Domestic consumers have long appreciated the products of the Krasnoyarsk Heating Equipment and Automation Plant, which in turn is a huge production unit. Two types of heating boilers are manufactured at the plant's production facilities: solid fuel models and Zota electric boilers.

We are interested in the latter, because a large number of consumers today give their preference to electric heating units. There are several reasons for this.

There are excellent technical characteristics, and a variety of model range from economy class to luxury options that can heat rooms with an area of 30-4000 m2, reasonable price and ease of installation and maintenance. And as practice shows, it is all this in a compartment that makes Zota boilers popular.

The lineup

So, there are five models in the Zota model line of electric boilers:

Model Econom

This is the cheapest model, but in terms of operational and technical characteristics it is not inferior to any other model. This is a fully automated design with a remote control panel. The boilers can be installed in heating systems with natural and forced movement of the coolant.

A distinctive feature is that the boiler and the process control unit are located in different buildings. They are installed separately and connected by wires. It should be added that Zota boilers of economy class with a capacity of 3-15 kW can operate both from power relay installations and from standard magnetic starters.

The automatics of the heater makes it possible to regulate the temperature regime in the range from + 40C to + 90C. These are the optimal limits that allow you to adjust the mode to save fuel consumption. Note:

- Zota boilers of economy class with a capacity of 3-15 kW are adjusted manually.

- Units with a capacity of 18-45 kW are configured in automatic mode.

All boilers of this model are equipped with a self-diagnosis system. This allows you to identify in advance the flaws in heat engineering processes and breakdowns of units and parts.

Lux

The Lux model is considered the most demanded and popular. It is intended for heating houses with an area of 30-1000 m2. it is a fully automated electrical unit that is improved every year with new options and functions.

All boilers of this model are equipped with heating elements made of stainless steel tubes. The most advanced automatic equipment has been installed, which allows good savings on fuel consumption.

MK

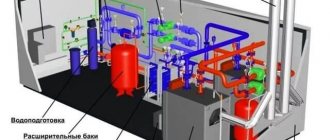

These are mini boiler rooms, which include:

- An electric boiler with characteristics like the Zota Lux boiler.

- Power block.

- Control block.

- Expansion tank of membrane type.

- Circulation pump.

- Security block.

- Pipe junction with shut-off valves.

And all this in one building. What does this give in practice?

- Firstly, due to the compactness of the device for mini boiler rooms, a large installation space is not required.

- Secondly, this configuration allows you to save on additional materials.

- Third, it is easy to install. Here it is only necessary to connect to the power supply network and connect the pipes to the circuits of the heating system of the house.

Advice! For the convenience of monitoring and configuring the MC, we recommend installing a GSM module, which will allow you to control all heat engineering processes using a cell phone while far from home. This option is installed on demand only.

We add that MK Zota are produced with a capacity of 3 kW to 36 kW.For small country houses, this is the best option for heating.

Features of the device and application of electric boilers Zota

After choosing a model of an electric boiler, you should think about installation. You can install it yourself or contact a specialist. The efficiency of work, the service life and the condition of the equipment depend on the correct installation.

How to connect an electric boiler Zota

Installation does not take much time and effort. In addition, you do not need to purchase additional circulation devices. Low wattage models can be plugged into an outlet according to the instructions.

For an electric boiler with a high power, a voltage of 380V is required. To control the equipment via a smartphone, an external thermostat can be connected to the control unit.

Features of using Zota boilers

For normal operation of an electric boiler, you should treat the device with care and use it for its intended purpose in order to prevent malfunction.

Before purchasing heating equipment, it is necessary to calculate the area of the room and the power of the equipment. It is recommended to add 15% to the result obtained to take into account heat losses. It is not necessary to use high power, since in this case the boiler will overheat and problems with the electric boiler will appear.

For remote access, you can connect GSM, but it is not recommended to do it yourself. To do this, you need to invite a specialist who can connect the device to the voltage line.

Electric boilers from the manufacturer Zota have proven themselves in the market. The equipment is used to heat residential buildings and industrial buildings. The main thing is to choose the right purpose and model of the electric boiler.

Installation rules

Like all types of electric boilers, the Zota brand is available in two variations: floor-standing and wall-mounted, single-phase and three-phase. The rules for installing single-phase models are simple:

- It is necessary to install the unit itself.

- Connect it to your home heating system.

- Plug it in.

The only thing that must be done is to run a separate power cable from the switchboard and install a separate machine. It is more difficult with three-phase analogs. If you are not an electrician, then the installation is best left to a professional. It is both reliable and safe.

The operation of the boiler is quite simple. There are provisions in the instructions with which you can easily adjust the device to the air temperature parameter you need. The device will do the rest by itself.

A fairly wide range of Zota electric boilers allows you to choose the required model exactly to the requirements of the consumer. Additional options will help to increase the usability. They, of course, increase the cost of the product, but the quality of work only improves from this. Therefore, it is worth paying attention to the options and choosing those suitable for the operating conditions.

The domestic company ZOTA is known not only in Russia, but also abroad. It specializes in the production of heating equipment and additional accessories. By installing the ZOTA electric boiler in their home or in the country, people make their choice in favor of a high-quality and reliable product from a Russian brand. In this review, we'll cover:

- About the main lines of electric boilers;

- About popular models;

- On the connection and operation of ZOTA boilers.

Finally, you will get familiar with user reviews.

User reviews about Zota electric boilers

Valentin, 33 years old, Perm. It has been worth Zota for several years, raises no objections, heats up quickly. It is rather difficult to configure, it is better to call the wizard first. Our water is hard, the heating element has to be cleaned more often than according to the passport, but it does not burn out and cope with the load.

Igor, 41 years old, Tver.Zota is a normal money decision. Sometimes he goes over the consumption of electricity, sinning on bad power grids and improper adjustment of the boiler itself. But uninterrupted - it has never shown critical errors.

Electric boilers Zota are one of the best types of equipment for heating small and medium-sized premises with an ideal price / quality ratio. Durability is confirmed by many years of trouble-free operation of most of the equipment sold. Small size, safety, ease of installation and operation ensure their use in many sectors of the national economy.

Features of ZOTA electric boilers

Developing electric boilers ZOTA, the manufacturer does everything possible to ensure that the equipment is of high quality and modern. Therefore, today it is one of the leaders in the heating market. The manufactured boilers are reliable and economical, they can be remotely controlled, and their functionality fully meets the requirements for modern technology.

For remote control of ZOTA boilers, a GSM module and a special application are used.

The ZOTA company produces equipment for heating buildings for various purposes - it can be private houses, industrial premises, administrative buildings, warehouses and much more. The power of the models varies from 3 to 400 kW, which corresponds to the area of heated rooms from 30 to 4000 sq. m. Remote or built-in consoles are used for control, as well as mobile phones that control boilers via GSM channels. There are five model lines for the choice of buyers:

- ZOTA Econom - inexpensive ZOTA electric boilers for homes and buildings up to 480 sq. m. The line is distinguished by its simple and affordable prices;

- ZOTA Prom is a special line of especially powerful boilers designed for heating rooms from 600 to 4000 sq. m;

- ZOTA Smart - electric boilers with GSM modules for remote control. They are literally crammed with all kinds of electronics;

- ZOTA MK - mini boiler rooms with remote control. Designed to heat rooms from 30 to 360 sq. m;

- ZOTA Lux are compact boilers with many functions and advanced design. Equipped with GSM modules and temperature correction circuits.

Let's take a closer look at these rulers.

Electric boilers ZOTA Econom

This line includes simple electric boilers used to heat buildings for various purposes. Low-power models are well suited for creating home heating systems

... The boilers are equipped with remote controls that provide automatic temperature control. Despite its simplicity, the ZOTA Econom boilers have self-diagnostic systems. To ensure reliability and long service life, the company has equipped them with rotation systems for power units and heating elements.

Electric boilers ZOTA Prom

This line includes especially powerful electric boilers designed to heat large buildings. They are also used to prepare hot water. All models in the range are floor standing oriented. To ensure efficiency, the boilers are equipped with automation systems, and a long service life is ensured with the help of a heating element rotation system. Management is carried out using remote controls.

Electric boilers ZOTA Smart

Compact electric boilers ZOTA are distinguished by the presence of well-thought-out electronic control. They are equipped with automation systems, weather-dependent modules, heating and pump control systems, as well as self-diagnostic systems. All models on the market have built-in GSM modules for remote control

... The design of the boilers includes stainless steel heating elements, numerous sensors, as well as ports for controlling three-way valves and circulation pumps.

Electric boilers ZOTA MK

These are no longer just boilers, but whole mini-boiler houses. A distinctive feature is the presence of a built-in piping - inside there is an expansion tank for 12 liters, a circulation pump and a safety group. Control is carried out using a built-in remote control, new models provide the ability to install GSM-modules. The lineup is distinguished by its small dimensions and neat design.

Electric boilers ZOTA Lux

Electric boilers ZOTA Lux are designed to heat homes and industrial premises. They are equipped with continuous power control, protection systems, remote control, external equipment control systems, as well as durable heating elements. A pleasant addition will be the presence of weather-dependent automation and the ability to work with two-rate meters.

If you need to provide excellent heating for a private household, then ZOTA Lux electric boilers will be the most optimal choice - they have a long service life and advanced functionality.

Product Features

Like any manufacturer, Zota have their own modifications... Among them, there are more common models of electric boilers, and there are those that have not yet been able to find their grateful user.

Line of boilers

There are six modifications of boilers from this manufacturer. Four of them are quite common. These include:

- suite;

- smart;

- economy;

- prom.

Zota Smart electric boilers are a variant of an electric heater, which performs its function by installing a special heating element. Power in comparison with the previous model, this device is much less.

The system includes:

- circulation pump;

- expansion tank;

- special overheating protection.

Thanks to such built-in devices, the owner of the electric boiler has the opportunity to use a heating system, the pressure in which is up to 6 atm.

This boiler model is different Internet connection, automated systems completely dependent on weather conditions. You will also be able to use the Internet while controlling the boiler.

The economy version provides for a remote control unit for the device. You have the opportunity to install such an electric boiler in that part of the room where it is necessary. The boiler control panel functions like a magnetic starter.

From the very name of the device for heating the room, it is clear that you can save on its purchase and use. This is expressed in the fact that the electric boiler Zota economy during operation uses little energy... This is due to the fact that the electric boiler has various transmission stages. All of them work automatically, which simplifies the use of the electric boiler.

The electric boiler Zota prom is intended for installation in a floor covering. These are devices that are used exclusively for commercial premises. An electric boiler is capable of producing about 9 cubic meters of heated water in one hour. The device is equipped with a modern control unit, convenient programs for autonomous operation are built into it. The device is fully oriented to operate as a stand-alone station, in the absence of human intervention.

Electric boilers Zota Lux

The Zota Lux electric boiler stands out in that it has an additional security system. She reliably protects equipment with sudden power surges. You have the ability to manually set the required power.

If necessary, you can connect two circuits to the electric boiler at any time.It is very convenient that when connecting, you do not need absolutely any additional fittings to regulate the device.

Electric boilers of this series have many advantages:

- the devices are lightweight, they are also quite small in size;

- you can easily change the heating element blocks using ordinary keys, access to them is open;

- due to the peculiarities of work, the productivity of boilers of this model range is very high;

- there is a possibility of connecting a two-phase meter;

- the ability to reduce energy consumption using a special pump;

- sound equipment;

- self-diagnosis of possible malfunctions with an indication of a specific problem on the screen;

- the ability to save the selected settings in the user menu.

This modification is the most popular among the other three. Such an electric boiler can be used both at home and in the country, or in another room with the proper comfort.

Popular models of boilers ZOTA

The electric boiler ZOTA 6 Econom is a good option for heating private non-gas-fired small houses.

The electric boiler ZOTA 6 Econom became the leader in popularity

... This is a fairly simple model for wall mounting. Control is carried out from the remote control, purchased separately. The boiler can be operated from both single-phase and three-phase networks. Distinctive features - three-stage power adjustment, electronic control, overheating protection. The possibility of working with warm floors is provided. The boiler power is 6 kW, the maximum heating area is 60 sq. m.

The list of top models includes electric boilers ZOTA Lux - these are ZOTA 7,5 Lux, ZOTA 9 Lux and ZOTA 12 Lux models. The power of the boilers is indicated in the numerical indexes of the models presented. They are made according to a single-circuit scheme and are equipped with electronic control. There are programmers, self-diagnostic systems and security systems on board. Boilers can work with warm floors and room thermostats. It also provides the ability to control via a GSM channel.

7.5 and 9 kW models can operate on single-phase networks. The ZOTA 12 Lux boiler operates exclusively from a three-phase electrical network - this is due to its high power consumption.

Our list of popular models included the ZOTA 12 MK mini boiler room. Power of 12 kW allows you to heat houses and buildings up to 120 sq. m. The device is equipped with a programmer, security group, circulation pump and security systems. The boiler is powered by a three-phase electrical network. In models released after 2012, it is possible to connect GSM modules.

Installation and connection

It is not difficult to install an electric Zota boiler, moreover, it does not imply any additions in the form of a circulation pump or other equipment. Econom models, small in power, can be connected to a standard 220 Volt electrical network. The connection diagram can be found in the instructions.

For more powerful heating devices, you will need a 380 volt network. The technical characteristics of the boiler are such that the equipment will function even in the event of overloads and drops in the power supply network.

An external thermostat is connected to the control unit. All options assume an Internet connection. You can download a special application to your mobile phone and control the electric boiler from a distance without difficulty. If desired, you can configure the start of the system by time and change the intensity of space heating based on the selected mode.

It is worth following the manufacturer's recommendations, otherwise there is a risk of damage to the technical part of the heating device and excessive consumption of electricity.

The piping of the electric boiler may require the installation of a filtration system for supplying hot water and making up heating.

Owner's review of the Zot electric boiler It seems to be good boilers, but it seems disgusting. Affected by the usual Russian assembly with savings on materials. It seems that when selecting components, no one takes into account their short service life. Glitchy automatics, sticky relays, strange operation of temperature sensors. But there are also pluses - convenient control, ease of installation, cost-effectiveness (it adjusts itself to the air temperature). If you eliminate a few shortcomings, our market will have really high-quality equipment that will compete with imported boilers. So far, in terms of quality, I put four with a minus. Konstantin

Instructions for use

The attached instructions for the ZOTA electric boiler will allow you to quickly install and carry out the initial setup. Before connecting the boiler, preparatory work is carried out. If the power of the device is more than 3 kW, a separate electric line is laid to it

... It is not necessary to install an RCD, since it is found in almost all models (if not, select an automatic machine that is suitable for current strength and voltage).

Heating circuit with a ZOTA electric boiler as a heating element.

When choosing a place for installing an electric boiler ZOTA, you need to make sure that there are no water vapor and aggressive gases in the room, and the air temperature is in the range from +1 to +30 degrees. Simple tap water or a special non-freezing liquid is used as a heat carrier. Boilers are installed strictly vertically. When connecting the equipment to the electrical network, it is necessary to provide grounding - it is connected to boilers and pipes.

Installation of ZOTA boilers is carried out according to the attached instructions - observing the distance to ceilings, floors and adjacent walls. The device must be in such a position that it does not obstruct its cooling (natural ventilation is used here). At the last stage, the boiler is connected to the heating system. Next, a tightness test and a test run are carried out.

Remember that the pressure in the heating system should not exceed the parameters specified in the passport. Failure to do so may result in equipment damage.

Operation and adjustment of the electric boiler Zota Lux

___________________________________________________________________________

- Electric boiler Zota Economy

- Electric boiler Zota Lux

Check the reliability of the protective grounding. Fill the heating system and electric boiler Zota Lux 9/12 with water, excluding the ingress of water into the casing. Check the tightness and tightness of all water circuit connections. For a hot water system, open the valve on the cold water supply line. Turn on the input automaton to the “ON” position, while the “MAINS” LED on the front panel lights up and the current water temperature in the system is displayed on the digital indicator. If after switching on the Zota Lux 9/12 electric boiler the “TROUBLE” indicator lights up and the digital indicator shows the malfunction code, then several types of malfunctions are possible: - (H-1) breakage of the water temperature sensor; - (H-2) short circuit of the water temperature sensor; - (H-3) wrong polarity of the water temperature sensor; - (H-4) pump protection circuit breaker is disabled; - (H-5) there is no water in the electric boiler; - (H-6) the water temperature is higher than 95C or the overheating sensor is faulty. Simultaneously with the display of the type of malfunction, various beeps sound corresponding to each type of malfunction.

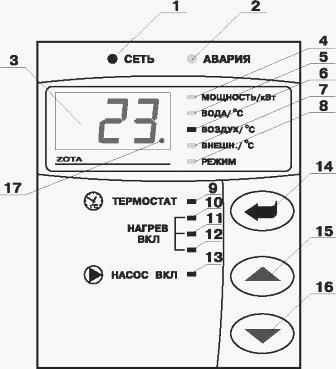

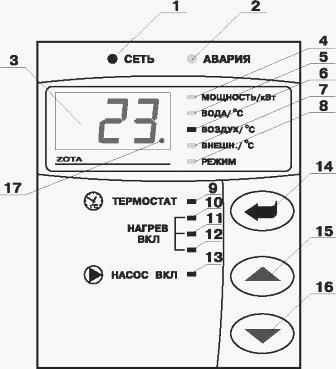

Fig. 2. The location of the controls on the front panel of the Zota Lux electric boiler 1 - mains voltage indicator, 2 - emergency mode indicator, 3 - digital indicator, 4 - water heater power display mode indicator, 5 - heating agent temperature display mode indicator, 6 - room air temperature display mode indicator, 7 - outdoor air temperature display mode indicator ,8 - indicator of the display mode of the internal thermostat, 9 - indicator of the thermostat 10, 11, 12 - indicators of switching on the power stages of the water heater, 13 - indicator of pump operation, 14 - button for entering the operating modes of the water heater, 15 - button for increasing readings, 16 - button for decreasing indications, 17 - indicator of operation of the module-GSM Using the buttons marked with symbols T7, you can change the information displayed on the digital indicator. When these buttons are pressed, the indicator sequentially displays the current values: maximum power of the Zota Lux 6/15 electric boiler, water temperature, indoor air temperature, outdoor air temperature, operating mode of the internal thermostat. Each press is accompanied by a short beep. In this case, the indicators (4), (5), (6), (7), (8), Fig. 2 light up, respectively, indicating the display of the current value. To change the setting of the displayed parameter, it is necessary to press the enter button, the indicator starts blinking and, using the Y and T buttons, you can change the setting of these parameters. It must be remembered that when the room air or water temperature is set to a lower value than is currently available in the room or heating system, the heating will not turn on until the water and air temperature drops below the set values. If you set the power to 0 kW, the heating will also not turn on. In the outdoor air temperature indication mode, the value of this temperature affects the operation of the boiler only if the weather-dependent regulation mode is enabled. In this mode, you can set the temperature when the heating is not turned on. When the weather mode is off, the enter button does not work. To prevent accidental changes in the temperature settings of water, air in the room and power in the electric boiler, a blocking is provided. To turn on the blocking, press and hold the button for 10 seconds, after which (C-1) is displayed on the indicator for a while and the Zota Lux electric boiler goes into blocking mode. In this mode, it is only possible to view the temperature of water, air and power, changing the settings is impossible. To disable the lock, press and hold the button for 10 seconds, the indicator displays (C-2) and the electric boiler goes into normal operation. To return to the factory settings, hold down the У and УТ buttons - turn on the boiler. The indicator will light up SBR and a sound signal will sound. The following settings will change: power-0, water-75 ° C, air-23 ° C, thermostat-0. The factory settings of the table will also be restored. If the digital indicator shows a malfunction symbol in the indoor or outdoor temperature display mode, you must eliminate the malfunction following the instructions for the type of malfunction. The absence of air temperature sensors in the room and outside does not affect the operation of the boiler and the regulation is carried out only according to the temperature of the water in the boiler. In the absence of an outdoor air temperature sensor, the weather-compensated control mode does not work. When the water is heated above 95C, the emergency temperature protection is triggered, the “TROUBLE” indicator (2), Fig. 2 lights up, the heating is turned off, and the digital indicator shows the malfunction code / H-6 /. When the water cools down by about 20C, the heating turns on again. To protect the heating elements, there is a water level sensor, which is triggered when the water level in the Zota Lux electric boiler drops, while the “EMERGENCY” indicator lights up (2) Fig.2, the digital indicator displays the inscription / H-5 / and the heating is turned off. The circulation pump can operate in two modes of operation: constant, without shutdown and periodic, with shutdown of the pump. When the circulation pump is running continuously, the indicator (13), Fig. 2, “PUMP ON” is on.The pump is connected through a circuit breaker, and when the machine is turned off (for example, with a short circuit of the pump circuit), the supply voltage is not supplied to the pump, the indicator (13) goes out, the inscription / Н-4 / lights up on the digital indicator and the heating is turned off. In the case of the pump operating in intermittent mode, shutdown occurs after all heating stages have been turned off and after a certain time delay. In this case, it is necessary that the temperature of the coolant drops below 70 ° C, if the temperature is higher, the pump works constantly until the temperature drops. In this mode, when the pump is running, the indicator (13) "PUMP ON" is on, if the pump is turned off, the indicator goes out. The pump operating mode can be set in the user menu. The built-in thermostat operates according to three preset programs that are set in the MODE menu: - Mode 1 (workday) - Mode 2 (weekend) - Mode 3 (weekly cycle) - Mode 0 (thermostat disabled) To enable or disable thermostat, it is necessary to select the menu item mode, press the enter button, select the number 0-1-2-3 and press the enter button again using the buttons marked with the U and U7 symbols. When the internal thermostat is on, the “THERMOSTAT” indicator (9) is permanently on. If mode 0 is selected, the indicator turns off. When an external programmable thermostat is connected to the T1, T2 blocks, the heating in the boiler is turned on if the thermostat relay contacts are closed. When the contacts are opened, the “THERMOSTAT” indicator (9), Fig. 2 starts to flash periodically, and the heating of all stages is turned off simultaneously. An external thermostat can be used as a programmable timer that turns heating on and off at a programmed time. In this case, the room temperature sensor is connected to the boiler and works in normal mode. If the external thermostat is used as a timer with the regulation of the room temperature schedule according to a certain program, then the room temperature sensor (blocks A-, B +) must be turned off. When connecting an external thermostat, the internal one must be disconnected to ensure the correct operation of the electric boiler. For the internal thermostat of the Zota Lux 6/15 electric boiler to work properly in accordance with the indicated modes, you must set the internal clock in accordance with your time zone. If the time differs from the one set at the factory, then it must be reset in the user menu. The weather-dependent regulation mode, which is provided in the water heater, is used to regulate the temperature of the coolant in the heating circuit depending on the outside temperature in the event that it is not possible to regulate the temperature using the room temperature sensor. The room temperature sensor is not connected in this case. When connected to a room temperature sensor, it acts as a limiter for the maximum room temperature. When operating in this mode, the temperature of the coolant in the heating circuit is regulated according to the schedule. There are several lines on the graph, the slope of which takes into account the heat loss of the building. If the building is not sufficiently insulated, a slightly higher temperature of the coolant in the heating circuit will be required to compensate for the heat loss and, accordingly, the slope of the line will be steep. If the house has good thermal insulation, then the slope of the line is more gentle. To enable weather-dependent regulation, it is necessary to select the slope coefficient of the regulation line according to the presented graphs and write it to the heater's memory in the user menu. This graph is built taking into account the condition that heating is not turned on when the air temperature outside reaches + 20C and, accordingly, the air temperature in the room is also equal to the outside temperature. This temperature is recorded in the memory of the water heater at the manufacturer.To change this temperature, it is necessary to switch to the display mode of the outdoor air sensor temperature in the menu, press the enter button and use the buttons and set the required temperature. Then press the enter button again. To turn off the weather-dependent regulation, it is necessary to set the coefficient K = 0 in item P-17 of the user menu. To connect the monitoring and control function using the GSM module, enter the settings menu and set the P-18 value of the menu to “1”. This will allow the operations of adding and deleting numbers from which it will be possible to control the machine. After the module is registered in the mobile operator's network, the indicator of the module-GSM (17) on the front panel of the control unit blinks. When the Zota Lux electric boiler is operating, the number of heating elements turned on is selected automatically depending on the difference between the set temperature of water and air, and the one currently available in the heating system and in the room. When limiting the maximum power, respectively, the number of operating steps is reduced to 2 or 1. When the power is set to 0 kW, the steps are not switched on. To ensure the same operating time of each heating element for the entire period of operation of the boiler, an automatic enumeration of the included heating elements is performed according to a specific program. At the same time, the resource of the heating elements is significantly increased.

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and device of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and assembly of the Baksi Slim boiler

- Adjustments and maintenance of the boiler Beretta Chao

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the gas boiler Termet

- The meaning of the error code and malfunctions of Vilant boilers

- Determination of faults and errors of Wisman boilers

- Questions about the maintenance of boilers Navien

- Questions on malfunctions of Kiturami diesel boilers

- Junkers boilers - Masters answer user questions

- Experts answer questions about Electrolux boilers

- Expert answers for the repair of Nova boilers

- Questions about the service of Hermann boilers

- Answers from Daewoo boiler maintenance masters

- Questions about the maintenance of boilers Ferroli

- User questions on the repair of electric boilers Evan

- Because of what the gas boiler AKGV lights up and immediately goes out

- What is the malfunction of the Alpha Color boiler, if it shows the error code E01

- Because of what the AOGV boiler ignites and goes out quickly

- How to eliminate error E01 on the Baltgaz boiler

- What is the breakdown if Dani's boiler ignites, but immediately goes out

- Why does the Danko boiler light up, but quickly goes out?

- The Demrad boiler stopped holding pressure, what is the problem

- Because of what the Gazlux boiler began to warm up and make noise

- What is the reason if the Keber gas boiler lights up, but quickly goes out

- How to fix error code 01 on the Kiturami boiler

- Because of what the Conord boiler ignites, but immediately goes out

- What is the reason if the Lemax boiler ignites and quickly goes out

- Why does the Mimax boiler ignite, but it goes out sharply?

- Why the boiler The hearth ignites, but immediately goes out

- Why the Ross gas boiler lights up, but goes out quickly

- What is the malfunction if the Siberia boiler lights up and goes out sharply

- Why does the boiler Signal light up and go out sharply?

- Because of what the Termet boiler can make noise and heat

- Why does the gas boiler Thermotechnician ignite, but suddenly goes out?

- How can I fix the E01 error on the Thermon boiler

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons the Ferroli gas boiler gives an error with the A01 code

- For some reason, the Immergaz boiler does not function on hot water supply

- Why does the Navien gas boiler constantly turn off and turn on immediately when heated

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Heating boilers piping

- STS boilers

- Solid fuel boilers KBT

- Pellet boiler Peresvet

- Steel floor boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the gas boiler Termet

- Repair of Thermon boilers

- Repair of boilers Nova

- Boiler service Hermann

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Maintenance of Daewoo boilers

- Boiler malfunctions Demrad

- Mora boiler malfunctions

- Boiler repair Westen

- Immergaz boilers malfunctions

- Types of solid fuel boilers

- Combined boiler models and designs

- Oil and double-circuit boilers

- Cast iron boilers for coal

- Boilers with simulating burners

- Imported boilers for heating systems

Installation of the Zota Master boiler and heating system

The installation of the Zota Master 20, 12, 18 boiler and the heating system is carried out by a specialized organization in accordance with the project and calculation of the heat losses of the room:

Place the boiler in the designated place and connect it to the chimney.

Connect the heating pipes.

Filling the heating system with water

Water for filling the solid fuel boiler Zota Master 20, 12, 18 and the heating system must be clean and colorless, without suspensions, oil and chemically aggressive substances, with a total hardness of no more than 2 mg equiv / dm3.

The use of hard water causes the formation of scale in the apparatus, which reduces its thermal parameters and may damage the heating element unit. If the water hardness does not meet the required parameters, the water must be treated.

The deposition of 1 mm of limestone reduces the heat transfer from metal to water in this place by 10%. During the heating season, it is necessary to maintain a constant volume of heating water in the heating system.

It is impossible to disassemble the water from the boiler and the heating system for different needs, except for the necessary drainage during repairs. When draining and refilling water, the risk of corrosion and deposits increases.

Add water to the heating system in a unit cooled down to 70 C. In addition to water, an antifreeze coolant diluted with water at a concentration of no more than 1: 1 can be used.

When using these heat carriers, it is necessary to comply with the requirements for their use in heating systems. It is forbidden to use fluids that are not intended for heating systems as a heat carrier.

Fig. 3. Installation diagram of the Zota Master boiler

Before installing the boiler on a combustible building structure under the apparatus and in front of its front by 500 mm, it is necessary to lay steel sheets with a thickness of 0.6 - 1.0 mm on asbestos or basalt cardboard, 3-5 mm thick. The boiler installation diagram is shown in fig. 3.

Safe distance from combustible materials:

When installing and operating a solid fuel boiler Zota Master 20, 12, 18, it is necessary to maintain a safe distance of 200 mm from combustible materials.

For flammable materials (e.g. paper, cardboard, glassine, wood and fibreboards, plastics), the safety distance is doubled (400mm), the safety distance must also be doubled if the degree of flammability of the building material is unknown.

Location of the Zota Master boiler, taking into account the space required for servicing:

There must be a handling space of at least 1000mm in front of the unit.

On one side, it is necessary to leave a space for access to the rear of the device and the heating element block of the boiler at least 400 mm.

Fuel placement:

It is forbidden to place fuel behind the boiler or near the boiler at a distance less than 400mm.

It is forbidden to put fuel between two devices in the boiler room, the manufacturer recommends keeping the distance between the boiler and the fuel at least 1000 mm or placing the fuel in another room where there are no boilers.

To improve the conditions for natural circulation of water in the heating system, the Zota Master boiler is installed so that the return water pipe is located below the radiators of the building's heating system.

From the wall to the radiator at least 3 cm;

From the floor to the bottom of the radiator, at least 10cm;

At least 10 cm from the top of the radiator to the window sill.

The bending radius of pipes must be at least 2 outer diameters of the pipe.

The uprights must be plumb. The permissible deviation should not exceed 3mm at 3 meters of pipe height.

Horizontal piping should be laid with a slope to bleed air from the system. The slope must be at least 10 mm per 1 linear meter. meter of the pipeline.

The chimney must be made of refractory and heat-resistant materials resistant to corrosion. It is recommended to use chimneys and flues made of stainless steel with insulation that can withstand high temperatures.

The correct choice of the height and cross-sectional area of the chimney has a great influence on the operation of the boiler. When choosing the dimensions of the chimney, it should be borne in mind that for the efficient operation of the boiler, the vacuum must be at least the required value.

Fig. 6. Chimney installation options

The installation of the Zota Master boiler and the installation of the chimney must be carried out in accordance with SNIP 41-01-2003 as shown in Fig. 6.

In a closed heating system, the units must be installed with a membrane expansion vessel.

The pressure in the heating system in working condition at a maximum water temperature in the boiler of 95C should not exceed the maximum operating pressure of water in the boiler, that is, 0.3 MPa (3.0 kg / cm2).

A safety valve for a pressure of no more than 0.3 MPa (3.0 kg / cm2) must be installed on the supply riser, installed at a distance of no more than 1 meter from the boiler.

The section of the pipeline from the device to the safety valve must not have turns. Do not install shut-off valves between it and the safety valve.

If the heating system provides for filling and replenishment from the water supply network, it is necessary to install a pressure reducer set to a pressure of less than 0.3 MPa (3.0 kg / cm2) and a check valve in front of the tap of the supply pipe. Fill the system at a pressure not exceeding the maximum operating pressure of the boiler.

The booster pipe must be vertical and at least 2 meters high. Test (pressure testing) of the heating system (pipes, radiators) with the device disconnected, while the pressure should not exceed the maximum working pressure specified in the design of the heating system.

The volume of the expansion tank depends on the volume of the heating system and is calculated during the development of the heating system project.

Heating system maintenance

Fig. 4. Closed heating system diagram

1 - Boiler, 2 - Expansion tank, closed type, 3 - Heating devices, 4 - Supply pipeline, 5 - Circulation pump, 6 - Return pipeline, 7 - Heating system valves, 8 - Water drain valve, 9 - Safety valve, 10 - Filter sump, 11 - Draining into the sewer, 12 - Automatic air vent, 13 - Thermo-mixing valve

Fig. 5. Open heating system diagram

1 - Boiler, 2 - Expansion tank, open type, 3 - Heating devices, 4 - Supply pipeline, 5 - Return pipeline, 6 - Heating system valve, 7 - Water drain valve from the system, 8 - Overflow, 9 - Drain into the sewer, 10 - Boost section

When operating the Zota Master 20, 12, 18 boiler in closed heating systems at t = 30 - 40 C, the pressure in the system and in the pneumatic part of the expansion tank should not differ and it must be maintained periodically by supplying water to the system or pumping up the pneumatic part of the expansion tank.

If there is a knock in the system (water hammer due to vaporization), immediately stop burning in the furnace and let the water cool down to a temperature of 70 C, then top up the system with water through the tap (item 8, Fig. 4) and re-heat the boiler.

In winter, if it is necessary to stop the furnace for more than a day, it is necessary, in order to avoid freezing, to completely empty the device and the heating system from water through the drain taps (item 8, fig. 4) or (item 7, fig. 5).

During operation, the hot water temperature in the unit must not exceed 95 C.

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

_______________________________________________________________________________

__________________________________________________________________________

OPERATION AND REPAIR OF BOILERS

This arrangement is one of the significant advantages of this model over others. The electric boiler allows you to place the control unit in a place convenient for you, while you are not tied to the pipes of the heating system where the heat exchanger is installed. The power cable of the wiring is laid exactly up to the control unit.

The scope of delivery of the ZOTA - 12 boiler also includes a water temperature sensor, an air temperature sensor, a four-core flexible cable for connecting the heat exchanger to the control unit, fasteners and instructions.

First of all, we connect the electronic control unit (ECU), having previously fixed it in a convenient place for us on the wall. As you remember, before the control unit, we laid a five-core cable with a cross-section of 4 sq. Mm; during installation, they should be inside the unit.