Home ›Apartment and country house› Construction and repair ›Warm floor under tiles. Which one is better to choose?

- Installation of underfloor heating under tiles

- Water heated floors

- Installation under tiles

- Electric underfloor heating

- Varieties of electric underfloor heating

- Universal warm floor

- Ultrathin underfloor heating

- Heating section

- Heating mats

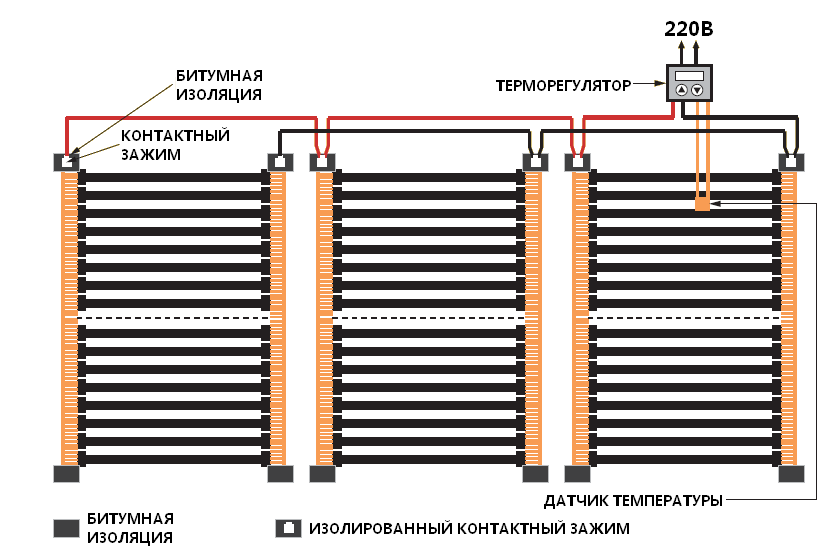

- Heating infrared film

- About strengths and weaknesses

- 40 photos of tile ideas for underfloor heating:

To understand what is warm floor under the tiles and choose the right one which is better, you need to get an overview of the types of underfloor heating and installation features. Because the choice of the type and type of underfloor heating is determined primarily by external factors related to the level of the floors, the height of the ceilings, the area and geometry of the room, the possibility of making global repairs.

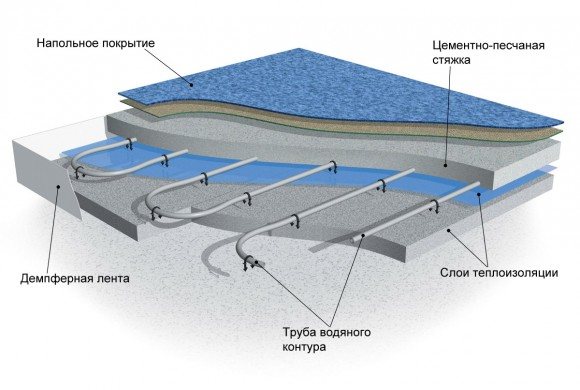

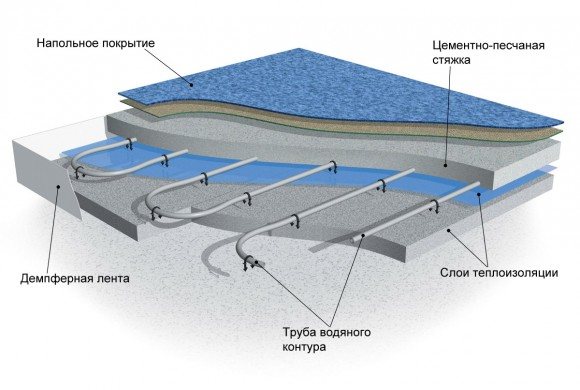

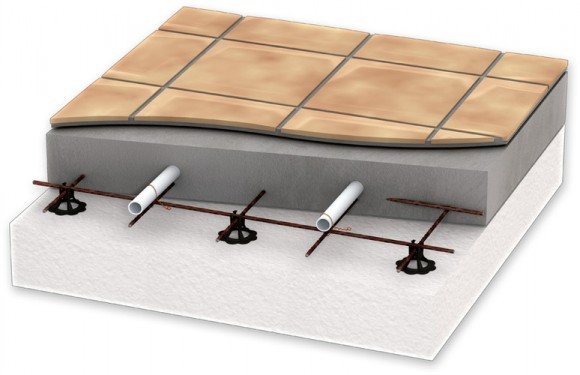

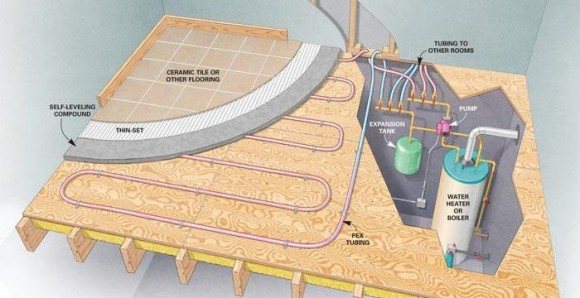

Water heated floors

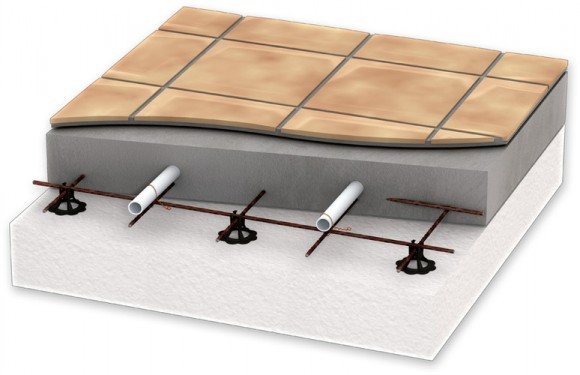

A pipe system recessed in a cement-sand floor screed, with hot water circulating in it, is called water underfloor heating. Since it will not heat up by itself, the pipelines are connected to the heat supplier. It can be both an autonomous and a centralized system that provides heat supply.

The warm floor, providing a comfortable thermal regime, is a pipeline made of metal-plastic or polyethylene pipes connected to a temperature controller and a source of heat energy supply.

Flexible pipes with a high coefficient of thermal conductivity have low resistance and provide maximum heat transfer. Almost all of the heat generated is directed outside, heating the concrete screed and ceramic or stone tiles laid on top of it. As a result, the floor surface heats up completely and gives off heat.

Modern water underfloor heating is controlled, and the room temperature is adjusted to the desired one, using a special device. It is called a coolant mixing unit. Therefore, the presence of this element is important to take into account already at the design stage.

System testing

After fixing the line to the floor, the system is tested. It is necessary to check the underfloor heating for leaks. The instruction assumes the following steps:

- A plug is installed on one end of the pipe.

- A tee is connected to the second end. Connect a pressure gauge and a valve.

- A compressor is connected to the valve.

- Air is injected into the pipeline, creating a certain pressure in the pipeline. It is necessary to look at the operating and maximum pressure of the equipment in the technical passport. The pressure gauge controls the mode.

- After the circuit is filled with air, the valve is closed.

- Leave the system for 12 hours.

- If the pressure gauge shows the same pressure level, then the system is in order. If the pressure has decreased, then the tightness of the pipeline is questioned. Air exits through the hole: the process is accompanied by a certain sound. If no sound is heard, then the hole is looked for with water. Bubbles will appear on the surface of the liquid.

We recommend: How is the installation of PЕrt pipes for underfloor heating carried out?

Follow the step-by-step instructions when performing testing. Otherwise, a line break may occur during air injection. If the results are positive, the system is connected to a comb or to a thermostat.

A test run is carried out. Pressurized water is injected. Allow the coolant to cool down and only then perform the concrete screed. Water is not released from the main line. It is in the pressurized circuit.

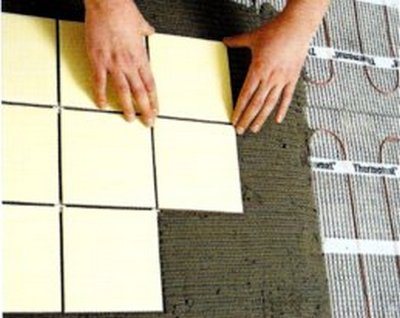

Installation under tiles

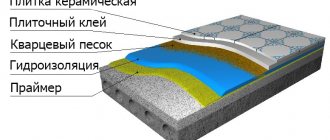

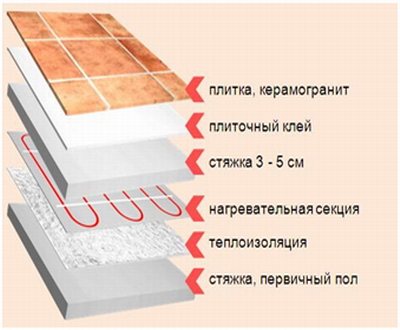

The installation of such warm floors indoors requires a significant amount of repair and construction, installation and commissioning work. First, the old floor coverings are dismantled down to the concrete base. Then determine the floor level.

If the difference is more than ten centimeters, then first the leveling screed is poured, after which, in the order according to the instructions (taking into account the slope, angles of rotation, etc.), pipes are laid through which hot water will pass.

Advice! The thickness of the screed over the heating pipes should not be less than 5 cm. Then the threat of their mechanical damage by dowels at the time of installation work on the installation of plasterboard partitions, fastening of floor equipment is reduced. In this case, pins should be used with a length of 1 cm less than the thickness of the screed.

The next stage is the installation of the coolant mixing unit and the connection of the finished pipeline to the heat source. The final part is laying the floor tiles.

It is difficult to do this work on your own. This requires the skills and knowledge of several construction trades.

Installation, tie-in and connection of a gas boiler, or a direct tie-in to city heating networks requires special approvals issued by authorized regulatory organizations.

If the area is not gasified, it is prohibited to connect to central heating, there is a possibility of flooding the lower rooms or in other similar situations when it is inappropriate to install such a warm floor, you should use floor systems, the heat source of which is electric energy.

Prepare a rough base

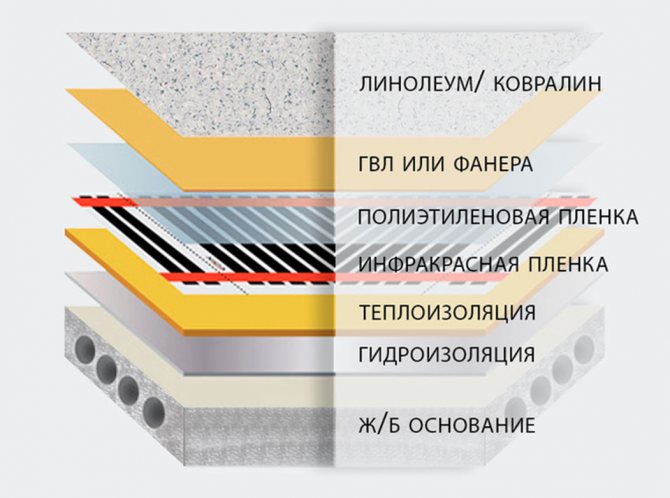

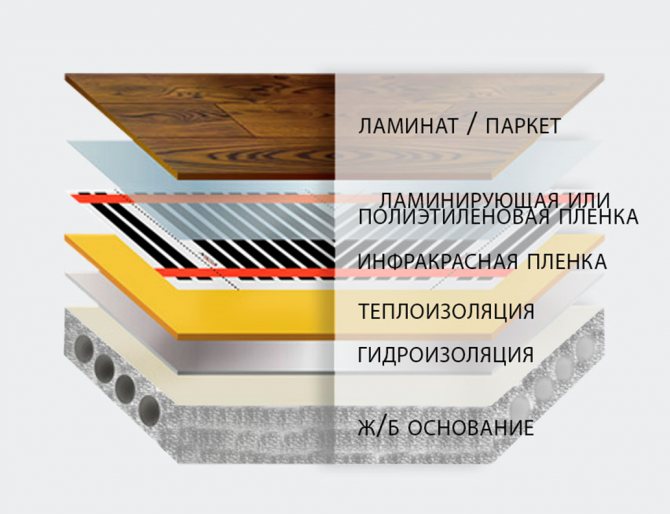

Place the underfloor heating material on a flat surface. It is necessary to build a rough base. To do this, use a concrete screed, self-leveling floor, self-leveling mortar. The surface is insulated, a waterproofing material is laid on it.

When installing underfloor heating, you must follow the instructions. What are the steps involved in preparing a rough base?

- A layer of sand of 10 cm is laid on the ground. It must be tamped.

- Next comes a layer of expanded clay 10 cm. This is the basis for the subfloor.

- The surface is protected from moisture penetration. For this, roll material is used, membranes based on bitumen. Laying is carried out over the entire surface, capturing the walls at a height of 40 cm. Bituminous tape is used for fastening.

- For underfloor heating to be effective, it is necessary to insulate the sub-surface. In this case, the heat will not spread to the foundation or to the ground. All energy is channeled up to the floor. Mineral wool, expanded polystyrene plates are used as insulation: they have locks for connection. Plates are easy to install, if necessary, adjust their size with a mounting knife. The thickness of the insulation depends on the freezing of the foundation. The optimum thickness under normal climatic conditions of the region is 10-15 cm.

- The thermal insulation material is protected from condensation with a polyethylene film. There is no need to strengthen it. It fits snugly against the coating.

- A damper tape is installed on the lower perimeter of the walls. If there is no adhesive layer on it, then self-tapping screws are used for fastening.

- Concrete screed is carried out. It is recommended to use the M500 brand.

We recommend: What kind of underfloor heating mats are there?

Insulation for roughing is used in cold regions where the foundation can freeze. In regions with mild climatic conditions, it is enough to isolate the base from moisture and fill it with concrete. In the future, the steps to form a rough floor for a warm floor are repeated: waterproofing, insulation.

As protection against moisture, it is not recommended to use materials based on bitumen. When heated, it emits toxic fumes.The concrete surface and part of the walls are covered with mastic and a primer with moisture-repellent properties.

Insulation, polyethylene film and a reflective screen are placed on the prepared coating; This is a 3-5 mm thick foil substrate. The material allows heat to be directed to the floor.

The preparation of the rough coating involves several layers of waterproofing. They protect the foundation, insulation, concrete screed from the effects of condensation, which forms due to temperature extremes. The material is not protection against flooding in emergency situations in the liquid floor line.

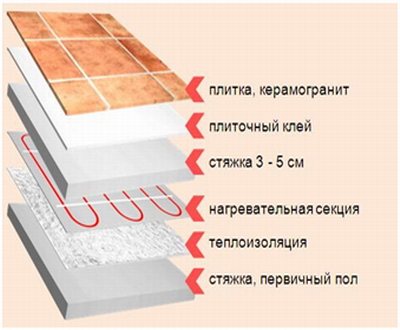

Electric underfloor heating

This type of heating is safe to operate and easy to install. It can be used to organize main or additional heating.The variety of varieties of electric underfloor heating allows you to mount them at any stage of construction and repair, as well as during the operation of the premises. It all depends on the need, feasibility, power and desire of the owner of the premises.

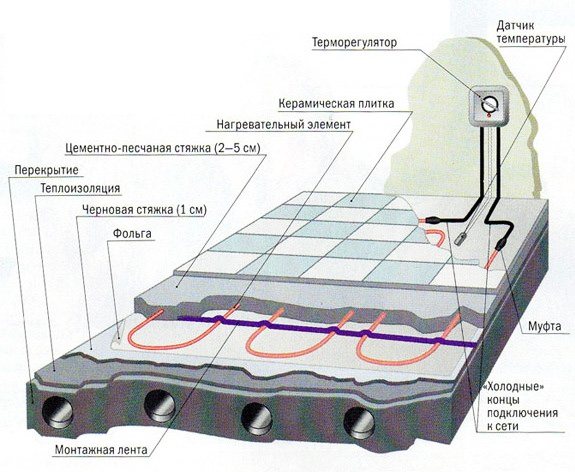

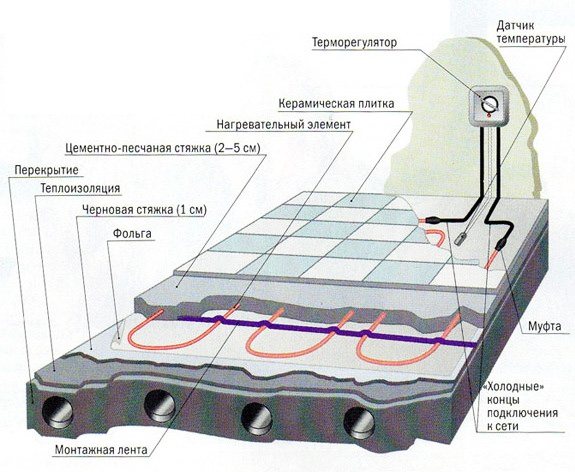

Electric underfloor heating is an integral closed space heating system. It includes elements that convert electrical energy into heat, a power cable for supplying electricity, temperature sensors and thermostats.

Important! In order for the system to work effectively, it is necessary to make accurate calculations, prepare a project or scheme. This can only be done by a qualified technician. Correct installation and professional setup are equally important.

Installation kit for heated floors

Mounting kit

Description of the installation kit, which does not depend on the type of heating system:

- Heating sections - a piece of cable of a specific length with specially prepared mounting ends. The advantage of a two-wire cable is that the connection occurs from one side.

- Mounting tape - the pieces are laid on the rough base plates.

- Thermal insulation - for using the floor heating system as the main heating, it is recommended to purchase 30 mm solid polystyrene foam. If the system is used as an additional heating, foam material 10 mm thick is used, and where the floor is equipped on the ground - 3 cm foam.

- Foil insulating material to reduce energy costs. It must also be purchased separately. The saving rate when using it is up to 30%.

Thermostats for underfloor heating

- Thermostat - with its help, energy consumption is controlled, since it determines the need for voltage supply based on the temperature. It is also used to set the heating program. It is purchased separately.

Varieties of electric underfloor heating

In the construction market of the country there is a large selection of all kinds of electric floors, so their installation under the tiles is possible in any room. To select the most suitable ones, you need to know the technical features and have at least a minimal idea of the specifics of the installation of each type.

The principle of electric underfloor heating is that the supply cable supplies electricity to the heating cable, which, in turn, converts it into heat. Temperature sensors located in the room transmit information about the room temperature to the thermostat, and based on the received data, it stops or restarts the power supply to the system.

Heating cables are of two types: single-core, which have practically ceased to exist, and two-core, which have firmly taken their place. They are fundamentally different.

Single core cables create an electromagnetic field. And, although its values are within acceptable limits that are not harmful to health, the installation of systems with such a cable is not recommended in rooms where a person spends a significant amount of time.

A two-core cable for underfloor heating does not generate an electromagnetic field and can be installed in rooms for long-term stay of people: in bedrooms, offices, classrooms. The installation of a two-core cable can be stopped anywhere, based on the length of the section, but systems with single-core cables are mounted in such a way that the beginning and end of the heating cable must be at the same point.

A novelty on the heating system market is a self-regulating cable. In conventional systems, cables are heated evenly along their entire length, so when installing them, areas for furniture sets, bookshelves, wardrobes, beds and other stationary furniture must be free from cable routing. Furniture rearrangements in such rooms are often impossible. Even transferring the carpet from one part of the floor to another will become problematic, since if you lay it in the place where the heating cables pass, they will overheat and fail.

Recently, such inconveniences can be avoided due to the self-regulating cable, which is heated unevenly. The special technological design allows him to independently lower the temperature in any area.

Different types of warm electric floors are manufactured in one configuration or another. The choice of this or that option is based on the need to change the floor level. Power, dimensions, reliability and technical characteristics depend on the manufacturer.

Easy programming of floor temperature

A programmable regulator is a more complex regulator model to control compared to mechanical thermostats.

Setting up a programmable regulator during operation is usually intuitive, but at first you may need instructions to learn all the possibilities of the regulator and how to properly control them. However, this nuance more than compensates for the economical consumption of electricity, because the heated floor will work only at certain hours of certain days of the week.

To set the operating time of the underfloor heating, the thermostat has built-in programs, from which the user selects the most suitable one and sets the operating hours on his own. The following algorithms are possible from the built-in programs:

- maintaining the same temperature on the floor both day and night on any day of the week

- automatic lowering of the floor temperature day and night

- automatic lowering of the floor temperature only at night

- automatic lowering of the floor temperature during the day and at night on weekdays, on weekends only at night.

Each day of the week is divided into 4 time periods: morning, afternoon, evening and night. The start and end times of each part of the day are programmed independently.

In addition to time programming, the user can configure the parameters for selecting a temperature sensor:

- underfloor heating operation based on the floor temperature sensor in rooms with existing heating

- operation of underfloor heating according to data from air and floor temperature sensors in rooms where underfloor heating is used as the main and only source of heating

- operation of underfloor heating without a floor sensor using one air sensor.

As additional options for the thermostat, you can name such useful functions as setting the maximum and minimum floor temperature, child protection with locking buttons using a hidden button (you must press it with a paper clip or a pin), frost protection in rooms that can cool down to outside temperature maintaining the minimum air temperature of + 5 ° С, hard reset of the thermostat with a return to the factory settings in case of incorrect programming, warning of a malfunction of the regulator (clock failure due to a power outage, overheating of the regulator, break and short circuit of the temperature sensor, overheating of the floor above the set temperature).

Heating infrared film

Suitable where rough finishing work has been completed. The film is laid directly under the laminate, tiles and even linoleum. It is produced in rolls, in which cutting lines are provided at certain distances, or in separate mats.

This floor will fit under the tiles in bathrooms. In these rooms, where the infrared floor is switched on for a short time, it is quite possible to do without a thermostat.

Attention! Some types of infrared floors cannot be mounted under tile adhesive or screed.

Advice! If in the room where it is planned to assemble the underfloor heating system, the finishing finish is completed, the correct solution would be to install an infrared film.

About strengths and weaknesses

The question of choosing a warm floor for tiles is far from unambiguous. Everyone decides it for himself. Therefore, mention should be made of the advantages and disadvantages of underfloor heating.

Advantages of a water-heated floor:

- relatively low cost of the coolant;

- low installation cost if connected to central heating.

Disadvantages:

- with a screed, it is easy to damage the pipelines, and it is almost impossible to notice;

- for efficient operation of the system, a circulation pump is used;

- installation in apartment buildings is prohibited in many regions; special permission is required for installation.

An electric underfloor heating is much simpler from the point of view of the possibility of its device, regardless of the type, purpose and occupancy of the room. But he is not perfect either.

Benefits of electric underfloor heating:

- long service life (up to 50 years);

- low power consumption when working properly;

- tolerance of negative temperatures in the room, at rest.

Disadvantages:

- in rooms with a large area, two or more systems are assembled into one;

- single-core cables create a negligible electromagnetic field.

The advantage of each type of underfloor heating is the absence of convective drafts. This means the same temperature in any part of the room (vertically), no dust floating in the air. Well, in addition, a warm floor is a pleasant sensation, comfort and convenience.