indicate the characteristics of the material from which the heat exchanger is made, therefore information should be obtained from the sales consultant. In addition, you need to pay attention to what pressure indicators are indicated by manufacturers as the maximum allowable. The higher they are, the more reliable the equipment is.

Another important parameter is the efficiency of the unit, which depends on the efficiency. Modern manufacturers have managed to achieve a fairly high level of efficiency - 90-93%. When choosing a unit, it is worth giving preference to the one with a higher indicator.

Having decided on the main parameters, you need to decide which version of the boiler is suitable for a particular room, since the manufacturer offers two options for connecting to the gas and water supply, on the right and on the left.

Characteristics to Consider

The best parapet gas boilers are reliable and have a number of distinctive qualities. Before choosing a device, you need to pay attention to:

- The thickness of the material. The metal in the equipment should not be more than 3 millimeters. If the thickness is greater, then the heat transfer process slows down, and the efficiency of the device decreases.

- The quality of the material. You can determine the properties of the metal by looking at the maximum pressure level recommended by the manufacturer. The higher the indicators, the better the quality of the material.

- Heat exchanger design. When choosing a boiler, it is important to calculate its efficiency (efficiency). The efficiency and economy of the equipment depends on this indicator. Most gas boilers have an efficiency of at least 90-92%. Ideally, you need to choose a technique with a high value, because even a couple of percent is a tangible increase in efficiency.

Choosing the best and most reliable gas boiler Buderus gas boilers: characteristics

- Dimensions of the device. Size is an individual characteristic for each customer, which affects the conditions and place of the boiler installation.

- Location of connectors for connection. Pay attention to the position of the connections. There are boilers in which the connectors are on the left or right. There are versatile models that can be connected from either side.

- Unit power. The quality of heating and costs depend on this indicator. If you take a boiler that is too powerful, then a significant part of the electricity and fuel will be wasted. When calculating the optimal indicator, you need to take into account the thickness of the walls, the height of the ceilings, the number of windows, the presence of drafts, etc. The calculation formula looks like this: for every 10 square meters of room, 2 kW of power is required.

Please note: A parapet boiler is an easy-to-install and operate equipment that performs the function of a water heater, convector and oven.

…

Floor standing gas boiler installation technology

First of all, you should remove the device from the packaging and check its contents again. To know what should be in the box, you need to take the operating instructions, which the manufacturer necessarily puts in the packaging, and check everything on it.

If you find a shortage, you should immediately contact the seller.The same should be done in the case when there are traces of repair work, dents, etc. on the case of the device.

Another important point is the verification of technical data. Those that are applied by the manufacturer to the case of the device must exactly match those written in the technical data sheet. If you find a discrepancy, you should contact the seller.

All plugs are removed from the device, pipes are washed if necessary. This way you can make sure that there are no random garbage in them that could get inside during collection.

The floor-standing gas boiler is installed on a sturdy podium made of refractory material

The installation process for floor standing equipment can vary greatly depending on the type and modification of the equipment. In general terms, it is the installation of the device in the place intended for it, the subsequent connection of communications and the arrangement of the chimney. Let's take a closer look at each stage.

#one. Heater installation work

First you need to put the equipment in the place prepared for it. This can be a concrete base, a small podium made of refractory slabs, etc. A solid wooden floor is covered with a metal sheet, which should protrude about 30 cm beyond the boiler drum around the entire perimeter.

For private houses, a different option is used. Here, a recess is prepared for the heating devices, which is 0.3 m below the floor level.

The bottom of such a pocket is poured with concrete, and the walls are trimmed with any non-combustible material. More often tiles. A floor-standing gas boiler is usually a fairly massive equipment.

For its transportation, wheels are used, with which the device is most often supplied by the manufacturer. The device is placed on a prepared base and carefully leveled.

The figure shows a diagram of one of the options for installing a floor-standing gas boiler

It must be understood that the uninterrupted operation of the device largely depends on the accuracy of its setting. Therefore, the horizontal of the installation must be checked using a building level.

The equipment is leveled in place using the adjustable feet. If they are not there, small pieces of any non-combustible material, for example, metal sheet, are placed under the supports.

# 2. Chimney installation

First you need to make holes for the chimney. Once again we check the diameter of the outlined parts, it should be slightly larger than the cross-section of the chimney pipe. We make holes in the ceiling and roof.

Then we put on an adapter adapter on the boiler outlet, which will be connected to the chimney. An important nuance. Corrugation, as in the installation of wall devices, is strictly prohibited in this case.

The adapter must be made of sheet metal only. After installing the part, we mount the tee and the so-called revision, through which the inspection and cleaning of the chimney will be carried out.

Next, the rest of the elements are attached: straight pipe and elbow segments. For the passage of the chimney through the ceiling and roof, special parts are used. Special attention should be paid here to fire safety.

A special nozzle is installed on the upper part of the chimney, which protects the structure from precipitation, debris and wind

Therefore, sections of passage through the floors must be equipped with non-combustible materials. The chimney must be installed with a slight slope towards the street. The exact value of the slope can be found in the technical documentation for the boiler. This is necessary for the unimpeded removal of condensate, which inevitably accumulates in the pipe due to temperature differences.

The assembled structure is securely fixed to the wall or ceiling with clamps and brackets. The step of fixing the first is 2 m, the second - 4 m.It is recommended to strengthen the connections of the elements, for this they are covered with clamps, tightened with bolts or wire.

The pipe brought out to the roof surface or on the wall is raised to the desired height, after which a tip is necessarily mounted, which will protect the chimney from precipitation, debris and wind.

You can familiarize yourself with the technology of assembly and installation of a coaxial chimney in a popular article on our website.

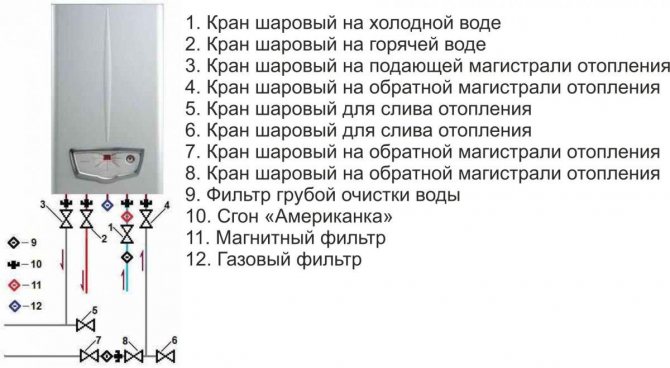

# 3. Heating system connection

At this stage, you need to connect the boiler to the drain and supply pipe of the heating system. For a single-circuit device, this is where the work will end. For a double-circuit, you will also need to connect to the water supply.

First, we connect the heating pipes. Depending on the operating heating system, which can be either two or one-pipe, the number of pipes for connection may be different.

All connections must be carried out in strict accordance with the rules and regulations, as well as with mandatory sealing

In any case, experts strongly recommend installing a coarse mesh filter to protect the boiler from scale particles and dirt that can get into it from the heating main.

The heater is not very sensitive to the quality of the coolant, but if its parameters are very different from those recommended by the manufacturer, additional cleaning equipment should be installed.

This can be, for example, a polyphosphate dispenser or other similar system. It is advisable to install shut-off taps on the return and supply lines, which will help prevent airborne radiators and make it more convenient to repair the heater.

All connections of the elements are carried out strictly according to the rules with mandatory sealing. To seal the thread, you can use the usual tow and paint or more modern means.

The procedure for connecting the boiler to the water main is almost the same. It is also highly recommended to install a filter to prevent unnecessary contamination from entering the device. It is also advisable to install cut-off taps on the water pipes.

It is best to use the so-called "American" with detachable connections, which allows you to quickly replace a worn out unit if necessary and greatly facilitates installation.

Only tow can be used to seal gas pipe connections.

#four. Gas connection

You need to know that according to the norms for installing gas floor boilers, only a specialist with an admission can perform this operation. You can do the work yourself, but an invited professional will still check the assembly and make the first start.

Connection work is carried out extremely carefully and accurately. They start by connecting the gas pipe to the corresponding element of the heating boiler.

Only tow can be used as a sealant. No other material will give the required tightness of the connection. It is obligatory to install a shut-off valve, which is additionally equipped with a filter.

At the same time, gas workers strongly recommend installing a high-quality system here. An insufficiently effective filter can cause boiler breakdown.

For the connection, it is recommended to use copper pipes, the diameter of which can vary from 1.5 to 3.2 cm, or special corrugated hoses. In any case, special attention should be paid to the quality of the sealing of the joints. Since gas tends to leak from loose connections and accumulate in the room, which is fraught with the creation of an explosive situation.

A flexible connection must be located behind the filter, which is only made with a corrugated hose. Rubber parts are strictly prohibited as they develop cracks over time, creating channels for gas to escape.

The corrugated parts are fixed to the boiler nozzle using a union nut. An obligatory element of such a connection is a paronite gasket.

After installing and connecting the gas heating unit, it is necessary to check the quality of the connections and assemblies. The simplest control is to apply a soapy solution to the compound. If it bubbles, then there is a leak.

#five. Test run

This completes the main work on connecting the gas boiler. An exception is appliances with a closed firebox. They need to be connected to the electrical network. Better to do this through a stabilizer.

Then the system can be filled with a coolant. This is done as slowly as possible in order to displace most of the air present in it. The liquid is pumped until a pressure of 2 atm is reached.

All connections are carefully checked for possible leaks. After the gas service representative inspects the connection made and allows the gas supply, you should also carefully inspect all the connections on this pipeline. They need to be coated with soapy water and make sure there are no bubbles. Now you can carry out the first start of the equipment.

A service contract should be concluded with a representative of the gas company that installed the equipment, according to which the organization undertakes to conduct regular inspections to study the technical condition and repair the unit as necessary.