From time to time, the heating main needs to be cleaned. The fact is that during operation, rust and scale settle on the inner walls of the pipes. Lime deposits reduce the throughput of the pipeline, and besides, scale does not conduct heat well. As a result, in order to keep the room temperature at the proper level, heating costs have to be increased. For flushing work, there is a set of special equipment, the main tool of which is a compressor for flushing the heating system.

Pipe after 10 years of continuous operation

Important! Pipes that have served for 10 years are 50% clogged with scale. Every millimeter of deposits increases fuel consumption by 25%. Thus, even a single flush of the system will increase its efficiency and help save energy costs.

Choosing a device for flushing the heating system

It is best to purchase an electronically controlled heating system flushing apparatus. It won't be just a pump for solution or compressed air. Such a device is able to analyze the intensity and nature of the oscillations of the working medium in the circuit. The operator's task will only be to regulate the frequency and power of the pulses.

The equipment must also be provided with pressure and fluid flow sensors, protection against accidental activation. Let's list some brands that are in high demand among the consumer:

- Rockal

- Ropulse

- Cillit-Boy

- Virax

- RIDGID

High-quality compressors can flush not only the heating system, but also water pipes, solar collectors, as well as the underfloor heating system.

Flushing equipment

- Flushing chemicals... These chemicals are required for descaling work on copper and steel pipes. This concentrate prevents foaming of water (heat carrier), and this protects against corrosion, and also increases the service life of the pump. The spent chemical changes its color, so the active product has a red color, and the spent chemical has a yellow-orange color. To prepare an aqueous solution based on water, you will need from ten to thirty percent of the chemical. After the work related to descaling, the process of neutralizing chemical residues in the system takes place;

- Romantic 20 (descaling device). This device has an automatic regulation of the flow reversal interval and is used to remove heavy deposits and scale in installations with a volume of up to three hundred liters. As for the characteristics, such a technique has a pressure head of ten meters and a productivity in the region of forty liters per minute, and also maintains a pressure of one and a half bar. These devices can be equipped with work programmers, and the price for them is affordable;

Romantic 20

- Ropulse... Microprocessor-controlled combined heating system flushing unit. It is also used for flushing water pipes, including drinking ones, in accordance with existing requirements. In addition, it is used for washing: underfloor heating systems and solar collectors for home heating, which have been exposed to silt deposits; after repair or installation; cold water pipelines and hot water pipelines. This equipment can be used for the disinfection of drinking pipelines;

- Rockal... Hand pump for flushing the heating system. Its main task is to remove scale and deposits, and you can see photos and videos of this pump in the gallery of our website.It is used to remove deposits in installations and systems with a volume of up to three hundred liters. It has a high productivity, in the region of forty liters per minute, and a pressure slightly over a bar. The device is well suited for descaling copper pipes and steel pipes.

Cillit-boy station

The heating flushing equipment, which is electronically controlled, provides an evenly pulsating mixture of water and air, and the compressed air is supplied from the connected compressor. Such a mixture passes through a heating system or a household gas heating boiler, and then is drained into the sewer.

Sillite Boy Station

The ripple can be adjusted and changed step by step depending on the goals. The device has an indication board.

The equipment is used for:

- flushing drinking water supply systems from sludge and other contaminants;

- for disinfection from bacteria in drinking water pipes;

- washing of heating systems and warm floors.

The principle of operation of this device is as follows. The device, controlled by an electronic unit, performs uniform flushing with a mixture of air and water. The compressor generates the required head. This mixture is passed through a heating circuit or heat source and cleans its interior surfaces.

Washing technology

Before starting work, you should diagnose the system, find out the condition of the pipeline, boilers and heat exchangers. Based on these data, the cleaning method and the operating mode of the flushing equipment are selected. Typically, one of two flushing options is used:

- Filling. The circuit is filled with water or a chemical reagent and left for half an hour. After that, the compressor is turned on and compressed air is supplied to the pipes. After a certain period of time, close the valve on the supply line, open the valve and drain the dirty water. The procedure is repeated until a clear liquid appears.

- Flow-through method. Most effective. It consists in a long and continuous supply of compressed air and water (or solution) to the heating system. Not all compressors support both technologies - many of them supply either water or compressed air. When buying, you should pay attention to the technical characteristics of the equipment.

https://youtu.be/kvANkqsX3D0

Used devices

Cleaning of pipelines can be done in different ways, and for each of them a specific unit is selected. The price of some devices can be quite high, since their efficiency is at the proper level. Individual work can be done by hand using inexpensive devices.

Hydrodynamic installations

The main equipment is high pressure water jet machines. With their help, it is possible to remove deposits in pipelines with a diameter of 20 mm and above. The high efficiency of the method is achieved due to the use of special nozzles.

Compact size water jet device.

Hydrodynamic technology for removing scale and other contaminants is considered the most gentle, since during work, excessive pressure is not created inside the communication system. This operation is completely safe for the installed elements.

Its features are discussed below:

- The advancement of the nozzle is provided by jet thrust, which is created under the action of high-pressure water flows coming out of the holes in a special nozzle.

- This heating flushing unit works most efficiently when using high-performance nozzles.... Their choice should be made depending on the nature of the blockage.

- For the most difficult congestions, chain carousels and rotary tips are used... The formed plugs in the communication network are successfully removed by punching nozzles.

This is what the pressure cleaning nozzle looks like.

Addition! After carrying out hydrodynamic flushing, the throughput of the conductive elements of the heating system is restored directly to its original values.

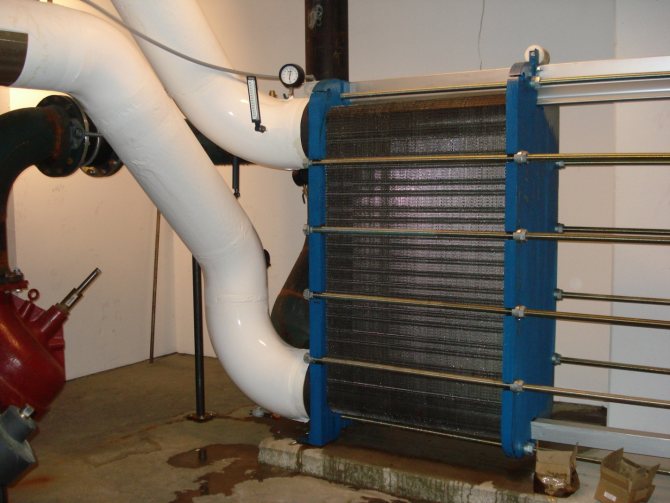

Pneumohydraulic units

The main device is a compressor for flushing the heating system or a pump that allows you to accumulate compressed air and produce a sharp blow at a certain point in time. In this situation, cleansing is performed by creating a kinetic impulse in a liquid medium. Water swirls remove deposits from the pipeline surface.

The pneumohydraulic design has a special container for compressed air, which is usually pumped by a compressor. However, a dedicated pump can also be used to flush the heating system. It is a cylinder equipped with a piston.

One side of the device is in contact with air and the other with water.

A unit for pneumohydraulic flushing is being demonstrated.

- At the very beginning, the device is connected to the heating elements by means of a switch and adapter hoses.

- After that, water is poured into the system, which enters directly into the cylinder of the main device, moving the piston to its original position.

- Next, the cylinder is charged until the required pressure is created.

- At the main stage, a shock wave is created with the help of a piston, which allows cleaning the pipes.

Note! The main disadvantage of this method is some limited kinetic force. The impact power is usually reflected in the technical documentation of the device.

Mechanical impact devices

In this case, flexible shafts with a drive are used, on one side of which there are metal brushes. The tool that rotates the rod is usually a drill.

The following is an instruction describing the procedure for carrying out the work.

Presented flexible shaft assembled.

- At the initial stage, the system is being prepared for carrying out treatment activities. The coolant is completely drained, pipe fittings are untwisted in the right places.

- A structure is being assembled, which will mechanically remove scale and other contaminants from pipelines. A metal brush of suitable sizes is attached to one end, and a drill is attached to the other.

- Gradually, the flexible shaft is inserted into the interior of the conductive elements of the system. When the device rotates around its axis, scale will fall off from the pipe walls.

Reference! Flexible shafts are available in long or short lengths, which greatly simplifies selection. They should be stored in such a position that the bending radius is maximized.

Electro-hydraulic devices

The principle of operation of such installations is based on the fact that a coaxial cable is introduced into a liquid medium, which has a connection to a high-voltage pulse device. The device generates repetitive electrical discharges with a frequency of 1 to 10 Hz. Thanks to this, the accumulated deposits are destroyed.

An example of an electrical installation.

Many models of this type of cleaning equipment are capable of cleaning pipelines with diameters ranging from 10-100 mm. Additional devices may be supplied with the equipment.

Heating system cleaning methods

To clean the internal channels of heating networks, several methods are used: hydrochemical, pneumohydraulic and hydropneumatic impact.

Chemical washing

This is the most common cleaning method.Its essence lies in the fact that a chemically active liquid is supplied to the system for flushing the heating system together with a corrosion inhibitor. An aggressive solution dissolves deposits layer by layer and flushes them out of the pipes, and the inhibitor additionally passivates the pipes from the inside (creates a stable anti-corrosion coating, increasing their service life).

Important! After draining the reagent, the system should be flushed with a neutralizer or water, and then filled with coolant.

Such work is performed using a pump for flushing the heating system, pumping a chemical fluid under pressure.

Important! Flushing work can be carried out in winter without interrupting the heating process. Flushing the pipes with a reagent, carried out on our own, is fraught with a major overhaul of the entire system. Contact the specialists!

Chemical cleaning will extend the operation of the heating network for 10-15 years and significantly reduce heating costs.

Bubbling: pneumohydraulic cleaning

The procedure will require a compressor that creates high pressure in the flushing hoses. The compressor delivers a water-air mixture to the pipes, which loosens deposits and removes scale, grease, sodium, calcium, magnesium salts, chemicals and rust from the walls. This method is widely used to remove sludge from cast iron radiators.

Equipment for pneumohydraulic flushing

Battering ram: hydro-pneumatic cleaning

The method is based on the creation of a shock pulse passing through the highway at a speed of 1500 m / s. It is used on pipelines with a total length of no more than 60 m. The kinetic shock is produced by a special device. The result of the passage of the shock wave is the detachment of scale from the inner surface of the pipes.

Attention! Only a trained specialist can perform this operation!

A device for creating a shock wave in a pipeline

The ways

Typically, flushing is done in the following ways:

- Water-pulsating mixture. This flushing method is carried out using pulsating water and compressed air. Due to this, sediments, rust, plaque, silt, sand are removed in the pipes. This flushing method reduces energy costs and extends the life of the heating system elements. However, special equipment must be used to carry out this flushing.

- Biologicals. The use of biological products during flushing ensures deep penetration into clogged areas and complete dissolution of all deposits. When flushing with biological products, it is not necessary to turn off the entire heating system. Water-based supercleaners are mainly used as biological products. The principle of action of these drugs is based on loosening scale, oil-mud, hard crystalline, corrosive and organic deposits.

- Pneumohydroimpact. During flushing in this way, special equipment is used. This method is very convenient since you do not need to disassemble the battery assemblies. Also, there is no need to use special cables and chemicals. With the help of the equipment, a pneumohydraulic impulse is supplied to the system. The main blow falls on the main column of the coolant with deposits. Due to this, the deposits quickly break down and dissolve. The efficiency of this method is very high. In addition, ruptures and cracks in pipes are excluded.

- Chemicals. This cleansing method is based on the use of preparations containing organic and inorganic acids. The preparations, getting into the pipe, completely dissolve scale, rust, and deposits in the form of salts.

Heating system flushing agents

Before buying a reagent, you need to consult with an expert about the composition of the layers in the pipes. Based on this, chemistry is selected for flushing the heating system. Acid concentrate acts faster, but alkaline is safer for the pipeline.The instructions always indicate which metals the reagent has a destructive effect on.

Attention! Do not wash aluminum radiators with acidic or alkaline solutions. Special means are provided for them.

Pipe after flushing

Flushing Signs

For the normal functionality of the heating system, nothing should interfere with the movement of the coolant through the channels built for it.

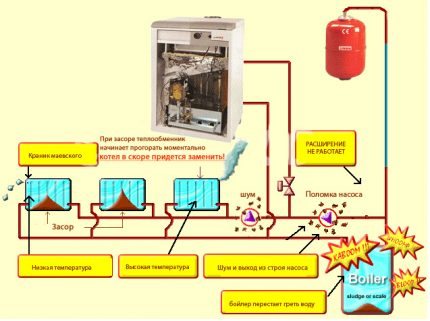

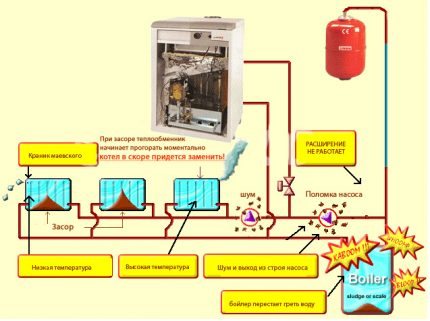

It can be diagnosed by carefully monitoring the operation of the entire system and the appearance of a number of indirect signs:

- the system warms up longer than before (for autonomous heating systems);

- the operation of the boiler is accompanied by sounds uncharacteristic for it;

- increased consumption of gas or electricity; the temperature in different parts of the radiators varies significantly;

- radiators are noticeably cooler than the supply pipes.

However, weak or uneven heating of batteries is not always a sign of clogging. Perhaps they were airborne. In such a situation, it is enough to dump the airlock through the Mayevsky crane.

In houses with a centralized heating system, it should be flushed by employees of the heat supply company. In a private house, this procedure is carried out by the owners or invited specialists.

For example, in district heating systems, the coolant must go through a water treatment cycle, which reduces the degree of pollution. True, this rule is not always fulfilled. And the system itself has often been in operation for the third or fourth decade and the amount of garbage circulating inside increases every year.

But for both centralized networks and stand-alone systems, it is recommended to flush annually. Which, by the way, is confirmed by the requirements of building codes. It is this period that is considered critical for the accumulation of the amount of garbage inside the circuit, which significantly reduces the efficiency of work.

If the system is not flushed before the start of the heating season, the pipeline is clogged, devices and heating equipment fail prematurely

Professional flushing of pipelines

Responsible homeowners rarely decide to flush the heating system themselves, especially when it comes to multi-storey buildings. The risk of being left with emergency heating is too great. The best solution would be to contact a company that specializes in such services. Engineers will assess the technical condition of the pipes and carry out preliminary pressure testing of the pipeline. Based on the results of the check, an act and an estimate for flushing the heating system will be drawn up.

After completing the work, the contractor must dispose of the used reagents. They cannot be drained into the sewer.

Quality control of flushing of the heating system is carried out in accordance with SNIP 3.05.01-85. According to the standards, water must be taken in different sections of the pipeline, as well as in the heating unit. It is assumed that a competent commission will assess the amount of suspended matter and the transparency of the coolant. In fact, representatives of the housing office use a more effective method: they open several radiators in apartments and entrances, unscrewing the blind plugs. The thickness of the scale layer in the battery is visually assessed, as well as the presence of solid particles on the cork. If the result is unsatisfactory, a period for re-flushing the system is assigned.

Let's summarize. It seems that flushing heating pipes is easy. In fact, the process is quite complicated and requires the use of special equipment and chemical reagents.Damaged pipes, numerous leaks and bursts in weak points of the system can be the result of unprofessional actions. Contacting a specialized organization will be a guarantee of competent and responsible performance of the entire range of flushing work.