The use of gas boilers for heating private houses or apartments is becoming common.

Homeowners are reluctant to indulge the appetites of resource company owners who are constantly raising utility rates.

Some villages are located remotely, their networks are not able to provide new subscribers.

These reasons have caused an increased demand for heating equipment, which is represented not only by European, but also by domestic manufacturers.

Consider gas boilers from Ochag.

Gas boilers by Ochag

, which is the owner of the Ochag brand, is located in Ulyanovsk. The year 1993 is considered the beginning of its activity.

Today the company produces a wide range of heating equipment and individual units for it of its own design.... There are many standard sizes and designs of gas boilers in production, capable of heating rooms from 70 to 1000 volts. m.

The company carries out its work on the basis of the principles of simplicity and reliability, the stability of its equipment. The main advantage of Ochag boilers is their low cost, which makes them preferable and affordable for the mass buyer.

At the same time, the functionality and quality of the boilers are at a high level, which confirms the high demand and positive user ratings.

The boilers are non-volatile, which for the Russian user is a guarantee of the reliability and continuous operation of the heating system.

Device and technical characteristics of a gas boiler Hearth

The main feature of the described boilers is the ability to adapt them to any heating system. If necessary, you can:

- choose the place of the front door based on the needs - right, left;

- supply the coolant from the side convenient for it - from behind or from the side, thanks to two return lines.

Key elements:

- body;

- automation;

- heat exchanger;

- if the boiler is double-circuit, then the second circuit is also present;

- safety system.

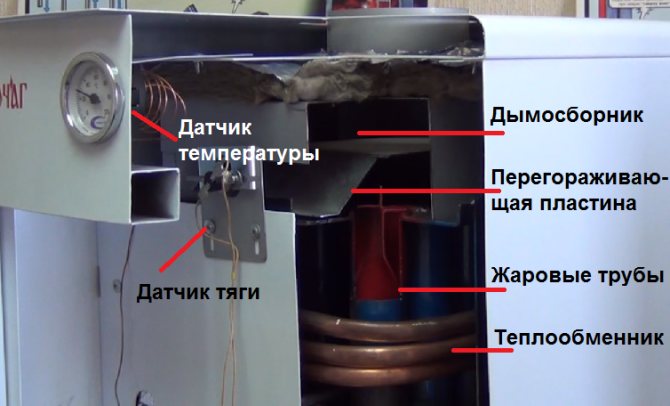

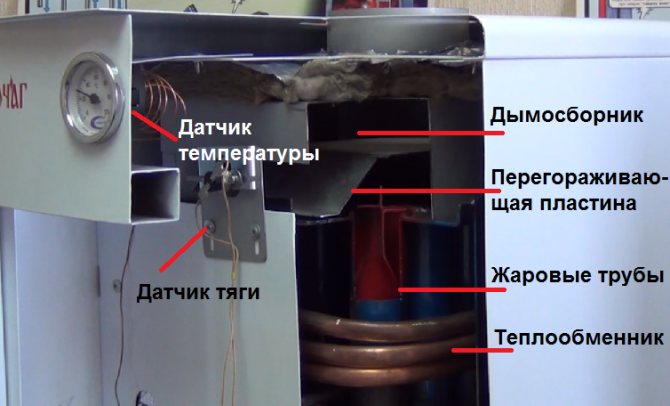

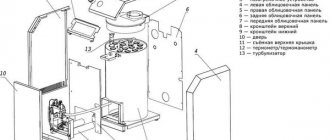

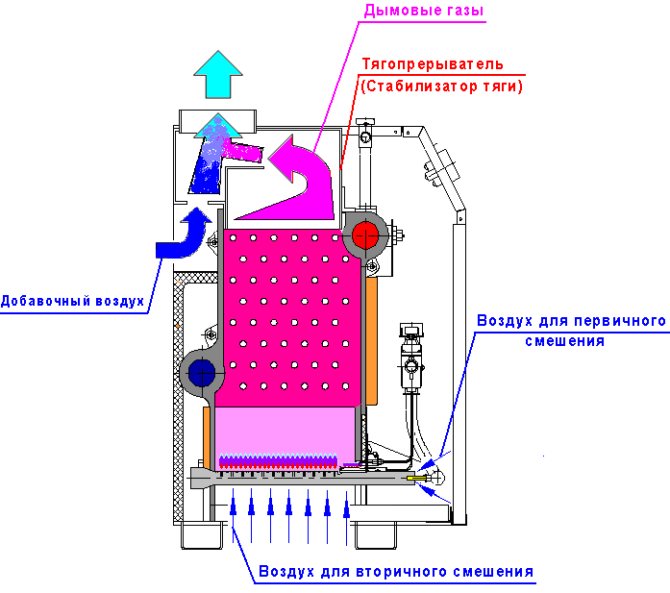

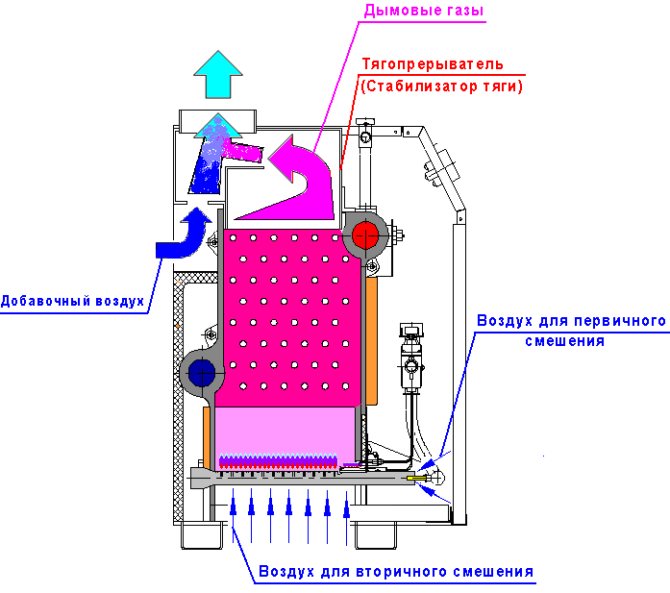

The design consists of three parts:

- In the lower part there is a firebox, which is closed from the lateral and rear sides with a water jacket. A heat exchanger is located above it. Thanks to the flame tubes of the heat exchanger, the efficiency of heat transfer and heat exchange between the gases that are removed and the water is achieved.

- A smoke extractor and built-in draft stabilizer are located at the top of the structure.

- In the middle part there is a partition, thanks to which the operation of the equipment is stable, without failures, regardless of the ambient temperature.

Thanks to the joint work of the smoke extractor and the heat exchanger, the boiler is self-sufficient, it can work without a user and does not require constant manual adjustments. Thanks to the stabilizer, even with an unstable draft, the boiler operation will be stable.

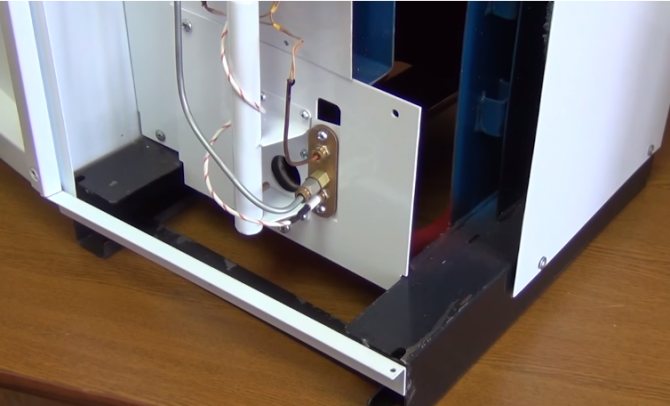

A ServiceGas burner is located in the firebox. Components - front panel, burner pipes, safety sensors - flame and draft, control unit SABK AT. Under the pipes there is a grate damper, which is responsible for supplying secondary air to the burner.

It is necessary to install the device in a room in such a way that free air access is provided along the bottom of the device to the burner pipes.

Boiler structure Hearth

Views

Firm Ochag manufactures various types of construction boilers:

- Floor standing... They do not need specific installation, since they can be placed directly on the floor. This expands the installation options compared to wall-mounted models.

- Wall mounted... They need hinged installation on solid, preferably load-bearing walls.Temporary or plasterboard partitions are not suitable for this. The specificity of the installation requires a reduction in weight and a reduction in the size of the boiler, which affects the power and productivity.

- Parapet... They can be used both for operation as part of a heating circuit and as an independent heat source.

By functionality:

- Single-circuit... Designed only for hot water supply to the heating circuit.

- Double-circuit... They are capable of simultaneous heating of the coolant and preparation of hot water (DHW) for domestic needs.

By type of combustion chamber:

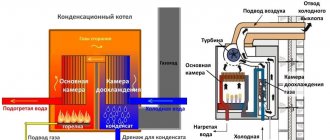

- Atmospheric (open)... Smoke is removed through a common building chimney using a furnace-type draft, and combustion air is taken directly from the room.

- Turbocharged (closed)... Fume extraction and air supply is carried out by a special turbocharger fan. Possible only on volatile models, but independent ones can be modified using an external turbo nozzle.

There are many options for the design of boilers Hearth, the user can choose the most suitable option for his purposes.

The best German and Italian manufacturers of gas boilers

VAILLANT

Vaillant is the flagship company of the concern of the same name, whose enterprises produce heating and water heating equipment and supply it to more than 100 countries located on 5 continents. In the manufacture of devices, the emphasis is on innovative solutions, as well as the qualifications and professionalism of the personnel - there is practically no cheap assembly line for the devices.

The brand was founded in 1874 in Remscheid, a city in western Germany. The range of products is represented by convection and condensing, wall-mounted and floor-standing, turbocharged and atmospheric boilers in 1- and 2-circuit VU and VUW versions. The buyer can choose from many different models, not only well-known, but also new ones, including turbo FIT and eco VIT / 5. The power range of the units is from 4 to 280 kW.

Advantages:

- high-tech equipment, including electronic stuffing, contributing to ease of control and ease of use - maximum information is displayed on the LCD monitor;

- high level of safety - the presence of autodiagnostics, gas supply control, as well as protection against overheating, freezing and pump blocking;

- the ability to choose between an open and a closed combustion chamber;

- efficiency - thanks to the automatic mode of operation, fuel consumption is relatively low;

- environmental friendliness - a small amount of emissions of toxic nitrogen oxides;

- the ability to work with both natural and liquefied gas;

- high efficiency: for convection models - 92 ÷ 94%, for condensation - about 109%;

- ergonomic stylish design;

- a wide range of products - the main lines: atmo TEC, turbo TEC, iro VIT, avto VIT;

- wide service network - about 100 regional centers.

Disadvantages:

- lack of voltage stabilizers;

- expensive and not always fast service.

The company's devices are highly rated by users - they are considered excellent, although not entirely perfect. High-quality and reliable systems are easy to install, easy to operate, and serve for a long time. True, sometimes there are troubles with different details, but they are insignificant and do not significantly affect the overall positive impression.

BUDERUS

Buderus is a large German manufacturer specializing in the production of heating equipment and related products. Founded in 1731 - since 2004 it has been part of the newly formed Bosch Buderus Thermotechnik company. The manufacturer's products are widely represented in the markets of other countries, are popular with buyers, are often awarded and awarded at various international forums.

The range of models: wall-mounted - condensing Logamax plus (14 ÷ 100 kW) and convection Logamax (7.8 ÷ 35 kW); floor-standing - condensing Logano plus (16 ÷ 1200 kW) and convection Logano (20/25 ÷ 270/1200 kW).The systems use 1 or 2 circuits, natural or liquefied bottled gas, different types of burners. To expand their capabilities, the devices are equipped with Logamatic automation. The boilers can be controlled remotely - via the Internet.

Advantages:

- high energy efficiency, the coefficient of which for condensing devices is up to 109%, for convection devices - up to 95%;

- availability of options that simplify control and operation: pressure gauge, indication, thermometer, auto ignition, modulation, display;

- easy adjustment of systems to working position;

- smooth adjustment of water temperature;

- safety is ensured by all kinds of protections, gas pressure control, automatic diagnostics;

- perfect combination with branded water heaters and other equipment;

- thanks to special equipment, effective heat and sound insulation is provided;

- mainly cast iron is used for heat exchangers;

- high efficiency and environmental friendliness;

- aesthetic modern look and affordable price.

Disadvantages:

- make-up taps are made entirely of plastic;

- there is no overvoltage protection.

The boilers are very popular, especially the Logano series - they surpass many famous competitors in sales. The reasons for this: quality, reliability, cost-effectiveness, versatile functionality, ease of maintenance and affordability. In addition, devices rarely fail.

VIESSMANN

Viessmann is a well-known trade mark under the name of which climatic, water heating and heating equipment is produced. The main products are floor-standing and wall-mounted boilers operating on natural gas and diesel fuel. Belongs to the brand of the German family company Viessmann Werke GmbH & Co. KG, whose history began in 1917. After 100 years, the corporation consists of 23 enterprises located in 11 countries, and its products are present in the markets of more than 74 countries.

The user is offered units of various designs - the most popular among them are included in the series: wall-mounted Vitopend convection (12000 ÷ 34000 W) and Vitodens condensing (1800 ÷ 150000 W); floor-standing Vitogas convection (29000 ÷ 420,000 W) and Vitocrossal condensing (2500 ÷ 635000 W). Depending on the capacity, the device can be installed both in a bathhouse and in an apartment building.

Advantages:

- availability of models with 1 and 2 circuits, sealed and open combustion chambers - both natural density and liquefied gas are used;

- The efficiency of condensing and conventional devices is, respectively, up to 109 and up to 93%;

- protection against overheating and pressure drops, and in modern systems - against power surges;

- ease of use due to the presence of all the necessary functions, in addition, control is provided for both electronic and external;

- built-in time relay, which allows you to set the operating mode by day / week; low energy consumption - thanks to an outdoor sensor and an internal thermostat, the device always maintains the set temperature;

- in a 2-circuit design, the system not only quickly heats up the water, but also delivers it to remote points of analysis;

- high environmental friendliness and low noise;

- the use of gray cast iron with a constituent graphite increases the service life;

- wide range and elegant design.

Disadvantages:

- uninformative control panels;

- high prices, including repairs.

The overwhelming majority of buyers are satisfied with the units, although sometimes minor complaints arise. In general, the machines operate reliably, quietly and economically. Minor malfunctions, as a rule, are corrected on their own.

ARISTON

Ariston is a global brand of popular household appliances, including gas boilers and other water heaters. Officially registered in 1945 with reference to the company founded in the 30s by the Italian Aristide Merloni.For 2020, the brand belongs to the Indesit Company concern, which consists of 14 factories.

Among the many products, the manufacturer produces traditional boilers that are adapted to operate in conditions of voltage surges and low pressure, in addition, they are equipped with mechanical filters and a self-diagnostic option. Condensing models are offered with improved performance: fuel is saved by a third, work is performed silently, and the atmosphere is not polluted. The range of products is diverse - the most demanded devices are: convection - Egis Plus, Cares X, BS II, Clas Evo, Clas X, Genus Evo; condensing - Clas Premium Evo, Genus Premium Evo HP, Clas Premium Evo System.

Advantages:

- modern technology, low energy consumption, environmental protection;

- energy output: for traditional devices - up to 94.5%, for innovative devices - up to 109.8%;

- full adaptation for conditions with unstable gas pressure, voltage rating, water pressure;

- electronic and manual control;

- high productivity of hot water: as an option - 13.6 l / min at 25 ° С;

- the presence of important parts, functions and capabilities: measuring instruments, comprehensive protection, semi-automatic ignition, flame modulation, multifunctional panel with a display;

- safety is ensured by protection, control and diagnostics systems;

- the main heat exchanger is made of copper;

- options with open air access and forced;

- compact size, stylish Italian design, adequate cost.

Disadvantages:

- in some cases it is impossible to do without manual adjustment;

- increased noise during the operation of the exhaust fan.

Boilers professionally cope with their tasks - they work out their money in full. In addition, they practically do not create problems during operation - parts rarely "fly".

BAXI

Baxi is an advanced Italian company, mainly producing hot water boilers, as well as condensing and classic gas boilers in wall and floor versions. Founded by an Austrian family in 1924 - currently (2017) is part of the BDR Therma holding, has certificates of quality and environmental friendliness of production, sells its products in more than 70 countries.

In the arsenal of the manufacturer of the line: wall gas - Eco, Luna, Main, Nuvola, Fourtech and energy efficient Compact, Luna, Nuvola with a Duo-tec attachment, as well as Luna Platinum +; floor standing atmospheric Slim and high efficiency Power. The following series are in particular demand: Main Four (2 circuits, 18 ÷ 24 kW, efficiency up to 92.9%), Nuvola Duo-tec + (O and hot water supply, boiler, 16 ÷ 33 kW, efficiency up to 107.8%), Slim EF (non-volatile, atmospheric, cast iron models, 22 ÷ 60.7 kW, efficiency up to 88.7%), Power HT (45 ÷ 150 kW, efficiency up to 108%). Not less popular: Eco-4s, Eco Four, Luna-3.

Advantages:

- the widest assortment with functional diversity;

- a total system of protection against potential threats: lack of pressure, overheating and freezing of the coolant, blocking of the pump and 3-way valve;

- electronic and manual control and adjustment, including the set temperature in hot water supply and heating networks;

- Convenient LCD display that gives out the necessary information to the maximum;

- the possibility of using a coaxial pipe, bithermal exchanger and internal thermostat;

- built-in automation that reacts to weather changes;

- the heating system provides for regulation in 2 temperature ranges;

- the presence of flame modulation, contributing to economical gas consumption;

- easy installation, operation and maintenance;

- aesthetic appearance, reasonable prices.

Disadvantages:

- "Capricious" electronic filling;

- thermal sensors do not always work correctly.

Devices are decent - most users praise. Subject to the instructions and regular preventive maintenance, the units stably maintain the required temperature in the premises and supply hot water to the parsing points on time. True, sometimes there are emergencies - there is a need to replace a part and (or) professional adjustment, which costs money.

Series and models

Firm Ochag produces several model lines:

- Premium... The series is represented by single and double-circuit floor models AOGV and AKGV with power from 8 to 29 kW. There are models with different types of automation - Italian SIT or the company's own development.

- Standard... A series of floor-standing single and double-circuit gas boilers. The power of the models is in the range of 7-20 kW. Used automatic equipment EUROSIT or SABK-AT.

The most common models are KSG 7, 10 and 15.

They have a capacity of 7, 10 and 15 kW, respectively, which makes it possible to provide heat energy to rooms with an area of 70, 100 and 150 m2, which makes it possible to heat private houses of the most common sizes.

These are non-volatile floor standing boilers, designed in a modern compact style and perfectly fit into the interior of any room.... There is a possibility of conversion to liquefied gas.

A sturdy stainless steel burner was used.

IMPORTANT!

All models of boilers Hearth are manufactured in accordance with the requirements of the European standard ISO 9001-2011.

Boiler Hearth premium

Let's consider a series of Premium AOGV and AKGV. This line has a power from 10 to 35 kW, and serves as a heating device for a residential building up to 300 square meters. The devices are characterized by high performance and reliability. The manufacturer provides for the operability of the equipment from natural or liquefied gas. In the case of a planned connection to a liquefied gas cylinder, it will be necessary to purchase an additional set of nozzles with subsequent adjustment of the equipment.

Specifications

| FLOOR GAS BOILERS AOGV PREMIUM | |||

| Name | Heating area | Dimensions / Weight | Natural / liquefied gas consumption |

| Heating Gas Water Heating Unit, one circuit and works only for heating. | |||

| AOGV - 8 C / E | 80 m2 | 350 * 450 * 760/38 kg. | 0.81 / 0.63 m³ / hour |

| AOGV - 8 11.6 C / E | 100 m2 | 350 450 850/57 kg. | 1.18 / 0.91 m³ / hour |

| AOGV - 17.4 C / E | 160 m2 | 350 450 850/61 kg. | 1.76 / 1.36 m³ / hour |

| AOGV-23.2 C / EM | 210 m2 | 430 565 850/66 kg. | 2.35 / 1.82 m³ / hour |

| AOGV-29 S / EM | 260 m2 | 430 565 850/82 kg. | 2.95 / 2.28 m³ / hour |

| AOGV-35 S / EM | 320 m2 | 430 565 850/96 kg. | 3.6 / 2.79 m³ / hour |

| AOGV-45 C / EN | 400 m2 | 500 650 930/102 kg. | 4.6 / 3.54 m³ / hour |

| Combined Gas Water Heating Unit, two circuits, one for heating the room, the other for heating hot water. | |||

| AKGV - 11.6 C / E | 100 m2 | 350x450x850 / 57 kg. | 1.18 / 0.91 m³ / hour |

| AKGV - 17.4 C / E | 160 m2 | 350 450 850/62 kg. | 1.76 / 1.36 m³ / hour |

| AKGV - 23.2 С / ЕМ | 210 m2 | 430 565 850/68 kg. | 2.35 / 1.82 m³ / hour |

| AKGV - 23.2 С / ЕМ | 210 m2 | 430 565 850/68 kg. | 2.35 / 1.82 m³ / hour |

| AKGV - 29 С / ЕМ | 260 m2 | 430 565 850/86 kg. | 2.95 / 2.28 m³ / hour |

| AKGV - 35 С | 320 m2 | 500 640 930/96 kg. | 3.6 / 2.77 m³ / hour |

Specifications

Consider the parameters of gas boilers Hearth:

| Options | The values | ||

| KSG-7AT | KSTG-16 | AMG 24 | |

| Boiler type | Gas heating convection | ||

| Fuel type | Natural gas convertible to LPG | Natural gas with the possibility of using solid fuels | Natural gas convertible to LPG |

| Functions | Heating | Heating | Heating and hot water supply |

| Mounting method | Floor | Floor | Wall |

| Efficiency | 85 % | 75 % | 90 % |

| Power | 7 kW | 16 kWt | 24 kWt |

| Power supply | Is absent | Is absent | 220V 50Hz |

| Life time | 15 years | ||

| Warranty | 36 months | ||

Model overview

The combined KSTG-31 model runs on several types of fuel

Characteristics of the most popular modifications of the Hearth equipment:

- Boiler KNG 24. Compact wall-mounted unit, double-circuit. Its modern design allows it to be installed in a residential area, it works silently. Maximum productivity is 24 kW, gas consumption is 2.5 cubic meters / hour, efficiency is 90%.

- Model KSG-11. Floor-standing, steel heat exchanger, capacity 11 kW, gas consumption 1.34 m3 / h, efficiency 90%. The design allows the use of automatic equipment EUROSIT 630, SABK-AT.

- Boiler KSTG-16. The simplest single-circuit floor-standing unit, power 16 kW, runs on coal and gas, efficiency 74%, not equipped with automation. Designed for space heating up to 160 m2.

- Model KSG-10 AT. Floor heating installation with a power of 10 kW.It runs on natural gas, you can change the jets for heating with liquefied gas. Compact, lightweight, equipped with SABK-AT automatic control devices.

- Boiler KSG-7 E. Budgetary, the choice of functions is limited, the power of the unit is 7 kW, the efficiency is 85%. Heats a room of 80m2 area. Single-circuit, floor-standing, works stably at low pressure in the network. Small size, modern design, low cost makes it popular for heating small buildings.

- Parapet modification. Wall mounted. The smoke is evacuated through the supplied pipe. Available in two types - single-circuit KSGZ and double-circuit KSGZV. The boiler body is covered with a layer of mineral wool insulation, which can be removed to remove scale from the heater. Productivity 85%.

Ochag boilers are not the best among modern heating equipment. Their advantage is low cost, simple design and maintenance. It is possible to purchase units with a wide configuration and capabilities, with full control automation at a higher price. This budget option does not imply long-term operation, the service life of the brand is 10-15 years.

Advantages and disadvantages

The advantages include:

- Strength, reliability, stability of the boilers.

- A wide range of models, allowing you to obtain the optimal design and boiler capacity.

- The energy independence of the units ensures the uninterrupted operation of the heating system in all situations.

- High performance of boilers.

- Simplicity of design, ease of management and maintenance.

- Low fuel consumption.

- Attractive appearance, compact size.

- Low price.

The disadvantages of boilers are considered:

- The complexity of the ignition.

- The need to ensure the slope of the system, which ensures the circulation of the coolant.

- For more stable operation, the use of external devices is required - a circulation pump and a turbo nozzle.

For non-volatile boilers, these disadvantages are quite typical and are, rather, design features.

Gas boilers Ochag from Ulyanovsk - an overview of the KSG, KNG, KSTG models

Gas boiler The hearth is produced domestically. This unit is made in various designs and is designed to supply heat to both private houses and apartments. The maximum area that the device can heat is 1000 m².

Gas floor boiler Hearth

About the manufacturer

The ServiceGas company began its activity in 1993 in the city of Ulyanovsk. Today this manufacturer supplies more than 60 modifications of gas boilers to the domestic market.

The products are in great demand among users due to their good technical characteristics and reasonable price. At present, the average cost of gas-fired units is 14,000-17,000 rubles. Boilers are capable of heating rooms from 70 to 1000 m², it all depends on the specific model.

Advantages of a gas boiler Hearth

Among the advantages of gas units, the Hearth, we note the following:

- First of all, it is high performance, the efficiency reaches 90%, this is due to the special design of the steel heat exchanger.

- Secondly, the devices have a rather attractive appearance, so they will perfectly fit into any interior.

- High level of technical equipment.

- Maintenance of equipment is simple and inexpensive.

- Heating devices do not depend on external energy sources.

- The boilers are of high quality, the manufacturer guarantees that all devices are multi-level tested at the factory.

- The package includes reliable Italian Eurosit automation.

- The units are economical, they consume gas reasonably. The device is equipped with a stabilizing device that is responsible for equalizing the pressure. Due to this, the gas consumption is reduced by 30%.

- Gas boilers The hearth is characterized by high environmental friendliness, because emission of substances is minimized.

- Accuracy of temperature control.

- Compact size.

Device and technical characteristics of a gas boiler Hearth

The main feature of the described boilers is the ability to adapt them to any heating system. If necessary, you can:

- choose the place of the front door based on the needs - right, left;

- supply the coolant from the side convenient for it - from behind or from the side, thanks to two return lines.

Key elements:

- body;

- automation;

- heat exchanger;

- if the boiler is double-circuit, then the second circuit is also present;

- safety system.

The design consists of three parts:

- In the lower part there is a firebox, which is closed from the lateral and rear sides with a water jacket. A heat exchanger is located above it. Thanks to the flame tubes of the heat exchanger, the efficiency of heat transfer and heat exchange between the gases that are removed and the water is achieved.

- A smoke extractor and built-in draft stabilizer are located at the top of the structure.

- In the middle part there is a partition, thanks to which the operation of the equipment is stable, without failures, regardless of the ambient temperature.

Thanks to the joint work of the smoke extractor and the heat exchanger, the boiler is self-sufficient, it can work without a user and does not require constant manual adjustments. Thanks to the stabilizer, even with an unstable draft, the boiler operation will be stable.

A ServiceGas burner is located in the firebox. Components - front panel, burner pipes, safety sensors - flame and draft, control unit SABK AT. Under the pipes there is a grate damper, which is responsible for supplying secondary air to the burner.

It is necessary to install the device in a room in such a way that free air access is provided along the bottom of the device to the burner pipes.

Boiler structure Hearth

Varieties of models

All versions of gas boilers The hearth can be divided into 4 groups:

Devices manufactured under these names can function in open and closed heating systems. Coolant circulation - forced or natural. Next to the marking there is a figure that indicates the power of the device - 7-35 kW. Also, the marking indicates the type of automation:

- T or AT - SABK AT;

- S - SABK S RD;

- E or EM - Eurosit.

Almost all models are made in accordance with the trends of minimalism. There is a pressure gauge in front and the other automatic elements are housed in the case.

A characteristic feature of the products manufactured by ServiceGas is white color. The radiator is made of steel, and the burners are made of heat-resistant stainless steel. Condensate collection is included in the package of the device.

How to ignite?

The process begins by turning the control knob clockwise, then the sequence of actions is as follows:

- it is necessary to turn the handle until the mark is in the direction of the pointer;

- then you need to press and hold the "start" button;

- the piezo ignition button should be pressed until a click is heard, the igniter is ignited;

- "Start" must be kept pressed in order for the thermocouple to warm up. On the igniter, the gas block operates in automatic mode;

- then you need to turn the knob counterclockwise - to the desired temperature regime.

Gas boiler selection Hearth

When choosing, you should pay attention to the material from which the heat exchanger is made. Models are allocated that are made of:

- Become. This material has good ductility, the risk of cracking due to thermal stresses is minimal here. Usually steel heat exchangers are presented in inexpensive models. Its service life cannot boast of its duration, tk. is susceptible to corrosion.

- Cast iron. Such a design weighs a lot and the price for it is higher than for others. As a disadvantage, one can single out the fact that due to temperature changes such a heat exchanger can crack. However, its advantage is that it is not subject to corrosion and can successfully serve for 40-50 years.

- Copper.This material is lightweight, corrosion resistant. Most often, copper heat exchangers can be found in wall-mounted models.

Designations

Heating devices are designated by an alphabetic abbreviation. Each letter contains specific information:

- K - boiler;

- Г - gas-burning equipment is included in the package;

- T - can be used as a solid fuel;

- C - steel;

- M - heating elements and an expanded combustion chamber can be installed;

- B - there is a water heater.

By understanding what the letters mean, users will be able to decipher the basic information about the product.

Models and their characteristics

Let's note the technical characteristics of the most popular models of gas boilers Ochag.

KSG-7AT

This volatile single-circuit unit has an affordable price. The approximate cost is 10,000 rubles. The material used for the manufacture is steel. Available in floor-standing design, the device is very simple and convenient to operate.

Gas boiler Hearth KSG-7 AT

This gas boiler Hearth uses fuel economically, the device is able to efficiently heat a room with an area of 80 m². Specifications:

- power is 7 kW;

- high efficiency - 85%;

- water pressure - 0.1 MPa.

The unit operates without interruptions and malfunctions even with minimal pipeline pressure. The package includes a gas block, built-in pressure and draft stabilizer, compact steel heat exchanger. The burner is made of high temperature resistant stainless steel. It is simple and convenient to maintain - the cover can be easily removed, gas is connected on both sides. There is a device that collects condensate.

Users note that this model has good characteristics. If you replace the burner nozzles, then liquefied gas can be used as fuel.

AMG 24

Outbreak KNG-24

The approximate price for such equipment is 25,000 rubles. It is double-circuit, wall-mounted, small in size. Differs in stylish design.

In operation, the device is absolutely silent - you can mount it right in the room, it will not create discomfort.

On the front panel there is a liquid crystal display, which shows the current parameters. The boiler can be used for heating rooms that are equipped with a water heating system, as well as for heating water.

Technical indicators:

- high productivity, efficiency reaches 90%;

- efficiently heats rooms up to 220 m²;

- the maximum heating power is 24 kW;

- auto ignition is present;

- gas consumption is 2.6 m³ / hour.

Such units can be connected to a floor heating system. The combustion chamber is closed, it can operate on natural or liquefied gas. There are several stages of automatic protection. The weight of the boiler Hearth KNG 24 is 36 kg.

KSG-11

KSG-11 is a floor-standing gas boiler Hearth, designed for heating premises for various purposes.

Installation is simple and convenient, because gas can be connected from any side. The door can be mounted on any side convenient for the user.

There is a device for collecting condensate, the heat exchanger is made of steel, the thermal insulation is 30 mm. The type of combustion is low-flame; during operation, the device does not emit any noise.

Technical specifications:

- heating capacity is 11 kW;

- the maximum area that the unit can heat is 125 m²;

- Efficiency - 85-90%;

- gas consumption is 1.34 m³ / hour;

- weight - 48 kg.

KSTG-16

Combined single-circuit boiler, maximum power is 16 kW. The device operates on gas and coal. Designed to supply heat to premises up to 160 m². Floor-standing installation, without auto-ignition and flame modulation. The efficiency is 75%.

KSG 10-AT

The unit is floor-standing, with a heating capacity of 10 kW, and heats a room with an area of up to 100 m².

Gas boiler Hearth KSG-7 AT

The fuel consumption is 1.11 m³ / hour.The cost of the device is 11,000 rubles.

If you replace the burner nozzles, then liquefied gas can be used as fuel. The unit has a compact size, dimensions - 25x47x75 cm. Weight - 48 kg. Tank capacity - 18 liters.

KSG-7 E

Floor-standing single-circuit gas boiler Hearth KSG-7 E, which is characterized by stable operation at reduced pressure in the gas supply pipes. It is small in size, has an attractive design, is fuel efficient, and efficiently heats houses up to 80 m² in size. The weight of the device is 37 kg.

The combustion chamber is open, there is no auto-ignition, and there is also no flame modulation. This model is inexpensive, but its functionality is also very narrow.

Summing up all of the above, it is worth noting that the Ochag gas boilers occupy a worthy place in the domestic market among the variety of heating devices. A wide range of models in terms of technical characteristics, appearance and price allows each user to choose the most optimal option. Owner reviews of the Hearth boilers are mostly positive. Their efficiency and ease of use are noted.

teplofan.ru

Operation and setup

Operation of gas boilers The hearth takes place practically without human intervention, in automatic mode.

The owner is required only:

- Filling and draining water from the system.

- Switching the boiler to summer / winter mode.

- Periodic cleaning of the case from dust and dirt.

The operating mode is configured during installation and initial start-up. Boilers are sold already tuned and adjusted.

At startup, only adjustments are made to the factory settings for the most efficient operation in the given conditions.

The adjustment must be carried out by a specialist from the service center, who has the appropriate admission and qualifications.

Any independent intervention in the boiler design automatically terminates the warranty agreement.... In addition, an inexperienced user can permanently disable the boiler by his actions.

Boiler Hearth standard

Specifications

| FLOOR BOILERS FOR FLOOR GAS SERIES KSG-STANDARD | |||

| Name | Heating area | Dimensions / Weight | Natural / liquefied gas consumption |

| Single-circuit heating only | |||

| KSG-7 C / E | 80 m2 | 244 * 470 * 710/46 kg. | 0.78 / 0.64 m³ / hour |

| KSG-10 C / E | 100 m2 | 244 * 470 * 710/46 kg. | 1.11 / 0.88 m³ / hour |

| KSG-12.5 C / E | 120 m2 | 300 * 470 * 710/49 kg. | 1.39 / 0.97 m³ / hour |

| KSG-16 C / E | 160 m2 | 300 * 470 * 710/49 kg. | 1.78 / 1.1 m³ / hour |

| KSG-20 C / E | 200 m2 | 376 * 470 * 710/60 kg. | 2.22 / 1.41 m³ / hour |

| Double-circuit with hot water supply | |||

| KSGV-12.5 C / E | 120 m2 | 300 * 470 * 710/50 kg. | 1.39 / 0.97 m³ / hour |

| KSGV-16 C / E | 160 m2 | 300 * 470 * 710/49 kg. | 1.78 / 1.1 m³ / hour |

| KSGV-20 C / E | 200 m2 | 376 * 470 * 710/61 kg. | 2.22 / 1.41 m³ / hour |

The gas boiler Hearth KSG is operated in automatic mode. Maintains the temperature of the heat carrier in the heating circuit set by the consumer at the same level. Provides multi-layered protection in the event of emergency situations. Among other things, a system of sensors monitors the attenuation of the flame on the pilot burner and monitors the occurrence of a situation of lack of draft - in each case, the gas supply is immediately blocked.

How to light a boiler

The procedure for firing up a gas boiler with SABK-AT automation:

- Open the gas cock.

- Set the handle of the gas block to the “Ignition” position.

- Press the "Start" button, hold it for about 10 seconds, then press the piezo ignition button 2-3 times until it clicks (ignition is possible through the viewing window using a burning match).

- Hold the "Start" button for another 20-30 seconds to warm up the thermocouple. The gas valve can then be held open by a magnetic plug.

- Turn the knob on the gas block to position 5 and check that the burner flame is stable.

- Set the required temperature on the gas block.

To ignite the burner of boilers with EUROSIT automatics, perform the same actions, only in step 5 the knob must be turned to position 7.

Download instruction

Download the instruction for the gas boiler Ochag.

Boiler Hearth Benefits

- Laconic design;

- High efficiency up to 92%;

- Self-developed gas units of the ServiceGas concern;

- Completely non-volatile. No need to connect to the electrical network;

- Possibility of re-equipment for further operation on liquefied gas;

- Stable operation of the device in case of low gas pressure;

- Heat-resistant stainless steel burner.

- Stabilizer of gas pressure and draft is built into the boiler Hearth;

- Routine maintenance using easily removable turbulators in the gas passageways adds to the ease of use;

- Easy installation with a choice of one of two gas connection options.

- Thermocouples serve as additional protection against breakdowns during operation;

- Service maintenance due to the special fastening of the smoke collector does not interfere with convenient work with the flue part

- Reduced installation costs are facilitated by small nozzle diameters = 1.5 inches;

- Service life is not less than 15 years;

- the warranty period from the manufacturer is 2 years.

The floor-standing gas boiler KSGV Hearth serves as a device for heating rooms with an area of up to 160 m2. Considering that the ceiling height does not exceed 2.7 m. Higher ceilings are likely to require a more accurate calculation of heating equipment. The two-circuit model provides the consumer with heat in combination with hot water supply, as indicated by the "B" index.

Explanation of the abbreviation KSGV S -12.5 AT

The letter designations that the Hearth boiler have are intuitive and do not make it difficult to decipher: "K" - boiler "C" - steel "G" - gas "V" - the possibility of supplying hot water (water heater coil is installed) "12.5" - boiler power in kilowatts "A" - a - possibility of operation as a solid fuel "E" - EUROSIT "C" automation - SABK-AT automation

The unit uses a gas pressure regulator to regulate the mains pressure and ensure a uniform and stable flame on the main burners without changing the thermal performance. A new heat-resistant stainless steel burner, atmospheric type is used. It is installed at the bottom of the heat exchanger, maintaining a uniform heat zone in the combustion unit. The design has a uniform placement and does not allow zonal overheating of the heat exchanger and its failure.

The built-in draft stabilizer balances the pressure at the inlet to the ejector of the main burners and at the outlet from the slotted slots. Thus, constant discharge and stable combustion of the gas-air mixture in the furnace are ensured without additional regulation.

Why does the gas boiler go out?

The fading of the flame of a gas boiler can be caused by external or internal reasons.

External reasons include:

- Reverse thrust... The most difficult case, almost impossible to eliminate by conventional means. Sometimes it helps to eliminate drafts, to open or close some doors or windows.

- Strong gust of wind outside... Cases of flame blowout by the wind are frequent, they are the result of an unsuccessfully located chimney or a low height above the roof surface.

- Drafts indoors... This situation is quite solvable, the main thing is to determine the source of the draft and close it.

Internal problems can be:

- Cut off the gas supply to the mains.

- Gas valve failure, problems with gas equipment.

- Burner nozzles clogged with soot and combustion products.

In the event of such problems, you should call the gas service and clarify the reasons for the lack of gas. The fuel supply valve must be closed before this.

Call a specialist from the service center and entrust him with the repair of gas equipment.

It is forbidden to try to repair the gas block on your own; this can cause very dangerous and even fatal consequences.

The best Russian manufacturers of gas boilers

ZhMZ

ZhMZ - Zhukovsky Machine-Building Plant, specializing in the production of aircraft special equipment for airfields and is the largest Russian manufacturer of gas heating boilers for domestic use. The manufacturer's assortment includes over 30 models of AKGV, AOGV, KOV, which are part of 3 lines: "Universal", "Zhuk", "Comfort".

The devices are manufactured by qualified personnel using modern equipment with a capacity of 11 ÷ 68 kW using imported automation units. The manufactured machines are of high quality, environmental friendliness, technical level, as well as an affordable price and excellent consumer characteristics. All devices have passed the sanitary and epidemiological examination and certification, after which they "received" permission from the technical supervision authorities for manufacture and sale.

Advantages:

- thanks to the improvement of automatic units and the design of the heat exchanger, atmospheric pollution has decreased, and the efficiency has increased up to 89%;

- non-volatile ignition, which is relevant in places with power outages;

- flame burning indication and German automatic filling;

- the presence of systems with natural and forced air supply;

- the ability to choose between liquefied and natural gas;

- gas pressure control and overheating protection;

- improved ergonomic and aesthetic parameters;

- there are no problems with spare parts;

- relatively low cost;

- warranty obligations for a period of 3 years.

Disadvantages:

- poor quality of manual welding - as opposed to automatic;

- noisiness.

Floor-standing convection appliances in 1- and 2-circuit design are not stuffed with electronics "to the eyeballs", nevertheless they do their job soundly. These boilers are not devoid of weak points, but they pay for themselves completely.

LEMAX

Lemax is a Creative and Production Association, consisting of several enterprises, the main activity of which is the manufacture of household gas equipment. The history of the company began in 1992 in the city of Taganrog.

After 25 years, the buyer is offered a wide range of products - gas boilers: wall-mounted Prime series with indicators of 10 ÷ 32 kW / h and efficiency ≈ 92%; floor steel "Premium" with a capacity of 7.5 / 70 ÷ 60/100 kW and Patriot (6 ÷ 20 kW), as well as cast iron "Leader" and Wise (16 ÷ 50 kW). In the arsenal of "Lemax" there are other lines that are no less in demand among buyers: "Premium" N, "Gazovik", Clever. In addition, it is always possible to purchase a suitable 1-circuit version only for heating, and for DHW + O, it is available from the 2-circuit versions. Modern products are developed by the engineering department of the company.

Advantages:

- use of components from well-known European manufacturers;

- adaptation for operation in Russian conditions - the differential pressure of gas is taken into account, the voltage range is expanded, the protection of the board is strengthened, and electrically independent units have been created;

- airtight sound and heat insulation, contributing to the correct installation in apartments;

- simple control that can be controlled via the Internet;

- independence of the DHW heat exchanger;

- output of technical information in the required volume on the LCD display;

- constructive protection of vulnerable parts against scale and corrosion;

- use of composite materials in structures;

- wide service network - quick troubleshooting;

- elegant appearance, 2 or 3 year warranty depending on the model.

Disadvantages:

- sometimes it happens that the torch goes out during burner operation;

- the device is "afraid" of corrosion in some places.

Both externally and according to operational data, it is clear that the company's specialists worked hard on the creation of boilers, and not in vain. The vast majority of users are satisfied with the devices. Sometimes some parts fail, but not more often than those of competitors.

Major malfunctions

The main malfunctions of gas boilers The hearth is problems with the burner - a weak flame, attenuation after a few seconds of burning, frequent flame outages for unknown reasons.

There can be many reasons for a malfunction of gas equipment; in order to eliminate possible problems, knowledge of the design and features of the equipment operation is required..

All work must be carried out by service technicians authorized to work with gas equipment.

The only possible independent procedure may be to clean the burner nozzles from soot.

We eliminate probable breakdowns at the boiler Hearth of KSG

_______________________________________________________________________________

_______________________________________________________________________________

Can anyone please help solve a specific issue. The floor-standing boiler KSG 10 Hearth with SABK automatics is in operation. When you light it up, the main burner starts to burn brightly, but after 10-20 seconds it turns off. Repeated action brings no change. What could be? The first step is to check the performance of the draft sensor and thermocouple. Make a diagnosis of the circuit contacts. Carefully dismantle the pilot burner and clean. Adjust the pilot burner towards decreasing gas pressure. Most likely, the draft has decreased, and now there is not enough air for the pilot burner at the time of ignition of the main burner. The torch smokes a lot and the gas burner device burns continuously, without extinguishing. The temperature above the regulated one cannot rise, although the torch continues to burn. A lot of burning. Gas service says bad traction. What can be done? It looks like there is little air. It is imperative to perform full-fledged prevention. Disassemble the gas unit, clean and wash the burner and jets. It is recommended to clean the outside of the heat exchanger. Can you tell us what the problem is if the appliance smokes? What should be done to solve this problem? Most likely, there is a low level of draft in the combustion chamber. You should clean your chimney. How to act, tell me, when the gas boiler KSG 16 Hearth does not go on firing? I try to hold the control handle, squeeze the ignition button, then hold it for about eight minutes, release it, and the apparatus goes out. The ignition tube is likely clogged. In this situation, maintenance is required. Another problem may be oxidation of the terminals on the draft sensor. It is recommended to remove the clamps and clean them from oxidation. Problems with the boiler KSGV 23-2 e Hearth Standard with an automatic unit Minisit 710. While pressing the ignition button, there is no gas flow to the burner device. What could have happened? When you press the button, gas fuel flows only into the pilot burner, it does not flow to the main burner. You have completed the installation of this unit. I do not like the process of switching from the pilot burner to the main gas burner. It turns out two claps. It should be? We assume that it is imperative to adjust the gas pressure automation. A unit of the same model was put into operation with the Eurosit 630 automation unit, which stops when the temperature rises somewhere around seventy degrees. Please help me fix the problem? The thrust sensor may be triggered. It is imperative to inspect the chimney. The device is of the same model in operation. It had a heating failure at 40 degrees that week with the torch burning continuously. What is the reason? Most likely, the gas supply pipe from the automation unit on the gas burner device is clogged, and besides this, the burner nozzle. There is a gas boiler KSG Hearth 12.5 with automatic SABK. About three days ago, he got out a malfunction. The unit starts to go out when the wind blows on the pilot burner. Not so long ago I replaced a thermocouple, but there is no result. How to fix? When you turn on the main burner, this leads to a decrease in the flow of fuel to the pilot burner, that is, the automatic protection is activated. You need to increase the flow of fuel to the ignition mechanism.This can usually happen due to a decrease in pressure in the system. In another case, the chimney draft has weakened if it is not installed correctly. Please tell me why this device periodically turns off, mainly if there is a strong wind and bad weather outside. How should the issue be resolved? When the igniter is started, the solenoid valve is triggered in about 20 seconds. When the ignition device goes out, the EMC valve will stop working in an interval of ten seconds, 0 you will hear a clicking sound. Several years ago, I installed a KSG-10 E boiler in a private house. The house is small, about forty meters in area. It seems that the consumption is small, and the coolant cannot heat more than 55 degrees. The room has two 12-section batteries connected. I don't understand how to increase the temperature of the coolant? Installation of a circulation pump will help you. A decrease in pressure in the gas line can often occur. For what reason does the boiler overheat systematically during operation? The main source - the circulation in the heating circuit has disappeared. It is also possible that the filters are dirty or there is an excess of air in the heating system. We have a problem. If we close the cold tap and start opening the hot water supply, then water comes out of the heating circuit. What's happening? Most likely, the make-up valve of the heating system is malfunctioning. It allows water to move in both directions. If there is water pressure in the system, then there should be no reverse flow. Because of what the unit starts to make noise, gurgle, and occasionally howls for a long time and claps strongly? The water in the system is highly oxygenated. When heated, the air evaporates, causing you to hear noise. If the unit is configured incorrectly, then the gas valve or bypass valve howls. Loud bangs during start-up indicate a problem with ignition. At the end of 2014, the repairmen installed the floor-standing boiler. Hearth KSGV 16. About 3 months later, a problem arose. I adjust the temperature regime, but it does not hold it. Tell me what could be? Probably, there was a malfunction of the automation, and when the temperature rises by 65 degrees, the nozzles are turned off. It is necessary to configure the automation for the correct execution of functions. Another factor may be that the selected unmatched capacity of the unit in relation to the heated area. Completed the start-up of this unit at the beginning of August. They transferred it to liquefied gas. For 4 months, almost nine cubic meters were spent. At this time, there is an excess of soot inside the apparatus, and the burner also began to smoke. Why is this happening? Too much soot in the firebox indicates that the burner is poorly adjusted and the gas is not completely burnt. There may also be an unsatisfactory gas composition. In order to avoid soot from the burner, it is necessary to systematically wet cleaning. The same device is in operation. During start-up, the gas burner ignites and immediately goes out. I believe there is no ignition spark. How can this problem be repaired? You need to check if the sound of an ignition spark is heard when the ignition wire is disconnected. If not, you must replace the ignition transformer. If a sound appears, replace the ignition electrode or gas burner. A few days ago, a malfunction with the boiler was discovered. Hearth KSG 7. Water flows from it. He was at work no more than 3 weeks. Maybe someone will tell you why the leak occurs? Dripping can occur due to increased system pressure. Probably, the walls of the heat exchanger collapsed. Water hammer also causes leakage in boilers. In the apartment, we would like to install this device. Inform us, what is the nominal pressure for natural / liquefied gas supply for these devices? In this type of equipment, the declared gas supply pressure for methane / propane is 150/300 Pa. This device was installed for me.The other day there was a problem with him. It starts, but the house does not heat up. How can this be explained? Most likely, the accumulation of air inside the batteries or there is scale in the heat exchanger. It is necessary to rinse it. We operate this unit indoors. Until now, he worked without question. Now there is a malfunction in it. The unit goes into overheating every day. Can you help fix this accident? Most likely, there was a clogging with scale, as a result of which the duct was clogged. You must clean the device. Recently there was a problem with the heating boiler. I have been in work for a total of 3 months. Then he suddenly stopped raising the adjustable temperature. Perhaps someone will tell you what are the reasons? The system may have a gas pressure less than recommended. We need to check the gas tap. Most likely, there is a lot of grease inside. Just remove the excess. Tell me how to properly pump the expansion tank? The expansion tank is pumped up with any car pump to the pressure required according to the instructions. Typically an approximate range of 1 to 1.5 bar. To pump up the expander, it is required to drain the coolant from the boiler. This is done by means of a drain connection or using a water tap, drowning the flow to the hot water supply. Floor-standing gas boiler KSG 12 The hearth does not start. If you keep the start button pressed, the burner ignites. But if you do not fix the key, the device goes out. What is the cause of the breakdown? Probably damaged thermoelectric converter or gas valve. There may also be a decrease in gas pressure on the inlet pipes. Sometimes there is a lack of voltage on the control board. Tell me, what service work should be done in case of conversion of liquefied gas to natural gas? To do this, you need to replace the main burner nozzles. Next, change the supply voltage of the modulator. And finally, adjust the range of the highest and lowest pressure. What is the operating principle of the safety valve in the heating system? This component, which is adjusted to the required pressure, protects the heating system. Do not use the safety valve to drain water from the system. The pressure in the heating system is constantly increasing. I reduce the pressure of the expansion tank to the level of 2.1-2.3 atm. Is it possible that the heating circuit water comes from the DHW pipes? The rise in pressure in the heating system is formed by the following main factors. The pressure for the expansion vessel has not been set. The make-up tap allows water to pass through. A problem has recently occurred. The inclusion is very difficult. The pilot ignites, but the main burner has no flame. Help me figure out what is the reason? The ignition device may be defective. You need to service the device and clean the ignition mechanism. Can anyone help sort out the chimney? Soon it was three days, when the reverse draft appeared, in which the smoke penetrates directly into the kitchen. I made the chimney myself. It consists of a metal tube. Perhaps there is some inaccuracy. The main factor may be an incorrectly executed chimney design. Sometimes there is a deposit of soot on the pipe walls, which greatly weakens its efficiency. In addition, it is advisable to control the exhaust vents in the house.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Elimination of malfunctions in boilers

- Gas water heaters

- Malfunctions and repair of gas water heaters

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Elimination of malfunctions in electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Features. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and check. Maintenance.

- BAXI SLIM

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI - REPAIR

After starting, a malfunction appeared.He does not want to turn on, he worked for two years, now the entire display is on fire, as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler is turned off with an E35 error (parasitic flame). Tell me what to do? The first season is in operation.

- BAXI - SETTINGS

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

- BOSCH - REPAIR

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

- BOSCH - ADJUSTMENTS

If you disable the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

- ARDERIA - REPAIR

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

- BUDERUS WALL

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation turboTEC plus VU / 5-5 compared to / 3-5?

- VAILLANT - ADJUSTMENTS

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

- DAEWOO

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

- KOREA STAR

Malfunction of the Koreastar boiler. The heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

- JUNKERS

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. Fan overrun cannot be set.I bet 30 seconds, but still 2 minutes. twists.

- OASIS

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

- VIESSMANN

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

- WESTEN

The problem of starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, after a crackling error E01. Rearranged the fork in places.

- BERETTA

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

- SIME

Malfunction of the metropolis dgt 25 bf boiler. The hot water supply stopped working, the heating is working, it does not give an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, with any attempt to turn it on or hot water, gives a GS error.

- WOLF

The Wolf boiler is in operation. Recently, he began to behave strangely: in the pause between starts, he turns on the burner for one second five times, and 70 degrees jumps out on the display. Where to find the malfunction?

- ACV

ACV Wester Line works very unstable: it often goes into an accident, at startup it emits a characteristic knock and stalls, and at times everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, gas is no longer supplied to the burner. The piezo element clicks, but there is no ignition. Everything is in order with the gas stove, there is gas. What is the reason?

- KITURAMI

Malfunction of the Kiturami world boiler, stops periodically. I wipe the flame sensor and the apparatus works well for a while, but soon everything repeats itself. He also began to smoke heavily. Maybe it's a short chimney, and you need to lengthen it?

_____________________________________________________________

- IMMERGAS - ERRORS

Errors of boilers Nike Star, Eolo Star / Mini, Mythos. Boiler malfunctions with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler in winter mode systematically raises the temperature to 80 degrees. I summoned the master three times. He said that this is for many imergaz models, and offered to install a programmer, but not the fact that it would help. Tell me how to solve this problem and will this programmer help?

- AOGV

Model 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The gas boiler AOGV was installed and put into operation. Hot water dispensing problem. The heat exchanger has been flushed. Less than a month has passed, and the water does not flow again. We put the filter on the water, but time has passed, and again hot water does not flow. What could be the breakdown?

- AGV

Assembly and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and work order. Automation adjustments.

- NEVA LUX

Malfunction of the boiler Neva lux 7023. With a frequency of 2 times a month, it gives an error E7. But after a reboot it still works. Now it gives an error E6. It will work for 15 minutes, and then it turns off. What could it be?

- ROSS

Construction and automation unit. Firing up procedure. Malfunctions and repairs.

- ATEM ZHITOMIR

Tell me if the Atem Zhitomir boiler goes out because of the weak gas pressure, it clicks and goes out. What is the problem? Is it possible to turn off the automation for a while and how?

- LEMAX

A gas boiler Lemax KSG-12.5 Premium was installed. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me?

- KEBER

A gas boiler KS-G was installed and connected, for 250 sq. m.When fired up, it does not turn off, the temperature rises, if I am not mistaken, automatic Arbat 1. The flame is not regulated - too large. What to do?

- LIGHTHOUSE

I installed a gas boiler Mayak and connected it. It works fine. But the reason is this. When it works on a unit, it beeps strongly, if the regulator is turned 2-7, the squeak disappears. Tell me what could be?

- DANKO

We installed and connected the Danko gas boiler with the Kare automatics, it works fine on the igniter, but it is worth adding the power on the burner, it completely fades out, yesterday it faded out for 5 minutes, today it works for 20 minutes and completely goes out. Who faced this problem?

- GAZLUX

The boiler gazeko 18 is in operation. When hot water is turned on, the pressure in the system drops after make-up, the pressure reaches 3 bar. Have to dump. What's the matter, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, while it goes into an overheating accident. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Malfunction of the Rinnai 167 RMF boiler. Recently started showing error 14. How can you fix the breakage?

- CELTIC

The Celtic ds boiler heats up to 45 degrees and costs the whole day it does not turn off and does not heat up the batteries, sometimes it shows an a3 error. How can this problem be resolved?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

Seoul wall mounted gas boiler stopped turning on due to no ignition error. How can it be eliminated? What exactly is out of order?

Price range

Average prices of boilers Ochag are in the conventional range of 12-20 thousand rubles. Before buying, you should clarify what additional devices and devices will be needed for the normal operation of the boiler itself and the entire system as a whole.

In addition, you will need to conclude a warranty agreement in order to be able to urgently restore the system to work.