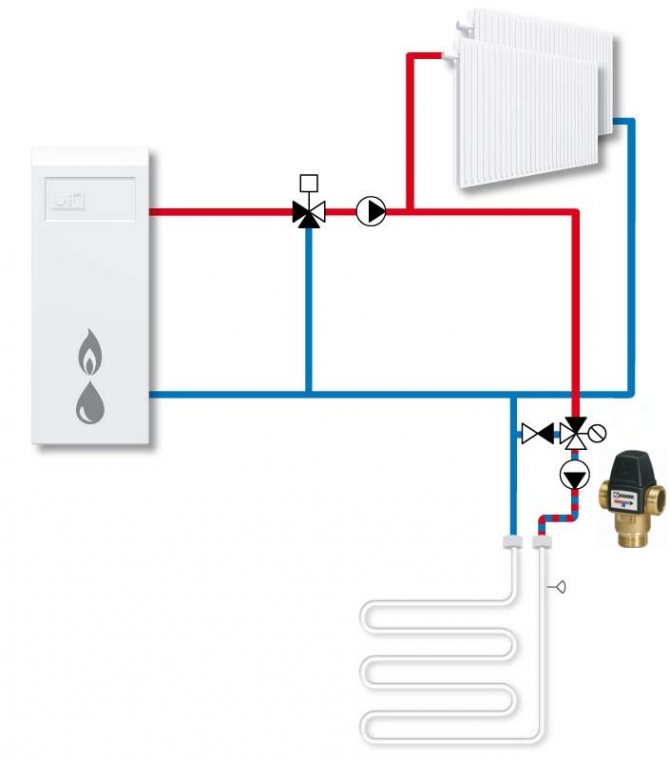

When arranging any living space, considerable attention is paid to the issue related to floor insulation. In most cases, water insulation is used as a solution to this problem, in which a mixing unit for a warm floor is a key element. If for radiator heating systems the most optimal temperature will be in the range of 80-90 degrees Celsius, then for underfloor heating systems the temperature regime should be lower (about 35 degrees). Mixers for underfloor heating allow you to ensure the normal operation of low-temperature systems, lowering the temperature by mixing the return with a hot coolant.

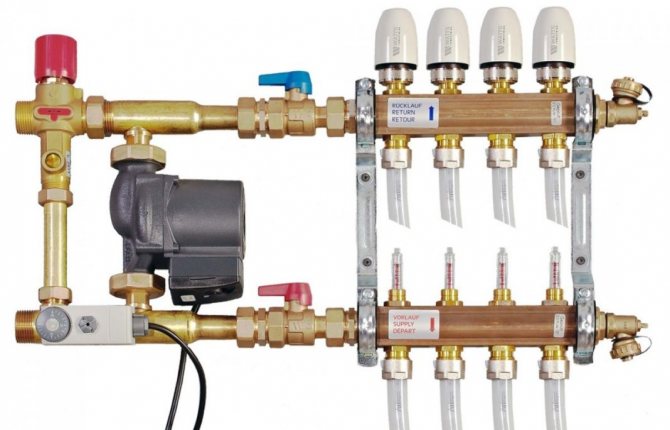

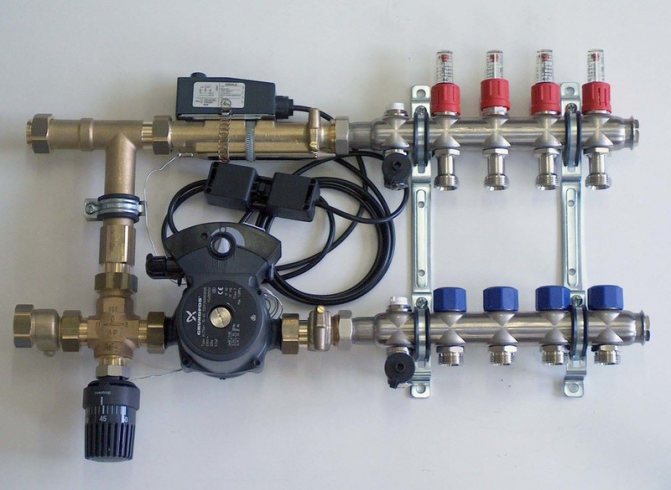

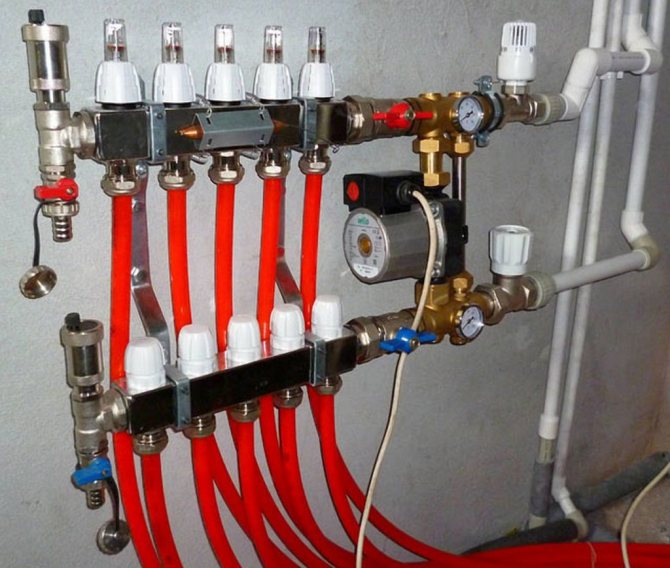

Floor heating mixing unit

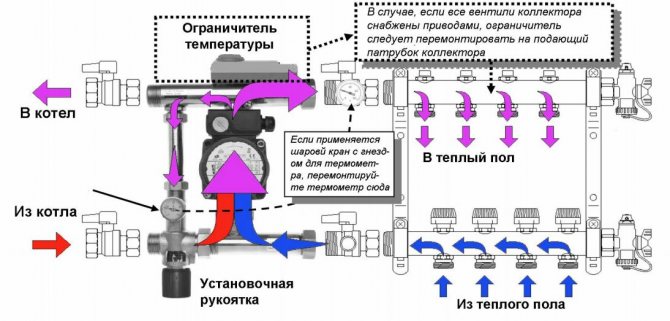

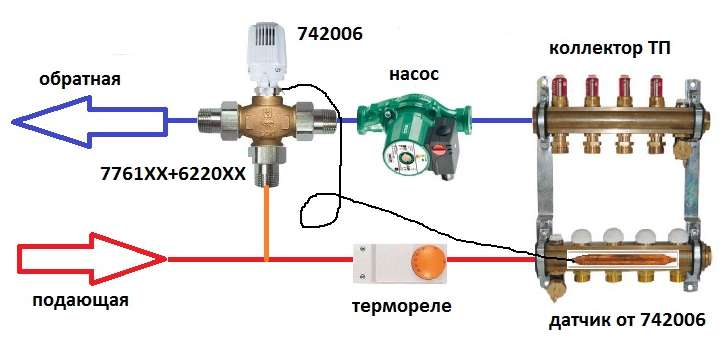

Devices of this action are perfect for connecting a single distribution manifold. Naturally, they can be used as stand-alone instruments. Heat carriers are additionally equipped with a circular pump, which is required to provide forced circulation of liquid in the heating system. In these devices, as a rule, two-way and three-way supply valves, which ensure the constant addition of cold water from the return to the coolant.

What is a mixing unit for?

If for ordinary heating with batteries a temperature of 80-90 degrees is required, then for floor heating it should be lower, 30-40 degrees, so that it is comfortable to walk on the floor without the risk of getting burned. It is with the help of a mixing unit for a warm floor that you can get favorable conditions for the full operation of invisible heating elements.

The mixing group for underfloor heating is a key component of water heating devices.

Systems of this type make it possible to connect a collector unit that provides the necessary combination of water at different temperatures to obtain favorable conditions in the room. But the use of such a device as an independent control device is not excluded.

The pipeline is equipped with a small pump, by which the forced circulation of the heat source along the circuit is carried out. These devices have supply valves with two or three strokes. They are necessary to obtain a constant addition of cold liquid from the circulation to the coolant.

Other types of devices with which you can regulate the temperature of the warm floor

- For a room that does not exceed 10 square meters, ordinary valves can be used. It is enough to install two such devices, one for the water supply and one for the return flow, and perform the adjustment in the same way as it is done on a conventional radiator: screw the valve - lower the temperature, you need to raise it - open the valve harder. The disadvantage of such a mixing device in comparison with a thermostatic three-way valve is manual adjustment. There are no devices that will show you what temperature is obtained at the exit, the actions take place by the "poke" method.

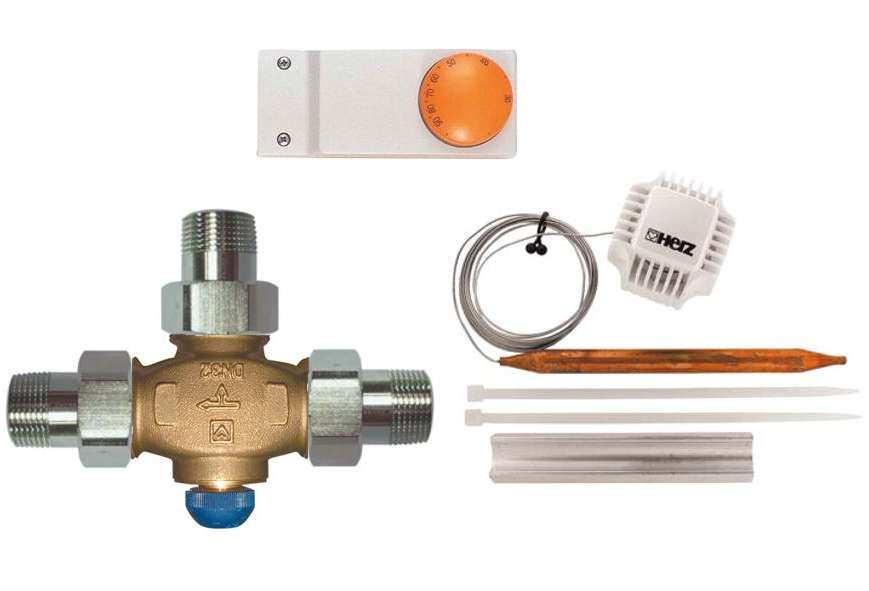

- Thermostatic mixers are not only three-way, but also two-way. Such a valve can be installed instead of one of the manual valves (the way of regulation with a valve, described above), and it will already maintain the set temperature automatically.

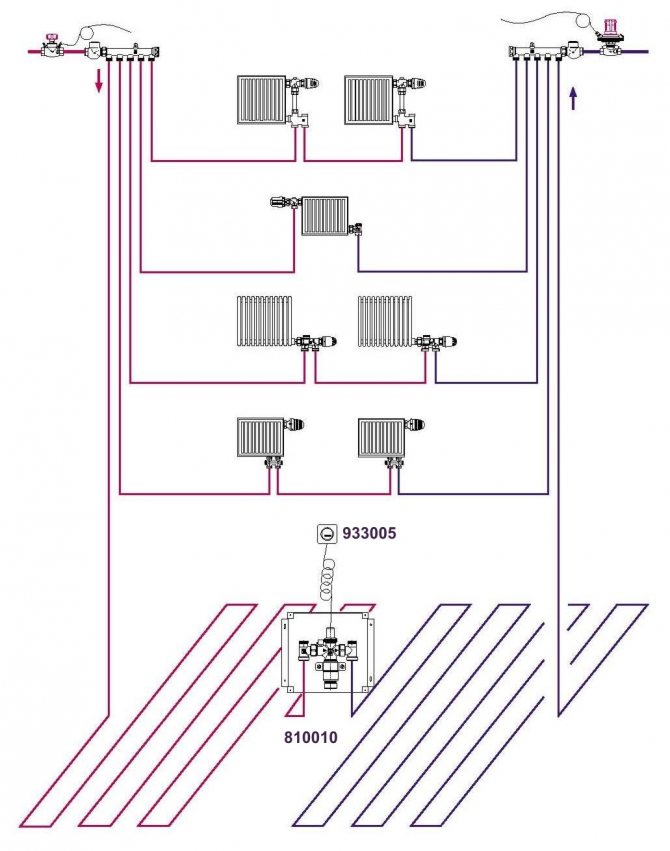

- For underfloor heating that will occupy large areas, use a mixing node. This device represents a whole system of a supply and return manifold, a circulation pump and a thermostatic mixer.

Advantages of mixers

The internal equipment, which has a mixing unit for underfloor heating, has a list of advantages that make this unit productive and in demand. Its main advantages include:

- Economy. Unlike electric hidden heaters, water heaters with a mixer for a warm floor can save up to 60% of electricity.

- Security. People often forget how high the temperature of the heating element is, which leads to severe burns. The use of a special thermo-mixer allows you to prevent such situations and protect yourself from danger.

- Long service life. The installation of such a heating block is very beneficial in comparison with other devices of similar functions. And if it is laid in accordance with all the rules, then it will last more than 50 years. The coolant is subject to wear, but the manufacturer notes that its service life is at least 50 years.

- Purity. Caring for the invisible block is not difficult and does not require much effort. In addition, due to the fact that the coating is constantly heated, it dries very quickly, which eliminates the risk of mold and mildew.

- Ambient temperature control - the system is equipped with a static thermal valve connected to the regulator. This means that you can adjust the heating level taking into account changes in temperature indicators outside.

- The presence of mechanical control, in which the unit for the warm floor is independently regulated.

- Limit mode application. This allows you to set a suitable room temperature. For example, you set a specific temperature using a thermostat, upon reaching which the system will maintain it at this level, preventing the coolant from overheating or cooling.

How to choose the right 3-way valve

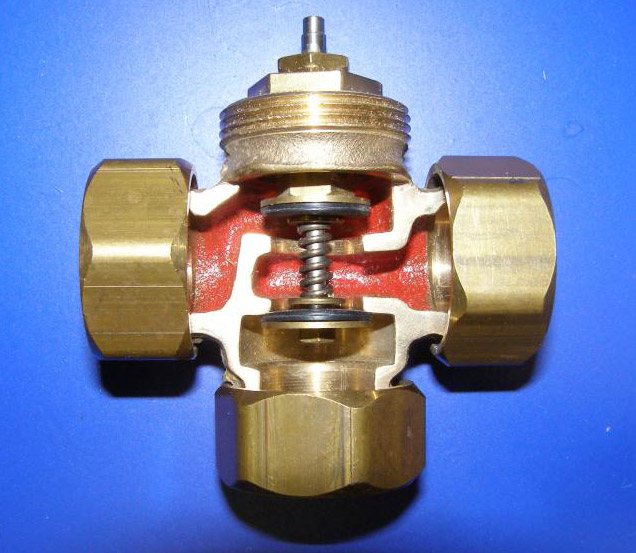

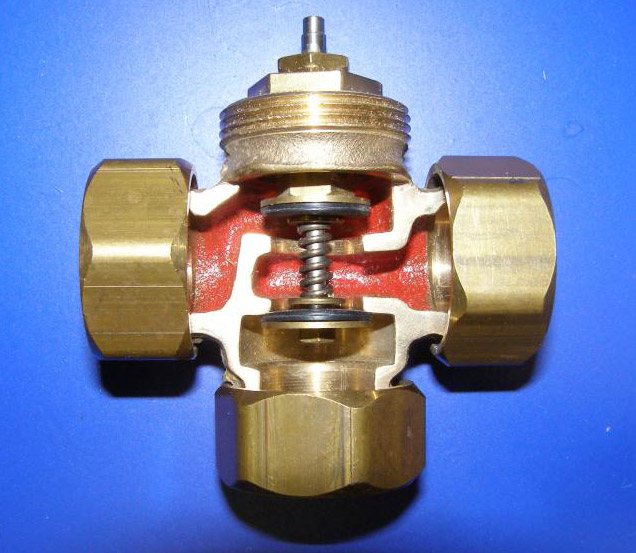

The key parameter of any three-way valve is throughput, i.e. the volume of water that the device is capable of passing through itself per unit of time. When choosing a device, this parameter should be correlated with the boiler performance.

One more nuance should be taken into account here. Even if the diameter of the inlets and outlets of the valve seems to be suitable in size, this in no way indicates the actual capacity of the device. This parameter is entirely determined by the internal section of the holes, which, depending on the design, are closed by a ball lock or a regulating head.

In some models, the dimensions of this hole can be 4 times less than the inlet diameter. In order not to be mistaken and not to be faced with the need to rework an expensive unit, you should carefully study the accompanying documentation before buying.

Another important parameter of the device is the cross section. Ideally, the valve should fit exactly the dimensions of the pipes of the heating system. If an exact match cannot be achieved, you will have to buy adapters.

In addition, you should pay attention to the following nuances:

- It is imperative to check the availability of accompanying documentation: warranty coupons, instructions for installation and operation, certificates and licenses.

- When choosing a material, you should give preference to brass or bronze. It is these metals that are best combined with hot liquids, and also have a low level of thermal expansion. You can distinguish products made of non-ferrous metals by weight - they are much heavier than cheap “stamping” made of pressed powder materials that do not have the required level of strength.

As for specific models, on the market you can find products of several companies that have long established themselves as reliable manufacturers:

- Esbe... A Swedish company whose products are distinguished by reliability, good performance and attractive appearance.The warranty period is at least 5 years.

- Valtec... A joint Russian-Italian venture producing thermo-mixing valves that combine affordable cost and good technical characteristics. The whole range of devices is guaranteed for 7 years.

- Honeywell... An American manufacturer, who has placed at the forefront the ease of installation of manufactured products. Three-way valves of this brand have a striking design, high reliability, but also no less high cost.

We recommend that you familiarize yourself with: How to choose a brass water-folding ball valve

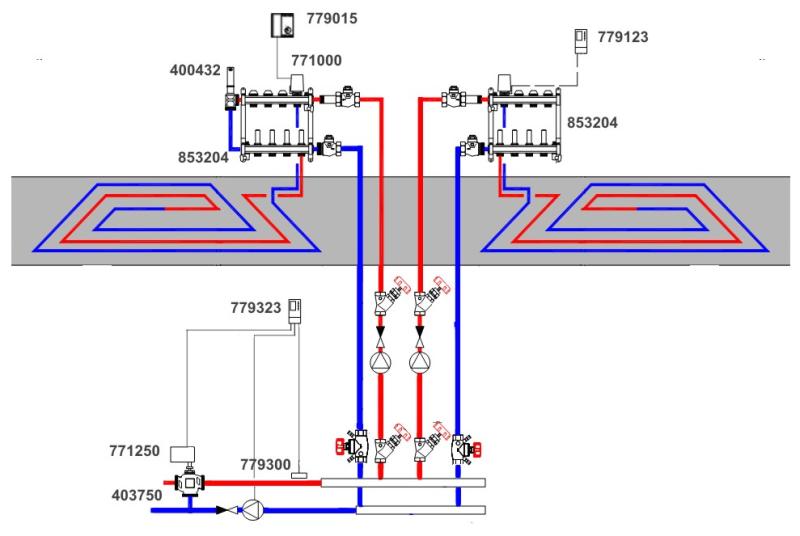

Types of collectors and their features

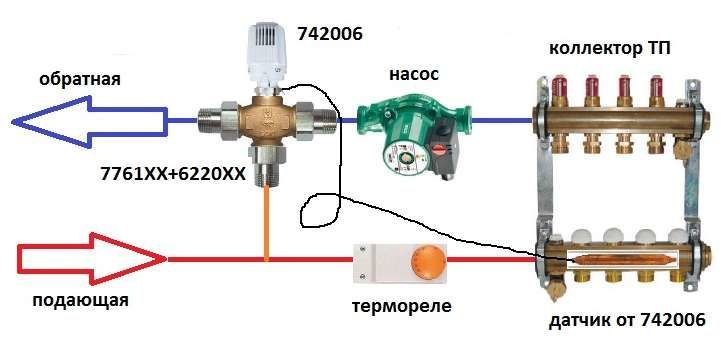

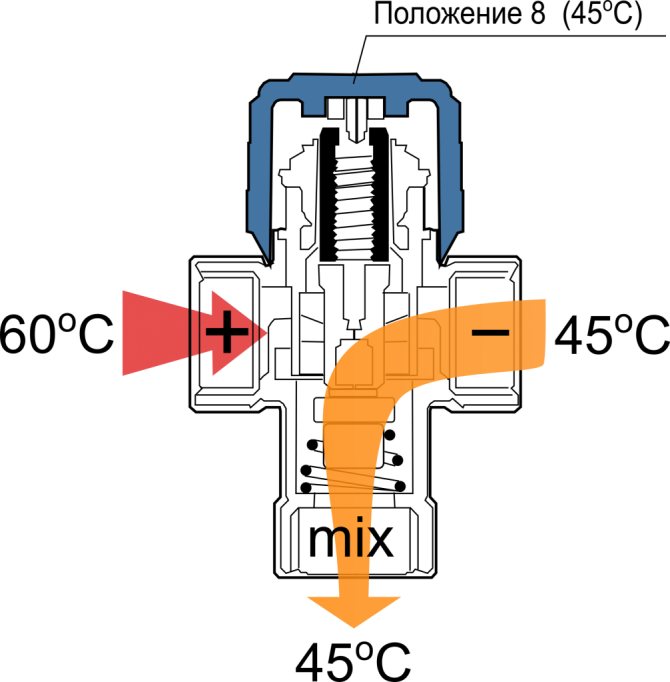

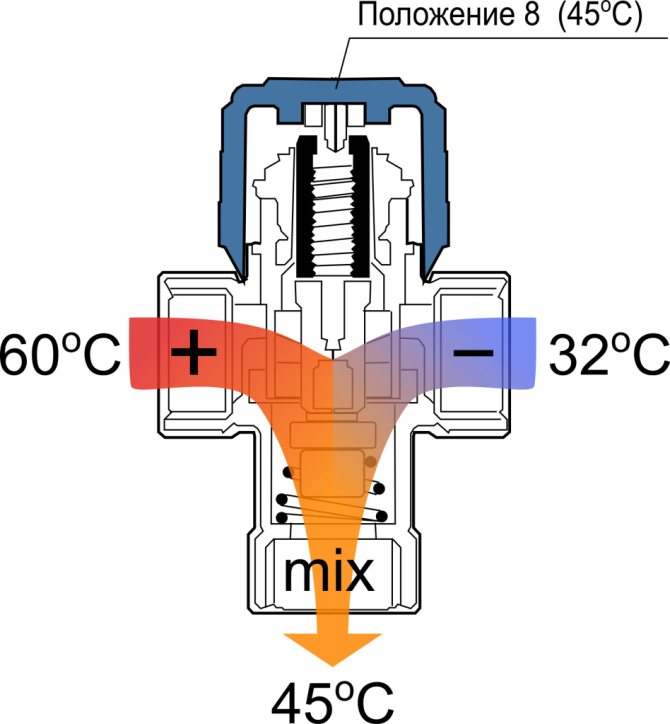

The work of type No. 1 is based on a three-way valve for a warm floor, the task of which is to combine a new heat source from a heating boiler with a spent cooled one.

The throttles are equipped with a servo drive, by which the thermostat and weather sensors are controlled. This type is the most optimal, but at the same time it has some disadvantages.

First of all, I would like to highlight the situation when the valve, upon notification of the thermostat, can open in full and run a large amount of hot liquid into the pipeline, the temperature of which varies within 90 degrees.

A sharp jump in the heat source can cause a rupture of the coolant, since the pressure in it becomes too high. Another disadvantage of this method of regulation is the high throughput. This is challenging because any change in temperature setting can affect floor heating.

Even if there are drawbacks, hidden heating with a device of this type is considered an indispensable assistant in heating rooms with a large area.

View No. 2 is equipped with a two-way control valve. Unlike the previous version, the combination of a heat source is not performed upon notification of the thermostat, but in a constant mode, which prevents the risk of an increase in the set temperature regime of the floor.

Moreover, the thermostatic 2-way valve has a small flow capacity, which allows uniform and stable regulation of temperature conditions. But at the same time, experts do not advise installing invisible heating devices equipped with such a system in rooms larger than 200 m2.

Two types of thermostatic valve in the direction of flow

One of them is chosen based on the ease of installation in a specific scheme, and on the type of installation.

- The first type is a T-shaped scheme... In it, the outlet stream flows out of the middle, and hot and cold water enters in opposite directions. This scheme is also called symmetrical.

- Second type - L-shaped scheme, asymmetrical. Hot water is supplied here from the side, cold water - from below, and the mixed flow, respectively, from the opposite channel to the hot inlet.

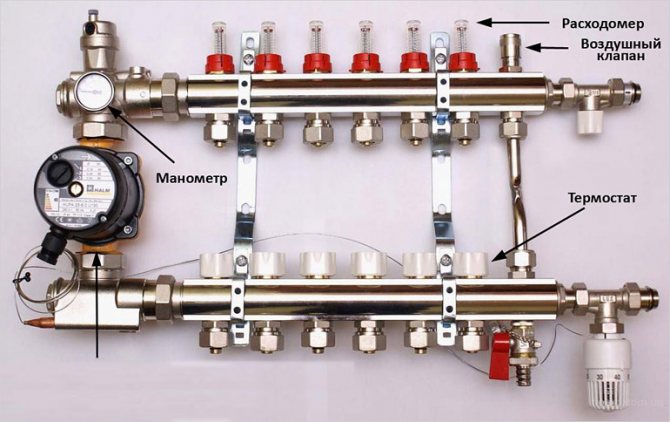

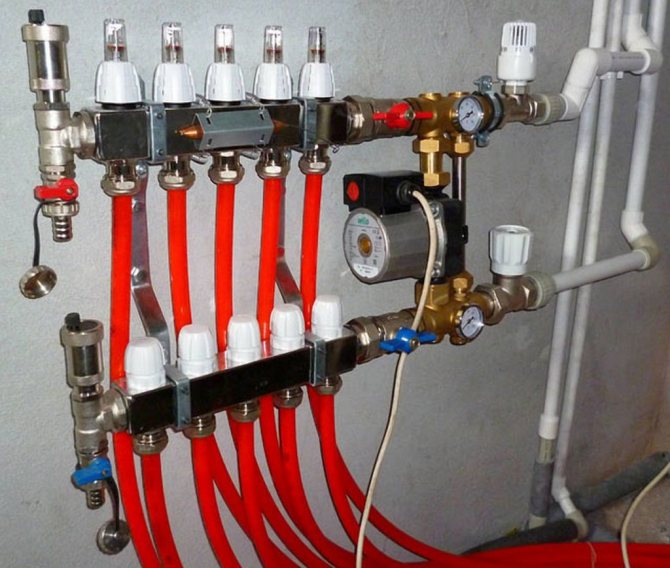

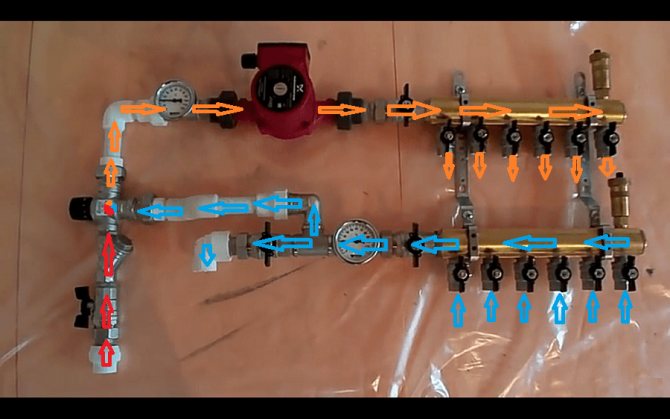

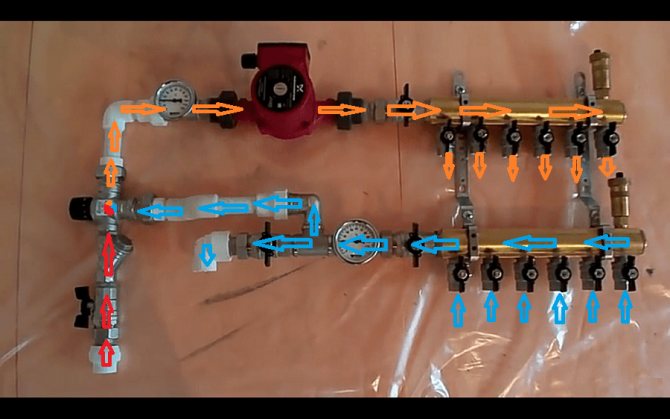

Manifold distribution unit

The collector is one of the important parts of the heating system, which is responsible for adjusting the mode of the heating element. The main task of this device is to distribute the heat source through the pipeline.

And in order to get a full-fledged and productive operation of the collector, you need to equip it with thermal valves and a flow meter. If you resort to the help of specialists who install the valtec floor heating mixing unit themselves, they will select all the necessary accessories for installing the manifold block.

Installation steps

All measures for connecting such a device must be carried out by specialists. In addition, many firms that sell mixing units and underfloor heating systems, as well as a mixture for underfloor heating screed in Moscow, offer their installation services, giving a long warranty.

But if you decide to connect a mixing underfloor heating yourself or are simply interested in how to connect it correctly, then our information will be useful.

So, all activities are divided into 5 stages:

- A place for the collector is identified and the supply and return pipes are supplied.

- The valves and the manifold for the underfloor heating are connected, after which preparation for the installation of the circuit is carried out.

- All connecting temperature and pressure sensors are installed.

- Then the mixing unit for the underfloor heating is set up with our own hands and several test starts are performed to check the correct operation of the device and the entire system.

- The system is tested for air tightness. In the absence of leaks and correct operation, the installation is considered complete.

Installation process

Valve installation consists of connecting it to the correct piping. Before connecting, it is necessary to make sure once again that the connection is correct and that there are no errors.

For connections, the device has an external or internal thread onto which a union nut (or corresponding fitting) of the pipeline is screwed. First, it is necessary to wind up the thread with a sealing material - FUM tape, natural or other materials.

When connecting, use the standard gaskets supplied with the product, or use separately purchased gaskets of the required thickness and diameter purchased from the store. All connections must be fairly tight to avoid leaks, without misalignment along the thread.

Attention! The operating conditions of the device are rather difficult, the density of threaded connections can be weakened from high temperatures, therefore, you should treat the valve connection responsibly.

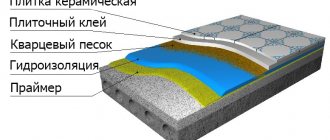

Laying schemes for a water-heated floor

First of all, you need to remember that the uniformity of heat distribution in the room depends on the method of laying the water-heated floor. This is because the water passing through the pipes gradually cools down. Therefore, you need to start the installation from the walls, moving along the laying pattern to the center or exit.

The "snake" laying scheme leads the pipe first along the perimeter of the outer walls, then from one of the walls it goes back in a wavy line.

The "snail" laying pattern constantly goes along the perimeter of the room, narrowing towards the center with each new circle (you need to lay the pipe through one row to leave room for the return stroke). The combined installation scheme includes both of the above. For example, half of the room can be laid with a "snake", half - with a "snail".