Vapor barrier tape and its types

The replacement of windows in the house is always accompanied by the installation of protection for the joint between the frame and the wall. Polyurethane foam is applied between the opening and the frame - a traditional and proven thermal insulation. Foam regularly performs its role, but with extreme exposure to moisture or ultraviolet radiation, its quality may change for the worse.

In order to exclude the possibility of such a situation in advance and save yourself in the future from replacing the polyurethane foam, you should think about sealing the seams. To do this, you need to install additional insulation.

Window butyl vapor barrier tape as an element of additional insulation

A complete set of insulation allows you to avoid freezing of the room and to exclude the penetration of moisture and noise into the interior as much as possible.

Self-installation of film on windows

The installation of the protective film is carried out during the assembly of the glass unit. It is installed on the inside of the glass. This ensures its protection from moisture and mechanical damage. But there are alternatives for already mounted windows.

For self-gluing the film on a glass unit, you need to measure the dimensions of the glass unit and add technological indents of 15-20 mm to them. You should purchase a special coating designed for installation on the outside of the glass.

List of required materials and tools:

- A container with soapy water;

- Plastic spatula;

- Drywall knife.

First, the glass surface is cleaned of dust and then degreased. Then a layer of soapy water is applied. Since it will drain, it is best to do the work on a dismantled glass unit, located horizontally.

The film is neatly placed on the glass and leveled. Excess liquid and air bubbles are removed with a spatula. The edges of the protective coating are cut with a knife. It is desirable that the glass unit lay for 12-18 hours for the coating to shrink. Only then can you install it in the window. Glazing beads will press the interlayer, so they need to be installed carefully.

This technology does not guarantee the required appearance and expected effect. One of the main requirements for installing a protective film is complete sterility of the room - no dust, minimum humidity and temperature. Providing such conditions at home is problematic. Over time, the coating can peel off from the glass.

Vapor barrier

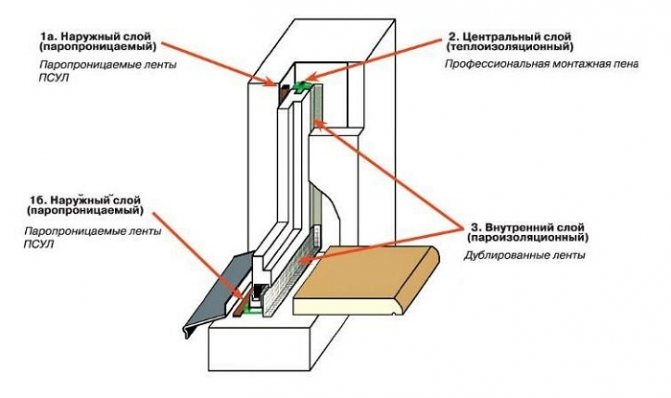

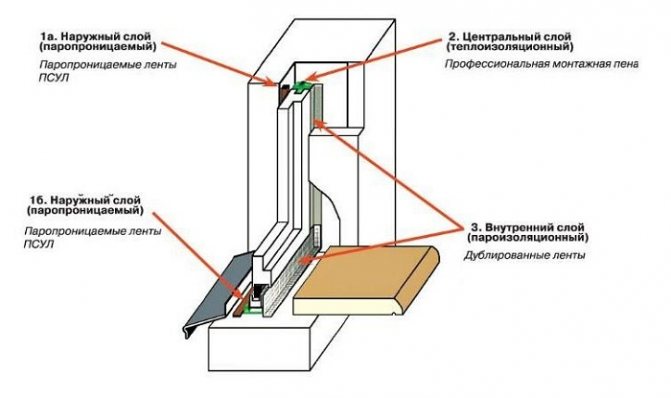

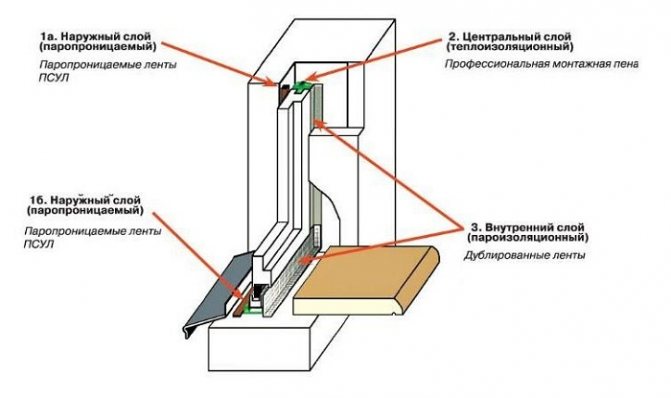

The insulation of the wall-window joint consists of three layers:

- Outer. Its function is waterproofing, which means protecting the room from any weather conditions - snow and rain.

- The bearing layer of insulation is located in the middle of the joint and is responsible for heat and sound insulation. Frost protection is provided by a porous material resembling polyurethane foam. The sealant prevents moisture from getting inside.

- The inner layer is also considered to be heat insulating. Here the mechanism of heat conservation is different. This layer does not allow heat to escape from the inside, in contrast to the outside, which protects the premises from cold air currents from the street.

Window insulation layers

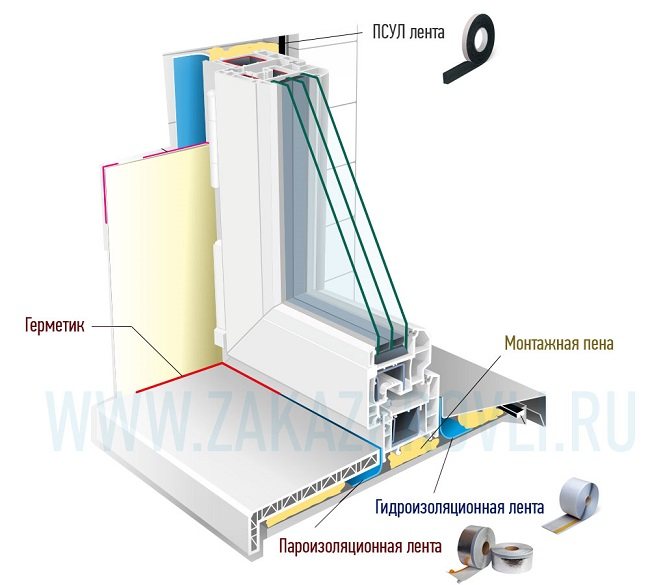

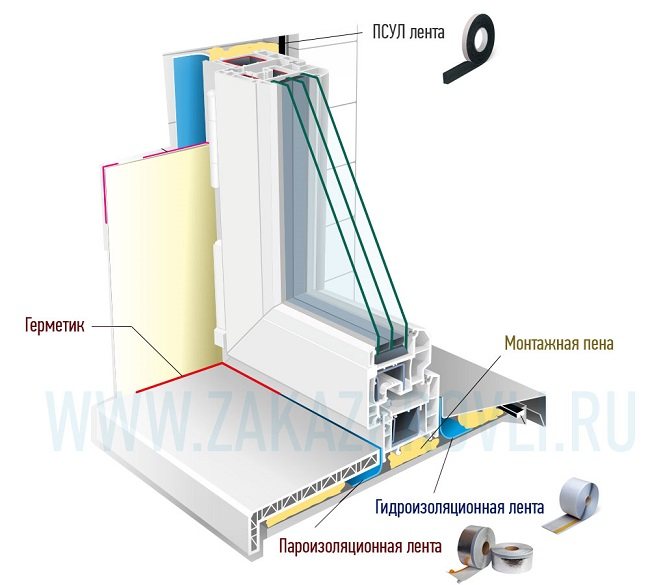

Vapor barrier of windows refers to the inner layer, but is not always included in the insulation system. One-sided self-adhesive vapor barrier tape or double-sided vapor barrier tape is an additional protection. The need to use tape increases if the window is installed in a room with a high moisture content: kitchen, sauna, bath.

Installation of vapor barrier tapes in complexity does not surpass the installation of other types of seam insulation. However, a vapor barrier can help avoid subsequent serious problems with the entire window protection system.When installing a vapor barrier, in some cases, you may need a couple of additional accessories, for example, an adhesive tape for vapor barrier. It is worth considering.

disadvantages

In the selection process, you need to pay attention to a number of points:

- thermal insulation properties. Such a film can provide privacy, but it certainly will not provide protection from the cold in the winter or from the scorching sun in the summer;

- color fading. There are several varieties. Some types are designed to cover windows that are constantly exposed to the rays of the sun. But the colored type, most often, is not intended for this - the paints quickly fade, and the coating itself turns into a canvas with a large number of mini-cracks. Accordingly, you must either refuse to use it, or you will have to replace it regularly at intervals of several years;

- opacity. The fact that the film is opaque plays both a positive and a negative role. Indeed, it will protect the interior of the room from outside viewing, but at the same time it will also limit your opportunities for viewing the street.

- a decrease in the light transmission of the window and the appearance of an undesirable shade in the room. Therefore, designers recommend careful use, finding a balance between beauty, privacy and convenience.

Classification of vapor barrier tapes

Vapor barrier tapes are manufactured in two versions:

- tapes with one adhesive side;

- double-sided vapor barrier tapes.

Butyl vapor barrier tape for window

The first type of tape is attached to the window frame of the window. The second makes it possible to choose the place of attachment: both on the frame and in the opening.

In addition to differences in adhesive structure, tapes are divided into two types according to climatic performance:

- for predominantly warm average annual weather, "summer" vapor barrier films are suitable;

- in the presence of subzero temperatures, "winter" tapes are used.

Adhesive surface of vapor barrier tapes

All vapor barrier films are equipped with an adhesive strip. The absence of the need to independently apply glue eliminates the possibility of poor-quality fastening of the tape, as well as the ingress of moisture into the heat-insulating environment.

The material for the adhesive layer of the vapor barrier tape is butyl rubber or, in cases of high humidity, metal. Tapes containing rubber foil are used for windows, balconies and doors in almost all types of premises. The basis of such a vapor barrier is a non-woven fabric.

Types of vapor barrier tapes

The most common types of tapes, depending on the material:

- Some of the most popular butyl rubber tapes are PSUL (pre-compressed sealing tapes), which are responsible for the external vapor barrier, finishing of the external joints and the tight connection between the frame and the wall.

- GPL polyethylene tape is made of foam material. On the one hand, it is processed by lamination. The strip contains metal inserts and an adhesive part along the entire length and width. Thanks to its well thought-out composition, it is practically universal and is recommended for insulating all types of door and window frames.

- Vapor barrier tape for VS windows. Suitable for insulating joints if a subsequent dry method of finishing slopes is planned. Usually applied on plastic or plasterboard elements. The bonding tape protects the surfaces from condensation. The wide adhesive strip makes the installation of the vapor barrier strip quick and easy.

- VM vapor barrier tape. As well as other types of tapes, it is perfectly attached to window and door frames. Installation is carried out in sequence from the frame. The strips of tape are overlapped in order to avoid possible heat leaks during the operation of windows or doors.

Butyl rubber tape has a high specific gravity. The PSUL tape weighs about 5 times more than the tape made with reinforced aluminum foil at the same width.The differences between the types of tapes also lie in the surfaces for which they are usually used. Thick rubber tape is able to adhere firmly to the wall, and there is no need to use heavy insulating materials for gluing with slopes. For this case, lightweight foil-reinforced strips are preferred.

GPL tapes

GPL - steam waterproofing tapes that perform moisture protection as the main task. These tapes form the outer layer of insulation with an additional vapor barrier function.... Self-adhesive vapor barrier tape is made of foamed polyethylene.

Polyethylene foam has a porous structure, has good thermal insulation properties and practically zero hygroscopicity (does not absorb moisture). The presence of this material in the tape makes it elastic and ensures high-quality sealing with any surface, including uneven ones.

Architectural and facade films

Architectural and facade films on windows are no different from polymer coatings known under other names. They also serve to provide sun protection and to decorate buildings. It's just that these two terms are sometimes used as generalizations for all types of films - shockproof, decorative, sunscreen and athermal. In some cases, a facade film can be called with the effect of one-sided visibility. This is due to the fact that such polymer coatings are used in fully or partially glazed business centers and shopping malls to ensure confidentiality. Such films limit the view only from the street side. In addition, an external film can be called a facade film.

Vapor barrier tape for PVC windows. What is it and how to glue it

Photos from the site: izollab.ru

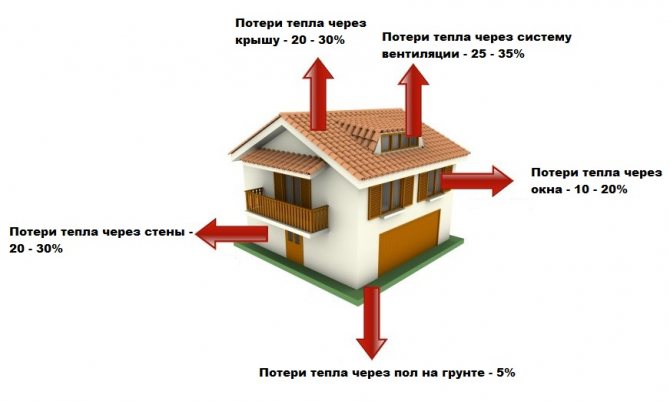

If we talk about the vulnerability of any building to a wide variety of influences, both from the inside and outside, then such places as, for example, the joints of the windows of the window frames themselves with openings in the wall immediately come to mind. The thing is that it is in these places that, with improper installation of window structures, heat can be significantly lost, also from the outside, if there are cracks, noise and extraneous sounds can penetrate inside, and on top of that, there is also dust that is ready to penetrate through the smallest holes ... In order to keep the heat inside the house with high quality, as well as to ensure the long-term service of the structures, a vapor barrier tape for plastic windows was invented, which many simply do not install, thinking that this is simply an extra hassle.

Advantages of plastic window structures of our production

- Silence.

Our windows will reliably protect you from street noise and bad weather. Our products are able to displace a bustling and loud city outside the boundaries of your apartment. - Cool in hot weather.

Thanks to a special coating, the glass unit reflects most of the infrared rays, and this is several times more effective than conventional glass, approximately as protection from heat using blinds. - Keeping warm in winter.

During the winter months, PVC windows significantly reduce heat loss in the apartment. The building does not cool down so quickly with them. - Enhanced security.

Our metal-plastic windows are absolutely not dangerous to the body. The special material does not cause allergic reactions, and the children's accessories ensure the safety of the child. Film for plastic windows provides additional safety when they are broken.

Mandatory three layers: vapor barrier for PVC windows

Photos from the site: izollab.ru

Whatever one may say, the correct vapor barrier from the inside, as well as waterproofing from the outside, really plays a huge role in preserving the walls and the window structures themselves, preventing cold air from getting inside, as well as warm air leaking out. Moreover, the places of the assembly seam are the most vulnerable, which is why they must be performed taking into account all technological nuances, one of which is the vapor barrier of window slopes, seams, openings, and so on. Moreover, professional builders distinguish three main layers, the quality of which must be monitored.

Correct installation of window structures that provide three levels of insulation, that is, when the seam is three-layer, which can be read about a little below, can completely exclude freezing through it during the winter cold. This also completely eliminates the appearance of condensation on the slopes, prevents them from cracking and deterioration. That is, you can pick up a wide variety of materials for yourself, since the market provides such an opportunity, however, there should be three layers of embedding in any case.

- The middle seam, which is just under the window structure, performs the function of heat and sound insulation, and it can be safely considered the main one, as it were, load-bearing.

- The layer on the outside is considered waterproofing, since it prevents moisture from entering the inside, which can lead to the entire structure, a terrible black mold may appear, and so on.

- The inner layer is vapor barrier, which just does not allow the heat from inside the premises to leak out.

Useful characteristics.

The PVC film protects the structure from dust, rain and wind. It prevents insects and cold air from entering the house. The material is transparent, so that sunlight can pass through unhindered.

The film also has a number of useful characteristics:

- safety (from an environmental point of view). The PVC film contains no toxins that emit harmful substances into the atmosphere. It does not cause allergies;

- waterproofness. The material does not stretch when exposed to moisture. Thanks to this, the PVC coating withstands atmospheric precipitation in the form of rain and snow. Besides, it can be washed with water;

- strength. The material does not lose its working qualities when exposed to rain, snow or sunlight. He is not afraid of gusts of wind or sudden changes in temperature;

- elasticity. PVC film has a flexible structure that is resistant to tearing;

- low price. Affordable cost allows it to be used by a wide range of consumers.

These characteristics make the film for windows an ideal solution for the decoration of various structures.

Vapor barrier tape for PVC windows: general information

Photos from the site: izollab.ru

It is clear that if you really want to ensure the reliability and durability of a brand new PVC window, so that it will last the maximum period with the lowest cost, you should always do everything thoroughly and according to the technology. High-quality materials for embedding, high professionalism of the installers themselves, good quality of the window frame and glass unit, as well as a good vapor barrier tape for windows can guarantee high performance in all necessary parameters. Moreover, it is worth knowing that the higher the humidity inside the premises, the better such a vapor barrier should be, preventing moisture from entering the slopes, frames, and so on.

First of all, you need to know that all vapor barrier tapes can be conditionally divided into those that have only one adhesive surface, with which they will be attached to the frame itself, or double-sided. The second option can already be fixed not only on the window structure itself, but also in the opening. Among other things, before the vapor barrier of a PVC window is purchased and installed, you need to find out what weather and climatic conditions it is intended for. Moreover, there is a summer version of films on sale, designed for temperatures from five to thirty-five degrees of heat, as well as from zero and below, that is, a winter version.

The progress of work on the insulation of wooden and plastic windows

Each of the insulation methods above are effective. But any work carried out in a complex is much more effective than using them separately. Let's look at the order of compaction work

Step 1: Replacing the seals

People who are faced with the problem of violation of the thermal insulation of windows, the first thing to do is to replace the seal. It is best to do this work in dry and warm weather.Replacing the seal on wooden windows is quite simple. But with plastic, the situation is different - the seal on them wears out after 5 years of operation. It is recommended to replace only one that is already worn out and does not cope with its functions. In other cases, using silicone putty a couple of times a year can extend the life of the seal. To replace the rubber seal on the windows, you must pry on the old one and pull it out. Before inserting a new seal, it is necessary to wipe the grooves from dust. A new seal must be purchased of the same thickness and preferably from the same manufacturer. A new seal is inserted into the cleaned grooves. For the convenience of performing this operation, it is recommended to remove the sash, thus replacing the seal on the sashes and window frame. To change the rubber gasket that protects the glass unit, it is necessary to perform more complex and time-consuming operations.

Important! Seals from different manufacturers have a different structure, and may also differ in color.

First, remove the glazing beads that hold the glass unit. Now you can easily remove the glass and pull the seal out of the grooves. Just as when replacing the gasket on the sash, the grooves must be cleaned. It is recommended to cut the rubber gasket with a margin of 6 cm, in which case it will fit snugly around the entire perimeter of the glass unit. The new seal is placed in the grooves, after which everything can be assembled back. You can use glue for additional fixing of the seal.

Step 2: Adjusting the clamp (new designs only)

For many, this function in plastic windows may seem like a novelty, but manufacturers recommend adjusting the pressure 2 times a year. It should be different for each season. To make this adjustment, you will need a 4 mm Allen key or pliers, depending on the window design. At the end of the sash there is an eccentric with a notch, which is required. An eccentric is a device for adjusting the fit of the sash to the window frame. In plastic structures, it is possible to set winter and summer modes, as well as medium, which is set by default.

Build a greenhouse with polycarbonate, wood, and polypropylene pipes.

By rotating the eccentric, you can adjust the tightness of the flaps. Using the winter mode allows you to keep warm in the room due to a tighter fit. And with the onset of warm days, the windows are switched to summer mode, which allows increasing air circulation. In some cases, such an adjustment is not enough, therefore, additional adjustment of the loops is carried out. If winter ventilation is provided for in the window design, then both the lower and upper hinges are adjusted. And in cases where such a function is not provided, it is enough just to adjust the lower hinges. To make such settings, you need to open a window. In the open position, set the sash to the ventilation position. Only in this position can the upper hinge be adjusted. By turning the adjusting screw, you can change the tightness of the sash to the frame.

Step 3: Insulation of slopes

A variety of materials can be used to insulate slopes. The most popular of them: polystyrene, expanded polystyrene and a sealant with a layer of polyvinyl chloride. They all provide good thermal insulation. Before deciding on the material for compaction, it is necessary to investigate the external and internal slopes. Poorly performed work or wear of the material can lead to the fact that the thermal insulation of the room is broken. In such a situation, before starting the insulation, it is necessary to remove the old material and reinstall the slopes. Thermal inserts can be used to insulate the slopes from the inside. After their careful fixation and strengthening, a cosmetic finish of the slopes is performed. Basalt wool can be used as such inserts. Another option is to stick the foam on the inner surface of the slopes.Then it should be putty or covered with drywall.

Did you know? There is a myth that thermal insulation materials scare away mice, but such materials do not exist.

Another way of finishing and sealing is the installation of so-called "sandwich panels". Such a panel already has a heat-insulating layer, which makes them a convenient option for insulating slopes. For additional sealing, a layer of cotton wool can be used as a base for the sandwich panel. An important point in the process of insulating slopes is the inadmissibility of the presence of air gaps.

To avoid this problem, you can use special adhesives. They are applied along the perimeter of the surface to be treated, as well as on the seams. Correctly applied adhesive promotes good adhesion to the slope surface

Step 4: working with the window sill

Another problem area in window thermal insulation is the window sill. Its poor-quality installation can lead to big problems during operation. For example, if the space under the windowsill is not sufficiently filled with polyurethane foam, air pockets can form there, which violate the thermal insulation. Another problem is the destruction of foam under the influence of mechanical stress or thermal factors.

Important! When installing window structures in winter, you need to use the so-called "winter" foam, which provides better sealing.

In such situations, re-sealing with polyurethane foam is required. To carry out such work, first of all, it is necessary to remove the old foam, and then fill the space with a new layer. But such material does not allow closing small cracks. You can seal them using a sealant. It penetrates well into cracks and completely seals them. In addition, it repels water well. The combination of such materials will close all problem areas.

Step 5: pasting the glass

Sometimes, after eliminating all the problems, heat loss remains at a fairly high level. In such cases, glass is pasted over to provide thermal insulation. Various materials can be used for this. For example, for better protection against the effects of low temperatures, you can tape over the junction of the glass and the frame with tape. An energy-saving film can also be used as a heater for glass.

For the insulation of windows, a packaging film, or, as it is also called, a film with bubbles, can be used. This film can be purchased at any hardware store. It helps protect the house from the cold well and improves the energy efficiency of the building. It takes very little time to install it, and subsequently it does not require special care. The film can be glued and peeled off repeatedly. Such a seal does not prevent sunlight from entering.

Installation requires scissors, a spray bottle and bubble wrap. Cut the film to the size of the glass and wet its flat side. Apply the film with the wet side on the abundantly moistened glass. Water provides good adhesion to the surface. We level the attached film well. Such insulation helps to protect the glass from unnecessary heat loss, and most importantly, it is a very convenient and economical method. The use of the film leaves no residue, which makes it easier to clean the window after removing the seal.

Step 6: Insulation from the outside

Slopes and low tide are insulated from the outside of the building. Lack of thermal insulation of external slopes will not allow to reliably protect windows from drafts and cold. For thermal insulation of external slopes, foam plastic 5 cm thick and a mounting mesh are used. Decorating slopes from the outside is often accompanied by complete insulation of the building, but this work can be carried out separately.

Important! The foam must cover part of the window frame and completely cover the assembly seam.

In the process of performing such work, pre-prepared strips of foam plastic are tightly glued to the previously cleaned surface. At the end of such work, the foam must be plastered, which will protect it from further destruction. When performing thermal insulation work, it must be remembered that for the correct distribution of light in the room, the slopes must have a deployed angle in relation to the window.

Draining is a very important point to ensure the tightness of the window. To prevent moisture from accumulating, the slope should have a 5 ° bevel and protrude 4 cm from the building, and the side edges should be bent up. This shape will allow water to drain freely without penetrating under the ebb. For additional protection from moisture, the places where the low tide fits to the window and slopes are additionally sealed.

The best mounting tape for windows: what it can be

It is also worth knowing that the adhesive tape for vapor barrier can be made of butyl rubber, and this particular option is intended for insulation of balcony, window, as well as door blocks and interpanel joints. Inside such a tape, a reinforcing layer of non-woven fabric necessarily goes.

Photos from the site: gidroizolyaciya-pro.ru

The second option is a metallized tape specially designed for the insulation of seams and joints in rooms with high humidity. It also has an adhesive layer, which greatly simplifies the installation of the structure, as well as the subsequent finishing of the slopes, and so on. In addition, the width of the belts of this plan can also vary, depending on the manufacturer. You need to choose one that is several tens of millimeters wider than the assembly seam itself.

A full-butyl vapor barrier tape made according to the Robiband system has all the prerequisites to ensure high-quality ventilation of the assembly seam. Moreover, this system fully complies with all, without exception, the standards and requirements that apply to it.

Photos from the site: gidroizolyaciya-pro.ru

- First on the list is a material like PSUL tape that can really provide a secure fit for a door or window frame to a wall. Full-butyl vapor barrier PSUL tape is intended for external vapor barrier. It will help to qualitatively close up all joints and seams.

- The insulating tape VS is intended for sealing joints in cases where a dry finish is meant. For example, for drywall, sandwich panels, plastic and so on. It has a layer of adhesive coating along the width of the tape, which greatly simplifies installation, and is also able to prevent condensation from falling on the slopes from inside the room. Likewise, the version with BC + tape is also designed for interior work, for dry finishing. It is also glued over the entire surface, protected by an anti-adhesive film.

- Robiband VM vapor barrier tape is another extremely good quality option. It is also used for interior work, and wet plaster can already be applied on top of it. A more advanced version of such a tape is VM +.

- Hydro-vapor barrier tape, that is, GPL is made of high-quality foamed polyethylene, laminated on one side, and also equipped with a metallized layer, as well as with an adhesive surface in the entire width of the tape itself. This tape is completely universal and can be used in almost all cases. There are also variations on the theme, for example, the GPL-S tape.

It is imperative to understand that a vapor barrier tape with a protective polypropylene strip resists all kinds of mechanical damage quite well. Among other things, it has an enviable resistance to aggressive environments, that is, it is not afraid of acids, alkalis, or organic solvents.

The right solution is always at hand: how to make a vapor barrier for PVC windows with your own hands

Photo from the site: remoo.ru

When you somehow managed to figure out the materials, as well as their properties and purpose, it is worth thinking about how to glue the vapor barrier tape on the windows so that it provides maximum efficiency, both as a vapor barrier and as an insulator in general. Most often, a vapor barrier film or tape on PVC windows is installed where the humidity is steadily increased, for example, in bathrooms, saunas, swimming pools, and so on.

However, in an ordinary house, it also does not interfere at all and will only bring exclusively benefit and nothing but her. Moreover, it takes all the burden of eliminating moisture loss on the slopes, which will help make your windows more durable, reduce the risk of fungal infections and similar risks.

Photos from the site: tremco-illbruck.com.ua

It is worth knowing that such tapes can be equipped with two or one adhesive strip, which greatly simplifies installation, it is actually elementary simple and even a small child can cope with such a task, not to mention an experienced adult man. Just choose the right width and temperature (winter / summer), and follow the instructions, which are ridiculously simple.

- First you need to thoroughly clean the window opening from all kinds of contamination, for example, from construction debris and dust.

- The PVC structure should also be wiped with a dry cloth before installation, and then put in place, marking with a pencil the places where the tape is attached to the frame and wall.

- We take out the window back, and then directly along the perimeter we glue the vapor barrier tape on the surface of the frame.

- Do not forget that before installing the window structure in the opening, you will also need to take care of the protective film, which must be removed from the tape.

Photos from the site: 1pooknam.ru

It is necessary to understand that for one window, door structure or balcony block, you need to use only one, single piece of tape, therefore it is better to cut off a little more than less. It is completely unacceptable to allow the mosaic to be folded here. Moreover, the tape on the windowsill, which is placed at the very end of the installation, must be glued last.

The installation of a window structure must necessarily be carried out according to the developed technology, if you want it to serve faithfully and without failures and breakdowns, as well as for a sufficiently long time. Many people give a damn about vapor barrier and then suffer severely from all sorts of inconsistencies. It is worth thinking ten times before giving up the vapor barrier, so that later you will not complain about fate and your own stupidity.

Care of tinted glass unit

Installing a protective film on the outer part of the glass unit increases the requirements for window care. Minor scratches may appear on the surface of the layer if detergents or abrasive cleaners are used. Film hardness is significantly lower than that of glass.

To care for it, you need soft microfiber napkins or cotton cloth. Removal of dirt and dust is carried out without the use of liquids, as they can change the density of the coating. If it is partially or completely peeled off, the installation procedure can be repeated again, but more carefully.

Experts recommend ordering double-glazed windows in window structures already coated. The manufacturer will be obliged to ensure that the original appearance is preserved during the entire period of the warranty, but subject to compliance with the rules of operation.

Vapor barrier tape for plastic windows

Vapor barrier tape, internal duplicated full butyl, under a slope, Bauset ST-I 150 mm (15 m)

Vapor barrier tape, internal duplicated full butyl, under a slope, Bauset ST-I 150 mm (15 m)

Vacation rate: 15 m

Cost per 15 m: 545 .55

Bauset tape internal duplicated 150mm (25m)

Bauset tape internal duplicated 150mm (25m)

Vacation rate: 25 m

Cost per 25 m: 429.25

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 70 mm (15m)

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 70 mm (15m)

Vacation rate: 15 m

Cost per 15 m: 277 .05

Bauset tape internal duplicated 100mm (25m)

Bauset tape internal duplicated 100mm (25m)

Vacation rate: 25 m

Cost per 25 m: 384.50

Bauset inner metallized MR tape 2x100mm, under the windowsill (12m)

Bauset inner metallized MR tape 2x100mm, under the windowsill (12m)

Vacation rate: 12 m

Cost per 12 m: 373.20

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 70 mm (15m)

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 70 mm (15m)

Vacation rate: 15 m

Cost per 15 m: 277 .35

Vapor barrier tape, internal duplicated full butyl, under a slope, Bauset ST-I 120 mm (15m)

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 120 mm (15 m)

Vacation rate: 15 m

Cost per 15 m: 443 .85

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 200mm (12m)

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 200mm (12m)

Vacation rate: 12 m

Cost per 12 m: 657 .96

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 100 mm (15 m)

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 100 mm (15 m)

Vacation rate: 15 m

Cost per 15 m: 389 .55

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 150mm (12m)

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 150mm (12m)

Vacation rate: 12 m

Cost per 12 m: 568 .08

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 100 mm (25 m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 100 mm (25 m)

Vacation rate: 25 m

Cost per 25 m: 462.00

Bauset inner metallized MR tape 2x70mm (12m)

Bauset inner metallized MR tape 2x70mm (12m)

Vacation rate: 12 m

Cost per 12 m: 346 .08

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 45 mm (15m)

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 45 mm (15m)

Vacation rate: 15 m

Cost per 15 m: 214.20

Bauset inner metallized MR tape 2x50mm (12m)

Bauset inner metallized MR tape 2x50mm (12m)

Vacation rate: 12 m

Cost per 12 m: 283 .08

Internal tape, duplicated, under a slope, Bauset MR 70mm (12m)

Internal tape, duplicated, under a slope, Bauset MR 70mm (12m)

Vacation rate: 12 m

Cost per 12 m: 390 .96

Internal double tape, Bauset MR 100 mm, under a slope (12m)

Internal double tape, Bauset MR 100 mm, under a slope (12m)

Vacation rate: 12 m

Cost per 12 m: 528 .36

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 150 mm (25 m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 150 mm (25 m)

Vacation rate: 25 m

Cost per 25 m: 549.25

Bauset MR tape 200 mm, internal duplicated, under a slope (12m)

Bauset MR tape 200 mm, internal duplicated, under a slope (12m)

Vacation rate: 12 m

Cost per 12 m: 729.24

Bauset MR tape 150 mm, internal duplicated, under a slope (12m)

Bauset MR tape 150 mm, internal duplicated, under a slope (12m)

Vacation rate: 12 m

Cost per 12 m: 631 .56

Tape, vapor barrier, inner metallized, under the windowsill, Bauset MR 45mm (24m)

Tape, vapor barrier, inner metallized, under the windowsill, Bauset MR 45mm (24m)

Vacation rate: 24 m

Cost per 24 m: 546 .96

Vapor barrier tape, isolon 3 mm, Bauset MR 250mm, sloped (12m)

Vapor barrier tape, isolon 3 mm, Bauset MR 250mm, sloped (12m)

Vacation rate: 12 m

Cost per 12 m: 1 186 .32

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 120 mm (25 m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 120 mm (25 m)

Vacation rate: 25 m

Cost per 25 m: 524.50

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 70 mm (25m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 70 mm (25m)

Vacation rate: 25 m

Cost per 25 m: 433 .75

Bauset tape internal duplicated MR 1,5x120mm (12m)

Bauset tape internal duplicated MR 1.5x120mm (12m)

Tapes for window installation in accordance with GOST

High-quality glazing requires a serious attitude towards itself and is impossible without proper isolation of the gap between the opening and the window.Often, organizations installing translucent structures are limited to traditional polyurethane foam, which is subsequently covered with plaster or other finishing materials. This approach has proven itself relatively well and in some cases does not cause complaints from the consumer throughout the entire life of the window.

However, glazing with one level of sealing of the opening does not meet the requirements of the state for the quality of the services or goods provided, that is, GOST. In order to comply with these requirements, additional insulation is required for the junction of the window to the opening both from the street side and from the side of the room. Such insulation is provided using special mounting tapes.

Scheme of application of mounting tapes on windows

View from above

Mounting tape for windows is a self-adhesive material on a polymer or fabric base, designed for additional sealing of window or door openings.

Why you need to trust us for the installation

- Experienced craftsmen will work on your windows.

- The pasting will be done correctly, neatly.

- All recommendations of the film manufacturers have been followed.

- The speed of work is prompt, strict adherence to deadlines.

- The cost is calculated immediately, no additional payments will be required.

- Work guarantee.

- We conclude a contract and fix all the important points in it.

- We work with trusted film manufacturers.

If it is important for you to have a durable coating on the windows, then contact us immediately. We will advise, answer all questions and get started!

Call us right now or leave a request on the site!

You can leave a request by phone or through the form below. We will call you back.

Varieties of mounting tapes for windows

The functions performed by the tapes are different and depend on the place of gluing, the state of the opening, the features of the future finishing of the slopes, as well as the requirements for the window block. Next, we will consider the most commonly used materials common in the modern construction market.

The pre-compressed sealing tape is mainly used on the outside of translucent structures. Its main purpose is to ensure the unhindered drainage of moisture from the area where the trap joins the opening.

In fact, this is a tape product made of elastic polyurethane foam (it looks like foam rubber), as a rule, gray or black. One side of the material is covered with adhesive, insulated with a protective film. The tape is supplied rolled into compact bobbins or rolls (depending on the standard size), which need to be unwound only during the installation process, since the material loses its quality over time.

Example of tape expansion over time

The main feature is the ability to fill joints as a result of expansion, which occurs as a result of contact with air. The tape insulates the gap from moisture and external influences from the outside, while allowing excess liquid to evaporate from the inside.

Scope of PSUL application:

- Additional sealing of joints between elements of prefabricated structures;

- Sealing the gap between the frame and the opening when installing windows and doors;

- Insulation of joints between small-sized movable units of building facades;

- Filling the external seam between the slope and the frame during the installation of PVC windows.

Advantages and disadvantages of tint film

Film tinting of plastic windows has gained wide popularity for a reason. This technology has the following advantages:

- Relieves Excessive Sunlight Exposure

... If the windows face south, then in the summer it can be very hot in the apartment. It harms people, animals, plants, and even furniture. Tinting of plastic windows saves from heat and sun glare, which also bring no small discomfort when watching TV or a computer.Of course, you can draw curtains, but this artificially created darkness is more likely to lead to depression. - Protects from the gaze of curious passers-by

... If PVC windows are pasted over with a mirror film, then in the daytime no one will be able to spy on what is happening in the apartment. - Increases safety

... Even ordinary tint film, not to mention its protective counterparts, will keep the fragments in the event of a glass break. In terms of safety, this can be very important if small children are present at home. - Decorates the window

... Glass tinted with a mirror film looks very attractive, as well as any pattern can be applied to it.

The disadvantage of tinting plastic windows will be the relatively slow heating of the apartment. Before covering the glass with a tinting film, you need to think carefully about this decision. If the windows of the apartment face north or they may be shaded by trees in the future, then it is better to abandon the idea with tinting.

What is the tint film made of?

The basis of production is polyester, on which a small layer of metal is sprayed, due to which the film acquires sun-protection properties. They mainly use titanium, aluminum or nickel, sometimes silver.

Manufacturers advise to glue the tint film in such a way that the spray layer is directed to the glass, this will provide a more effective reflection of sunlight.

The film for tinting PVC windows can be made of several layers. This is used when it is necessary to paint the material in any color. At the same time, the colored layer retains its tone longer, as it is protected by the outer coating. The layers are connected using a so-called laminator.

What other glass tinting technologies are there?

The tint film will eventually become unusable, and you can accidentally scratch it. Tinting of plastic windows can be carried out even at the stage of glass production.

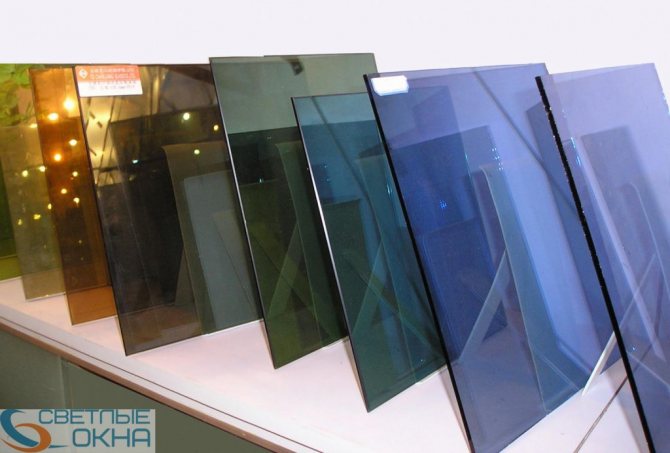

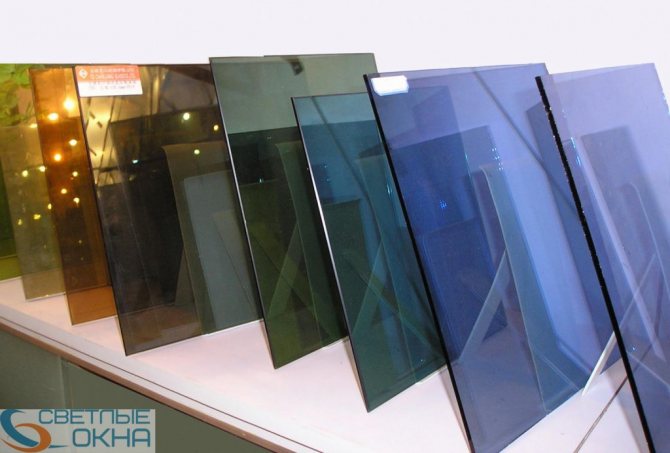

For example, there is mass toning technology

... Metal oxides are added to the liquid glass mass, as a result, the glass unit acquires sun-protection characteristics and a characteristic shade (gray, blue, green, gold).

There is one more way for tinting windows - sputtering

reflective metal particles on the glass.

You can order the installation of inexpensive plastic Rehau windows with tinted glass units in ours. To calculate the cost of PVC windows, an online calculator is provided on the site. If you have any questions, please leave a request for a call back.

Installation features

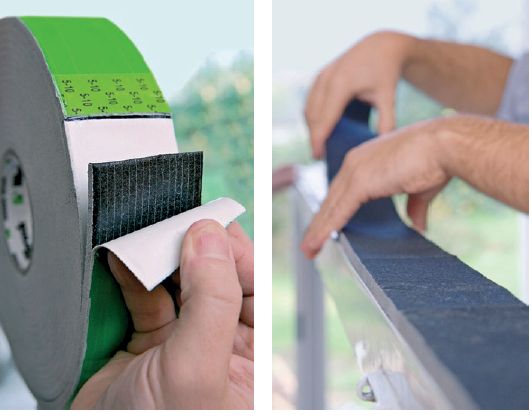

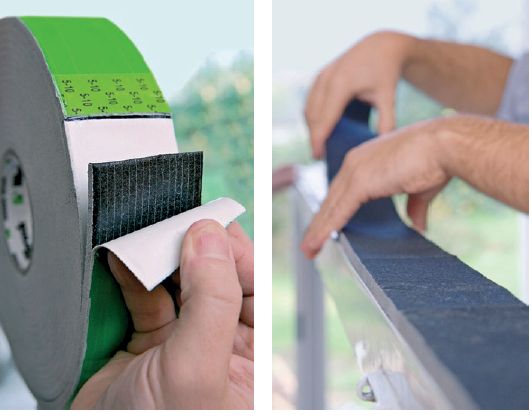

The tape is glued both before fixing the window block in the opening, and on already installed structures. The first option is more convenient in cases where external insulation is installed.

Let us consider the algorithm for using tape insulation using the example of gluing a pre-compressed sealing tape (PSUL) and an internal GPL-S with an additional strip of double-sided tape:

- We prepare the opening. If there is an old window block, we dismantle it as carefully as possible, without causing unnecessary damage. After dismantling, we align the surfaces adjacent to the future structure, clean them from extraneous contamination.

- We carry out a test installation of the block in the opening, temporarily fixing it. This is necessary to mark the edge of contact between the walls and the window, so that when gluing the tape is hidden behind the outer slopes.

- We measure the window block. In accordance with the obtained dimensions, we cut the PSUL for gluing on top and on the sides of the frame, prepare the diffusion tape to isolate the area of attachment of the casting profile.

- We proceed in the same way with the GPL-S (internal slopes) and butyl rubber tape (for the window sill profile). The material is measured for each side with a 10 cm allowance to form corner joints.

- We glue the tape, gradually removing the protective layer from the PSUL adhesive surface.

We glue GPL-S to the inner side of the window profile using a strip of double-sided tape (we do not remove the protective film from the main adhesive surface at this stage).

- We fix the window in the opening. We wedge it, then fasten it with anchors or by means of mounting plates. We fill the seams with polyurethane foam.

- After complete polymerization of the foam and rough preparation of the inner surface of the walls, we fix the GPL-S on them (remove the protective paper and glue to the slopes).

It should be remembered that the tape must be selected in accordance with the weather conditions. Working in the winter, it is possible to glue only material intended for use in low temperatures.

Useful video on the topic:

What tinting with a film gives you

Today tinting is not only about darkening windows with a film. You select the functionality to suit your needs.

Tint film on your windows:

Absorbs glare, leaving natural light in the room;

Creates a comfortable environment for you and your houseplants;

Makes the appearance of your apartment, office or other space attractive and modern;

Eliminates visibility, protecting from prying eyes;

Makes glass safe. Broken glass does not disintegrate into fragments, but sticks to the film.

Dimensions and approximate cost

Diffuse insulating tape for outdoor installation (under low tide):

- Width -70 mm;

- Length in a skein - 25 m;

- The price of a skein is 436 rubles.

PSUL for use at subzero temperatures:

- Width - 20 mm;

- Thickness - 8 mm (40 in uncompressed state);

- Length - 5 m;

- Price - 160 rubles.

Internal duplicated tape:

- Width - 100 mm;

- Length in a skein 25 m;

- The price of a skein is 377 rubles.

Internal metallized tape:

- Width - 45 mm;

- Length - 24 m;

- Price for 24 m - 523 r.

Window sill tape:

- Width - 200 mm;

- Length - 12 m;

- Price - 600 rubles.