The need for waterproofing

Everything is quite obvious here. Such a measure will allow heat to be directed upward, preventing it from passing through the floors. Quite often, many forget about waterproofing under a warm water floor, but its need is explained by several reasons at once:

- it is imperative to arrange waterproofing under a warm water floor, since violations of the tightness of the pipes in which the heat carrier moves can cause damage to the base. And if the apartment is not on the first floor, the neighbors living below you will suffer from the flood;

- under the water and electric floor, a waterproofing layer is necessary to separate the insulation material from the concrete floor. From changes in temperature and cold emanating from the base, condensation will appear, negatively affecting the layer of insulation material;

- in the premises of the first floor or located on the ground, it is recommended to install waterproofing between the ground and the screed to create protection from capillary moisture. The second option for solving the problem is laying waterproofing between the insulation layer and the rough screed.

When using an insulation material that is vulnerable to water from either side, experts advise placing it between two waterproofing layers in the following situations:

- the underfloor heating system is being installed, but there is a possibility of leaks;

- the device of the floor is carried out with a wet method, and the insulation must be protected from the water that is in the solution;

- the floor is installed in a bathroom or other room with a high moisture content, and there is a possibility of water penetration through the floor coverings.

As a rule, in underfloor heating systems, the underlay acts as a waterproofing layer for insulation from above. For example, foamed polyethylene with a foil surface is responsible for reducing heat loss, uniformity of its distribution, and protects the insulation layer against moisture.

Many are interested in whether waterproofing is needed under a warm floor in principle, and whether there is a need to lay waterproofing on top of a warm floor in wet rooms - corrosion can begin from water leaks, and in the case of an electrical system, there is a possibility of a short circuit.

Such excitements are groundless, since heating elements and coolant pipes are created in such a way that they can be easily mounted under a screed, which creates an aggressive environment before final drying.

Cable and electrical systems of underfloor heating, like water systems, have their own waterproofing, so that moisture penetration from above does not pose a threat to them.

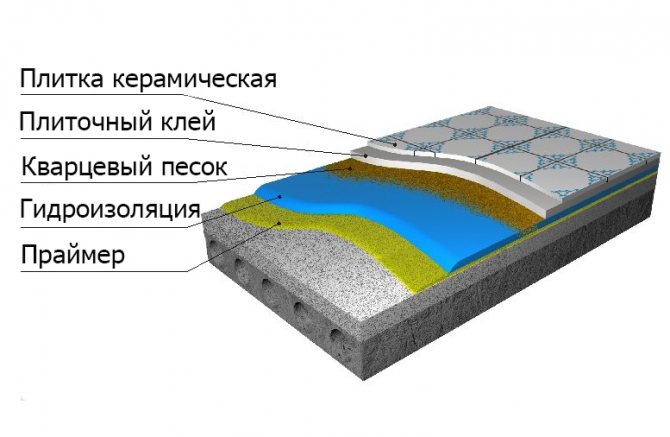

Floor waterproofing device

High-quality waterproofing helps to protect not only the structural elements of the floor, but also to extend the life of the flooring.

This type of insulation is used to protect the concrete base, prevent decay of wood and other materials that were used in the construction of the house. High humidity has a detrimental effect not only on the materials used in the decoration of the premises, but even on the structural elements of the building itself, making them unusable for further use. High-quality waterproofing of the base allows avoiding these problems.

When buying material for waterproofing, you need to focus on the selected technology:

- Floor coating is carried out using epoxy resins, synthetic or bituminous mastics.

- Roll (pasting) waterproofing involves the use of roofing felt, roofing felt and other materials with good performance.

Whatever type of waterproofing you choose, the sequence of works will be the same for everyone:

- preparation of the foundation;

- laying of insulating material;

- waterproofing seal.

If in the process of building a house you want to insulate the entire room, then the best option would be to use gluing materials. If the work is carried out only with the floor, then it would be better to use the coating option.

The glued waterproofing is easier to use than the coated waterproofing, moreover, it is strong enough and creates additional sound insulation.

To create coating insulation, mastics are used: bitumen-rubber or bitumen-polymer. They contain oxidized bitumen, combined with an organic solvent, and a filler (crumb rubber, plasticizer, latex). The mastic can be applied without any special preparatory work, it has good adhesion. This type of waterproofing can be done with minimal time and effort.

It is necessary to start applying the mastic from the wall opposite the door. In this case, the material is leveled with a spatula or a wide brush. All materials for this type of insulation contain instructions on the packaging, which indicate the method of application, the required number of layers and the time for complete drying.

Materials for gluing waterproofing are sold in rolls. They include a bitumen base, polymers, reinforcing fiberglass and polyester. Among the main advantages of this insulation, it is worth highlighting such as:

- ease of installation;

- the ability to use the floor immediately after pasting;

- high strength;

- additional sound insulation.

Disadvantages:

- careful preparation of the base is required;

- in the process of work, an unpleasant smell of bitumen appears;

- when laying it, the floor height due to the screed increases by 50 mm or more.

Criteria for the selection of waterproofing materials

According to the specifics of the application, such materials are divided into different types, but the same requirements are imposed on their choice:

- atomic resistance - protection from moisture should be distinguished by the ability to maintain its original properties and quality characteristics for the longest possible period;

- moisture resistance and resistance to water is a very important criterion that determines the ability to not pass or absorb water;

- chemical resistance - this parameter is important in order to avoid destruction from the effects of chemical elements during operation;

- resistance to temperature extremes - this property helps to maintain the original performance at certain temperatures;

- biological stability - this characteristic allows you to prevent the penetration and effects of bacteria and microorganisms on the structure of the waterproofing material.

When deciding which waterproofing material to use for floor heating, it is recommended to pay attention to the following important aspects:

- cost. As a rule, roll materials are cheaper. Mastic materials and primers are more expensive, but better protect against moisture;

- features of the premises - for rooms with a small area it is better to use mastic, but it is easier to cover large rooms with roll materials;

- the possibility of waterproofing on our own - it is easiest to work with impregnating compositions, but difficulties may arise with the deposited layer.

In most cases, manufacturers of underfloor heating systems recommend the types of waterproofing materials as recommendations. These include:

- polyethylene and polyvinyl chloride film materials. They are equipped with thermo-reflective layers.For the convenience of laying, the edges are warmed up and joined, insulation is performed with adhesive tape;

- cement-polymer - a freshly prepared elastic composition is applied to the surface with a roller or spatula, a special tape is laid at the joints. The result is a durable and waterproof coating that is excellent for concrete surfaces. Many people note its elasticity, which is very important with changes in temperature and shrinkage of buildings that have recently been commissioned;

- cast - the most reliable option. Today, for this purpose, liquid silicone membranes are used, which create good adhesion and are distinguished by elasticity.

Liquid silicone membranes - a type of waterproofing for underfloor heating

Types of waterproofing under the water floor

There are several types of waterproofing materials that differ in composition, principle of operation, efficiency.

Roll

The inexpensive and most common insulation option. For this type of protection, roofing material is used, a dense plastic film. Bonded waterproofing materials are applied by gluing with preheating with a gas burner or a construction hairdryer.

Water based mastic

Creates maximum surface protection against moisture penetration. Recommended for use in multi-storey buildings, for maximum protection against water leakage if the water circuit has lost its integrity. In order to prevent leaks, the water circuits of heating systems are embedded in special corrugations as an additional measure. This measure ensures that if the integrity of the pipes is broken, then the water will not flood the lower floor.

Water-based mastic is one of the waterproofing options for underfloor heating

Preparing the subfloor in the bathroom

Before starting waterproofing work, you need to prepare the base of the floor. Initially, it is necessary to remove all dirt, dust, debris from the floor, and to dedust the surface of the base. If necessary, if the floor is uneven and has severe cracks, level it with a screed. In the event that the floor is even and the difference is no more than two millimeters, then just prime it.

In any case, whether you will screed or not, the base of the floor must be primed in order to increase the adhesion to the waterproofing of the base of the floor. After the primer is dry, you can proceed with the waterproofing. Do not forget that all joints must be glued with a reinforcing sealing tape so that the water does not go away.

Laying principle

The laying technique and preliminary surface preparation will be determined by the selected material. There are simple application options that are performed independently, in other cases special skills and appropriate tools are required.

Roll materials

Such waterproofing under the warm floor is laid along the rough screed. The materials are spread over the surface in such a way that the joining areas form an overlap of several centimeters.

If bituminous covering materials are used, then the waterproofing is arranged as follows. The base must first be leveled and treated with a primer. The roll of waterproofing material is gradually rolled out, while its lower surface warms up. The seams are processed especially carefully. Bituminous materials are glued to the base, creating a high-quality protection against water penetration and condensation formation.

Roll materials for waterproofing under floor heating

Liquid mastic

It is quite simple to work with such material on your own. The mastic is applied with a brush or spray gun in several layers. Impregnations penetrate deeply into the surface, creating a moisture protective layer.Ultimately, reliable protection against leaks is provided if the water circuit breaks through. It is worth noting that this type of waterproofing under a warm floor is recommended for a device in the bathroom.

The technological process of working with mastic implies a thorough surface treatment, applying the next layer perpendicular to the previous one.

Waterproofing prevents the formation of condensation, provides high-quality protection against leaks if damage occurs in the water circuit. If there is no such layer, it means that the installation work was performed with a gross violation of technology.

Lubricants

Waterproofing with coating materials is most often made from oxidized bitumen and various fillers added to it. Latex, rubber crumb and plasticizer are chosen for fillers, since with their help there is a significant increase in the elasticity of the coating, and it also becomes more reliable and stable.

Bituminous mastics have very good adhesion to the base of the floor, but such waterproofing will only be protected if the base of the floor is a screed based on reinforcing fiber.

Cement-polymer mastics are also used for waterproofing the floor. They are made from dry cement, water and mineral filler. This mixture resembles liquid plasticine.