Table of contents:

- Why is it wet in the basement

- Why do you need internal waterproofing

- Types of waterproofing

- What materials are used for waterproofing

- Penetrating insulation

- Cement-based waterproofing (cement mixtures)

- Roll insulation

- Liquid insulation (coating)

- Membrane waterproofing

- Liquid glass

- Polyurea

- How to order waterproofing on poliol.ru

80% of buildings without waterproofing begin to collapse in the first years. The foundation and basement of the building are in contact with the soil, which means with groundwater and moisture, as a result of which:

- Water corrodes metal and erodes support structures.

- If dampness enters the basement, the temperature regime is violated, mold, fungus, insects appear.

- With periodic flooding of the foundation, cracks and surface faults are formed.

Drainage and protection of the interior of the building from moisture ingress can prolong the life of the house.

findings

Protecting the foundation from negative wet effects is a responsible and rather complicated matter. And if you decide to equip the waterproofing yourself, you should remember that the key to success in this situation are:

- the right choice of material;

- competent determination of the method of waterproofing;

- as well as adherence to the sequence and timing of the necessary work.

If everything is done correctly, follow the instructions and listen to the opinion of experts, one can hope that the rebuilt foundation and the house above it will last a long time without requiring major repairs.

(67 voice., middle: 4,90 out of 5)

How to properly waterproof your roof

Extension to the country house

Similar posts

Why is it wet in the basement

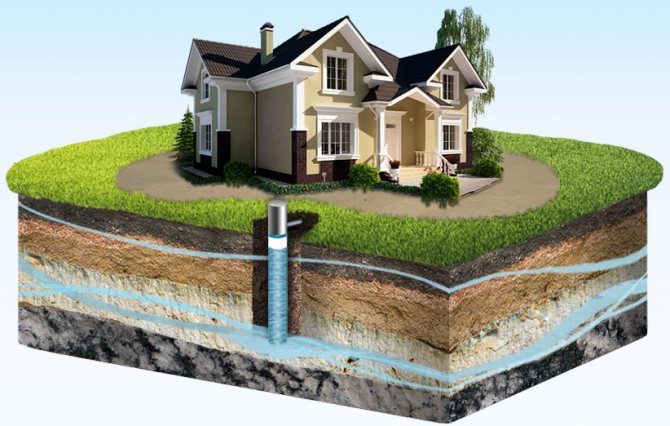

Heavy rainfall, wind, temperature changes - all this affects the foundation and basements in houses. Moisture is contained in the surface layers of the soil, melt and rainwater collects in the upper layer of the soil.

The reasons may be as follows:

- poor ventilation;

- microcracks and faults in the foundation and supporting structures of the building;

- overload: the building presses on the soil, groundwater penetrates through loose joints and increases the amount of moisture.

Causes of moisture in the basement

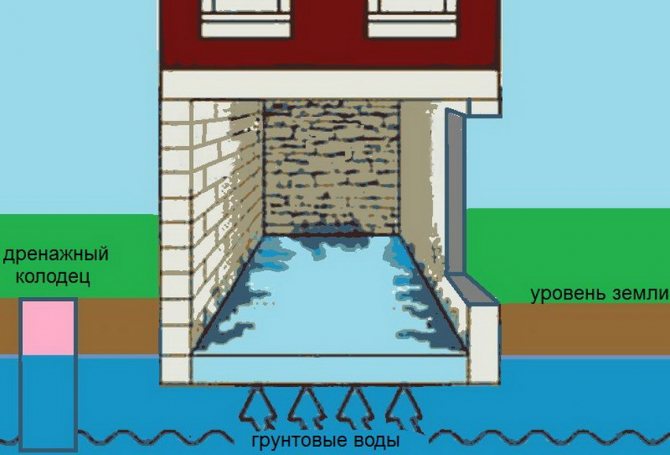

Groundwater causes flooding of the unequipped subfloor or the formation of condensation on its surfaces. Increased humidity also appears due to violations of building codes during the construction of a building. Damage to existing basement waterproofing can be another cause of the problem.

A seasonal or geologically determined high groundwater level (GWL) leads to an increase in humidity in the underground rooms of the house. This is facilitated by regular heavy precipitation. Leaks occur due to defects appearing in the outer or inner waterproofing layer of the walls. Technical reasons also include the absence or breakdown of the exhaust ventilation.

Types of waterproofing

There are several ways to isolate the cellar from groundwater. To choose the best option, you need to take into account the climatic conditions of the region, the features of the structure and communications inside, the level of melt and groundwater.

- Vertical protection walls from the inside are required if the groundwater is very close or there are no drainage systems around the house. Waterproofing is arranged along the perimeter inside the building.

- Horizontal insulation it is necessary if we are talking about clay soil, which prevents steam exchange, and the base is adjacent to the places where groundwater is released. As a rule, vertical and horizontal foundation insulation is combined with each other.This helps to enhance the protective properties of the materials.

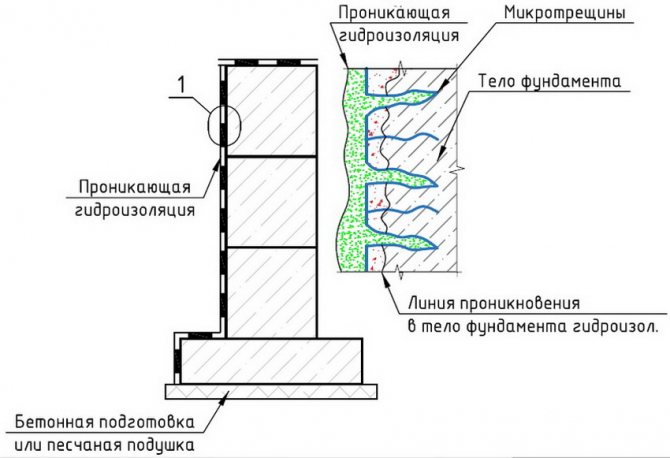

- Penetrating waterproofing relevant when it comes to the pressure of groundwater and the lack of drainage. The idea is to use water pressure, which pushes the protective material harder against the surface of the house. Penetrating waterproofing is designed to fill cavities that appear in walls and help stop moisture from entering. For example, concrete has a porous structure, if it is impregnated with a special hydrophobic solution, then it will repel water.

Waterproofing of foundations. Protection of basements from groundwater and moisture.

Protection of the foundation from groundwater.

To preserve the walls of the house from groundwater, drainage (waterproofing) of the foundation is arranged. There are several ways to insulate foundations:

–

A layer of cement-sand mortar, about 25 mm, of a 1: 2 composition is leveled, cemented, dried. Lay one layer of roofing or roofing material on top. -Prepare mastic from one part of heated bitumen to 1/2 part of fluff lime, sifted on a fine sieve. Lime can be replaced with dry sieved chalk by mixing it with resin in a 1: 1 ratio. Hot mastic is applied in 2 layers. More layers can be applied, not less. The total thickness must be at least 8 mm.

–

Lay two layers of roofing felt or two layers of roofing felt dry, but so that at the ends the seams overlap by at least 15 cm.

–

The most reliable insulation is on mastics (roofing felt - on tar, roofing material - on bituminous). The top of the foundation is covered with mastic and the first layer of roll material is glued onto it, which is again covered with mastic, and the second layer is glued. For these works, roofing felt and roofing material are used without sand and stone bedding.

Waterproofing

- a dense waterproof layer of paint, roll or other materials, designed to protect building structures or other objects from being moistened by groundwater or other liquids. Waterproofing is arranged in the form of several insulating layers of waterproof materials (roofing felt, roofing felt, etc.), laid on mastic (klebemassa) or cement mortar, as well as in the form of plaster with a fat cement mortar with the addition of ceresite.

Waterproofing materials

- used in the construction business to protect against moisture, dampness, aggressive waters, when installing drainage systems, protecting the foundation. For the isolation of critical structures (tunnels, pipes, metro). It is customary to distinguish waterproofing materials into the following types: - hot bituminous and asphalt mastics - cold bituminous mastics, emulsion pastes and cold asphalt mastics - furan and phenolic mastics and polymer concretes - cement-sand mortars with sealing additives

Drainage systems

The basis of an effective drainage system is perforated drainage pipes laid along the perimeter of the foundation in specially prepared trenches. Water from the ground penetrates through the holes in the pipes, and then is discharged into specially prepared containers. This ensures reliable waterproofing of the building foundation. In addition to the perforated pipe, a solid pipe is laid in the drainage system, which is designed to drain surface wastewater from roofs or paved surfaces (storm sewer

Waterproofing can be rigid, coated and glued. Hard

waterproofing is carried out by applying a dense waterproof layer of plaster 2-3 cm thick on the protected surface or by a lining made of waterproof concrete. Its top is brought to a mark of 0.5 m above the calculated groundwater level, and then waterproofing is arranged only from capillary moisture. The disadvantage of rigid waterproofing is the possibility of cracks appearing in it, even with small precipitation of the structure.In this regard, rigid waterproofing is carried out after the completion of the laying of the walls of the building and the installation of ceilings and the roof, when the settlement of the building is mainly ended.

Coating

(paint) waterproofing is a thin multilayer shell applied to the insulated surface by coating with asphalt, bitumen, coal tar. Lubricating waterproofing is usually arranged on the outer surfaces of the masonry, since this waterproofing can successfully work only on the side of water pressure. Lubricated insulation is easily destroyed during deformation of the structure, in addition, it wears out quickly. In this regard, it is recommended to use coating waterproofing only in those cases when, according to the operating conditions, its periodic repair is possible.

Okalechnuyu

- this insulation is made of several layers of rolled waterproofing material, glued to the protected surface using waterproof plastic mastics. As roll materials for this purpose, cardboard impregnated with petroleum bitumen (roofing felt, glassine, hydroizol), fabrics (metroizol, metrobit), cardboard treated with coal tar (roofing felt, roofing felt) are used. A serious disadvantage of gluing waterproofing is the high laboriousness of work on its manufacture and the inability to effectively mechanize it. Fig. 1. Waterproofing of a basement building with a basement height of more than 0.6 m, 1-sidewalk; 2-horizontal waterproofing; 3 - plank floor; 4 - underfloor preparation; 5 - coating with bitumen; 6- wall; 7 - foundation

Attentive test Only 5% of users score 100 points. How many points will you get?

one). The simplest case is protection against capillary moisture.

At a height of 15-20 cm from the top of the blind area, a continuous waterproof layer of 1 ... 2 layers of rolled material on bitumen mastic is arranged along the leveled horizontal surface of the walls (Fig.)

Fig. 14.14. Insulation of walls from dampness and capillary moisture:

a - the wall of a basement building; b - basement wall; 1- cement mortar or roll material; 2 - coating with bitumen twice.

2). If the groundwater level is below the basement floor (Figure 14.14 b), then moisture insulation is used to protect the foundations.

For this, hot bitumen is coated from the outer surface of the buried walls in 1 ... 2 times and roll insulation is laid in the wall at a level below the basement floor.

3). If the groundwater level is higher than the basement floor level, then the waterproofing is carried out in the form of a continuous shell that protects the buried room from below and on the sides.

- Vertical waterproofing is usually glued to the outside of the foundation, because in this case, under the action of the pressure of groundwater, the insulation is simply pressed against the insulated surface.

To protect the insulation from mechanical influences (for example, when backfilling), it is fenced outside with a protective wall made of brick, concrete or blocks. The gap between the wall and the waterproofing is filled with a liquid cement mortar.

- Horizontal waterproofing is glued to the preparation surface leveled with a cement screed and protected from above with a cement or asphalt layer t = 3 ... 5 cm.

four). Corrosion protection.

- In mildly aggressive waters, a clay castle is made from well-crushed and tamped clay along the entire height of the protective wall and from the sides of the foundations (Fig.14.16)

Fig. 14.16. Isolation of foundations from aggressive groundwater:

1 - clay castle made of crushed clay; 2 - coating with bitumen three times; 3 - protective wall; 4 - roll insulation; 5 - clean floor; 6 - reinforced concrete floor; 7 - protective layer; 8 - cement screed; 9 - crushed stone or gravel preparation on bitumen.

- In more aggressive waters, before the installation of a clay castle, the surface of the protective wall and foundations is covered 2 times with bituminous mastic or glued insulation made of bitumen roll materials.

What materials are used for waterproofing

Most often used:

- penetrating insulation - a mixture of sand, cement and polymers;

- cement mixtures - cement and polymer additives;

- roll insulation - bitumen, roofing felt, roofing material, brizol, waterproofing;

- liquid glass - an aqueous alkaline solution of sodium and potassium;

- membrane insulation - molding rubber for a snug fit to the surface;

- polyurea - sprayed two-component polymer.

For example, penetrating insulation is suitable for concrete surfaces; for buildings in regions with frequent and heavy precipitation, a bitumen-based coating mixture is used.

Let's consider in more detail in what conditions and how to use each material.

Work technology

To restore or re-make the basement waterproofing outside of the groundwater, the following sequence of work must be observed:

- dismantling of the blind area, excavation around the perimeter of the building. The width of the trench is at least 1 meter. If groundwater is available, it must be pumped out;

- dismantling of old plaster and waterproofing. Further work can be started only after the concrete has completely dried. This will take several days. Heat guns can be used to speed up the process;

- waterproofing is applied from the very base of the building to a level 10-20 cm higher than the basement level. This part of the structure must be well cleaned of dirt and soil. Surface treatment is best done with a brush with a brush;

- the seams between the structural elements of the foundation and basement are chosen to a depth of 10 cm.If the joints are tight, they are expanded to a depth of 4 cm and a width of up to 3 cm.All cracks, pin holes and other damage to building structures are also gated. It is allowed to use a drill up to 6 cm long for this;

- after cleaning the surface from dirt, the area is treated with a moisture-resistant primer or a solution of penetrating waterproofing. All grooves and detected places of defects are filled with cement mortar, to which waterproof polymers or water glass are added. It is preferable to use ready-made mixtures that can be bought at a building materials store. Further work begins after the preliminary layer of waterproofing has dried and the outer surface of the basement has been leveled;

- the first layer of pressure head waterproofing is made with plaster cement mortar. To give it strength, the plaster is reinforced with a polymer or metal mesh;

- the next step is the application of the main waterproof layer. To do this, use roofing material, mastics, which include bitumen or other materials, as well as coating mixtures;

- completes the waterproofing by applying an outer layer of plaster. It is fixed with a geotextile sheet, one side of which goes to the bottom of the trench. Then the channel is covered with coarse gravel and a drainage pipe is laid, which is led into a special well. Gravel is poured over the pipe. The thickness of this layer is not less than 10-15 cm. This entire multilayer "cake" is covered with geotextiles;

- the manufacture of waterproofing is considered complete, provided that the channel is backfilled with soil, the device of the clay castle and the blind area.

This technology gives a general idea of how to waterproof the basement from the outside. If you need to protect a new structure from moisture, impregnating materials are used for this, applying them even to raw concrete.

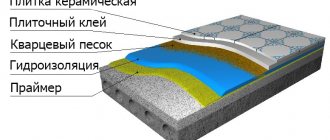

Do not forget about waterproofing the basement floor. Its installation is carried out on top of a sand pillow, on which roofing material or other roll material is laid.Then a concrete screed is made with the addition of liquid glass or other hydrophobic substances to its composition.

In a similar way, the waterproofing of the cellar is organized from the outside. If the groundwater level is low and there is no pressure, you can do with a clay castle or cover the walls of an underground structure with polyethylene. Alternatively, you can cover the walls with a moisture-resistant primer and bitumen-based mastic.

Penetrating waterproofing

Such basement waterproofing is used if the groundwater is high enough. Penetrating insulation is an umbrella term for a mixture of several components. It includes sand, cement and polymers. As a rule, such mixtures are diluted in water, and then applied to the surface to be protected from moisture. It is also a concrete or brick building. The liquid composition penetrates into cracks and capillaries, fills the concrete structure and crystallizes, leaving no chance for moisture to penetrate inside. At the same time, the ability to pass steam at the concrete remains, which avoids the appearance of condensation.

How to apply penetrating waterproofing

Remove grease and dirt from concrete. If there are cracks on the surface, they must be repaired with a putty and a homogeneous structure of the material should be achieved. This will help to avoid the formation of fractures and premature deterioration of the concrete. Then rinse the surface with water, prepare a waterproofing mixture and apply it on damp concrete in 2-3 layers. It is worth starting work from the corners and joints of the joints. After completion, we recommend moisturizing the treated surface for several days, this will promote uniform hardening.

Vertical waterproofing

The task number 1 of waterproofing such an arrangement is to protect the foundation from water penetrating from the sides of the house. These are melt water, rain and ground water, when the level of the latter rises.

Depending on the moisture content of the soil, vertical insulation can be:

- painting;

- pasting;

- or combined.

How to equip?

Vertical waterproofing is performed only after the completely rebuilt foundation and basement are dry. Arrangement of such waterproofing is a uniform coating (resinous, bituminous) of all fundamental planes that are in contact with the ground. Moreover, such planes should be:

- clean;

- dry;

- smooth.

Even the seams of the masonry should be smoothed so that there are no irregularities.

Bituminous paint or mastic is applied in 2 compulsory layers. First one (and then it dries), then (after the first is completely dry) - the second. The bitumen dries completely for at least 4 hours. At the same time, it is better to use bituminous mastic for the second layer hot. And the layers of waterproofing should be homogeneous in composition.

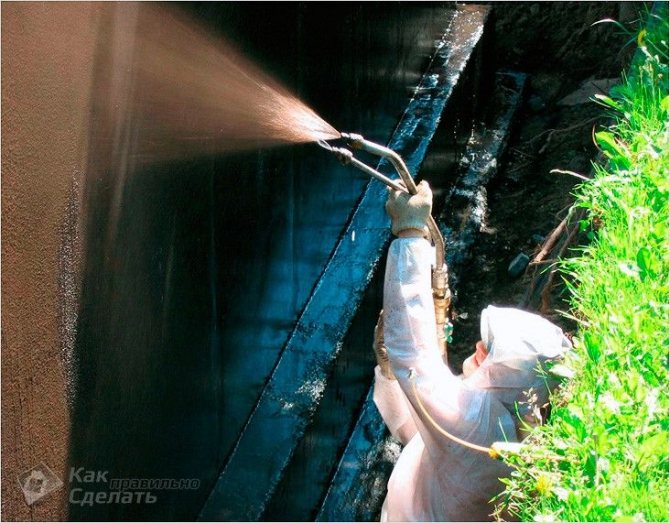

Cold bitumen mastic is applied with a brush or paint roller, smearing the entire foundation in the most thorough way. And in order to apply hot bitumen, you first need to warm it up to a liquid state in a special metal container. And only then the hot composition is distributed over a flat and clean surface.

To arrange vertical waterproofing, instead of bitumen or mastic, you can also use special PVC compounds. And in addition to them, pieces of roofing material, iso- or technoelast can become.

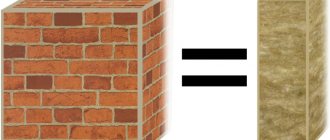

Cement-based waterproofing

This type of protective coating is also called plastering insulation. It adheres well to the surface, has strength and is applicable not only to concrete surfaces, but also to wood and metal. There are many options for cement-based waterproofing mixes, but the most resistant are those containing polymers. Chemical elements add elasticity to classic cement.

How to apply the cement mixture

Remove dust, soil residues, grease from the basement surface, brush with a steel brush or water.This is necessary in order to open the pores of the concrete for the mixture to penetrate inside. After that, prepare the cement mixture, mix thoroughly until it begins to resemble sour cream in consistency. Apply the solution to the surface with a brush in two layers, first lay it horizontally, after two hours - vertically. The composition will completely harden after 24 hours.

Plaster waterproofing

This type of waterproofing involves the application of protective compounds (solutions) by plastering the surface. As a result, a covering seamless layer with a thickness of up to 22 mm should be formed.

Most often, for the design of plaster waterproofing, a mineral-cement composition is used, to which special substances are added that increase the moisture resistance of the finished layer.

The following are actively used as such additives:

- polymer concrete;

- asphalt mastics;

- hydro-concrete, etc.

Plaster insulation reliably protects the foundation of buildings and structures from wet capillary absorption. However, cracks in the process can appear before the waterproofing protection is formed. Therefore, it is required to draw up it in an extremely hot way and always in several layers.

Having arranged high-quality waterproofing around the entire perimeter of the foundation of the house (that is, both vertical and horizontal), it will be necessary to bury the pit with oily clay, which, in turn, is also an additional natural waterproofing.

Roll insulation

Roofing material, roofing felt, waterproofing - all these are roll materials. They are used when it is necessary to protect the floors and walls in basements from the inside from moisture. The easiest way is to lay the rolls on the floor using an adhesive or bitumen mastic. If the house is located in a region with abundant floods, waterproofing should consist of 4 layers, if not, 2 is enough. Roll insulation is chosen because it is affordable and you can install it yourself. However, at low temperatures, it becomes brittle and cracks.

Technologies

Waterproofing is a complex process that must be carried out by highly trained professionals. Firstly, only an experienced person, on the basis of the obtained analysis of the construction object, will be able to choose the optimal technology, decide which material is most suitable in a given situation. Secondly, regardless of the method chosen, the work will be carried out in stages and each of these stages affects the durability and reliability of the waterproofing.

Fusion waterproofing

Fusion waterproofing is the most common technology and is used in 75% of cases. The process is as follows:

- the surface is cleaned of dust and covered with a bituminous primer;

- the lower bitumen layer of the roll material is heated by a burner and fused onto the concrete building structure with an overlap of several centimeters.

If the soil is very wet, then a two-layer coating is required.

Pasting

When waterproofing by pasting, polymer films and membranes are used, which are fixed with polymer, epoxy or bituminous mastics. Some manufacturers produce products with an already applied adhesive layer, which increases its cost.

In this waterproofing technology, it is very important to properly prepare the base, it is leveled, all protrusions, potholes are removed and defects are eliminated. Further, the surface is cleaned of dust and dried, only then the material is applied in 1 or 2 layers, depending on the level of groundwater at the site.

Penetrating mixtures

Penetrating mixtures can be used as an independent product, as well as in other formulations, depending on the type of construction and the level of groundwater.So, a liquid solution for waterproofing is applied to a damp concrete surface and, when interacting with the base, creates a high chemical potential. In this case, osmotic pressure arises, which promotes the penetration of the composition into the material of the building structure, increasing its hydrophobic properties.

Application technology implies preliminary surface preparation, as well as uniform application of the mixture.

Liquid insulation (coating)

Protective coatings are varied in composition. The mixture can be bitumen-based, bitumen-polymer, polymer and polymer-cement. Such formulations are suitable for concrete, stone and brick surfaces. They are easy to apply and protect basements from temperature extremes, moisture and salt. The most durable are polymer and polymer-cement. By adding active chemical elements, their lifespan is extended. Bituminous mixtures lose their elasticity at low temperatures, so cracking is highly likely.

How to apply liquid insulation

Clean the surface of dust and dirt, level if it is uneven and contains cracks. Then prime the walls of the cellar to increase the adhesive force. Moisten non-primed walls with water. After that, prepare the coating mixture according to the instructions and apply in two layers. The second coat can be applied when the first one has hardened, but not completely dry.

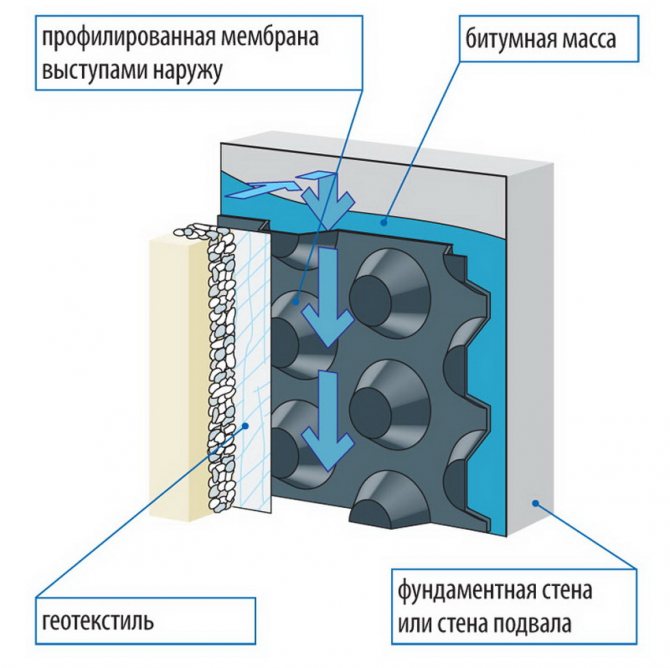

Membrane waterproofing

The membrane-type protective material is similar in principle to roll insulation. But it is lighter, produced in the form of a film with a thickness of two millimeters. To protect the interior of the house from moisture, a PVC (polyvinyl chloride) membrane is often used. It is fire resistant. Membrane coatings are produced in the form of a web with cone-shaped spikes, this helps to drain water. They are also easily attached to any surface due to the adhesive backing.

How to apply membrane insulation

The walls and floor in the basement or cellar need to be cleaned. If there are cracks and chips on them, putty and prime. Apply bituminous mastic, for better adhesion, fix the membrane to the surface with dowels, install an insulating material.

Basement waterproofing

The basement waterproofing, as well as the foundation, is provided taking into account the composition and characteristics of the soil, hydrogeological conditions, as well as the nature of the further use of this room (for placing communications, ventilation, as a grocery warehouse, etc.).

Waterproofing can be external or internal, but more often complex waterproofing of basements is carried out using various methods - coating, glued (roll), impregnating, mounted, etc.

You can combine waterproofing coating (mastic brands MBI, MBR, MBU, MBK, BKM) and pasted over (rolled bitumen and bitumen-polymer materials - hydroizol, hydroglass, glass insol, rubitex, stekloelast).

When it is difficult to repair and restore the outer waterproofing layer of the basement walls, an internal treatment is carried out. From the inside, basement waterproofing is provided by coating with mastic (with the formation of a film up to 3 mm), as well as plastering (layer thickness 1-2 cm), painting (layer thickness 1-2 mm) or impregnating (hydrostop, hydrotex, hydrofix, calmatron, hydrosite , "CeresiU," Thomsit ", etc.) in ways. Impregnating or sprayed waterproofing is also used.

Waterproofing with membranes is used less often due to their high cost and difficulty of work, since various complex elements are often mated in the basement, on which it is difficult to reproduce an integral layer of protective coating.

Helpful advice

The internal waterproofing of the basement has a significant drawback - it has to withstand water pressure from the outside.Ultimately, this leads to flaking of the insulation, the formation of voids and the penetration of water into the basement, which, in turn, causes the destruction of the basement walls, the foundation of the house, etc. Therefore, it is better to resort to a combined, combining external and internal, waterproofing.

The level of occurrence of groundwater relative to the level of the basement also dictates its conditions when providing waterproofing.

Liquid glass

This component contains an alkaline solution of sodium and potassium silicate. It is produced in the form of a powder, which must be mixed with water to obtain a waterproofing mixture. Outwardly, it resembles transparent rubber, which is why it got this name - liquid glass.

The composition can be prepared independently and applied too. Liquid glass protects the surface from corrosion. If the integrity of the coating is suddenly broken, it is easy to repair it. Most often, this material is used to protect concrete walls with metal inserts from moisture.

How to apply liquid glass

Clean the surface of dirt, degrease and level with a putty or primer if it is uneven. Then prepare a solution and apply to the entire surface, without bypassing joints, corners and crevices. The process should not be delayed, as the mixture hardens quickly. When the surface is dry, apply a layer of plaster.

Reasons for protecting the basement from moisture

The foundation is the main barrier between groundwater and the basement. Lack of moisture protection or an ill-conceived option contributes to the formation of mold, mildew and dampness. Therefore, it is necessary to carry out external waterproofing and basement. The porous structure of concrete is well impregnated with water, and subsequently:

- cracking;

- loss of room heat;

- the appearance of fungus and mold;

- the basement can be filled with water.

Therefore, it is necessary to provide for reliable protection of the foundation from groundwater and moisture. The work should be carried out at the initial stage of construction.

Polyurea

The polymer has high physical and mechanical properties, does not leave seams, unlike roll materials, dries quickly and serves for more than 30 years. It also easily adheres to concrete, metal, ceramic tiles, which makes it very versatile in many ways. It is polyurea that is used for waterproofing pipelines and swimming pools. It consists of two components that must be mixed together to obtain a spray mixture. The mixture is applied using a special installation.

How to spray polyurea

The material can be applied to the surface with a roller, brush or using a high pressure unit. It is better to use the latter method, this will allow you to spray the polymer in an even layer and avoid the appearance of bubbles. Before applying, mix components A and B from a two-component high-pressure unit, then the mixture is heated and sprayed with a gun. The surface on which the polyurea will be must be prepared in advance: clean, close the cracks and prime.

Selection of elements of a waterproofing system

Let's start with the foundation, or, more precisely, the material from which it is made - reinforced concrete. Concrete itself is a pretty good waterproofing material. The most standard ready-mixed concrete has a water resistance grade (denoted by W) of 4-6 kgf / m2. That is, it is able to withstand 40-60 meters of water column. From this it follows that our entire waterproofing system can only consist of concrete with a good waterproofing grade.

However, in order for concrete to perform well its waterproofing duties, several important rules must be followed:

1. The structure of the foundation should not allow the formation of cracks under any loads acting on it.

2.The entire volume of concrete must be poured without technological, and even more so "cold" joints, in one technological cycle, i.e. working from that corner until lunchtime will no longer work. Therefore, FBS blocks are not acceptable for these purposes at all.

3. If the technological seams nevertheless somehow appeared, then it is imperative to take measures to seal them with the help of swelling cords, sealants, waterstops, etc.

4. Working reinforcement must be installed in strict accordance with the project, the thickness of the concrete cover must be at least 20 mm.

5. Thorough vibration of the placed concrete, or the use of self-compacting concrete.

6. Thorough care of freshly laid concrete.

Important recommendations for making waterproofing concrete:

1. Work on the decoupling of the reinforcing cage and concreting should be carried out with the involvement of a specialized organization.

2. Use only ready-mixed concrete of appropriate grades for strength and water resistance. Methods of preparing concrete directly on site in a metal bath using shovels are categorically unacceptable.

3. Increasing the water resistance of concrete by introducing special additives (for example, penetrating) into it is encouraged.

4. It is necessary to cover the freshly laid concrete with a damp burlap and spill it with water every 2-3 hours (even at night) for three to five (and in hot weather, preferably seven) days.

5. Buy or rent a rebar locator and check the cover. It must be at least 20 mm.

If you are of the opinion that unprotected concrete is very destructive for the future foundation of the house, then we will proceed with the choice of material for the protection (waterproofing) of the foundation. Today, there are many different types of waterproofing materials on various bases.

Since we are talking specifically about waterproofing low-rise construction objects, we will discard all professional materials that require either complex technical equipment or technicians trained to install such material.

An example of waterproofing a foundation using modern waterproofing materials:

Using the "take and remove all unnecessary" method, we get the following types of materials in the bottom line.

Flexible membranes

Bituminous-polymer roll materials, mastic (coating) materials on an organic basis (bituminous, polyurethane, etc.), cement-based coating materials (flexible cement membranes).

Rigid membranes

Organic based lubricants (bituminous, epoxy, etc.), cement based lubricants (plastering compounds).

Flexible waterproofing membranes differ from rigid ones by the presence of such an indicator as elasticity or elongation at break. It is expressed as a percentage, and means that with various kinds of movements and deformations that may occur in the foundation, the flexible waterproofing membrane will retain its integrity. However, flexible membranes must additionally be protected.

Rigid waterproofing membranes do not need additional protection, but they cannot maintain their integrity when the foundation moves and deforms.

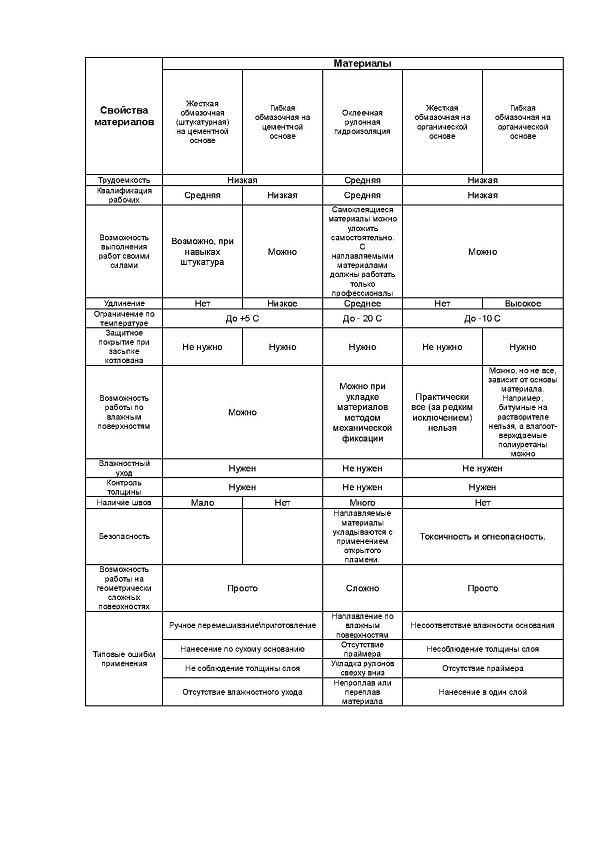

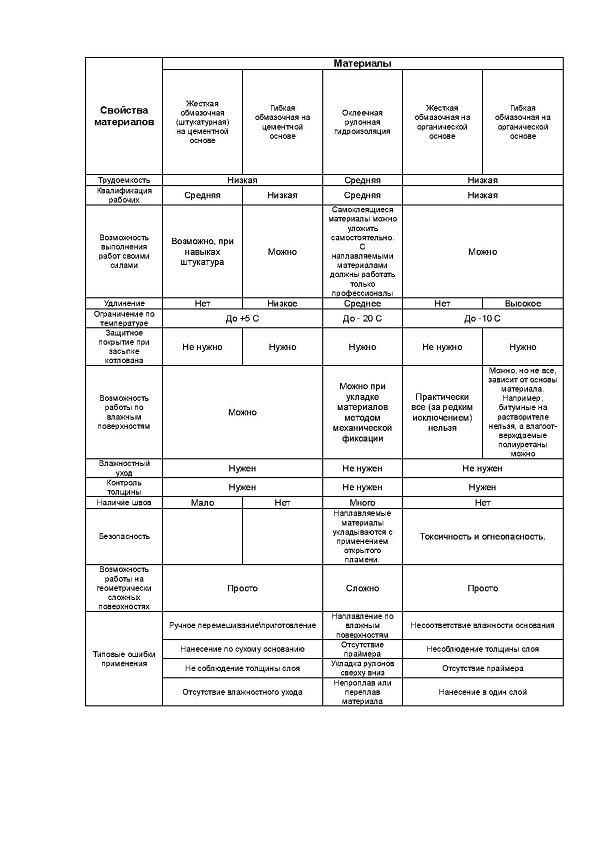

The choice of a specific material for the device of a waterproofing membrane is influenced by many factors. For convenience and clarity, we will summarize them in one table.

The data given in the table is a generalized information, and the technical and physical-mechanical characteristics of a particular material may differ from those given in the table. If necessary, pay attention to other characteristics that are not listed in this table, for example, the chemical resistance of the material.

And the last thing I would like to draw your attention to.The waterproofing membrane is horizontal and vertical. Try to keep them from the same material. It is quite problematic to dock some materials together, for example, welded roll materials and plastic wrap.

It remains for us to consider three more types of materials that are used in waterproofing systems:

- elements of foundation insulation;

- drainage elements;

- elements to protect the waterproofing membrane from damage.

How to order basement waterproofing from groundwater on poliol.ru

More than 550 teams of performers are registered on the site poliol.ru, ready to help you. To use the service, leave a request on the website for free. A waterproofing consultant will contact you by phone or chat on the website. He will advise on the materials and help you choose the performers.

You can also describe the task and post it on the site. All contractors in your region will receive notifications and send preliminary quotations - you choose the one that suits you. Our service is completely free.