Dimensions and weight

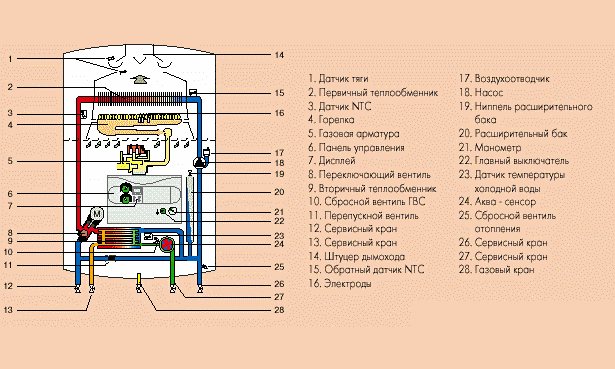

Dimensions are one of the most important differences between wall and floor gas boilers. The dimensions and weight of wall models are much more modest, otherwise it would be simply impossible to fix them on the wall without the risk of collapse. The lightness of the design is achieved not only by the general compactness of the wall models, but also by the material from which the heat exchanger is made.

For wall-mounted models, the heat exchanger is made only of steel, floor-standing models can have heat exchangers made of cast iron, which has a significantly greater weight, or of steel.

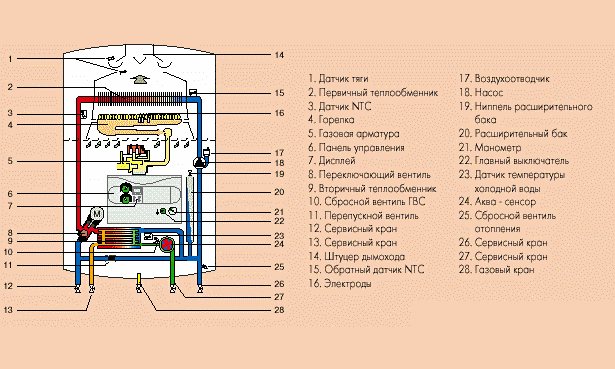

Wall-mounted boilers are often called mini-boilers. And this is no coincidence, because in a relatively small-sized case, not only the burner, heat exchanger and control system components are located, but the circulation pump, expansion tank and other elements, without which the operation of a conventional boiler room cannot do. The compactness of the wall-mounted boiler is its main and indisputable advantage. For such a device, you do not need to allocate a separate room, because you can place it anywhere, for example, in the kitchen.

Wall mounted gas boiler with coaxial chimney located in the kitchen area.

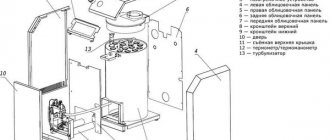

The floor-standing models inspire confidence with their dimensions. This is exactly what a powerful boiler should be, providing the ability to heat a large building. However, the dimensions of floor-standing boilers often turn into a problem for their owners. Sometimes, in order to bring such a "giant" into the room, you have to dismantle the doorways. There were cases when, due to the impossibility of bringing the equipment into the boiler room, the purchased floor-standing gas boiler had to be replaced with two lower power ones.

Floor standing gas boiler and indirect heating boiler.

Which boiler unit is best for a house and apartment?

A universal approach to the choice that specialists offer is that floor-standing devices are mainly purchased for heating individual households of a huge heating area according to a two-circuit version: heating and hot water supply, and wall-mounted ones - for small-sized housing stock, for example, for apartments and country houses.

The best source of heat supply for an apartment

For gasified apartments, it is advisable to purchase wall-mounted boilers for a heating area from 40 to 200 m2. Since there are space restrictions in such apartments, they purchase a wall-mounted or gas boiler with a double-circuit heating principle, which generates heat to load heating and hot water supply.

Since these apartments are also characterized by the absence of a chimney, wall-mounted units must have a closed combustion chamber. In a set, such a unit is equipped with a smoke exhauster or a centrifugal fan, which emit flue gases into a coaxial pipeline.

Popular wall-mounted boilers of domestic manufacturers:

- DON ECO;

- ZhMZ Gas equipment for autonomous heating systems, mechanical plant in the city of Zhukovsky;

- boilers "Siberia";

- Neva and NevaLux, produced by OJSC Gazapparat from St. Petersburg;

- boilers of OOO Signal-Teplotekhnika, modifications: Economy, Standard and Comfort.

Popular wall-mounted boilers from European manufacturers:

- Baxi DUO-TEC COMPACT 24 GA;

- Bosch ZSC24-3 MFK;

- Ariston CLAS X SYSTEM 28 CF NG;

- Buderus Logamax U044-24K;

- Chaffoteaux Pigma ULTRA SYSTEM 25 FF.

Gas boiler for a private house

In private houses, as a rule, there is more free space for placing heating equipment, and sometimes there are even separate furnaces.Therefore, in such conditions, it will be more reliable to place a floor-standing gas boiler of large dimensions and power. More durable are models with a cast iron heat exchanger.

Popular floor standing boilers of domestic manufacturers:

- Borinskoe AOGV - 23.2 (М) "EUROSIT";

- ZhMZ AKGV-11.6-3 Universal N;

- KCHM -7-GNOM 48 kW;

- Lemax WISE-16.

Popular floor standing boilers from European manufacturers:

- Ariston GPV-24 RI MET;

- Baxi SLIM / 1.300i 5E;

- Bosch F / 30, 26 kW;

- Buderus Logano G124, WS 20;

- Ferroli PEGASUS 56.

Equipment

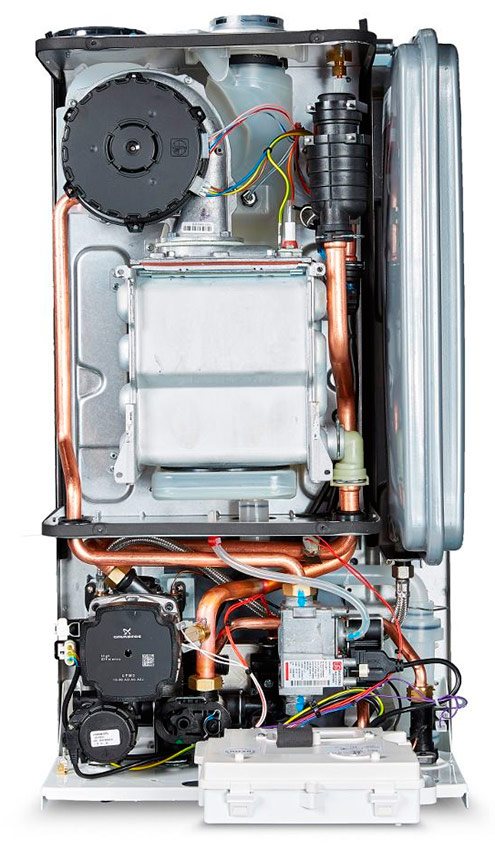

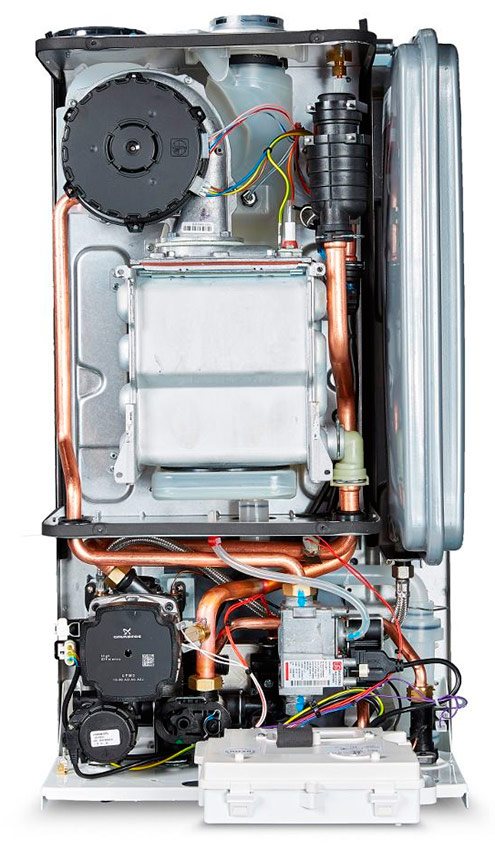

In the factory configuration of a wall-mounted gas boiler, as a rule, there is not only the heating device itself, but also a circulation pump, an expansion tank, control system elements, all the necessary sensors and valves. Moreover, all this is hidden in the body of the boiler itself.

By purchasing a wall-mounted gas boiler, you get a miniature boiler room for your use, that is, the minimum set that, after connecting to the heating system, is able to start full-fledged work to heat your home.

Of course, if you wish, you can additionally buy all kinds of room thermostats and regulators, outdoor temperature sensors, a GSM communication module and much more, improving the heating system of your home and increasing the comfort of its control.

A floor standing boiler is usually just a boiler. Circulation pumps, expansion tank and many other related equipment are not included in the delivery set - you will have to buy everything you need separately.

Wall mounted gas boiler with the cover removed.

Advantages and disadvantages of wall models

One of the main features that distinguishes this model from the floor-standing ones is the installation location. From the name itself, it becomes clear that such boilers are hung on walls, for which special brackets are included in the kit. But that's not all. Let's start with the merits:

- Small overall dimensions and not very large weight of the product (up to 50 kg). Accordingly, the installation process is simple, plus such boilers take up little space, so their installation in the kitchen or in the bathroom is a common thing. Just another wall cabinet appears in the interior. Moreover, modern wall-mounted gas boilers are devices with a presentable appearance. So there are no problems in terms of interior design.

- Basically, today the market offers double-circuit units that not only heat the coolant for the heating system, but also water for the hot water system. However, this position has several drawbacks. But more on that below.

- If we consider a wall-mounted device from the position of an internal device and use it to select a gas boiler, then this is a rather complex structure, which includes a circulation pump, and an expansion tank, and a complex automation system, and an inflation system. In fact, this small apparatus contains a small small boiler room that does everything by itself. In this regard, the indicator of convenience is at the highest level.

- And another plus is the chimney. Currently, manufacturers are producing more models with a closed combustion chamber. This means that the coaxial chimney is part of the structure of the wall model. It is a simple carbon monoxide pipe that does not take up space. But it works very effectively. Plus, considering the rating of double-circuit gas boilers, one conclusion can be made - this is an economical option in terms of the absence of the need to arrange a ventilation system in the room. This is the first thing. The second is the complete sealing of the device, due to which the combustion products do not penetrate into the room.

Gas boiler in the interior

Now there are a few disadvantages of this design.

- Complex automation system. It is she who is the most capricious block when it comes to boiler maintenance. Cases when automation malfunctioned are not uncommon.In addition, you cannot repair it with your own hands, and this is another item of your expenses.

- All the necessary devices that are responsible for the quality of the heating system are located inside the gas boiler. This complicates the device, makes it vulnerable, and complicates the repair work.

Boiler with boiler

Ease of installation

Which boiler, wall or floor standing, is easier to install? It would seem that this issue should not be of concern to the potential owners of the unit, but exclusively to the masters who will be engaged in the deployment of the heating system. However, do not forget that the buyer, that is, you, will have to pay for this, and the more laborious the work is, the larger the amount you will have to part with.

From the point of view of ease of installation, the wall-mounted boiler is the undisputed leader. In the case of a floor-standing unit, you have to equip an entire boiler room, because in addition to the boiler itself, you will have to install circulation pumps, an expansion tank and, perhaps, a boiler. The amount of work, as you might guess, differs very significantly, and the cost of work will also vary greatly.

Overview of both types of units

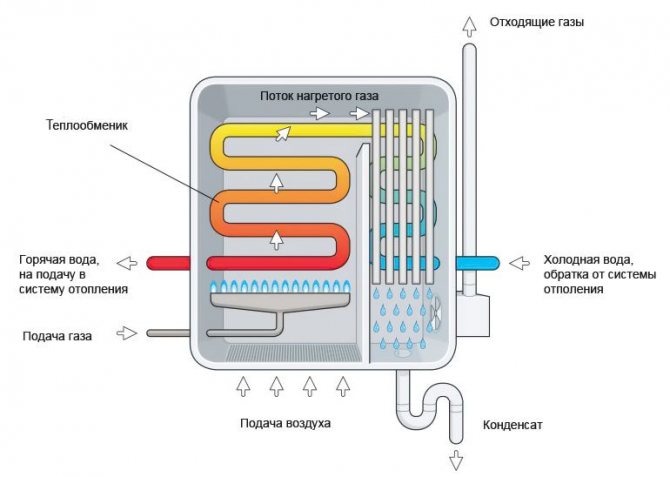

The main feature that distinguishes a floor-standing gas boiler is the equipment with a cast-iron heat exchanger of a fire-tube type, steel ones are practically not found in these heat generators. It is a chamber filled with water and permeated with vertical channels. Hot combustion products pass through them, giving thermal energy to water through the cast-iron walls. In addition, the heat exchanger is heated from below by the burner flame.

Floor standing gas boilers designed for heating private houses can be roughly divided into 2 categories:

- budget;

- expensive units with an extended range of functions.

When choosing a wall-mounted or floor-mounted heat source, homeowners most often lean towards budget heat generators. And not only because of the cost, but also because of their simplest design. In addition to the heat exchanger and the burner, such a heating unit is equipped with a minimum set of automation required by the rules of gas supply. At the same time, the apparatus is equipped with an open combustion chamber, and the range of the offered capacities is wide enough - from 7 to 200 kW and more.

In expensive models, there is a full set of various automatics that allow you to program the operating modes of the heat source, connect room thermostats and weather sensors, and also control the heating operation remotely. Such gas boilers are equipped with a closed combustion chamber with forced air supply, some modifications are equipped with a second circuit for heating water for the needs of hot water supply.

Wall-hung heat generators are equipped with steel heat exchangers and are available in various designs:

- with an open or closed combustion chamber;

- with a minimum set of automation or with a wide range of functions;

- equipped with additional equipment that turns the boiler into a mini-boiler room.

The last option is units with their own circulation pump and expansion tank installed inside. If you review all floor standing models from different manufacturers, you can find out that the built-in pump and tank are quite rare in them. Choosing a stationary or wall-mounted boiler, the owners of apartments and country cottages pay attention to this moment.

Life time

When buying any equipment, and even more expensive, we want it to serve, if not always, then at least as long as possible. This fully applies to gas boilers. What kind of boiler, wall or floor, will regularly heat our home for many years?

The service life of a gas boiler is primarily determined by the service life of its heat exchanger. There is no consensus at the moment about which material is the best heat exchanger - each has its own advantages and disadvantages.

In floor models, cast iron heat exchangers are usually installed. Cast iron is less susceptible to corrosion, but at the same time it is fragile, which means there is a risk of microcracking during transportation. In addition, it does not tolerate sudden changes in temperature. When using hard water as a heat carrier, the cast-iron heat exchanger is slowly destroyed as a result of the formation of scale and, as a consequence, local overheating of the material.

Cast iron heat exchanger.

For wall-mounted gas boilers, cast iron heat exchangers are not suitable, because they are too heavy. The most preferred material in this case is steel. The latter is not afraid of shocks during transportation, but strongly corrodes during operation, especially incorrectly.

Steel heat exchanger for gas boiler.

So which heat exchanger is better? Since the boiler does not have to be transported very often, corrosion resistance can be considered the factor that has the greatest influence on the service life of a given structural element. From this it can be concluded that a longer period of normal operation can be expected from a floor-standing boiler with a cast iron heat exchanger.

It should not be forgotten that the service life of the boiler is also influenced by the wear of other structural elements - circulation pumps, gas valve, electronics, etc. The quality of the unit depends on the quality of execution of each of its individual units. Practice shows that the average boiler from a well-known manufacturer, who is not indifferent to the reputation of the brand, will regularly serve you 15-20 years, no matter whether it is wall-mounted or floor-standing. Nobody knows what to expect from the “no name” unit.

Of course, in order for the heating equipment to work long enough, all the manufacturer's recommendations regarding operating conditions should be followed and the necessary maintenance should be carried out in a timely manner. The user is able to cope with many emerging problems on his own thanks to the self-diagnostics available in modern equipment.

Differences between floor and wall gas boilers: compare by selection criteria

Efficiency and economy

The efficiency (efficiency) of modern floor-standing boilers is quite high (on average 88-90%), but lower than that of wall-mounted boilers (on average 90-94%). Accordingly, this implies, on average, a greater consumption, therefore, wall-mounted gas boilers in most cases consume fuel more economically. This is achieved due to the difference in the principle of operation and functionality of the automation.

Floor standing models are usually convection (traditional). The burner heats up the heat exchanger, and the combustion products are immediately discharged through the chimney. Wall-mounted boilers can be both convection and condensing, in which the heat of condensate formed from heated gases and combustion products is additionally accumulated by the return. Thus, some of the heat is not simply “ejected into the chimney”. However, the disadvantage is the additional need for condensate drainage from the boiler.

The device is a simple condensing single-circuit gas boiler.

The efficiency of wall-mounted convection models (90-94%) is achieved due to efficient alloys, modulated burners, and smart automation. The efficiency of condensing models is 105-109%, since not only thermal energy is used during gas combustion, but also additional thermal energy of the condensate.

Floor-standing models can also be condensing, but their cost starts from 150 thousand rubles, and the power is from 50 kW. They can be found in manufacturers such as BAXI, De Dietrich, Vaillant. The cost of wall-mounted condensing models is only slightly higher than convection ones; there are enough models in the price category up to 50 thousand rubles.

Therefore, in terms of efficiency and economy, wall-mounted gas boilers are definitely better than floor-standing ones.

Reliability and service life

Floor standing boilers are considered more reliable, since almost all models, with the exception of the budget price segment, are equipped with a cast iron heat exchanger. It is thicker, practically invulnerable to corrosion and has a service life of over 25 years.

Virtually timeless, corrosion and scale resistant cast iron heat exchanger.

Wall-mounted models are usually equipped with a lighter steel or copper heat exchanger. Steel have the lowest cost, but are highly susceptible to corrosion, their walls are only 3-5 mm thick, such heat exchangers rarely last more than 12-14 years, no matter what alloys they are made from.

Copper heat exchangers have several times higher thermal conductivity and are less susceptible to corrosion, however, they are used only in expensive models due to their high cost.

There is also a myth that wall-mounted gas boilers, especially double-circuit ones, are less reliable due to the much larger number of elements and a complex compact design. In practice, the number of calls to the service center for the first 7-8 years of operation of models from well-known manufacturers practically does not differ. Therefore, first of all, reliability depends on the resource of the heat exchanger, which is much larger for most floor-standing boilers (with a cast-iron heat exchanger).

The rest of the elements, such as a circulation pump, automation or a turbine, rarely fail if the operating conditions are observed.

Equipment

The device of the Buderus Logamax plus GB072-24K model: use of the best materials, security and reliability of all nodes. Already installed safety relief valve, there is a condensate drainage unit.

Wall mounted heating boilers are a miniature boiler room. Despite their smaller dimensions, from the factory they are equipped with one or even two circulation pumps, a closed expansion tank, a pressure gauge and a thermometer, in most cases an air vent and a safety valve.

Floor standing boilers have a simpler design and are rarely equipped with additional elements; they require a separate installation of an expansion tank and a pump (if necessary) of a safety group and other instrumentation.

Energy independence

Almost all wall models are volatile, i.e. require an electrical connection. In the event of a power failure, they completely stop their work. The situation with interruptions can be corrected by installing a generator or UPS, which, of course, will cost an additional amount.

Almost half of floor standing gas boilers are non-volatile. They are equipped with simple automatic controls and an atmospheric burner that does not require the use of a turbine. The electricity generated from the heating of the thermocouple is sufficient to ensure absolutely autonomous operation, which does not require connection to the mains. The only drawback is the manual piezo ignition. Floor standing non-volatile boilers are an excellent choice in conditions with frequent power outages.

Automation functionality

The BAXI LUNA 3 Comfort 1.240 i model has a removable control panel with a large number of settings.

The automation of most wall-mounted boilers is more functional, which contributes to economy and comfortable operation. In more advanced models, there are weekly scheduling modes, precise power control (if a modulating burner is available).

Floor-standing boilers are most often equipped with only gas control and overheating prevention, less often with auto-ignition. Wall-mounted models are safer and have an anti-freeze mode, protection against overheating or lack of draft, self-diagnostics, protection against pump blocking.

Coolant requirements

Floor-standing models, especially single-circuit ones, can work with almost any coolant.Including with non-freezing liquids, which is very convenient for rare use in a private house, when the owners come only for the weekend, turning off the heating system for the rest of the time, without worrying that it may freeze and depressurize.

Many manufacturers of mounted models prohibit the use of low-freezing liquids as a heat carrier due to their higher viscosity, fluidity and a different boiling point. Antifreeze destroys light steel and copper wall heat exchangers much faster.

Burners and chimney organization

Burners can be single stage (on or off), two stage (0, 50 or 100% capacity) or modulating (20 to 100% capacity). Single-stage and two-stage are usually used in floor-standing models, rarely, in more expensive volatile boilers, modulated ones are installed.

In hinged gas boilers, modulating burners are installed in most cases, often even in budget models. They allow not only to more accurately adjust the temperature, but also to use gas more economically, to reduce the number of on and off cycles. Ideal burner operation is continuous combustion of fuel at minimum power.

More than 90% of floor standing models have an atmospheric burner and an open combustion chamber, i.e. air for gas combustion is taken from the room and removed by natural draft through a vertical chimney. Wall-mounted models are most often equipped with a closed combustion chamber, into which air enters and exits through a coaxial (two-pipe side) chimney. Its organization is much simpler, but in convection models, when frosts are more than -15 ° C, condensate forms in the chimney, which leads to icing and automatic stoppage of the boiler.

The way out of situation 3: selection of a condensation model, organization of an anti-icing structure, or simply timely mechanical de-icing.

Dimensions, weight and installation complexity

The advantage of wall-mounted boilers, as already mentioned, is their compactness and lightness, a more stylish modern design. It is not necessary to allocate a separate room for the boiler room; it is enough to hang the boiler in the kitchen, instead of one of the wall cabinets, or even hide it inside. This solution is especially important for small apartments.

A floor-standing boiler unit is unlikely to be installed in the kitchen due to its large dimensions and the need for space for strapping around it. For the same reason, it is more difficult to install a floor stand and only a few carry it out on their own, saving up to 5-7 thousand rubles on the work of masters.

The cost

Despite the more complex and compact design, greater functionality and safety, wall-mounted models are 20-50%, and sometimes even 2 times cheaper than floor-mounted ones. This is explained by the lower cost of components, the greater popularity and competitiveness of the wall mounting market. For example, let's compare prices for similar well-known wall and floor models:

| Wall models | Cost, rub. | Floor models | Cost, rub. |

| Ariston ALTEAS X 24 CF NG (23.7 kW) | 49 000 | Ariston UNOBLOC GPV 24 RI (24 kW) | 80 000 |

| BAXI ECO-4s 24F (24 kW) | 37 000 | BAXI SLIM 1.230 iN (22.1 kW) | 61 000 |

| Bosch Gaz 6000 W WBN 6000-24 С (24 kW) | 28 000 | Bosch Gaz 2500 F 25 (25 kW) | 48 000 |

| Protherm Panther 25 KTO (25 kW) | 43 000 | Protherm Bear 30 KLOM (26 kW) | 62 000 |

| Vaillant turboFIT VUW 242 / 5-2 (23.7 kW) | 44 000 | Vaillant atmoVIT VK INT 254 / 1-5 (25 kW) | 99 000 |

Coolant quality

The service life of a gas boiler and its output directly depend on the quality of the coolant. The use of water with increased hardness as a heat carrier leads to the formation of scale inside the heat exchanger. Scale, in turn, is the reason for a significant decrease in boiler efficiency and, as a result, an increase in fuel consumption.

Gas boiler heat exchanger clogged with lime.

Both floor-standing and wall-mounted boilers "suffer" from scale to the same extent, only the level of complexity of solving the problem that has already arisen differs. The ease of disassembling and flushing the steel heat exchanger of the wall-mounted boiler allows you to quickly restore the operation of the heating equipment right at the place of its installation.

Flushing the cast-iron heat exchanger of a floor-standing boiler is difficult and, moreover, not always possible (many manufacturers insist that its disassembly and assembly be carried out exclusively in the factory). Most often, a faulty or scum-clogged cast-iron heat exchanger simply has to be replaced, and this part is by no means cheap.

It follows from this that the installation of a floor-standing boiler with a cast-iron heat exchanger presupposes that you have a chemical water treatment plant. This device is not cheap, but in this case it is extremely necessary.

Power modulation

Depending on the implemented method of regulating the flame intensity, all boilers are divided into boilers with a staged or modulating burner. One- and two-stage burners have one or two operating modes respectively (usually 100% and 70% of maximum). The power of modulating burners can be smoothly regulated in a fairly wide range, which allows fine tuning of the boiler operation. Modulating burners provide fuel savings and maintain the desired temperature with minimal deviations.

A significant number of floor-standing gas boilers are equipped with one- or two-stage burners. Most of the wall-mounted models have a large power modulation range (from 40 to 100%), due to which they work "softer" - they turn on and off much less often than boilers with step burners.

Advantages and disadvantages of floor standing boilers

First, about the advantages of floor-standing units. Here is a list of them:

- there are many chimney models whose operation does not depend on electricity. This is the most reliable boiler for a private house located in an area with an unreliable power supply;

- the heat generator is structurally simpler and more reliable than its “brothers” suspended on the wall.

- low-power heat sources do not have to be located in the furnace; they can be installed in any room where there is a good chimney;

- the stationary version is easier to link with other boiler systems using separate circulation pumps.

- when a large thermal power and a significant water consumption for the needs of hot water supply are required, a floor-standing gas boiler is the best solution.

With regard to installation work. This is not to say that installing a stationary unit will cost more than hanging and connecting a wall unit. Indeed, in the latter case, you need to perform work on finishing the room or assembling the cabinet. So it all depends on the individual conditions.

Atmospheric heat generators placed on the floor require a chimney, this is their main drawback. If the cost of the boiler is cheaper than the suspended one, then the chimney device will cover this difference with interest. The conclusion is as follows: when the house already has a smoke shaft, then you can buy an atmospheric stationary model. If there is no chimney, then it is worth choosing a turbocharged version - floor-standing or suspended, depending on the required power.

Energy independence

For some consumers, an important parameter of a gas boiler may be the dependence of its operation on electricity. The energy independence of heating equipment is relevant for those whose house or summer cottage is located at a considerable distance from large settlements, i.e. in those places where power outages or power surges are possible, leading to the failure of expensive automation.

The autonomy of a gas boiler can be achieved in two ways. The first is to simplify the boiler control system as much as possible. That is, it is necessary to use a unit in which there is no electronics at all. All the automation of such a boiler is mechanical. The heating system, which uses a similar boiler, operating without electricity, must be with natural circulation.

The second method is the use of an electric generator, which converts the heat obtained during the combustion of gas into electricity necessary for the operation of the boiler automation. This option is preferable for most users as it creates fewer restrictions.

It is possible to find non-volatile models only among floor-standing gas boilers, which for some buyers will be a weighty argument in favor of the latter.

What influences the long-term work?

Wall-mounted, unlike floor-standing gas boilers, often break down with small voltage surges. In this case, the main board burns out. Replacing it costs a lot of money. An important point: floor-standing boilers are adapted to the processing of poor quality water. In wall-mounted boilers, heat exchangers are often made of poor quality, therefore they are easily clogged. Choosing a wall-mounted boiler, do not save on cost.

If your tap water is of increased hardness and salinity, it is better to purchase a floor-standing boiler with a boiler. They are not afraid of salt deposits.

Also, do not forget about the further maintenance of your gas boiler. Remember: the more its capacity, the more expensive the annual maintenance of gas services will cost.

Summing up and answering the question of which one to choose a wall-mounted or floor-standing boiler, it is necessary to take into account not only personal preferences and the appearance of the gas boiler, but also the following factors: the area of the room, power outages, financial capabilities and water quality.

For a small house with a stable electricity supply and high-quality piped water, it is better to choose a wall-mounted two-stage boiler. If you choose high-quality heating equipment, it will serve you for many decades and will bring a lot of benefits and warmth.

For a room with a large area and power outages, a powerful floor-standing boiler is suitable.

We suggest that you familiarize yourself with the Chimney through the wall: basic requirements and rules for safe installation

Having analyzed all these factors, comparing the conditions in which you live with the characteristics of the boilers, you can make the most optimal choice in favor of one or another boiler. The main thing is not to rush, do not get fooled by cheap advertising. Take the time to choose the boiler that is right for you.

Detailed video on choosing a wall-mounted or floor-standing gas boiler

Installation site requirements

Before choosing a floor-standing or wall-mounted gas boiler, you should decide on the location of its installation.

The wall-mounted boiler, due to its compactness, can be placed in almost any room. The main thing is that a number of requirements are fulfilled that guarantee the safety of its operation: a closed combustion chamber, connection to a coaxial chimney, forced removal of flue gases and air injection, which ensures the maintenance of the combustion process. Installing a boiler with an open combustion chamber in a kitchen with an exhaust hood is unacceptable, since in this case a so-called “draft flip” is possible, in which the smoke from the boiler will go not into the chimney, but into the room.

There are not so many options for placing a floor-standing gas boiler. Due to the size of the boiler itself, as well as all kinds of related equipment, we can only talk about a separate room - the boiler room. Despite the fact that the boiler room does not belong to living quarters, when installing a gas boiler, it is necessary to ensure the normal removal of fuel combustion products and the flow of air.

Types of gas boilers

General type gas boiler systems can be single-circuit and double-circuit.

A single-circuit boiler only heats the house, and a double-circuit one solves two problems at once, heating and heating water. In this case, the choice should be made based on your everyday needs.

Floor-standing and wall-mounted gas boilers can be single-stage, two-stage and modulating.The last of the listed ones are more profitable to use, since they allow the boiler to operate not at full capacity even in severe frosts. This will significantly save you money, especially in regions with cold winters.

An additional boiler can be connected to a boiler with a two-stage system. Also, this type of boiler will save gas and will last much longer, unlike a single-stage one.

Dual-fuel boilers are capable of operating on both gas and diesel fuel. Such models are the most popular. They are economical, safe and quiet. However, the owner of such an apparatus must constantly monitor the readings of the pressure gauge so that the pressure in the system is correct.

Power

The power of wall-hung gas boilers, as a rule, varies from 10 to 40 kW. This is roughly enough to heat a dwelling with an area of 100 to 400 square meters. m. However, if part of the heat is used to heat water for domestic needs, then this power will be enough for heating only a relatively small house.

The capabilities of floor-standing gas boilers are significantly higher. The power of floor-standing models can reach 80-100 kW, and if it is equipped not with an atmospheric, but a forced-draft burner, then even more. If you need to heat a huge house or industrial facility, then a floor-standing boiler is exactly what you need.

Final comparison of wall-mounted and floor-standing gas boilers

| Wall hung gas boiler | Floor standing gas boiler | |||||||

| Dimensions (edit) | Less | More | ||||||

| The weight | Less | More | ||||||

| Equipment | The boiler is equipped with additional equipment | Additional equipment must be purchased separately | ||||||

| Ease of installation | Simpler | More difficult | ||||||

| Life time | Steel heat exchangers are more susceptible to corrosion, which reduces the service life | Units with a cast iron heat exchanger can operate for a longer time | ||||||

| Coolant quality | The dependence on the quality of the coolant is high, but it is easier to flush the heat exchanger | The dependence on the quality of the coolant is average, but it is more difficult to flush the heat exchanger | ||||||

| Power modulation | More possibilities | Less opportunities | ||||||

| Energy independence | Fully volatile units | There are non-volatile units | ||||||

| Installation site requirements | Less | More | ||||||

| power, kWt | 10 — 40 | 80 — 100 | ||||||

| The cost | Below | Above | ||||||

If you notice an error, not a working video or a link, please select a piece of text and click Ctrl + Enter.

0

Installation features

Wall-mounted double-circuit boiler - functionality and compactness, however, it is forbidden to install such boilers in kitchens! More on this ...

Understanding which is better, a wall-mounted or floor-mounted gas boiler, it is necessary to consider in detail the characteristics of one and the other option. No specialist will be able to unequivocally answer this question, because the choice in this case is purely subjective.

A good video sketch about choosing a wall-mounted or floor-standing boiler

Such designs appeared later than floor ones, but they quickly gained high popularity among consumers. Wall-hung boilers include all the necessary components and do not require additional units to be connected to the system. Therefore, they are called mini-boiler rooms.

The main advantages of wall-hung boilers:

- Probably the main advantage is its compact size. Such equipment does not require the obligatory presence of a utility room and can even be installed in the kitchen.

- Convenient control by means of the remote control. Remote operation is provided for almost all wall-mounted models.

- Installation of a wall-mounted boiler is extremely simple and quick. It only takes a couple of hours to install a wall-mounted boiler. A professional will spend no more than an hour on the whole range of works.

Wall-mounted double-circuit boiler diagram

- Such a unit can be safely installed with a coaxial chimney.

- Acceptable cost. In terms of price, the difference between a floor-standing and a wall-mounted gas boiler is very significant. The first option is about twice as expensive as the second.

We recommend that you also study on this topic:

Pressure testing and hydropneumatic flushing of the heating system

The modern water heating system is a high-tech engineering network, which is complex and expensive. In addition to the efficiency of modern heating systems, a very important characteristic is their reliability, which indicates the possibility of uninterrupted operation. Unfortunately, one of the most common problems in heating systems is leakage of the circuits. For effective detection of problem areas, crimping of the heating system is used.

Naturally, wall structures cannot be devoid of disadvantages:

- Low power. A wall-mounted boiler is good for heating a house with an area of no more than 100 m2. For houses with a larger area, it is better to choose a floor-standing option, otherwise you may need to purchase several wall-mounted boilers.

- Such designs are suitable for use in forced circulation only systems.

- Low reliability. This equipment breaks down much more often than floor equipment.

- The service life is no more than 20 years, which is significantly less than that of floor-standing counterparts.

Floor-standing boilers are larger, but at the same time they have more power.

Floor structures have the following advantages:

- The presence of a high-quality heat exchanger in the system ensures a long service life of the equipment. It is the heat exchanger that experiences the greatest stress during the operation of this equipment. Floor standing gas boilers serve for about 50 years.

- Possibility of installation in any type of heating system: both with forced circulation and natural.

- Floor standing gas boilers do not have any restrictions in terms of power. Whatever area the house is, one such boiler will be able to heat it (naturally, subject to the correct choice of equipment).

We suggest that you familiarize yourself with Deciphering and eliminating errors 03, 09 and 27 on the Navien boiler

Disadvantages of floor standing boilers:

- Large dimensions and weight. To install gas boilers, it is necessary to allocate a separate room for the boiler room. It is important to take into account all the requirements of SNiP.

- Gas boilers cannot be used with coaxial chimneys.

- The equipment is expensive.

- Complex installation of floor-type heating boilers. To install such a boiler, you need to spend about four hours. It is imperative to carry out test runs to ensure that the installation has been carried out correctly.

How does a floor-standing boiler work

Readers find these materials useful:

When purchasing equipment, you need to pay attention to its fastening. It is desirable that the kit includes the necessary fasteners. If they are not available, you must immediately purchase all necessary fasteners.