Underfloor heating is now available in many implementations, ranging from classic water-based to modern electric film elements, also known as infrared underfloor heating. At the same time, the list of materials from which it is possible to effectively form a floor covering has expanded, in order to provide both heating of the room, and the durability of such a structure, comfort and ease of use.

There are a number of features in the bundle of film floor heating and laminate that will have to be taken into account.

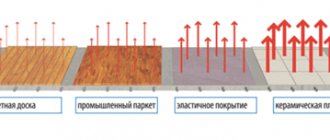

First, the choice of flooring. Conventional laminate flooring is not suitable for these tasks. Under the influence of high temperature, it can deform, shrink and crack. The thermal conductivity of common material is not suitable for efficiently transferring heat from the heating element to the surface. So the choice should be stopped on special offers from manufacturers, where the compatibility of the laminate with warm floors is indicated.

On the packaging of the laminate, there must be an emblem denoting a warm floor, moreover, it is electric. Option marked H20 does not fit. Further, the temperature regime is indicated, usually 27-28 ° C, some options reach 32 ° C.

There are also restrictions on the underfloor heating film itself. A standard requirement, more precisely, the prohibition of laying plates in those places where the installation of stationary furniture or equipment is implied. An exception may be furniture with high legs, under the stops of which additional reinforcement is specially made, which does not give a load on the film element.

Further, the design must operate within strict operating and maximum temperature limits. For certain types of laminate, the manufacturer indicates different readings of the maximum temperature and is almost always 28 ° C. Accordingly, the film element should only be adjusted up to this maximum mark. This can often be achieved with a control unit.

Characteristics of a "correct" substrate

Of course, in every case substrate requirements will be individual - they depend on the type heating elements, finishing coverings, rough basics and in general operating conditions... However, a basic list of optimal substrate properties can be applied in each case.

- The main requirement for the substrate is heat and waterproofing qualities, without which its benefits will be completely reduced to zero. The quality of the heating system will depend on these indicators.

- Professionals consider an important parameter also the ability of the substrate to provide thermal radiation reflection.

- Since the floor must be in direct contact with the heating components, it is also appreciated. ability to withstand temperature changes.

- In addition, good the substrate does not allow moisture to pass through, which is formed during the heating process.

- Resistance to deformation, since changes in the structure of the base can lead to serious malfunctions in the underfloor heating system.

- Environmental purity.

- In addition, it is worth noting and soundproofing - some models of electric and water floors have a slight noise effect, which does not contribute to comfort. therefore soundproofing the substrate will not be superfluous.

In addition to the performance properties, the underfloor heating should be easy to install... This will allow reduce installation time and reduce financial costs.

Back to content

Important functions

The choice of underfloor heating substrates is an important point.

When laying the substrate, it is necessary to connect the joints well

Attention should be paid to the following characteristics:

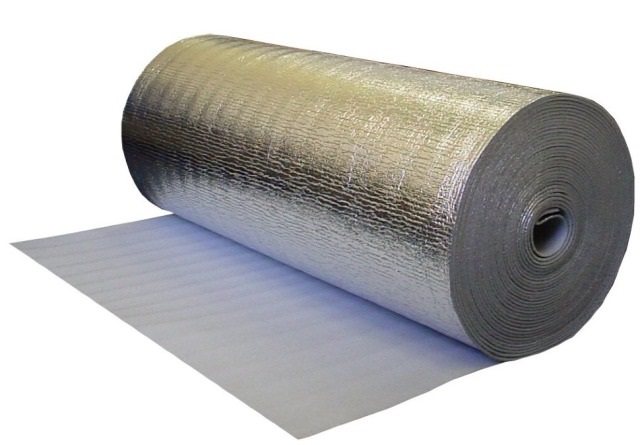

- Thermal conductivity... The smaller it is, the better the substrate works. This parameter depends on the material of manufacture of the product and the thickness of the layer. Modern liners have a foil-coated surface layer to enhance the effect by reflecting infrared rays. Heat saving parameters can be increased by 30%. The materials used today comply with construction standards.

- Manufacturability... The easier the materials are to work with, the easier it is to deal with them. Expanded polystyrene is considered to be the most technologically advanced. From it, thin substrates are obtained, the thickness of which is rarely more than 5 mm. Use regular scissors to cut them.

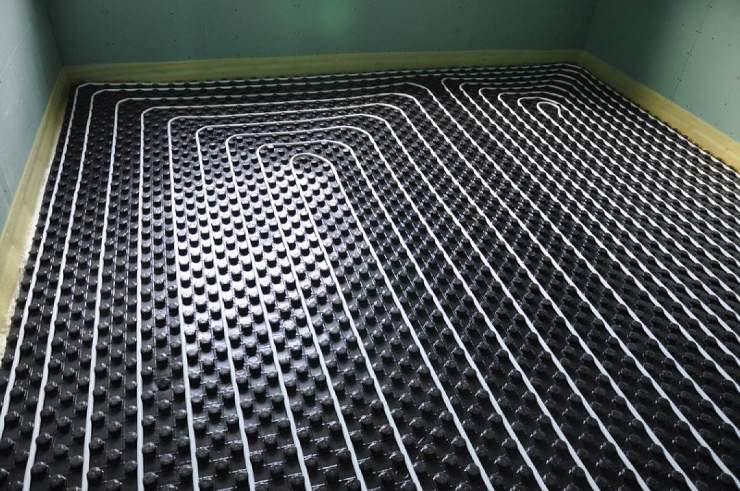

- Additional properties... Some products have special protrusions on the surface. There may also be a mesh drawn on the front side. These components simplify the pipe-laying process and make it possible to fix them at the same time as laying. As a result, it is not only possible to speed up the installation of products, but also to ensure long-term and stable operation of the system.

In this video you will find out whether penofol is needed under the underfloor heating screed:

Laminate underlay

When choosing a base for a warm floor, special attention is paid to compatibility with decorative coatingthat will stand on heated interlayer... Despite the fact that the substrate will be separated from the floor surface precisely by heating elements, its relationship with the finishing coating suggests its own nuances. The peculiarities of this combination can be considered using the example the most sensitive finishing surface - laminated board... Although the production of laminate does not imply the direct use of solid wood, the structure of this material contains wood inclusionsthat provide the coverage with appropriate characteristics... As a result - the panels take over both the pros and cons of a conventional board... It should be noted that substrate on a warm floor under a laminate, unlike other decorative coatings, it is a prerequisite.

In addition to eliminating the risk of damage to laminated panels as a result of floor heating, the base under the warm floor thereby protrudes noise isolatorwhich reduces the noise generated during floor work, without transferring vibrations and vibration effects to the finishing surface... In this regard, the optimal floor height for laminated flooring should be from three millimeters... During the operation of the floor, such bases undergo unfavorable sealing processes, however, the insulating parameters and properties of the substrate will not be lost in this case. In general, the thickness of the underfloor heating must determined based on the specifics of the finishing layer... Too high altitude will not allow warmth pass through it, and thin-layer material, as a rule, does not possess sufficient qualities of sustainability to mechanical damage.

Now it's worth going to the procedure installation of flooring from polyethylene substances under laminated boards.

Back to content

How to choose a substrate for water heated floors

Any underfloor heating system must provide high heat transfer. At the same time, thermal energy should not go to no one knows where. If the warm floor is based on water technology, then in the event of a possible accident, the substrate will also serve as a waterproofing agent.

Often, manufacturers use foil as a base for the substrate. It perfectly reflects heat, which will not be spent on heating the ceiling of the neighbors on the floor below. If the thickness allows, then the foil can be in pure form, or on the basis of various polymers. Together with good thermal insulation, a high-quality substrate also has high waterproofing characteristics.

For water heated floors, manufacturers offer products from extruded polystyrene foam or from cork in rolls. Isoplast is also used. Still, one of the most reliable and popular is expanded polystyrene.

In some cases, special foam-based molded coatings can be used. It is very easy to fix the pipes of the system in it. Roll materials should not be fixed in any way. The substrate is laid on a layer of insulation, and then pressed against the reinforcing screed.

Varieties and characteristics of various substrates

When purchasing a position, it is necessary to navigate the types and types of this material.

On sale you can find "Lavsan". This coating is based on polyethylene foam. The upper layer of the material is metallized and reflective. This material is resistant to various aggressive environments. This underlay is perfect for infrared warm floors as well as electric ones.

Lavsan differs in power density. It is necessary to choose the right material for the topcoat. So, for a laminate, a coating with a specific power of 150 W per m2 is suitable. If you lay a material with a higher power density, the coating will deteriorate due to overheating.

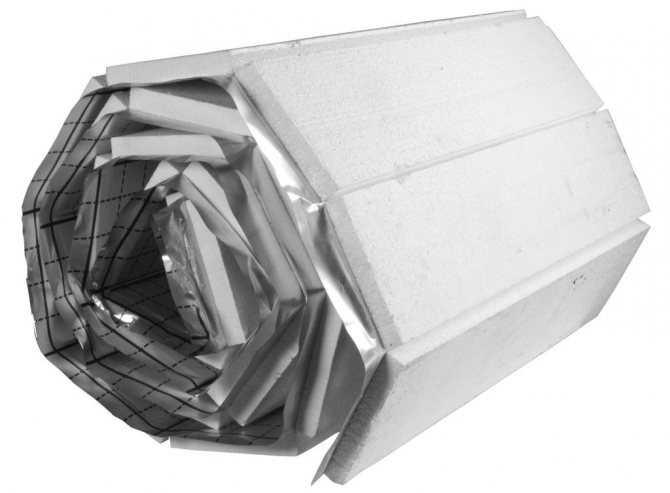

The market also offers expanded polystyrene. It is a cellular insulation that has a very high temperature threshold. The material does not lose its characteristics at temperatures from -180 degrees to +180. Also, foam polystyrene is characterized by crease resistance, and its sound insulating properties are also very high. The covering is either foil or polypropylene. This material is an excellent choice for working with water systems.

The peculiarity of this substrate is that it is produced in sheets with ready-made markings, which greatly simplifies the installation process. On sale you can find slabs with a thickness of 20 to 50 mm.

The cork backing is very environmentally friendly and hypoallergenic. This material is a malfunctioning compressed bark of cork oak with a binder. Among the advantages - this substrate is not eaten by mice and other rodents. The cork is ideal for laminate flooring and all types of warm floors. The plug does not burn, and is also very resistant to all kinds of mechanical stress.

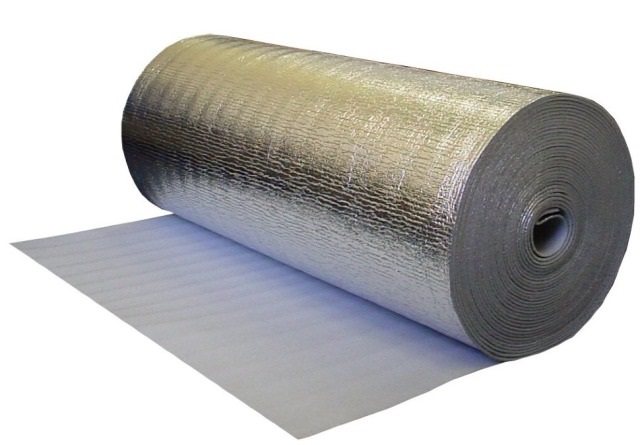

Polypropylene is a combined material based on foamed polyethylene, one side of which is covered with a layer of foil. This structure allows for excellent heat retention. The material is practical and also very durable. For an electric underfloor heating, this product should not contain aluminum, as there is a risk of short circuits.

Underlay for water floor systems

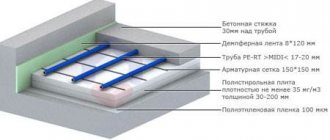

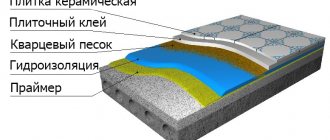

Regardless of the design of the warm floor, the role of the substrate will boil down to ensuring maximum heat transfer, which will allow the heating layer to more efficiently distribute heat through the decorative coating. However, in the case of floors in which work is envisaged liquid heat carrier, the functions of the substrate are complemented by the need to create waterproofing barrier - that is, it must be impervious to moisture. This quality is not so important if the substrate is laid under the film warm floor, but for the operation of water floors, this circumstance is directly determines heating efficiency.

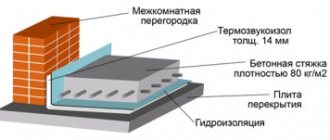

When laying plumbing it is recommended to use decking, which will also perform the task of a reliable basis for the installation of elements that regulate the circulation of the heat carrier. Such layers are characterized by the presence of special protruding components, intended for the installation of the entire water supply complex. Often such schemes are made of polystyrene.

In addition, during the installation of a heating coating with a water thermal carrier, it often occurs the need to lay an auxiliary reinforced mesh... This component will serve as plumbing fixer heating floor.

Such underfloor heating has the form of a "pie"including an interlayer with a heat insulator and a mesh layer.

Back to content

Underlay for warm electric floors

The underfloor underfloor heating is structurally similar to the options described in the previous section. But almost all models of such underfloor heating do not require preliminary laying of a waterproofing material under the substrate.

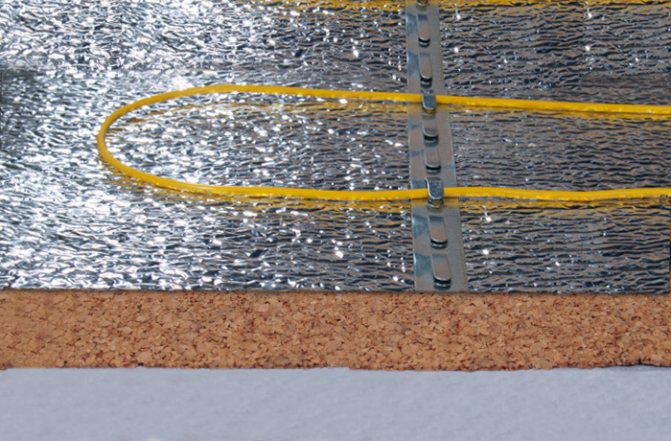

The surface is pre-leveled. Then a substrate is laid on it, on which a special mounting tape is attached. The heating cable is attached to it with special brackets.

Important! When installing under electric underfloor heating, it is not recommended to use such a material as a foil underfloor heating. This is explained by the fact that metal (foil) is a conductor, and if the contact in the system is broken, the probability of a short circuit is very high

The most suitable material in this case is a substrate made of the following materials:

- PP (polypropylene);

- Penofol (metallized film);

- Bung;

- Foamed polymers.

The leader in thermal insulation for underfloor heating is Energofloor Compact.

Infrared flooring

When laying infrared structures, use flooring with heat-reflecting thermal insulation qualities... In this case, the installation of the substrate is carried out right under the cover tape... In addition to roll flooring as a thermal insulator cork backing can be used under the warm floor, wood fiber tiles and magnesite parts... In the absence of such a flooring foil layer - you can use the above technology creating a "pie" from a thermal insulator and a foil layer.

Not a bad choice of material for insulating decking under the film coating will become and penofol with reinforced structure. It is different good thermal insulation properties and the presence of a foil layer that minimizes heat loss in the room.

Flooring for a film floor can be made from ordinary fiberboard or from the same magnesite panels. But in such cases, it is installed directly onto the cement screedpre-coated with aluminum foil.

Back to content

Products with electric heating

The underlayment for an electric underfloor heating is made of pressed cork and foil plastic. Products with increased thickness are made of extruded polystyrene foam. They have increased indicators of physical strength, due to which it is permissible to lay them under concrete. The underlay is used for all electrically heated floors, including standard versions. If the base is defective, it must be leveled. In this case, it is permissible to use chipboard and OSB substrates.

Read the same: about the properties of expanded polystyrene.

Polyphom is another option for a substrate. Here, polyethylene foam is combined with aluminum, paper and metallized film. Sheets are stacked in layers close to each other. In areas where moisture can seep, it is necessary to connect the polyethylene sheets with tape.

You can lay the underfloor heating yourself

An aluminum reflective layer is undesirable for electric floors, since in case of insulation failure, current leakage with negative consequences is possible. The reflective layer is installed on a polyethylene film and equipped with vacuum deposition. When choosing a specific brand, factors such as the topcoat should be taken into account. The lighter it is, the less durable the underfloor heating will be. Extruded materials are used for artificial stone and ceramic tiles.

In this video you will find out if you need foil for a warm floor:

When arranging a warm floor during the renovation of old premises, the total thickness of the "pie" ranges from 10 to 15 cm. It depends on the load-bearing floor and floor technology. These parameters are important when designing the height of window and door openings. When renovating, you need to make the floor thinner in advance. Thanks to this, there is no need to further reduce the height of the doors.

It is best to install a warm floor that does not interfere with opening and closing doors. The most unfavorable option is to equip the system, because of which it is necessary to lift the lintel of the doorway.

General nuances of installation

When installing the substrate under different types of finishing coat the following laying rules should be observed:

- In all cases, foil the reflective surface must point up... By the way, a substrate under an infrared warm floor with a foil layer capable of holding up to 97% heat fluxes, which is essential increases productivityb installed warm floor.

- Base flooring fits only according to the "butt-joint" method... It helps to avoid heat loss in these areas. metallized tape - with its help you should perform all connections substrate. In addition, such a mount will perform and moisture barrier and steam vapors.

- Heating components regardless of the heat source and the heat carrier itself must be installed on top of the layer, which will reflect thermal radiation.