Metal-plastic windows are identical in their structure and functionality to analogs made of plastic. The main difference between metal-plastic products is a reinforced frame made of galvanized steel and a large selection of shapes and non-standard designs. They can be made in the form of an arch, an oval.

Both metal-plastic and PVC models have excellent heat and noise insulation characteristics. The reinforced metal frame of the window made of metal-plastic, due to the additional weight, fits more tightly to the frame, ensuring tightness. The problems of thermal insulation of PVC windows are associated with the need for additional energy savings in cold climates or with deficiencies in the design or installation of window products. Therefore, if you are looking for an answer to the question of how to insulate plastic windows in the house, you should familiarize yourself with the device of the window structure.

Materials used in the insulation of window openings

The modern construction market provides a wide range of products. Most often, they choose as insulation for windows:

- expanded polystyrene;

- mineral wool;

- drywall in combination with polyurethane foam;

- thermal insulation film.

We chose these building materials because of their ease of use, durability and low price. Let's take a closer look at their properties and advantages of using them.

Styrofoam and styrofoam

Expanded polystyrene

Refers to polymer building materials. It consists of plastic foam with a fine cellular structure. Its main properties are:

- High performance of thermal insulation.

- Environmental friendliness.

- Light weight and ease of installation.

- Reliable degree of sound insulation.

- Affordable price.

Varying the composition of raw materials and changing the processing technology makes it possible to obtain expanded polystyrene of different density and strength.

Mineral wool

It is a popular heat insulator. It consists of many fibers intertwined with each other. There are three types of fiber, depending on the type of fiber. Its composition can be based on glass, rocks (stone) or blast-furnace slag. The main characteristics of mineral wool include:

- A wide range of applications (depending on the structure of the source).

- Resistant to high temperatures.

- Thermal insulation properties.

- Reliable degree of sound protection.

Using drywall

Drywall

A common material for interior construction work. Its structure includes two layers of cardboard and a filler in the form of gypsum. To fix the sheet, use gypsum mastics, liquid nails, polyurethane foam or screws.

The properties of drywall depend on the raw materials of production and the technology of its manufacture.

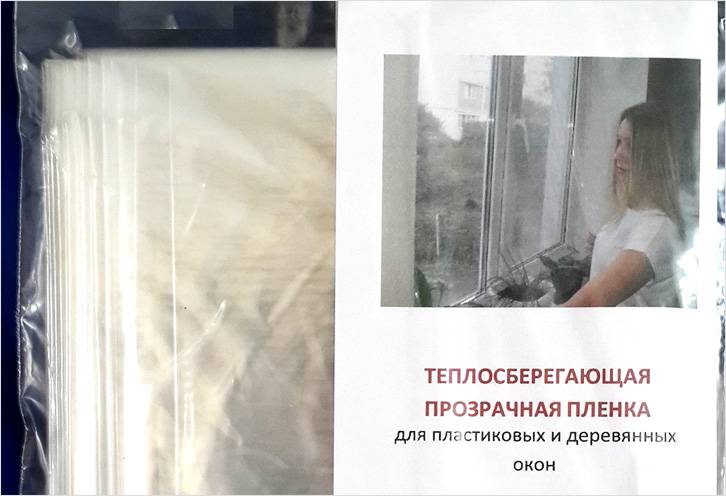

Heat Saving Film

It has established itself in the market due to its optimal price and high heat savings rates. When using this material as insulation of window openings, you can save one and a half times on heating. Another advantage is that the structure of the film keeps warmth in the winter and optimizes the room temperature in the summer.

Heat-saving film has a number of advantages:

- Transmits light through the windows.

- Aesthetic appearance.

- Environmental friendliness.

- High antistatic properties (does not collect dust).

- Prevents condensation formation.

- Ease of use during installation.

In addition to the materials presented, foam plastic, sandwich panels, special sealed glue, foam self-adhesive tapes can also be used.

Video: installation of slopes from sandwich panels

Conclusions and recommendations

"Warm" window installation is not a fashionable trend, but one of the typical units of an energy-saving house and a way to reduce heating costs and energy costs.

- For insulation and finishing of slopes, vapor-permeable materials cannot be used. - stone wool, drywall.

- Using the principles described in the article and the above scheme of "warm" window installation (by remaking it to fit your project), you can install the window structure in stone, frame houses, in cottages with insulated "wet" facades, etc.

- If the window is located in the area of soft insulation, for example, stone wool, then in the lower part of the opening, under the frame, you need to make strong and rigid support pads. This can be a brick leader or metal brackets screwed to the wall.

Detailed instructions for insulation with expanded polystyrene or foam

For external insulation of window openings with expanded polystyrene, you will need:

- expanded polystyrene sheets 2-3 cm thick,

- gypsum plaster,

- glue mixture,

- starting and finishing putty,

- reinforced mesh,

- perforated corners,

- dowels,

- putty knife,

- assembly scissors,

- knife.

Intermediate stage of insulation of window slopes with foam

The process should be carried out according to the following scheme:

- Clean the window from dirt and dust, and residues of polyurethane foam. If there are any irregularities, plaster them.

- Cut the expanded polystyrene sheet into strips. Their width depends on the size of the window.

- An adhesive mixture should be applied to the inside of the blanks and applied to the installation site.

- After complete drying, after about 2 hours, fix the slopes with dowels along the edges of the expanded polystyrene. This will provide a more secure fit.

- Apply a starting putty to the plane, covering all the cracks.

- Install the mesh on top to reinforce the required width, gently pressing it into the mixture with a spatula.

- Install perforated corners around the perimeter of the windows.

- After the layer has dried, cover the surface with a finishing putty again.

- At the end it is recommended to paint the polystyrene foam.

Video: foam slopes outside

Video: installation of a mesh on an outer slope made of polystyrene

Video: insulation of slopes with foam from the inside

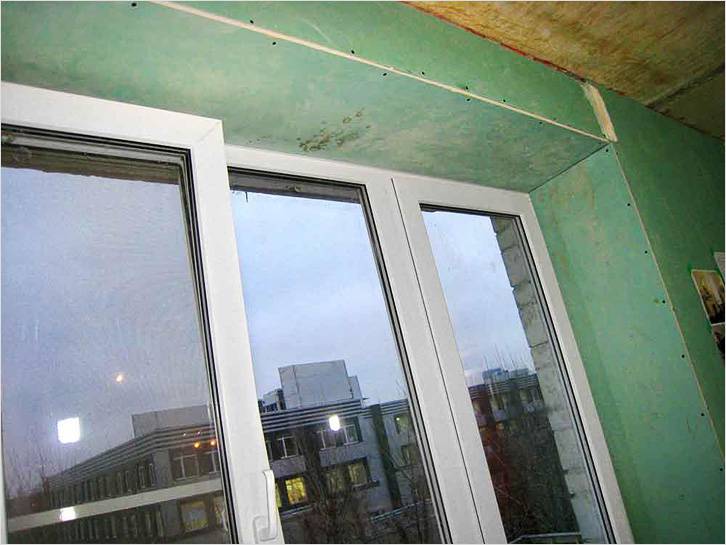

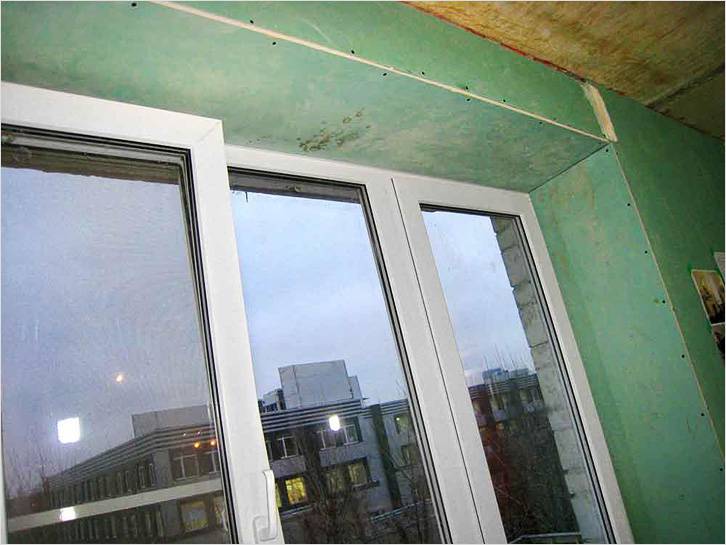

How to avoid the appearance of fungus on the slopes

For example, there is a wall made of aerated concrete. There is no insulation of the facade. Outside the house, the temperature is below zero, and in the room it is above zero. Let's say it's 26 ° C outdoors, and + 20 ° C indoors. Installed a window.

In this design, a window (even a high-quality one with several cameras and energy efficient) is a cold bridge. Those. at the installation site of the window, the thermal contour of the wall is weakened, and the effective thickness of aerated concrete (which affects the thermal resistance of the entire structure) is actually reduced, and the slope freezes over. This can be clearly represented as follows:

Because of this, part of the slope with the window frame is in the zone of the so-called. dew point. This, in turn, leads to the formation of condensation in this place.

The problem is aggravated by the fact that the slope is not covered with vapor-permeable material. Warm water vapor contained in the air of a dwelling tends to escape outside and freely penetrates into cold slopes, and conditions for moisture condensation are created in the structure. The slopes become waterlogged and mold and mildew appear on them.

Thus, although there are conditions for moisture condensation in the wall, there is no water vapor in the colder zone. The wall stays dry and healthy even at subzero temperatures.

Mineral wool insulation technology

For external insulation of window openings with mineral wool, you will need:

- mineral wool,

- plaster,

- glue solution,

- reinforcing mesh,

- perforated corners,

- dowels,

- putty knife.

The insulation process should be carried out according to the following scheme:

- Measure the width of the slopes and cut off pieces of the reinforcing mesh with an overlap of 10 cm.

- Plant the mesh on the slopes with adhesive solution.

- Lay a layer of mineral wool on top, having previously coated the surface with glue. Its width should be 1–2 cm more than the slope.

- To avoid the formation of airspace, the slabs should be applied as tightly as possible to the surface of the slope.

- Trim off the remaining strips of cotton that extend beyond the edge of the slope.

- After complete drying, apply glue to the edges of the insulation and wrap it with the remnants of the reinforcing mesh.

- Install perforated corners around the perimeter.

- Wait until it is completely dry and once again make the screed with glue using a spatula. In this case, the adhesive solution should be slightly thinner than the original one.

- Apply a primer and then paint the window façade.

Note!

The glue solution should look like a mastic. It is better to use several types of glue to increase adhesion.

Mineral wool insulation scheme

From the inside, mineral wool is used in combination with PVC slopes or sandwich panels.

Condensation on windows and mold on slopes: causes and solutions

Plastic windows "crying" in winter are a negative phenomenon familiar to many city dwellers and owners of private houses.

The second trouble is mold that has appeared on the slopes or windowsill.

How can you avoid this? To answer this question, you need to understand the mechanism of this phenomenon. With the classic scheme of heating and natural ventilation, radiators are placed below the window.

The radiator captures cold air and raises the heated stream upward. Near a cold window, in winter, part of this stream cools down and goes down.

Modern plastic windows, unlike old structures, through which cold dry air constantly penetrated from the street, are airtight. If there is a wide window sill at the bottom of the window (overlapping the radiator), or the radiator is mounted in a niche.

This prevents the natural mixing (exchange) of air masses and a stagnation zone forms near the window.

As a result, the blowing of the glass is disrupted. Warm air saturated with water vapor comes into contact with a cold glass unit, cools and condenses. This moisture flows down the window. It drips on the windowsill, accumulates in the corners, etc.

You can solve the problem like this:

- Reduce the width of the window sill.

- Make holes in the window sill to improve circulation of warm air from the radiator.

- Place a convector in the window sill or install heating elements, for example, a heating electric cable.

If the single-layer wall is very wide (in cold regions), then the window moves inward by increasing the thickness of the quarter. Thus, the width of the window sill is reduced, the stagnation zone is minimized and the blowing of the glass improves.

Diagrams of distribution of air flows and internal air temperatures in the area of the PVC-profile windows at different depths of their installation in the thickness of the outer wall;

- a - when placing the window block at the outer surface

- 6 - when the window block is displaced to the center of the wall

Also, in modern PVC windows, a valve is installed for micro-ventilation (air flow, ventilation and additional blowing of the window area) in the cold period.

The above is only part of the solution to the problem. Often, in addition to the "crying" windows in the house, slopes become damp and moldy.

How to insulate with drywall

For internal insulation of window openings with plasterboard, you will need:

- drywall,

- gypsum plaster,

- polyurethane foam,

- moisture resistant primer,

- sealant,

- wooden bars,

- roulette,

- painting knife,

- Scotch.

Plasterboard slopes

The insulation process should be carried out according to the following scheme:

- Cut out drywall blanks based on the size of the window.

- Treat the workpieces with a moisture-resistant primer and dry them.

- Make an incision with a knife around the perimeter of the window, 1 cm deep.

- Insert drywall of the required width into the recess.

- Fill the remaining gaps with polyurethane foam.

- For the convenience of fixing, use scotch tape and wooden blocks.

- Wait until the foam is completely dry, cut off its edges.

- Smooth the surface with gypsum plaster.

- Carry out painting work.

Video: the option of making plasterboard slopes

Errors that can be made when installing windows

There are a number of points that you should pay attention to when installing a structure so that it has a long term of use:

- it is impossible to install the window with glazing beads outward, as this reduces the anti-burglar resistance of the structure, since the glazing bead can be easily pulled out and removed the glass unit;

- you need to carefully consider the alignment of structures in the level during the installation of the window, otherwise it will be difficult to open and close the sashes;

- it is imperative to protect the polyurethane foam from direct sunlight in order to avoid its destruction;

- the choice of fixing the frame structure only with mounting foam will be wrong: it is imperative to fix it to the wall, otherwise it may simply fall out.

Observing all the installation rules, you can successfully mount the window structure yourself, and if you turn to professionals for services, you can control their work at any stage.

Other articles on this topic:

Installation of heat-saving film: instruction

For internal insulation of window openings with a heat-saving film, you will need:

- heat-saving film,

- double sided tape,

- household hair dryer,

- construction knife,

- scissors.

Installation of heat-saving film

The insulation process should be carried out according to the following scheme:

- Degrease the work area.

- Remove the handles from the window.

- Cut the film into one layer based on the parameters of the window. Make the edges 2 cm larger for easy gluing.

- Stick the film around the perimeter of the window with tape.

- Remove the protective strip from the tape.

- Holding the film by the top edges, attach it to the tape.

Blow out the window with a hairdryer to shrink the material and smooth out folds.

Frame fixing rules

When installing plastic windows, it is necessary to follow the rules for the location of fasteners, which ensures the rigidity of the frame:

- Vertically - the distance from the inner corner of the frame to the first fastener should be no more than 15-18 cm.

- Horizontally - from the impost to the fastening element, a distance of 12-18 cm is recommended.

- The vertical anchors should be spaced 70 cm (for PVC windows made of white plastic) and 60 cm (for colored laminated profiles).

Assembling the window

If the window is deaf, then the installation procedure for the insulating glass unit ends with the installation of a glazing bead with an angle of 45 °, located along the entire perimeter. The glazing bead is inserted using a special medium-sized hammer until a characteristic click sound is heard.

In the window opening unit, the sashes are hinged. When the sash is in place, it is necessary to check its functionality. If necessary, it will need to be adjusted using a special adjusting key. The open sash must be stationary, which indicates correct adjustment.