Often, the facade in a private house is one of the very last stages, when the construction has already eaten up all the money. Therefore, many decide to do it on their own, without hiring professional builders or call friends for help. The technology of work is being violated. Well, what, for a neighbor 10 years it costs so much and nothing! Yes, in the best case there will be nothing, and in the worst case you will not be able to live in such a house. To avoid popular mistakes and get the job done right, learn these important rules.

Warming options

There are 2 facade insulation systems:

Mineral wool (WM). Mineral wool is vapor-permeable, does not burn, insulates and insulates well. Suitable for any base. Ideal, but expensive - plaster, paint and primer must be vapor-permeable.

Polyfoam (VWS or PSBS). Suitable for thermal insulation of monolithic reinforced concrete, three-layer wall concrete and reinforced concrete panels. Walls made of expanded clay concrete or solid bricks can be insulated only for dry rooms. The minimum density of foam for insulation of the facade is PSB-S25f. Everything below is suitable only for interior work, it crumbles on the street.

Extruded polystyrene foam is only suitable for insulating the basement. It is vapor-proof and well suited to protect against moisture penetration from the soil to the base of the house. Without sanding the surface of the EPS, it has poor adhesion, the glue will not hold well.

Materials (edit)

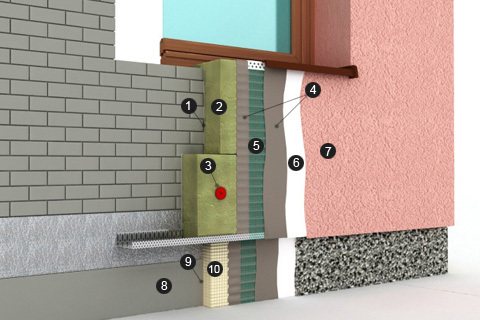

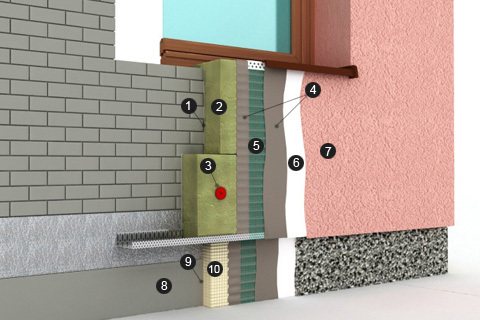

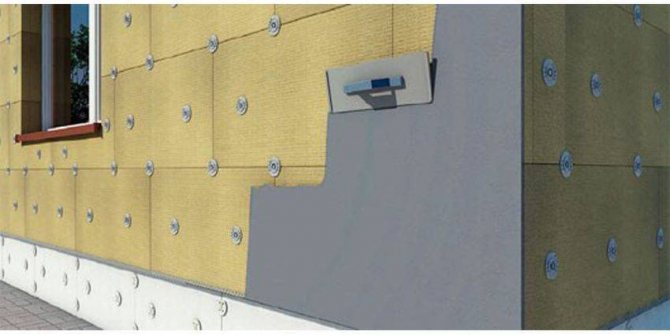

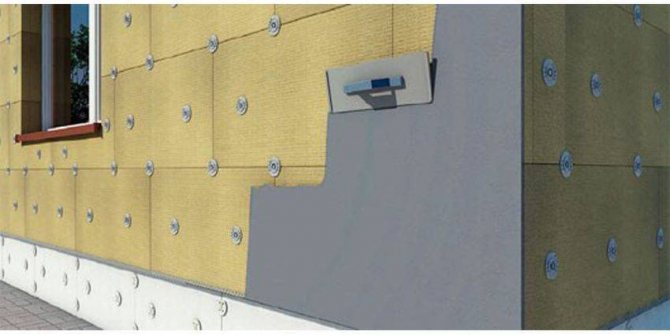

As mentioned above, the wet facade is made of insulation plates glued to the wall and plastered on top. When insulating the facade with a wet method, it is necessary to use the following types of materials.

- Only foam or mineral wool is used to mount the system. And each meets some requirements:

- Polyfoam, which is used to insulate the facades, must be low-combustible, intended specifically for finishing work. The use of extruded is more preferable, since it has a lower heat transfer rate;

- The second option is to use mineral wool. This type of facade will cost a little more, but this has its advantages. The material is immune to the effects of open fire, and also has a high vapor permeability, which allows you to create a "breathable structure". The permissible density of the boards should be at least 150 kg / m3, and the tensile strength should be 15 kPa.

- The glue solution, with the help of which the insulation is adhered to the wall, must be made on a mineral basis with mixing polymer additives. Such a composition increases its operational characteristics;

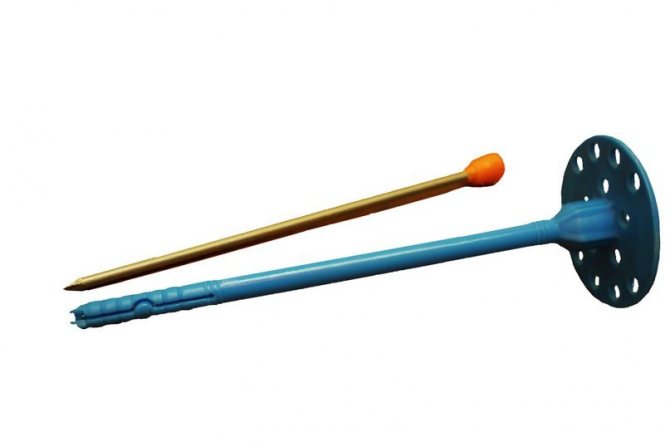

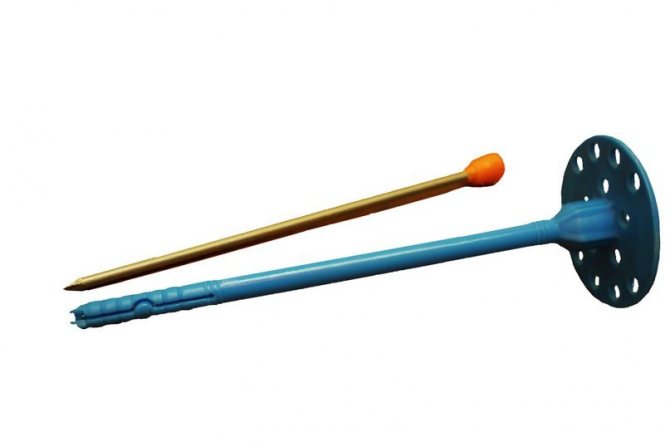

- Mechanical fastening. An ordinary plastic dowel with a head with a diameter of 7-8 cm. Its use allows you to additionally fix the insulation. There are two different lengths of "umbrellas": 8 and 25 cm. The specific choice of size depends on the thickness of the insulation and the distance between it and the wall of the house;

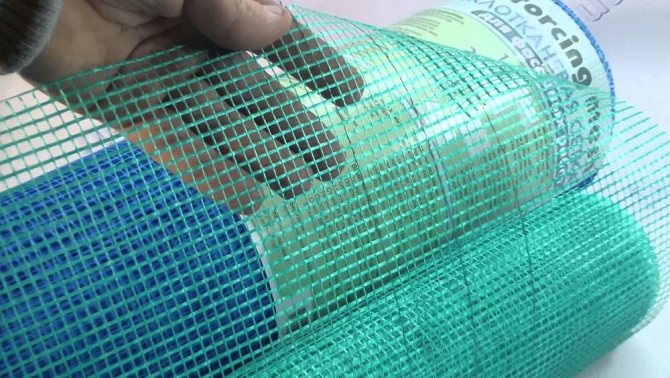

- Reinforcing mesh. Without its use, not a single type of plaster or glue will hold on to the surface of the insulation. In addition, it allows you to create a solid surface without mounting seams between sheets of foam or mineral wool.

- For the installation of a wet facade, only mineral wool or foam is used

Plastic dowel additionally secures the insulation

Without a mesh on the surface of the insulation, the plaster will adhere worse and fall off

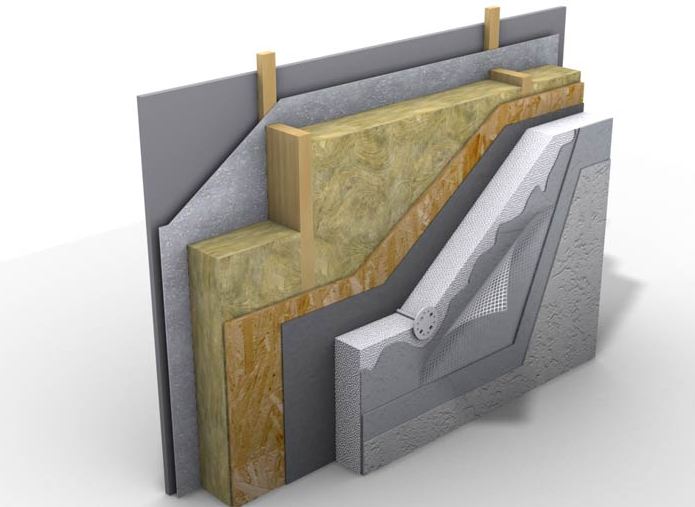

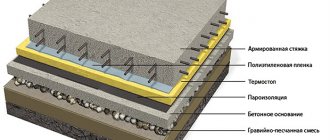

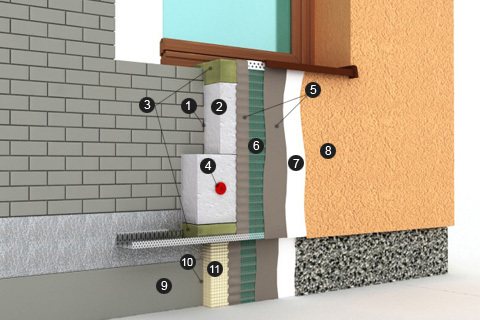

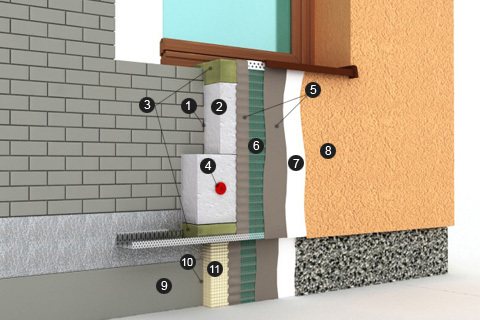

Warming cake

When insulated with mineral wool, the cake is as follows:

- Priming layer,

- Adhesive composition,

- Mineral wool,

- Disc dowels,

- Base layer of plaster,

- Glass network,

- Primer,

- Decorative plaster.

With foam insulation:

- Priming layer,

- Adhesive composition,

- Styrofoam,

- Mineral wool notch,

- Disc dowels,

- Base layer of plaster,

- Glass network,

- Primer,

- Decorative plaster.

For the base:

- Waterproofing,

- Glue,

- Extruded polystyrene foam.

Wet method of insulating the facade of a house

Preparation of walls before thermal insulation of the facade of the house with a wet method:

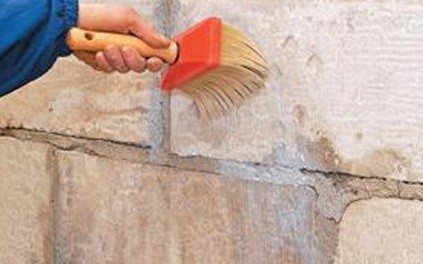

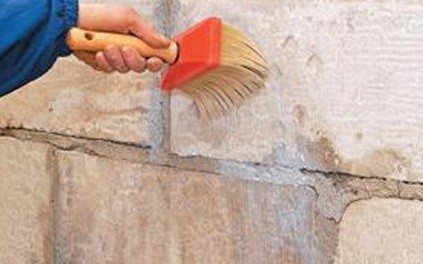

1. We prepare the surface well, remove any dirt.

2. We align the walls, eliminate cracks, if any.

3. Remove remnants of old plaster from slopes and openings.

4. Fully prime all facade surfaces.

The process of installing the profile on the base.

An important and prerequisite is to install a support bar! From below, a metal bar is fastened along the level (basement profile) so that the mineral wool slabs are laid evenly and to protect against rodents. It is on this profile that the main insulation system will rely.

To do this, we mark the entire perimeter of the building along the basement.

• We fix the support bar 30-40 cm from the ground surface.

• We leave a gap between the strips of 2-3 mm, so that there is an opportunity for the expansion of materials when changing temperatures.

• The profile itself is fastened with dowels in increments of approximately 20 cm.

How to apply adhesive to thermal insulation?

We glue the sheets of heat-insulating insulation on the prepared and primed facade of the house. First, we apply the adhesive to the entire perimeter of the insulation and a couple of dots in the middle. This will significantly reduce consumption while maintaining good strength. According to the rules, it is necessary that the adhesive should cover up to 40% of the area of the insulation.

• the slabs are fastened to the wall so that the vertical seams of the lower row at the joints are overlapped by the slabs of the upper, next row, at a distance, continuous seams must not be allowed! This also applies to corners.

• keep the distance between the seams of the heat-insulating plates to a minimum, and press the back side of the plates tightly to the base when fixing with glue, fix the side of the plate tightly to the adjacent one;

• if there was an excess of glue, and it protrudes at the seams, it must be removed immediately, without allowing it to dry.

After you have glued on the layer of thermal insulation, dry it thoroughly. This will take about 2-3 days, after which it is necessary to additionally strengthen the thermal insulation with dowels, taking into account the porosity of the material.

The sequence of fixing the insulation with dowels:

The glued insulation is additionally fastened with special dowels, called fungi, at a distance of about 30 cm from each other.

• to begin with, completely make all the markup;

• tightly join the disc-shaped parts of the plates, drill holes for fastening;

• hammer in the dowels themselves according to the markings.

Wet facade reinforcement mesh installation technology.

A few days after fixing the insulation, you can mount a fiberglass reinforcing mesh, which is fixed to the mineral wool using an adhesive with a thickness of 3-5 mm. First, window and door openings and corners of the building are reinforced, preferably with the help of special corner profiles with a mesh.

The walls themselves are reinforced at the end. The overlap of one reinforcing mesh on another must be at least 10 cm.

The sequence of installation of reinforcement on the insulation of a wet facade:

• a layer of glue is applied to the insulation;

• then the reinforcing mesh itself is fixed with glue;

• a covering layer of 1-2 mm glue is reapplied on top, which finally fixes and covers the entire mesh.

Remember! According to the technology, the layer of mesh plus glue should be 6-7 mm thick, no more. The gaps between the reinforcing layer and the outer surface are no more than 2 mm.

When the covering protective layer is dry, the surface is primed.

The final stage is finishing the walls of the wet facade.

So, we have come to the final stage of finishing - finishing plastering of the walls. Dry all the previous layers well again. In warm sunny weather, it will take about a week. The final finish must be moisture resistant and have good vapor permeability. And also withstand mechanical stress and temperature fluctuations. Once again, we proceed to work in dry, calm weather.

For finishing a wet facade, finishing with decorative plaster with painting or simply applying a vapor-permeable facade paint is suitable.

Insulation or thermal insulation of the facade of a house with a wet method, as you can see, is a fairly simple technology and is available to people who have already encountered decoration and are familiar with materials such as plaster. With a competent approach, you can insulate the facade of your house yourself, but even if you decide to hire a professional team, knowing the technology, you can easily control the quality of execution and compliance with all technological nuances.

Watch the video: Insulation of the facade of the house using the "wet" method

https://youtube.com/watch?v=TvgmhmRfk10

Source - Build your own house

Insulation from the inside

In no case should a residential building be insulated from the inside. This is the same as tucking a fur coat into panties. Here's an example of what happens when you insulate a house from the inside:

Mold and mildew have now developed in the place where the extruded polystyrene foam touches the wall. This is because the dew point has shifted inside the room. Now it is always wet there, any foundation will collapse: even brick, even concrete.

The only option when insulation from the inside is justified is on the loggia. But you need to make a good vapor barrier. The room must have good ventilation, otherwise it will be impossible to live in it - it will be inside like in a package.

Variety of systems and types of thermal insulation

Currently, there are various thermal insulation systems and various types of thermal insulation materials on the domestic market.

Initially, the process of choosing the required thermal protection of buildings is determined by the task and the planned budget.

It should be borne in mind that there is external thermal insulation, intended for the production of insulation work from the outside, and there is an internal one, which can only be used indoors.

Thermal conductivity of thermal insulation materials, their density and thickness, as well as the presence of additional properties or elements, for example, such as the presence of a foil or self-adhesive layer, are of great importance when choosing a specific type of thermal insulation.

The characteristics of thermal insulation materials, their specific properties and additional parameters, as well as reviews and advice from specialists, ultimately determine the choice that the consumer makes.

Foil reflective insulation

One of the most used options for insulation, used not only in everyday life, but also on an industrial scale, is thermal insulation with foil. It is produced on the basis of foamed polyethylene foam, mineral wool roll insulation of the MBOR type, as well as in the form of separate basalt mats or slabs of various thicknesses.

Foil insulation additionally enhances the fire-resistant properties of building elements and increases their group of fire-retardant efficiency. Naturally, reflective thermal insulation, in addition, significantly reduces the thermal conductivity of the thermal insulation materials themselves, as well as the structures enclosed by it.

The advantage of rolled thermal insulation can be considered the convenience of its use and a large set of available thicknesses, up to very thin options.This becomes very important when insulation is carried out in a confined, narrow space, for example, on a balcony, in attics and attic rooms, where the issue of the volume of space is of paramount importance.

Nevertheless, modern high-temperature thermal insulation makes it possible to obtain excellent fire-and-heat-shielding characteristics even with small thicknesses of heat-shielding material.

Foamed thermal insulation

Recently, the use of foamed thermal insulation has become quite popular, which allows quick and effective work to enhance the heat-shielding properties of various equipment and household premises.

Ultra-thin thermal insulation made of foamed polyethylene can have a self-adhesive layer, as well as have an additional foil coating. The range of thicknesses offered by manufacturers for this type of thermal insulation is so wide that it will meet the needs of the consumer for any type of insulation work.

The most famous type of foamed thermal insulation on the domestic market is Penofol thermal insulation, which is in constant demand among Russian consumers.

There is also a large number of similar heat-shielding materials, for example, self-adhesive thermal insulation "Magnoflex" or "Black Start Dact Al".

Thermal insulation with mineral wool

In addition to foamed polyethylene, one of the most popular materials for thermal insulation is basalt wool. Its natural composition allows it to withstand huge high-temperature loads for a long time.

Basalt thermal insulation with slabs is mainly used in the construction of large objects of residential buildings and industrial structures. The issue of thickness is not as relevant here as in the case of thermal insulation made of polyethylene foam, and determines, first of all, not the convenience of its use, but the degree of heat and fire protection of such materials.

For thermal insulation with mineral wool, rolled basalt canvas is also used, sometimes even with an additional foil layer, which makes it a very effective thermal insulation material when carrying out thermal insulation of pipelines.

There is also the possibility of insulation with mineral wool insulation such as basalt mats with various types of covers.

Vapor barrier and waterproofing

Wet insulation stops working. Vapor barrier is often confused with waterproofing. The names are similar, and steam and hydro, unknowingly, can be attributed to moisture. What's the difference?

The vapor barrier does not allow steam to pass through. It is attached to the bottom layer under the insulation to reduce the amount of moisture that will penetrate the insulation.

The waterproofing is vapor-permeable. Waterproofing is also called breathable or diffusion membranes. They release steam from one side, but do not let the condensate drop inside. Waterproofing is attached over the insulation to release moisture that has penetrated the insulation.

If you mix up the layers or put the waterproofing on the wrong side, mold will appear, the humidity in the house will increase, it will become cold, and the corners will blacken.

Insulation requirements

An important characteristic of a heat-insulating material is the minimum thermal conductivity. When moisture gets in, it is desirable that its thermal characteristics change minimally. The service life of the insulation is also important, no matter what insulation methods you have not applied.

The material must necessarily meet several requirements:

- Combine elasticity and rigidity at the same time;

- Be durable;

- Good fire resistance;

- Have low thermal conductivity.

Taking these requirements into account, it is better to use mineral insulation and glass wool.

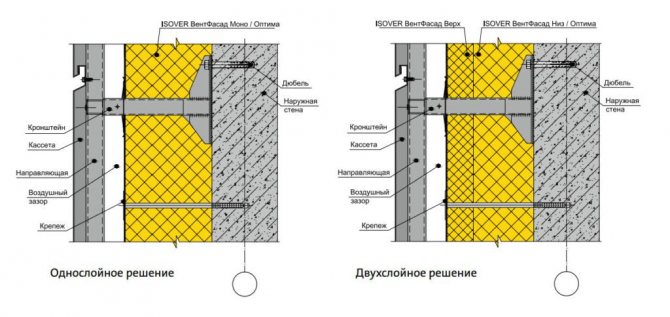

Calculation of the thickness of the ventilated facade

Calculation of the required thickness layer insulation under the ventilated facade are produced in strict sequence.It starts with calculating the heat transfer resistance, taking into account climate features region and temperature values in the house.

The density of the insulation and its blowing

With a small insulation density (up to 80 kg / m3), it is possible that its layer will be blown out by an air flow. As a result, significant heat losses will be observed. For this reason, a vapor diffusion membrane must be placed on top of the thermal insulation material. Insulation qualitywhose density exceeds 80 kg / m3, allows them to be used without protection from the wind.

Primer

Don't skimp on the primer. It is inexpensive, but it increases the adhesion to the surface many times over and does not allow the glue to dry out.

The primer is selected depending on the surface. Check with your purchase if the primer is suitable for your base.

For porous and rapidly absorbing walls (eg aerated concrete or loose cement-sand plaster) use a deep penetration primer. It will de-dust the surface, bind it and reduce absorbency.

If the substrate is smooth (eg monolithic concrete), a quartz sand primer should be used to improve adhesion.

Facade insulation plaster

For external thermal insulation of walls, a conventional cement-sand mixture is not suitable. To obtain high-quality insulation of the facade under plaster, special compounds should be used:

- mineral;

- silicone;

- acrylic;

- silicate;

- warm.

Mineral plasters are dry mixes that must be diluted with water before use. The next three are already ready for use and have a wide color fan. All of them are perfect for arranging "wet facades", the installation of which is supposed to be on heat-insulating materials.

For the arrangement of facades without insulation, "warm" plasters are considered the best option. There are several types of them. They differ in the type of thermal insulation filler. It can be expanded polystyrene balls, dry sawdust, expanded silicon, perlite or vermiculite, cork chips, foam glass. Warm plaster with expanded polystyrene filler is considered the most affordable and effective. It differs from analogues even in its class:

- the lowest thermal conductivity - only 0.059 W / m оС;

- low cost per square meter of finishing with a layer thickness of 10 mm;

- minimum consumption and material weight - one square meter 10 mm thick weighs only 2 kg;

- fire safety - polystyrene foam balls used as a filler belong to the class of non-combustible materials, its fire hazard class is K0, according to GOST 31251;

- good adhesion to any surface, including aerated concrete, aerated concrete and wood;

- durability and resistance to any atmospheric conditions;

- simplicity of application of the material and minimization of technological processes, which, with an excellent quality of finishing, provides a low cost of work.

Do you need fungi?

Yes, plastic dowels with a metal core (they are usually called fungi or disc dowels) are used when attaching insulation, but these are not the main fasteners. It is used for wind protection and as a support during the curing of the adhesive. The plastic around the core prevents a cold bridge from appearing at the attachment point.

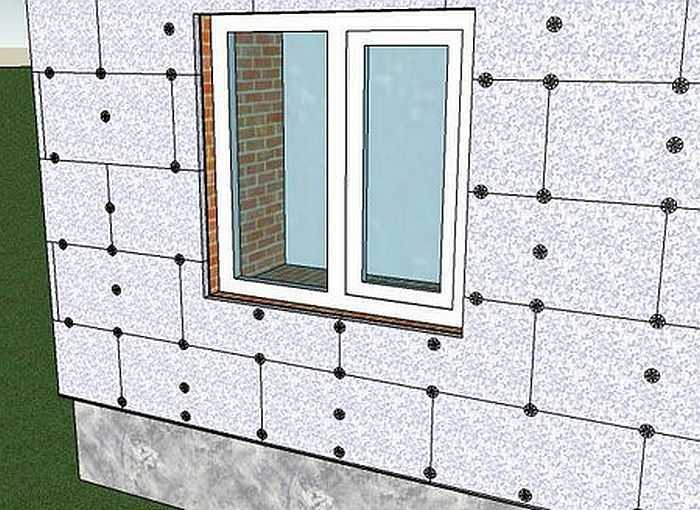

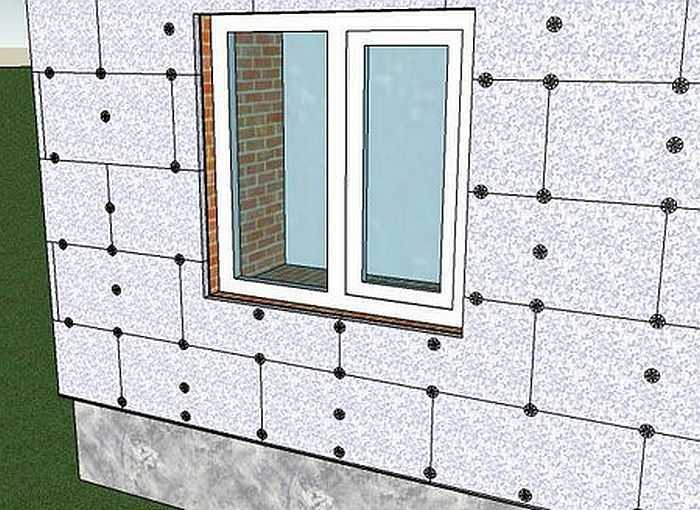

For good fixation, solid sheets of insulation are attached at 5-6 points. But for economy and speed of installation, the main part of the dowels holds 2 sheets at once. How this is done is shown on the model:

Works that we carry out on the installation of the wet facade system

- surface preparation - cleaning from dirt, efflorescence, obsolete coatings, sealing joints, leveling the surface, priming

- installation of a basement profile for fixing the first row of slabs by means of an adhesive composition (from bottom to top, with obligatory bandaging of the slabs)

- fastening slabs with front dowels

- installation of adjoining the insulator to door and window openings, strengthening (reinforcement) of the corners of the openings

- application of an adhesive reinforcing mixture to a layer of insulation and installation of a reinforcing fiberglass mesh

- applying a layer of decorative plaster

All installation work is carried out under certain weather conditions - the ambient temperature is from +50 o С to +30 o С.

Despite the fact that aerated concrete is characterized by high vapor permeability and heat capacity, the final decision on the need to install an insulation system should be made only after analyzing the following information:

- climatic zone in which the house is built

- material thickness, density

- thickness of construction joints

- material from which the mortar is made

Based on the data obtained, we can conclude that the insulation of a house from aerated concrete is performed in the following case:

- if the blocks were laid not on an adhesive composition, but on a building concrete mortar, the use of which leads to the formation of cold bridges

- the density of the building material is higher than D400

- when making load-bearing frames of a house from aerated concrete blocks

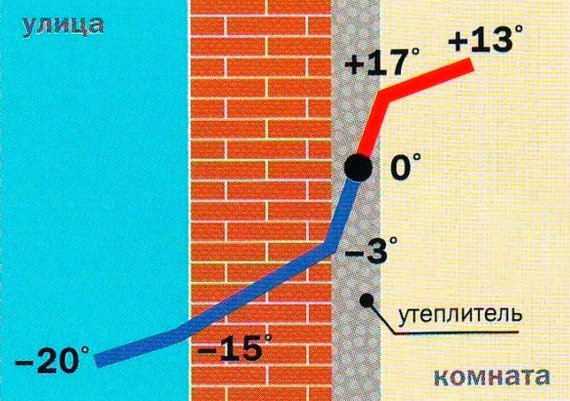

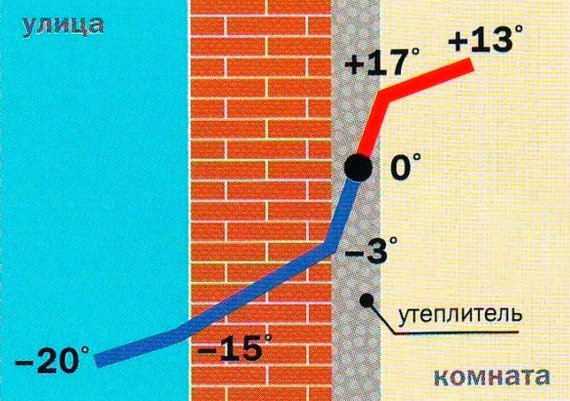

Dew point

In simple terms, dew point is the ratio of temperature, humidity and pressure in the wall where condensation occurs.

The diagram shows an error with insulation from the inside. After insulation, the wall began to freeze completely, condensation appears under the insulation. The same problem can arise if the thickness of the insulation is incorrectly calculated. The mineral wool can be squeezed out like a sponge.

Not sure which insulation to choose? We will help you!

The difference between two insulation systems ("wet" and "ventilated facade")

- Thermal insulation of the facade using the technology "wet facade»Has no restrictions on the building envelope, be it from a monolith, brick of any kind, aerated concrete, moisture-resistant materials, wood, etc. due to the lightness of the constructed system "wet type" in contrast to the "ventilated facade".

- Thermal insulation of the facade using the technology "ventilated facade»Has limitations due to the weight of the system. To start the production of work, it is necessary to conduct surveys for the strength and endurance of the existing facade due to the weight of the subsystem being constructed and the cladding of the building with porcelain stoneware or other facing material.