Home »Articles» Materials for waterproofing

May 04, 2020 No comments

There are many different materials that are used for specific types of waterproofing. These include rapidly hardening compounds for repairing emergency leaks, various types of sanitizing plaster, hydrophobic compounds for making concrete and bricks water-repellent, anti-salt and antifungal impregnations, etc. The most popular of them will be discussed below.

The choice of material should depend on the type of waterproofing used, taking into account the climatic features of the area, the design of the house or apartment and, of course, finances. It is advisable to make all decisions at the design stage and preferably coordinate with the designers or builders of the house.

Superdiffusion and diffusion membranes

This is a three-layer vapor-permeable material, in the structure of which there is a reinforced mesh made of polypropylene fibers. It is actively used in the construction of pitched roofs and ventilated facades.

The main advantages of superdiffusion and diffusion membranes are:

- increased water resistance (more than 2000 mm wp);

- good vapor permeability (more than 1400 g / m2 per day);

- high resistance to ultraviolet rays;

- the possibility of laying the material on top and close to the insulation;

- low weight, which allows you to make the roof lighter;

- the possibility of increasing the service life of the roof due to the fact that the service life of the material itself is 50 years;

Polymer films (membranes)

This group includes the following types of films: polyethylene, polyvinyl chloride (PVC), polypropylene, synthetic rubber (ethylene propylene diene monomer, or artificial rubber, such as EPDM).

Any polymer film has a number of undeniable advantages:

- durability (service life up to 50 years);

- the possibility of laying the coating on top of old bituminous roofing materials (for example, roofing material);

- the possibility of installation at any time of the year;

- high plasticity (the extensibility of the material at temperatures up to -45 degrees exceeds 400%);

Bitumen

Almost all bituminous, as well as most of the bitumen-polymer waterproofing materials and a number of polymer films and membranes have vapor permeability and good waterproofing properties. Although it should be noted that in terms of vapor permeability, these materials are still inferior to synthetic ones.

In the construction industry, petroleum bitumen is used, which is divided into construction (GOST 6617-76 (2002)) and roofing (GOST 9548-74 (1998)).

Self-adhesive waterproofing TECHNONICOL

The range of roll materials for low-rise construction is aimed at a simple solution to complex problems associated with waterproofing building structures from pitched roofs to waterproofing foundations. These are materials that can be used without the use of professional equipment and without the involvement of highly qualified contractors.

Each material is aimed at solving a specific problem. The packaging contains detailed instructions for use with step-by-step installation and what is required for this installation.

The physical and mechanical characteristics of the used roll self-adhesive materials are shown in the following table.

| Indicators | Self-adhesive waterproofing | ||

| Foundation waterproofing TECHNONICOL | TECHNONICOL floor waterproofing | TECHNONICOL flat roof waterproofing | |

| Weight 1m2, kg | 1,5 | 1,5 | 5,0 |

| Conditional strength, not less, MPa | 1,0 | 1,0 | |

| Maximum tensile force (along / across) - polyester, N / 50mm | |||

| Water absorption within 24 hours, no more,% | 1,0 | 1,0 | 1,0 |

| Flexibility at low temperatures on a timber R 15 mm, ° С | |||

| Water resistance at a pressure not less than 0.06 MPa | absolute | absolute | |

| Water resistance at a pressure not less than 0.01 MPa | absolute | ||

| Binder softening temperature, not less, ° С | |||

| Heat resistance, ° С | |||

| Elongation, not less,% | |||

| Bond strength, not less, MPa with concrete with metal | 0,2 0,2 | 0,2 0,2 | 0,2 0,2 |

| Type of protective coating top side | polymer film | slate | |

| Type of protective coating underside | release film | release film | release film |

| Length / width, m | 10x1 | 10x0.75 | 8x1 |

Foundation waterproofing TECHNONICOL

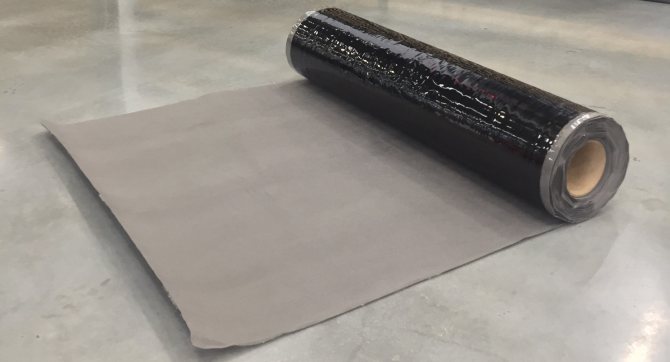

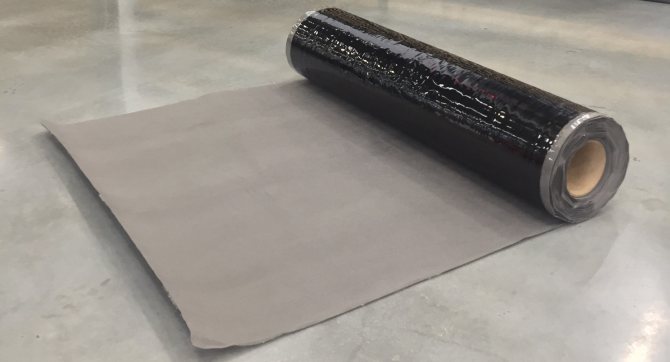

Rolled baseless self-adhesive bitumen-polymer waterproofing material.

Waterproofing of the TECHNONICOL foundation is obtained by applying a self-adhesive bitumen-polymer binder to the anti-adhesive film, followed by closing the binder from the front side with a polymer film.

Application

Waterproofing of foundations (up to 3m) of buildings with a technical floor or an unexploited room, in sandy soils with a low groundwater level (below the level of the foundation slab). Storm water protection.

Price

Waterproofing of the TECHNONICOL foundation (10x1m) - 155.00 rubles / m2

Manufacturing jobs

Installation is carried out on a base primed with a bituminous primer.

Bentonite mats

Waterproofing using bentonite mats allows you to create protective screens, prevents the building from sinking, provides good waterproofing of the walls, and also serves as protection against moisture capillary suction.

Bentonite mat is a layer of bentonite clay in the form of granules, enclosed between sheets of cardboard or geotextile. During operation, the cardboard shell decomposes in the soil, as a result of which the entire buried surface of the structure is surrounded by clay, which, even with a thickness of only 1-2 cm, plays the role of a shield.

Types of roll waterproofing

All existing types of roll waterproofing are divided into 2 forks:

- Polymeric. They are made from reinforced polyurethane or polyethylene. With their participation, a high-quality protection against water and steam of the roof surfaces is created. There is an option for making material using mastic.

- Bituminous. This material is used to protect floors, foundations, roofs. It can be self-adhesive waterproofing or welded.

There are different options for the size of waterproofing, which will be very convenient for buyers, since they themselves will be able to choose the most suitable width and length for themselves.

Self-adhesive roll-up waterproofing

This material reliably protects various surfaces and is easy to install.

Type of self-adhesive roll waterproofing

Characteristics and advantages of waterproofing:

- A ball of glue is applied to its inner side, and a sticky strip is placed along the edge of the surface, the width of which is 5 cm, on the front side.All this is done so that the roll waterproofing is immediately mounted on the base, and the edge joins in an overlap. In this way, it is possible to obtain a tight seam.

- Work with it can be carried out even at subzero temperatures (up to 10 ° C frost).

- After installation, the site is immediately ready before carrying out the following actions on it.

- For the convenience of cutting the material, markings are applied in the form of squares with a side of 10 cm.

- It is elastic and stretches well, so it can easily cover small cracks and joints in rooms.

- If during the work there were some damage to the canvas, then you can glue them with a piece of the same material.

If we compare self-adhesive waterproofing with weld-on, then the cost of the first will be higher. But at the same time, it will have reliability, long service life, and ease of installation (gas cylinders and burners are not needed for its installation).

Where it is necessary for steam to escape, but no longer get inside, a diffusion membrane is used. This is achieved through layering. With the help of this type of waterproofing, the strength of the foundation is ensured. The membrane has the ability to evenly distribute the load over the entire plane.

Self-adhesive waterproofing tape

In addition to roll insulation from moisture, there is also the same tape. If the materials are used for pasting the main surface, then the tapes are used for sealing joints between structures, or are used as overlays. They are used in the case of pasting the corner of two walls, as well as the angle between the wall and the floor.

Installation diagram of self-adhesive waterproofing tape

The common feature of waterproofing rolls and tape is that they both have self-adhesive surfaces. The difference lies in the width of these materials. Self-adhesive waterproofing tape is made of bitumen, polypropylene, butyl rubber.

There are many materials that people use to keep moisture out of joints and seams. Among others, waterproofing butyl rubber tape is considered an excellent choice because it is inexpensive and durable, easy to use, and has good technical performance. The tape is used for hydro and air insulation.

Hydroizol

Gidroizol is a traditional waterproofing material used in construction for many decades, which has good performance characteristics, a relatively simple installation technology and low cost. Hydroisol is available in rolls and comes in different lengths and widths.

Gidroizol is a coverless waterproofing material based on asbestos cardboard (paper) impregnated with petroleum bitumen. To prevent it from sticking together in the roll, another layer is applied, of coarse and fine-grained dressing, instead of which a polymer film is sometimes used.

Gidrostekloizol HPP (roll on Canvas with Polymer film) 2.5 mm (9m2)

Fiberglass canvas with polymer film (HPP) - It is a modern, plastic roll roofing and waterproofing fused bitumen material based on fiberglass.

Meanings of letters hydrostekloizol TKP, KhPP, KhKP, TPP 1. Material base: "T" -glass cloth "X" -glass cloth 2. Top coating: "P" -polymer film "K" -coarse-grained dressing 3. Bottom coating: "P" -polymer film

It is used for the construction of the lower layer of a waterproofing carpet for a flat roof, for waterproofing a basement, foundation, concrete foundations of building structures.

In the production of glass-fiber insulation, a layer of highly oxidized bitumen with modifying additives is applied to the upper and lower surfaces of the fiberglass, which increase the consumer properties of the waterproofing material. Thanks to this, glass insulating can be used for waterproofing works in various climatic conditions.

Fiberglass-based glass fiber is resistant to aging, water-resistant, not subject to decay due to the use of synthetic fiberglass, frost-resistant and heat-resistant, reliable (in comparison with waterproofing based on cardboard and roofing felt), retains elasticity during operation. The presented characteristics make it possible to form a durable waterproofing carpet that allows for long-term operation without the need for routine repairs. The service life is about 10-12 years.

The surface of the glass insulated sheet from the outside and inside is covered with a polymer film, due to which the sheet does not stick together during storage in a roll and facilitates the laying of the material, preventing dust and sand from sticking to the sheet laid on the concrete base.

Scope of glass insulation HPP:

- The bottom layer of a two-layer roof when installing an unexploited soft roof made of rolled bitumen deposited materials;

- The bottom layer of a two-layer roof when repairing a soft roof made of rolled bitumen deposited materials (current and capital);

- Device for waterproofing concrete foundations of engineering structures and structures, foundations, concrete floors, basements, garage;

- Strengthening of junctions, joints with walls, elements of engineering structures, parapets.

Glass insulation stacking technology:

Before laying the waterproofing carpet, it is necessary to clean the surface from dust, dirt, ice, remnants of the old roof, objects that prevent the dense adhesion of the glass-insulated sheet. Then the surface of the concrete base should be coated with a special bituminous primer or bitumen mastic using brushes, rollers or brushes, depending on the material used for priming.

The glass-insulated sheet is laid by the fusion method, in which the lower adhesive layer of bitumen is melted due to smooth, uniform movements with a gas burner or a high-temperature hairdryer, preventing ignition. For better adhesion of the seams, it is recommended to press them using a special pressure roller used for roofing work.

The sheets are laid on an insulated base with an adjacent lateral overlap of at least 80-100 mm. The end overlap of the canvases should be 150-170 mm. The laid canvas should not have deformations, waves, folds.

Gidrostekloizol

It is an alternative to waterproofing and one of the most promising modern waterproofing materials. Fiberglass, fiberglass or polyester serves as the basis for hydroglass insulation, and the impregnating bitumen is modified with special additives. The result is an absolutely waterproof material that is not affected by microorganisms and bacteria.

The tensile strength of hydroglass-insulated webs is 340 N based on glass fiber, 600-880 N based on glass cloth and 600 N - polyester. This material belongs to the IV group of flammability according to GOST 30244 and to the IV group of flame propagation according to GOST R 51032. Elasticity manifests itself at a softening temperature of more than + 80 ° C, fragility - at -20 ° C. The warranty period is 15 years or more.

Stekloizol

It is a modern weldable roll waterproofing material, characterized by high durability and absolute waterproofness. The operational life of glass-fiber insulation is 25-30 years.

The material is produced in two main grades - glass-insulated K with coarse-grained protective dressing on the outer surface and fine-grained or dust-like on the inner surface and glass-insulated P with fine-grained or dust-like dressing on both sides of the web. Sometimes, in the manufacture of glass-insulated P, the sprinkling is replaced with a polyethylene film 0.01 mm thick.

Do-it-yourself foundation waterproofing: methods, technologies, choosing the best material

"Ecotermix" " Do-it-yourself foundation waterproofing: methods, technologies, choosing the best material

Before going directly to the topic, it is important to immediately emphasize the fact that no one can waterproof the foundation better than professionals who specialize in solving this problem. Therefore, it is best to entrust the work to them. But if you are confident in your abilities, have free time, helpers, and also want to save a little, then waterproofing the foundation with your own hands will be for you, if not the best, then an acceptable solution.

Where to start waterproofing a foundation?

As you know, any construction starts on paper. Therefore, the foundation waterproofing technology should be initially reflected in the project. Let it not be professional project documentation, but for yourself you must solve very important issues that are better reflected on paper:

- Which waterproofing technology will be chosen

- What types of waterproofing will be used

- The total amount of materials (their cost)

- Additional materials and tools

- Schedule of work with exposure of technological pauses

But it is also important to understand what exactly should be waterproofed.

Foundation horizontal waterproofing

Waterproofing must penetrate all joints and crevices

In fact, this is a waterproofing of all horizontal planes of the foundation. Moreover, the waterproofing of its base is carried out even at the stage of pouring, so if it is already ready, then you will only have to process its upper surface. In this case, the choice of material is carried out in accordance with the type of structure and the expected loads transmitted by the supporting structures to the base.

Vertical foundation insulation

This is the insulation of all vertical surfaces of the foundation around its perimeter. Protects the base from the effects of groundwater and moisture on the sides. The choice of material is carried out on the basis of geological surveys, depending on the type of soil, the level of groundwater and some other indicators.

In the absence of a complete project, you can be guided by the SNIP for waterproofing foundations, but they always set minimum standards, so it is better to take it with a margin.

Types of foundations

Regardless of the type of foundation, it needs waterproofing. The only difference will be in the choice of specific materials. So, for example, for pile foundations, the most convenient option would be coated or sprayed insulation in combination with geotextiles. And the waterproofing of a monolithic foundation or its analogue made of reinforced concrete slabs, as well as strip foundations, can be carried out using almost any materials, which is the right time to talk about.

Foundation waterproofing materials

Absolutely all materials used for waterproofing foundations can be divided into three large subgroups:

- Coating waterproofing

- it includes resins (bitumen), some types of liquid rubber, mastics, as well as some types of penetrating waterproofing based on dry mixtures, liquid glass - Roll waterproofing

- all types of roll materials used for waterproofing, including roofing felt and its more modern fused and self-adhesive analogs, PVC membranes, waterproofing film - Sprayed waterproofing

- liquid rubber, polyurea

Rubitex

It is a modern durable bio-resistant material that is produced on the basis of fiberglass or non-woven polyester. The base is coated with modified bitumen, which makes the material inert to aggressive media, microorganisms and bacteria.

This material has a high tensile strength (900 N), its softening temperature is +90 ВС, elasticity remains up to -20 С. The guaranteed service life is 25-30 years.

Fiberglass

It is a modern third generation biostable roll-on weld material. It is absolutely waterproof and remains elastic at low temperatures (down to -15 ° C). The basis of fiberglass is fiberglass (fiberglass or fiberglass) or non-woven polyester.

This base is coated on both sides with a uniform layer of modified petroleum bitumen.

This composition determines a number of qualities of this material:

- softening temperature +85 ° С;

- brittleness temperature of the coating -15 ° С;

- tensile strength 490 N on a polyester base, 490 N on a fiberglass base and 784 N on a fiberglass base;

- water absorption 2% by weight per day.

Proffikrom

This is another of a number of new generation weldable roll materials. It is used for waterproofing roofs, underground structures, bridge structures, pipelines, including hot water and steam.

Profiqrom has high performance, reliability and durability. It is absolutely waterproof, resistant to microorganisms and putrefactive bacteria. Fiberglass, fiberglass or polyester are used as a basis for its manufacture. The base is impregnated with modified styrene-butadiene-styrene (SBS) or petroleum bitumen.

Floor waterproofing: a simple and reliable solution for those who are used to doing everything themselves

Today in Russia, half of new housing is private houses, many of which are traditionally built from wooden structures, including by the owners themselves or with the involvement of free teams. Therefore, for those who want and are used to doing everything themselves, all decisions should be simple, understandable, reliable and not time-consuming. As the saying goes: “I measured it, cut it off, glued it and forgot it. For many decades. "

Therefore, in order to live in your home with comfort, happily ever after, you need to take care of waterproofing rooms with a lot of moisture, where there is the greatest risk of leaks: bathrooms, toilets, kitchens, boiler rooms. For a wooden house, this is of fundamental importance, since leaks neutralize the dignity of wood, provoking the appearance of rot, fungus and the destruction of the bearing capacity of structures. In order to solve this issue as simply and quickly as possible on its own, TECHNONICOL offered homeowners a convenient roll-up self-adhesive waterproofing material.

Photo: TECHNONICOL

Due to its structure and the quality of the materials used, "TECHNONICOL Floor Waterproofing" allows you to make a floor in one working day, without any special building skills. In one day - from laying waterproofing to installing the final floor covering. That is, you can glue tiles or porcelain stoneware, as well as make a screed, immediately on "TECHNONICOL Floor Waterproofing". This distinguishes the material favorably from bulk waterproofing.

It is very important to note that the material does not require working with fire (fusing), therefore it is especially relevant for waterproofing rooms with wooden floors. Moreover, self-adhesive waterproofing is mounted three times faster than materials requiring fusion.

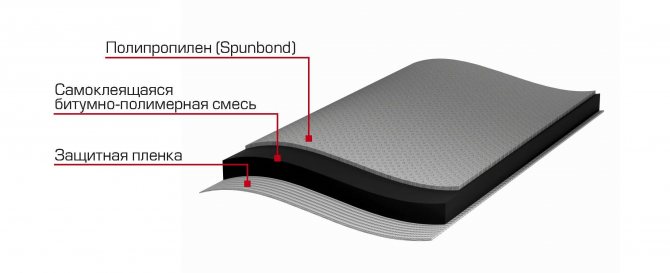

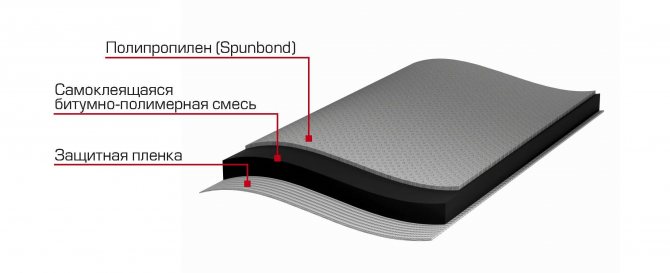

The advantages of TECHNONICOL Floor Waterproofing are in its structure. Polypropylene (Spunbond) protects the waterproofing layer from mechanical damage and provides high adhesion to tile adhesive or screed.

Photo: TECHNONICOL

A high-quality self-adhesive bitumen-polymer mixture provides reliable adhesion to the base, creating a continuous, even waterproofing barrier, and the good elasticity of the material creates absolute waterproofness even in the most geometrically difficult areas of the room, circles, protrusions, etc.

The protective, easily removable film retains the adhesive properties of the self-adhesive layer.

Photo: TECHNONICOL

If everything is done correctly, then the guaranteed reliability of the material is at least 45 years. These guarantees for home owners are additionally provided by the special insurance of Alliance Insurance Company. The work technology is simple. Dust, dirt and debris are removed from the surface. Next, the bitumen-emulsion TECHNONICOL primer is applied with a roller or brush, in which water is used as a solvent. Drying time of the primer is about 20 minutes. Complete drying is determined with a cotton swab: bitumen should not leave a trace on it.

Photo: TECHNONICOL

Next, the required length of the roll waterproofing is measured taking into account the end overlap (at least 150 mm). The resulting cut of the material is rolled into a roll from both sides, after which the protective film is carefully cut and the material is laid on the surface as the film is removed. Possible waves and bubbles are rolled out with a stiff brush or roller.

Photo: TECHNONICOL

It is recommended to additionally treat the overlapping zones with a primer or bitumen mastic and roll with a heavy roller. Everything - the installation is complete.

Let us remind you that TECHNONICOL Floor Waterproofing can be used both in individual design solutions and as part of a comprehensive construction solution from TECHNONICOL - TN-POL BARRIER KMS SYSTEM.More information about the structure and features of the use of complex systems can be found on the resource nav.tn.ru.

For private developers, there is one more convenience - the dimensions of the roll: 10 x 0.75 m. Such rolls are conveniently transported in personal transport. At the same time, the roll area (7.5 m2) is optimal for waterproofing small rooms.

Photo: TECHNONICOL

The advantages of TECHNONICOL Floor Waterproofing - speed and convenience - were clearly demonstrated last year at the Open Village exhibition. In the Chekhov District of the Moscow Region, in just a few months, the builders erected an energy-efficient wooden cottage "house-barn" Barn House, which used complex TECHNONICOL solutions, including roll waterproofing of a wooden floor.

- Bathroom, WC

Do-it-yourself bathroom waterproofing: an overview of materials and methods

Advertising

Glassine

Glassine is made on the basis of roofing cardboard, consisting of 20-40 layers of fibers of wood, straw, cotton, flax, wood and straw cellulose and semi-cellulose, rag pulp. Roofing cardboard is compacted by pressing up to 300-350 g / kV.

The base is impregnated with low-melting oil bitumen with a softening point from + 40 to + 53 ° С.

This is a soft roll material, which is produced under the brands p 250, p 300, p 350 and p 400. The initial letter of the marking indicates the name of the material (glassine - letter "p"), the numbers indicate the brand of the cardboard used to create the glassine.

Self-adhesive waterproofing TECHNONICOL

The range of roll materials for low-rise construction is aimed at a simple solution to complex problems associated with waterproofing building structures from pitched roofs to waterproofing foundations. These are materials that can be used without the use of professional equipment and without the involvement of highly qualified contractors.

Each material is aimed at solving a specific problem. The packaging contains detailed instructions for use with step-by-step installation and what is required for this installation.

The physical and mechanical characteristics of the used roll self-adhesive materials are shown in the following table.

| Indicators | Self-adhesive waterproofing | ||

| Foundation waterproofing TECHNONICOL | TECHNONICOL floor waterproofing | TECHNONICOL flat roof waterproofing | |

| Weight 1m2, kg | 1,5 | 1,5 | 5,0 |

| Conditional strength, not less, MPa | 1,0 | 1,0 | |

| Maximum tensile force (along / across) - polyester, N / 50mm | |||

| Water absorption within 24 hours, no more,% | 1,0 | 1,0 | 1,0 |

| Flexibility at low temperatures on a timber R 15 mm, ° С | |||

| Water resistance at a pressure not less than 0.06 MPa | absolute | absolute | |

| Water resistance at a pressure not less than 0.01 MPa | absolute | ||

| Binder softening temperature, not less, ° С | |||

| Heat resistance, ° С | |||

| Elongation, not less,% | |||

| Bond strength, not less, MPa with concrete with metal | 0,2 0,2 | 0,2 0,2 | 0,2 0,2 |

| Type of protective coating top side | polymer film | slate | |

| Type of protective coating underside | release film | release film | release film |

| Length / width, m | 10x1 | 10x0.75 | 8x1 |

Foundation waterproofing TECHNONICOL

Rolled baseless self-adhesive bitumen-polymer waterproofing material.

Waterproofing of the TECHNONICOL foundation is obtained by applying a self-adhesive bitumen-polymer binder to the anti-adhesive film, followed by closing the binder from the front side with a polymer film.

Application

Waterproofing of foundations (up to 3m) of buildings with a technical floor or an unexploited room, in sandy soils with a low groundwater level (below the level of the foundation slab). Storm water protection.

Price

Waterproofing of the TECHNONICOL foundation (10x1m) - 155.00 rubles / m2

Manufacturing jobs

Installation is carried out on a base primed with a bituminous primer.

The roll is rolled from top to bottom, the top edge is secured with a metal edge strip.

Installation instructions >>>

TECHNONICOL floor waterproofing

Rolled baseless self-adhesive bitumen-polymer waterproofing material.

TECHNONICOL floor waterproofing is obtained by applying a self-adhesive bitumen-polymer binder to an anti-adhesive film, followed by covering the binder from the front side with a protective layer (Spunbond).

Application

Waterproofing of floors of internal premises. It is possible to use in the system both with a protective screed, and without it, in the system without the use of a protective screed, ceramic tiles are laid on the material with cement glue. It is possible to use where it is forbidden to use an open flame; laying on combustible bases is possible.

Price

TECHNONICOL floor waterproofing (10x0.75m) - 169.00 rubles / m2

Manufacturing jobs

Installation is carried out on a base primed with a bituminous primer.

Installation instructions >>>

TECHNONICOL flat roof waterproofing

Self-adhesive bitumen-polymer roll roofing material.

TECHNONICOL flat roof waterproofing is obtained by impregnating a strong polyester base with a bitumen-polymer binder, followed by applying a self-adhesive layer to the underside of the canvas. As protective coatings, coarse-grained dressing is used on the front side and an anti-adhesive polymer film on the lower side of the web.

Application

One-layer waterproofing of flat roofs of unexploited buildings (garages with concrete and wooden bases, outbuildings, change houses, etc.), repair of roofing.

Price

Waterproofing of a flat roof TECHNONICOL (8x1m) - 209.00 rubles / m2

Manufacturing jobs

Installation is carried out on a base primed with a bituminous primer.

Installation instructions >>>

Waterproofing system

Roofing material

It is a roll-to-roll waterproofing based on roofing board impregnated with petroleum bitumen. On both sides, the roofing material is covered with a layer of refractory bitumen and sprinkled with sand or other sprinkling.

The length of the roofing material rolls is 10-15 m, the width is from 7.5 to 10.5 m.

Various powder fillers are added to petroleum bitumen - chalk, gypsum, talc, limestone, quartz sand, dolomite flour, etc. These fillers give the roofing material additional qualities - light, moisture and heat resistance, etc.

Fiberglass

Glass cloth is a close relative of glass, but its cloth, woven from glass threads (roving), has excellent flexibility, does not break and, unlike glass, does not break.

Glass threads for the manufacture of glass fabric "Roving 200"

This material is used in various industries, including construction, due to its fire safety, corrosion and chemical resistance, insensitivity to temperatures ranging from -200 ° C to +550 ° C, environmental friendliness, durability and wear resistance.

Fiberglass differs in density and type of weaving of threads, which corresponds to the types of weaving of textiles and can be plain, twill, satin, etc.

Bikrost

It is a modern build-up material for roof waterproofing. It has excellent waterproofing properties and is inexpensive. The basis of bikrost is fiberglass or fiberglass, sometimes polyester nonwoven fabric (bikrost based on polyester is not very elastic).

The base is treated with a layer of binder - oxidized bitumen. On top of it, a dressing (slate, asbagal, sand) or a special protective film is applied, which quickly burns out when laid.

Watch product video:

offers to purchase modern innovative materials for waterproofing at minimal prices.The products developed by us can be used to carry out work to protect against moisture, steam and corrosion of elements such as roofs, roofs and ventilation shafts, floors, bathrooms, balconies, foundations, piles, various seams, railway and auto roads, basements , tanks, pools, underbody and thresholds of a car, metal structures, concrete, pipelines, septic tanks, etc. We also carry out comprehensive work on the installation and repair of roof waterproofing on a turnkey basis from 350 rubles. m² is the lowest price on the market. For more information about what types of work we do and at what cost, see the section waterproofing.

Calculation of the cost and consumption of the universal liquid polymer bitumen composition Isostop, depending on the method of application and type of work:

Uniflex

This waterproofing material for roof protection has gained great popularity due to its combination of excellent performance and ease of installation.

Uniflex CCI

The basis for the production of uniflex can be fiberglass, frame and ordinary fiberglass and polyester. A bitumen-polymer composition is applied to the base on both sides.

The lower side of the web in a roll is additionally covered with a thin polyethylene film, and the upper side - with a film, sprinkling or aluminum foil.

Technoelast

It is a modern roll material based on fiberglass or polyester. The binder is bitumen, thermoplastic and various fillers. Additionally, layers of material are covered on both sides with coarse or fine dusting or a polymer film. The result is a multi-layer canvas.

Technoelast is considered a very reliable roofing waterproofing material. It can also be used to protect foundations and basements from groundwater and moisture. The warranty period of technoelast is at least 25 years.

(No Ratings Yet)

The essence of waterproofing

Why do you need waterproofing of a concrete foundation? This question seems quite reasonable given the fact that concrete in water only gains strength over time. However, things are not so simple. Inside any material there are pores.

Water gradually accumulates in them, and when it freezes, it expands, and the resulting loads lead to cracking. Internal moisture promotes the development of mold and mildew, which destroys the concrete. Finally, the steel reinforcement inside the foundation rusts and loses strength in contact with water.

Together with it, it loses its strength and all the foundation.

Thus,

the foundation must be protected from moisture penetration, which provides waterproofing.

Where can moisture penetrate into the foundation? First of all, groundwater is located below, which can create a significant water load. On the side of the foundation walls, moisture acts, penetrating into the ground during precipitation, snow melting, floods. In other words, the foundation needs to be protected from all sides.

Where do you start designing waterproofing? The choice of the type and thickness of the waterproofing layer depends on the specific operating conditions of the structure.

As initial factors such parameters are considered:

- groundwater level;

- heaving of the soil and its structure;

- flood situation;

- terrain relief;

- type and deepening of the foundation;

- special requirements for the structure.

Waterproofing must be applied in full at the stage of foundation construction. Keep in mind that fixing bugs is expensive. Waterproofing design should be carried out in conjunction with the development of a drainage system. It includes a mandatory foundation pillow, as well as a system for draining water from the structure during precipitation and melting snow.

Taking into account the need for comprehensive protection of the base of the house, waterproofing is divided into 2 types - horizontal and vertical... In addition, it can be made of various waterproof materials, which are applied and fixed in different ways. A number of modern, reliable polymers are currently being produced, but traditional materials remain popular as well.

We recommend: Making a foundation for a private house with your own hands. All stages of work from project to pouring