If you have a country house and gas communications are connected to it, then it will be quite simple to solve the problem of heating water and heating your home. The main requirement is the correct choice of the boiler, which will occupy one of the main places in the heating system.

Almost all modern boilers are reliable, easy to use and safe. However, many factors must be taken into account when choosing them. A huge number of heating boilers are sold all over the world, but gas boilers account for more than half of them. In order to make a choice towards a certain model, it is necessary to narrow the range of searches. First of all, you should decide whether the gas boiler will be single-circuit or double-circuit, floor or wall, with or without a chimney, as well as volatile or operating without the use of electricity.

In order to decide, it is necessary to consider several models. They can be from one or more manufacturers. You can make the task easier by considering boilers from one supplier. Among other proposals, one should especially highlight heating equipment, which will be discussed in the article.

Selection Tips

Gas boilers "Buderus" can be wall-mounted or floor-standing. The former are optimal for areas up to 350 m2. Such devices are distinguished by attractive design, compactness and ease of installation. Depending on the model, the exhaust gases can be discharged through a chimney or a small coaxial pipe. The latter option is safer and cheaper, because the combustion products will be removed outside the house using a simple fan. When installing such a unit, there are no additional requirements for the ventilation system.

Wall-mounted gas boilers "Buderus" can have piezo ignition, which is activated by a special button. You can choose a model with automatic electronic ignition. The latter is convenient, because in case of power outages, the boiler turns on itself as soon as the electricity comes through the wires. But with piezo ignition, the owner must turn on the unit.

In large rooms, floor-standing boilers are usually installed. They are distinguished by an impressive mass, so they cannot be hung on the wall. A foundation is often mounted under them. Choosing a floor-standing boiler, you will have to tilt your choice towards devices with a forced or atmospheric burner. The latter is cheaper, simpler and quiet. The first is characterized by a higher efficiency, but also an impressive cost. The atmospheric burner is included, but the pressurized burner will have to be purchased separately.

When considering gas boilers "Buderus", you should pay attention to details that increase the safety of operation, but entail an increase in price. Among these options are:

- thermostat to turn off the boiler;

- flame sensor;

- traction control sensor;

- blocking the boiler.

As for the flame detector, the element is necessary to shut off the fuel supply if the flame goes out. When you turn off the gas, you need a blocker, so it is better to purchase a model with this function. Pay attention also to the thermostat, it is designed to turn off the unit when the water temperature rises to the emergency level.

The most popular models of Buderus boilers

Let's consider the most famous and widespread models and note their characteristics.

Logano S131

This model is a solid fuel boiler that does a good job of heating small private houses. Today this model is produced in one variation, the input power of which is 15 kW. To some extent, the unit acts as a long-burning boiler.Due to the design features and special settings, it is possible to switch on the mode of slow burning and gradual smoldering of the fuel. The key advantage of such a device is its increased reliability. The combustion chamber with a wide door has a volume of 38 liters. If you load it completely, the fuel will burn for more than two hours. However, there are also disadvantages to the model, for example, to clean the grate, you first need to resort to dismantling it.

Boiler Buderus Logano S131-15H RU

Combustion efficiency depends to some extent on the quality of the chimney.

Logano S171 W

This sample is a full-fledged pyrolysis boiler, which is made of heat-resistant steel. The model was created on the basis of the previous ones, but it has many new functions, thanks to which the efficiency of the heating unit has increased. Due to the fact that a material such as steel cannot provide reliable protection and preservation of thermal energy, the manufacturer took care of this and uses fireclay bricks, which are characterized by high heat capacity and good resistance to burnout. The characteristics stated in the instructions indicate that, subject to all installation rules, the efficiency of the device can reach 90%.

Boiler Buderus Logano S171 W

Logano S 171 W is available in several variations, which differ in the volume of the loading chamber and power indicators:

- 110 l - 20 kW;

- 110 l - 30 kW;

- 133 l - 40 kW;

- 133 l - 50 kW.

Heat carriers in all units usually operate at temperatures ranging from 70 ° C to 85 ° C. The time of continuous work on one load can be 3-8 hours.

You can configure the equipment in such a way that you will automatically receive an SMS notification indicating the state of the devices at the present time.

Solid fuel boilers long burning Buderus Logano G221

Such boilers are very popular today, equipped with a long-burning heat exchanger made of cast iron. The design is very reliable and simple. Most often they are installed in private houses and industrial premises with an area of up to 400 m².

Solid fuel boiler Buderus Logano G221-20

The chamber can be loaded not only with coal and firewood, but also coke. The operating temperature of the liquid in the heat exchangers does not drop below 90 ° C. The efficiency is approximately 80%.

This model is represented by a whole line with units of different capacities: 20, 25, 32, 40 kW.

According to the manufacturer. the described device is a versatile highly efficient boiler that can work in conjunction with other devices that run on diesel fuel or gas.

You can read about combined diesel boilers in this post

One of the main advantages of the model is the presence of an improved unit for automatic fuel supply to the combustion chamber.

Model overview: Logamax U072-24K

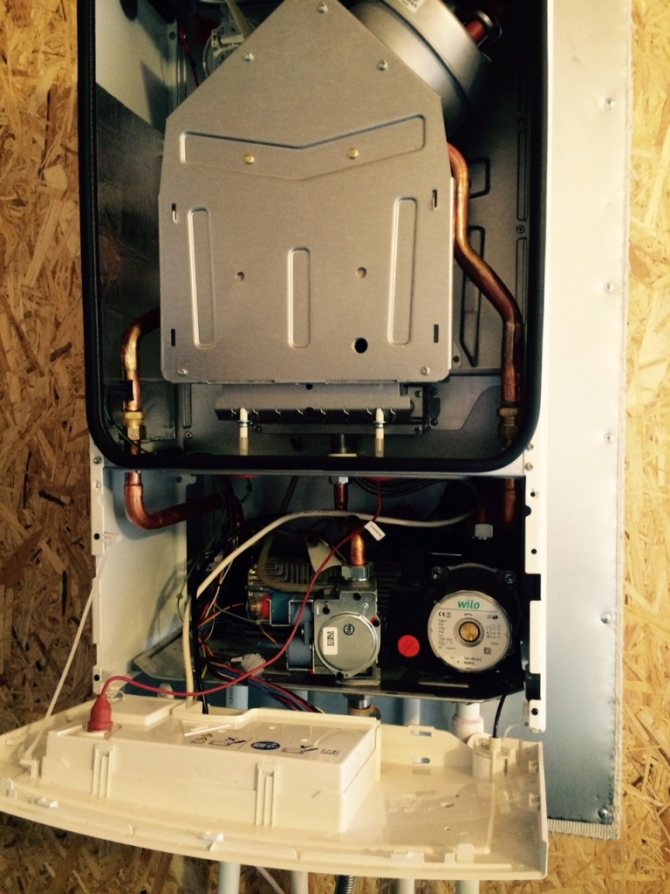

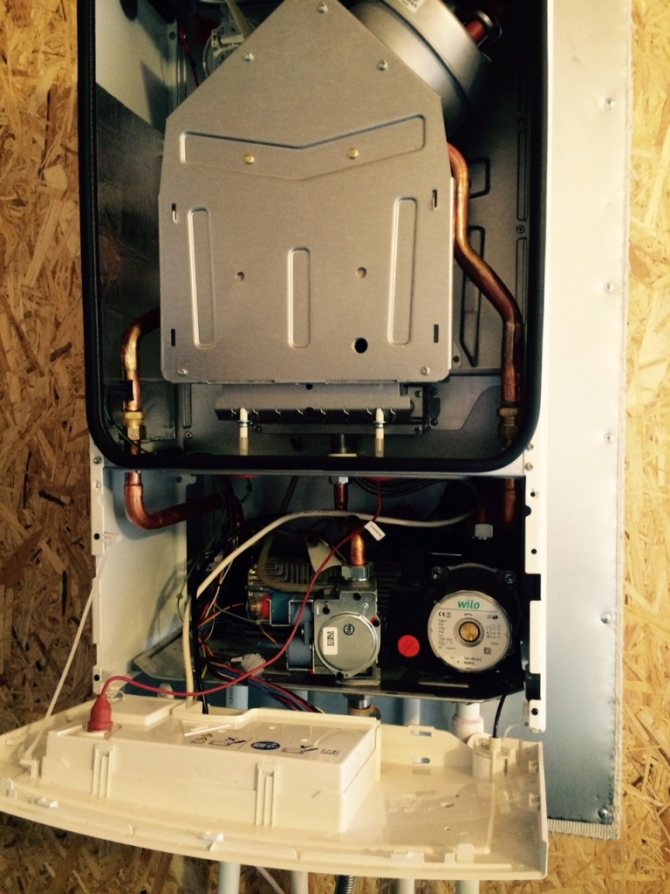

You can buy this model for 37,000 rubles. It is a wall-mounted model for heating water and heating. The unit is double-circuit and has a closed combustion chamber. The housing can be easily disassembled for cleaning.

The device operates on liquefied and natural gas. This Buderus double-circuit gas boiler is frost-proof and resistant to voltage and pressure fluctuations. There is a control panel on the body for easy monitoring of the operating status. With its help you can change the heating temperature.

Model Specifications

This double-circuit gas boiler "Buderus" 24 K is a piece of equipment, the marking of which indicates the power. It is 24 kW. The maximum consumption of natural gas is 2.8 m3. Liquefied gas will be consumed in a volume of 2 kg. The heating temperature varies from 40 to 82 ˚С. The capacity is equivalent to 6.8 liters per minute at 30 ° C.

This wall-mounted gas boiler "Buderus" weighs only 30 kg. Its overall dimensions are 400 x 700 x 299 mm. The volume of the expansion tank is 8 liters. The permissible pressure for natural gas is 0.016 bar.

Consumer reviews

With regard to additional benefits, among them consumers distinguish:

- boiler resistance to pressure drops;

- adaptation to Russian conditions;

- presence of flame control;

- the presence of a simulated fan;

- electronic ignition;

- frost protection;

- unpretentiousness to voltage drops.

Consumers love the LCD display and control panel. With their help, you can turn on, turn off and monitor the operating status of the device. The display also helps to regulate the temperature.

Logamax U072-18K wall-mounted boiler review

This equipment is a device for heating houses and apartments, as well as heating water. The wall-hung gas boiler "Buderus" is a traditional device with a permissible natural gas pressure of 0.016 bar. The volume of the expansion tank is 8 liters.

The overall dimensions are 400 x 700 x 299 mm. The device weighs 32 kg, operates at a voltage of 220 V. Productivity reaches 5.1 liters per minute at 50 ˚С. Hot water temperature can vary from 73 to 145 ˚С.

Solid fuel boilers Buderus - operation and regulation

___________________________________________________________________________________________

- Logamax U072

- Logamax U052, U054

- Logamax U042, U044, GB072, GB172

- Logano G124, G125, G234, G334, G215

- Logano G124, G125, G234, G334, G215

- Control systems Buderus Logamatic 2107, 4211

- Safety automation for gas boilers

- Errors and malfunctions of gas boilers Buderus

Logano S111 I choose a solid fuel boiler - I settled on the Buderus Logano S111-2-12 model. I just don't understand one thing - the volume of loading is 60 liters - it turns out that you can fill up the coal once a day? As I understand it, you need to stir up the grates from time to time, really make the computer stir them up (through a motor, the circuit is simple), and not approach the unit during the day? Everything depends on the consumption of coal, you can fall asleep once a day. And about the motor - also real. To fill up the full fuel receiver once a day, this is real, though only if it is -5 outside, then the consumption of the buderus is small (the unit is at low power). But this is individual for each owner. I have a power of 20 kW for three years. Lumber house 50 sq. + 30 sq. outbuildings + 12 kW for heating a boiler for indirect heating of water for hot water supply. For broken (burnt-out) grates and fireclay bricks - heat with brown coal of the 2BR grade (preferably Borodino coal) and never heat with stone. If you use Balatinsky coal, then it has a 3BR brand, a lot of impurities, and it's bad coal (I learned from my own experience). About whether it is possible to heat with firewood - you can, but you will not get enough firewood. In the summer, for the needs of hot water supply, sometimes I feed it with wood. The bathhouse has not yet been built, but it is necessary to wash, so I close the circuits for the house and outbuildings, start it for 1 hour and go quietly to take a shower. The TT boiler Buderus Logano 111 is in operation. Tell me how to set the grate shaking draft correctly? Now it stands like this, the course of the grate is small. If you turn up the arrow, you get a large course of the grates, and this is embarrassing. With such a course, the far grate opens and a lot of coal can spill out. This is the wrong position of the grate control lever, the thing where the grate control lever is inserted must stand vertically, and not, as shown, horizontally. I had the unit in operation for about two weeks, so it was one continuous torment, it could not accelerate to maximum temperatures, it constantly had to be pushed down every hour every two hours, it simply did not fall into the combustion chamber, due to the fact that the grates did not stand strictly horizontally, but at a certain angle, because of this, there was a jam in some places and the coal burned unevenly. After reading many positive reviews that the boiler works by itself, without straining the owner, I thought a lot why this is happening and what is wrong, I tried to pour coal in fractions of no more than 3-4 cm, it did not help. At one fine moment, when the coal burned out, I looked into the loading area, I was puzzled by the grates, they stood somehow crooked, after studying the instructions and comparing them with my design, it turned out that they were different, the grate stroke was very small and extremely not effective. Having rearranged everything worked, as it was necessary, and for the first time during the use of the unit, I slept all night in a warm place with an outside temperature of about -35 degrees. The Logano S111 is in operation with 20 kW, so I had a question.I fill up a full hopper of coal (the ash pan is empty), by the time the coal burns out a little more than half, ash and hot coals fall on the front wall (to the ash pan door) and almost completely shut off the air supply. And when I remove the ash, there is little ash from the back wall, and in front with a slide. Maybe my grates are not installed correctly? How is it correct? Share who has how? Probably rearrange the lever in a different way. You have it at the bottom, apparently, but you need to put it on top. Installed a Buderus Logano S111-16 boiler. The questions are: Does the smoke come from under the boot lid, plus when you open it to add fuel (wood), does the smoke come out strongly? Traction problem? Or is it all like that when you load fuel? 140x140 10 meters high is not enough for him? 10 meters shouldn't be too small. I have 7 meters from the boiler. In winter, when I clean it, the soot is sucked into the chimney and thrown out into the street. It's not about the length of the pipe. Maybe she got overgrown? If brick without sleeve and insulation, then it may well be. Is there a horizontal section? Is it clean? Is the gate at the boiler outlet open? Also see if the soot flap at the bottom in the middle section of the firebox is closed. Before opening the loading door, it is necessary to completely close the blower, then the smoke will be sucked from the loading hopper into the pipe. And the loading door should not be opened completely immediately, but little by little, first make a small crack, then open it slowly. Boiler TT Buderus Logano 111. Where is the tertiary air regulated? I look in the instructions, I look, I can't understand where the adjustment is. And what effect does it have on combustion, maybe because of it my coal does not wake up on its own? Or is it because of large lumps? Although now I generally chop coal, as small as possible. Tertiary air is supplied on the sides - two windows with dampers. This is tertiary air. The secondary air hole is located on the back wall of the combustion chamber - a square channel - you can see it when you look through the hole in the cover (the second one in front). Can you please tell me is this normal or not? 12 kW model. The area is about 100 meters. The bottom line is that when it heats up to 80-85 degrees, it starts to gurgle as if. Loud and alarming. I did not find anything like that in the instructions. It seems like it shouldn't boil at this temperature? By the way, if it does boil, what to do with it? It boils, this is a local overheating, with an open CO, nothing terrible will happen. Mine begins to hiss, like a boiling kettle at temperatures above 90 ° C. We installed the TT boiler Buderus Logano S111, everything was fine and there was not much coal left and the house was warm, but for three days we have not been able to raise the temperature to 60 degrees, it is catching up to 40 degrees and that’s all, the coal does not burn, but shakes slowly. Tell me, please, what can be done and why this can be so? There may be several reasons for this. Basic: traction disappeared; extraneous air suction, which should come only from the blower and tertiary air dampers; bad fuel. Has the unit been cleaned before? If you did, check to see if you replaced the soot flap that is in the penultimate chamber. Check the draft in the pipe by removing the ignition flap, insert a newspaper into the boiler outlet into the pipe and light it. It should burn merrily, even with a hum, and all the smoke should go into the chimney. Check for air leaks into the second and third chambers from under the top cover. Installed Buderus Logano s111-24. For a week I have been suffering, very quickly catching up with a huge temperature, twice tore the pipes. What's wrong? there is a safety group, but for some reason it does not work, how to adjust the damper was regulated according to the instructions. Adjust the thermostat, when the temperature set on it is reached (follow the thermomanometer), the blower flap must be completely closed. This is the main thing. Further - it is not clear what you heat, if coal, then its brand; what power is required from the boiler. It is necessary to check by increasing the pressure on a cold boiler. Now - about the blower damper. It should fit snugly (without gaps!) To the seal.Check that there is no gap, it should be no more than 1 mm! The hatch on the upper loading door - do not open at all! Check the unit for possible air leaks, maybe somewhere the seals are washed out, etc. Installed and launched Buderus S111-45D. Stainless steel pipe-sandwich 200/280 11 meters. TA-4 cubic meters (A bit too much for such a model, but this is for the future). Heated area - 400 sq.m. with different temperatures from 5 to 15 degrees C. In general, I am satisfied with the boiler, on brown coal, fell asleep and forgot for 10 hours at T on the street 0 +5. But two incidents got out. He periodically puffs, probably a short pipe. Even at 60grd. at the filing and about 30 grd. on the return line, if you fully open the air damper (twisting the lamb all the way), the unit begins to boil, boiling shallowly. And this is with the Grundfos 32/80 pump running. I think it shouldn't be like this. Does it feel like there is an air bag in the boiler? After all, this is a local overheating of the boiler structures. So I am puzzled, how will I be in the winter, when the forced mode is needed? Does anyone have similar symptoms? There are such symptoms. It puffs up when a new portion of coal flares up, a lot of gases are released from the coal at once, and then these gases are ignited. Thrust has nothing to do with it. As for the boiling point, there is a small air bell at the top of the apparatus, not in the heat exchange zone. Not dangerous. Buderus logano s111-16 burst partitions - fireclay bricks. I have been operating since September of this year, I have already replaced 1 and 2 more. What could be the problem? I think that due to the fact that I am burning with coal (its combustion temperature is high). But for some reason it seems that this is not the only point. What is wrong with you? The bricks must withstand T - 1200 degrees. Buying is an expensive and troublesome business. Cut them with a grinder from regular refractory bricks. Cheap and will last longer. Yesterday I bought an S111, 12 kW. I also drew attention to the regulator. Regulus RT 3, all metal, only the handle t exposed to plastic. In general, how reliably does this regulator work? Okay, if the blower closes, but suddenly the other way around. Works what will happen to him. When I installed and configured it according to the instructions, it turned out that my thermometer was not working on the boiler (it showed different things). It was good to serve a normal one, it is now working on it. But not much that you trust in his "sinlessness". All the same, it will depend on fuel, weather, boiler pollution. You still have to regulate, since it has a hook on the chain. The Buderus S111 manual says that the coal must be up to 40mm in size. And if more? Or dust? In general, do you need to sow and crush? Coal with large pieces (about 10 cm) can be used. But up to 50 mm is better. Coarse coal does not completely burn out. You just throw it away with ash. Not effective. Coal with dust also does not burn well. I tried. I personally sift. I have a fraction from 1 to 5 cm. I want to take the Buderus S111-16 boiler, but I'm all in doubt. There is a house, the first floor is 75 squares, the second is 50. The second one will be cold in the next few years. I would like to take immediately with a margin to the second floor. I am considering two models for s111 from 7 to 13.5 kW and from 6 to 16 kW. I would like to take the one that is more powerful. There are fears that the capacity will be great for the first time for one floor. Who thinks about this? Of course, take 16 kW, the excess power at the beginning will be compensated by a longer burning of one coal tab. Immediately after installing the boiler, remove the air gap of the control damper, then it will be possible to receive almost any power, up to maximum. There will be no tar from coal, only ash. Here, there will be more of it on the walls of the unit. And the damper is the one that is connected by a chain to the thermostat. The less air is supplied through it for combustion, the less the model's power. I had some problem with the Buderus S111 boiler - the smoke goes through the door of the loading window, I have to cover the blower almost to a minimum, as a result, the temperature does not rise above 60 degrees. There is an assumption that there is not enough traction.At the beginning of use, there was no such problem, maybe the pipe was clogged? I cut the pipe from the boiler into an old brick pipe with a 90-degree bend, plus a small horizontal stainless steel pipe. Maybe you would advise? You have all the signs that it is time to clean the machine. The last smoke chamber was clogged with soot and ash. Logano G221 I have the following problem, I am building a house on the ground floor 5x6 from a bar of 18x18 there will be an attic 3.5x6 plus a warm veranda 4x3 where I would like to put a solid fuel for 12 kilowatts, this winter I will not connect the attic to heating, there will be 3 radiators in total 20 sections. In general, it seems to me that the system for this unit is too small (there is not enough water in the system) will overheat. The question is what to do? Maybe it won't overheat. First try how the unit will behave on wood, and then if everything is fine, heat it with coal. True, the CO will heat up very quickly, and it will work in a reduced power mode. If it will actually overheat, then slightly open the doors in the staircase to the attic so that the heat from the first floor goes upstairs and these three radiators are unloaded. Ideally, add a TA (heat accumulator) to this model, if finances allow, or an indirect heating boiler. Problem with TT boiler Buderus Logano 221 (25 kW). I flooded it for the first time, about 11 o'clock yesterday. First, smoke poured into the room, and I was upset. After a few minutes (probably 5-7), the smoke went, as expected, into the chimney. In the absence of coal, he began to heat with wood, but with pine, in connection with which a lot of resin appeared on the walls of the unit. Flooded with wood, burned to coals, tossed coal. All perfectly! Smokes nothing, everything heats up (with nuances, but heats up). And yesterday, that is, after 2 weeks, the thrust disappeared. Disappeared right abruptly, I would say. (Chimney: horizontal exit no more than 1 meter, then up the wall 8 meters with one bend at 45 + 45 degrees). I opened the condensate collector from below, dumped 3 liters of ice from there, looked into the chimney itself, but there is no soot on it in a large amount, and the smoke from the boiler still pulls up well. But when you open the door to throw firewood, there is a lot of smoke. And smoke goes out through the viewing window in the door. This was not the case until yesterday. Inside, of course, was overgrown with soot, but I did not think that this affects traction so much. In general, I had to extinguish it at night by closing the blower tightly, and in the evening I will work again as a chimney sweep and remove the back wall to clean the horizontal section. But if you do this every two weeks, then I am very upset with such a unit. In my opinion, he could not get so dirty in 2 weeks, even if he was drowned for several days with conifers. Most likely, the matter is in coal, clean the boiler as expected, check the position of the cleaning flap well and melt it. If I understood correctly, you did not clean it at all. If the coal is hard coal, there is a high probability of build-up on the walls, these build-ups can also fall off in layers, so check. The inflow has nothing to do with it, most likely, it will not be needed, if there is no threshold under the door (there will be a gap) and even a couple of cracks in the walls, then this is quite enough. The Buderus Logano G221-20 lignite boiler is in operation. The big problem is smoking. The pipe seems to be about 6 meters high, brick, at the level of the roof ridge. The wind blows in the opposite direction. The chimneys are clean. It is spring now, I heat less often with wood once every 2-3 days (no electric heating). I start heating, the smoke does not go into the chimney at all, but directly blows from all the cracks. Another feature. When it heats up to 60 degrees. smokes less, but still smokes. Two problems - a brick chimney and "the wind blows". We need a sandwich and a pipe above (so as not to blow out). And everything will work without smoke. Solid fuel boiler Buderus Logano 221. At the first furnace, the smoke, after filling the coal and warming up the unit went to the mode, everything burned out, the second ignition is better, the third does not go into the pipe at all, as if the air plug was pushed into the chimney newspapers, they burn so-so, but on outlet 133 pipe height 10 meters at the outlet 4 meters asbestos-cement pipe, and in the middle there is titanium (water is heated for domestic needs), with the previous apparatus, there seemed to be no problems, and the smoke comes from the swivel lever and from the washers, this is not tight construction? It is necessary to clean the chimney, chimney and the unit itself. Potential leaks and leaks or incorrect installation (height). Boiler Buderus Logano G221-25 is in operation.And at what flow temperature does the load burn for such a time? (what is the temperature at the beginning during ignition and at the end of the furnace, when there is still coal and you can throw it in!) In the pulse mode (ignition-complete combustion-new ignition) coal will burn 50 percent more and it burns for a shorter amount of time. This is from my own 4 years of experience. Brown dry coal in a normally adjusted boiler at a flow temperature of 70-80 degrees (according to a standard thermometer) burns continuously for 12-13 hours. The burning time of a full load also depends on the draft in the chimney. If the draft is excessive (the size of the smoke channel is more than 200 mm), then the combustion time is reduced to 5-7 hours and the controllability of the boiler deteriorates, if the smoke channel is narrowed (less than 150 mm), then the time of complete combustion increases to 15-16 hours, but the service interval is reduced and the smoke level of the boiler room increases. The Buderus Logano G 221 - 20 kW, cast iron boiler does not heat the house. 1) the Leningradka heating system with natural circulation and a pump on the return line, 2) the area of the heated room is 170 sq. m. gas block walls, 3) 125 sections of cast iron batteries, 280 liters of water in the system. It picks up the desired temperature, heats up everything, but in the evening at 21:00, when the almost full chamber of coal is loaded, by the morning everything burns out and the temperature drops to 40 degrees. Is it really not enough power to warm up, despite the fact that the temperature outside is positive, and what will happen in frosts? I have a similar 38 kW model for 6 sections and heat 240kv / m. If you have a 4-section unit, then this power will go. Yes, and three sections will be enough, it is just that more coal will have to be loaded more often, but for that the efficiency will be higher. I just took the unit for myself with a margin, since I do not look at overruns due to loss of efficiency, but it burns longer, but this is just my opinion. If your boiler is now burning on one tab for 8-10 hours, then everything is fine, because in reality the house uses all the heat, as in severe frosts. If the house is new, then it can be dispersed in general for a month, and if with periodic residence, then 1-2 weeks of constant heating. But on the other hand, if you are raiding, it was better to take a model with 5-6 sections, so that it burns longer and heats up all the CO faster. But I repeat, and three sections will be enough, you just have to load more often. Yes, and just add coal and shuffle the grates before that. There is no need to do a full stop if the coal is not very ash and there are no large cakes and adhesions. The Buderus Logano G221 boiler is in operation. Who tried to heat with brown and bituminous coal? Which one is better to use? I have been using such a boiler since autumn, very picky about coal, not everyone burns for 12 hours, there is one that bakes and does not wake up at all, there is one that burns like gunpowder, and it is exactly 2 times less (6 hours) and ash more from him. And the lumps need to be pricked very small, otherwise they also do not wake up. Now I brought coal of the SS brand, so it is more or less stable with it, but still sometimes it does not wake up on its own, you have to push it with a poker, apparently due to the ingress of large lumps. Adjusted the temperature to 90 degrees. holds exactly 90 all the time. We ought to try to sink the brown ones. I bought an inverter for the pump, but it does not work with it, it hums somehow differently and does not twist (the power of the inverter is 400 watts). I don’t know, maybe it should be more powerful. I bought a TT boiler Buderus Logano G221 - 20 kW. Something like that I do not like. I decided to check first with paper, the paper burned out, then went out, and the smoke went from all the cracks. He eats firewood at a time, the bookmarks are enough for 2 hours. With coal it is a little better, but the temperature from it near the water is 80 degrees. If you heat with wood, then they can get stuck and not fall down. The chimney is made of 159mmx4.5mm seamless horizontal pipe 1.5m + 159x4.5mm welded pipe 5.5m (vertically), we also put on top (not enough in height) 1m long 160mm diameter stainless steel and an umbrella. The pipe is wrapped in 2 layers of foil insulation for chimneys and glued with reinforced tape. I do everything according to the instructions, the ignition damper is open, the flue gas damper is open, what is the matter, I do not understand.Why does it smoke? Insufficient chimney height and therefore a draft problem. Remove the turbulator from the boiler, the draft will be better. Is it possible to build a pellet burner into the Buderus Logano G221 boiler. The burner can be built into anything. The question is in the effectiveness of each specific link. It depends on the power of the unit when working on wood. According to the regulation of the Logano G221 boiler. It seems to me that the part of the hexagon to which we cling to the chain should be slightly below the horizontal line with a hot boiler, and higher with a cold boiler. This achieves the maximum opening of the damper. And in real life, each boiler has its own character and you need to adapt to it. The main thing is that the traction regulator correctly fulfills its purpose, that is, the amount of air necessary for the normal operation of the boiler must enter the blower, and when the set temperature is reached, the blower must close and prevent it from raising the temperature further. That is why, probably, the instructions do not contain a clearly prescribed position for the installation of the hexagon, and there is the possibility of manual adjustment. What do you think? Regarding the installation of the lever: the closer to the horizontal line is installed, the greater the stroke of the blower door. He exhibited his own on a cold boiler. In fact, the value is not critical a little higher or lower, just not vertically and not at an angle of 45 when the regulator is set to 90 (in a cold state). Boilers of this type (Buderus, Bosch, Dacon, Prometheus) are made from one drawing and are repeated in their row millimeter by millimeter. The difference in appearance, name and other little things such as grates and flange or threaded connection, which, in fact, does not matter. For example, I like flanged ones more, and vice versa. That is, they are standard for each power series, but the heating systems are individual, just like the fuel that we fill in them. Of course, the installation sites, chimneys and so on are also different. When I experimented with coals of different cuts for the first year, I had to adjust the boiler for each coal. The essence of the adjustment: if the regulator has 80, then the unit should also have 80 and not 70 or 90 (of course, the system is warmed up). In order not to move the hexagon of the regulator horizontally, I made it easier. At the bottom, where the chain clings to the blower, he turned out the screw, put it through a suitable chain link, put on the plastic and screwed it back to the door. And then, by turning the link around the axis of the screw (after loosening it), we shorten or lengthen the chain to achieve the specified conditions. Still, the regulator is more important than the blower screw. And on different coals I had to adapt to each, and I changed them in a week. Now I'm drowning myself and of course there is no need to adjust anything. In general, the device is flexible and is capable of working at a bad angle in start / stop mode and at a normal angle all season long with stops once a week for cleaning. Logano s131 Tertiary air dampers, when and how much to open on this model? I always keep them open about 2/3 of both. Look at the smoke from the chimney - I either can't see it at all, or - a whitish transparent smoke. When kindling, or after shaking, it can be gray, not for long. Installed a Buderus Logano s131 15 kW boiler. Do you think you've made a mistake? Tell me who installed the safety heat exchanger and is it needed at all? The house is almost 100 sq. the system will be closed. I will install a security group for anyone. It has an outlet for a heat exchanger. Don't know what to do with him? Not a bad model in its class, but lost or not, it all depends on the price for which you purchased it. In a closed system, it is advisable to install a safety heat exchanger or connect it to the heating system through a buffer tank, but it is imperative to install a safety valve.If you mean a safety heat exchanger, then it is connected to the water supply (cold water) through a thermostatic valve with a temperature sensor (there is a temperature measurement point in the unit), and the outlet of the safety heat exchanger is led to the sewer drain. Installed a solid fuel boiler Buderus Logano 131 instead of his old unit. For some reason, he doesn't heat well at all, all in smoke, when the doors are opened, the smoke tends to go through them. Pouring cold water into it, I reached the temperature up to 60 degrees in 2-3 hours. The assembly seemed to be assembled correctly. The chimney is assembled from a sandwich, from the unit there is a turn of 90g, then a tee of 90g, and pipes up, 7 meters long, sandwich vnutr. 150 stainless steel. Tell me what to do? Maybe someone also had their first launch? To begin with, which boiler was installed before this and how was it fired at the same time? What is the temperature outside, the presence of wind, how is the supply in the boiler room arranged? You need to know the system, the chimney, after that you can recommend something. Initially, it is clear that you do not have a thermostatic valve installed on the return line. Initial firing with wood with a small amount of coal to warm up the chimney and create draft in the chimney, after the main fuel filling. Tell me, did anyone put a thermostatic valve on a Buderus Logano s131-15 h boiler? Or in winter, when the unit is in non-stop mode, the valve is not so important and cleaning is not tiring? Why am I asking: on the one hand, the return flow temperature will not be lower than 60C, but on the other hand, let's say in the off-season it is necessary to "flood" a little, that is, not in the usual mode, because the valve again will not let the coolant go below 60, into the boiler and the water will flow through the bypass. I mean an automatic valve without a mixing type thermostatic head. For me, if the pump is not turned on when the boiler is fired up, the natural circulation of the coolant begins at a temperature above 60 degrees. On the thermometer, it reaches 60, then the temperature on the return line begins to rise (there is also a thermometer, so you can see it), and when the return line warms up, the temperature rises to the set one. I usually hold 75-80 gr. Heating problem, boiler 15 kv Logano 131 in the system with only 6 radiators. When stoked with wood, the unit kept the set temperature. Yesterday I tried to throw in a bucket of coal and started to boil. The regulator is tuned. Look at the damper that the traction regulator lifts, under it, fine coal got in during loading and blocked it in the open position, the boiler was also boiling. If the expansion vessel is defective, can this affect the temperature rise? And how do you know if it works or not? Does not affect the temperature rise. It's easy to check - measure the gas pressure in the expander. Should be equal to the sum of the empty expander pressures (to be recorded by the heating installer) + water in the system. I am using Buderus S131. In general, I like everything. There are general questions: 1. How to regulate the secondary air (it is written in the instructions in accordance with the used fuel)? 2. While I am heating with wood, all sorts of old boards, and so on. - the chimney is overgrown very strongly (the return temperature is maintained at least 50 degrees by an electric boiler). The resin flows directly into the blower. 3. The operating instructions do not coincide with the design of the boiler in terms of the number of furnace stones and the place of their installation. Try to heat it with coal, I saw how g221 was heated only with wood, so the resin clogged the whole chamber, as if tar, cleaned, converted to coal, all the rules. There was a need to install the TTK, I liked the logano s131 model. Questions to the happy owners of this model: how was the heating season, maybe who changed (improved) what in this design? The plans include: TTK + TA (600 liters) radiator heating, S = 80m2 (40 house + 25 annex + 15 tambour-stoker) 5 years (40m2) was heated by an EC 4.5 kW. The unit is good. If, in addition to coal, you also plan to use firewood, then the Logano S111 will not suit you. In the S131, the hopper is much more suitable for this type of fuel.Will 40m2 also be heated? If so, then these boilers will be too powerful for you. If the whole area is fine. The heating season went well. I did not make any alterations. Last week, I just could not melt it the first time, all the smoke went into the stoker. I thought about the strongest wind that day, but then I opened the lid to clean the boiler and found that the fireclay bricks at the back wall were covered with ash, limiting the draft. Shook it off and everything caught on fire! This was the first cleaning since November! apart from cleaning the walls of the boiler from resin. Compared to S111 (at a relative's neighbor), I heat a little more often, but our house is warmer. I think that I really miss the heat accumulator. If possible, I will definitely do it, but I haven't decided yet how. I want it as simple / reliable as possible, without a large number of taps / valves. And according to the model, then choose any, both are good! Boiler logano s131. Problems began, the system warmed up everything is fine, in the floors on the return flow 35-35C, but I can not overclock it more than 60C, I tried 2 types of coal, a Terrakov bucket, an almost full bunker burns for 4-5 hours, the temperature drops, I throw a bucket of coal again and max 60gr, blower open on the regulator 90gr. The unit hums like a blowtorch, but the tamper does not grow, in general, today he lived near it from 7-20, and threw the 4th bucket for the night, on the street for 10 days. Already scary, what will happen at -35-40? It is buzzing like a blowtorch, so you drown the street with a chimney What was the temperature in the house before, what is now, what was the flow rate before, what is now? There is no thermostatic valve on the boiler return, this is a minus. The boiler hums (fuel escapes into the pipe). Inspect the heat exchanger, chimney. Forget wood, just coal. It is quite possible that the temperature on a warmed-up house in it will drop, since the need for a house has approached a minimum. Boiler logano s131. How the grates should lie, I can’t control my own, I don’t raise the temperature above 50. Today I briefly boiled up to 75, the damper went down, and the temperature, too, seemed unable to pick up the combustion process. Tomorrow I want to try to put both grates horizontally, it seems like the burning area will increase, what do you think? I don't think that the horizontal position of the grates will change anything. You seem to have a fault either in the chimney or in the quality of the coal. I've just flooded, the traction is excellent and the temperature drives perfectly, although it's +5 on the street.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alpha Calor, Thermotechnik. Adjustment of gas automatics Eurosit 630. Replacement of the thermocouple and maintenance of the ignition burner.

Malfunctions and repairs of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Gas heating boilers Bosch Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Options for setting functions and modes.

Repair recommendation Navien Models Deluxe Coaxial, Deluxe Plus, GA. Errors and malfunctions. Work with remote control Ksital. System control. Setting work on temperature and pressure.

Floor standing boilers Buderus Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vilant boilers Turbotec Atmotec pro / plus VU / VUW INT models. Components and work functions. Adjustment programs. Gas system. Installation and assembly. Maintenance and prevention.

Floor standing boilers Protherm Repair of the Bear models KLOM, KLZ, TLO, PLO with a capacity of 20 to 50 kW. Breakdowns and malfunctions. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and settings Models of gas floor boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automatic equipment Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted coppers of Protherm Repair of the Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repair and adjustment Repair and operation of boilers Ciao, City, Novella, Exclusive. Wall and floor models. Malfunctions and error codes. Working functions and setting of service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of an automatic pellet burner APG-25, 36, 42. Settings of operating modes.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes. Troubleshooting tips. Operating modes and setting of service parameters. Maintenance.

Heating boilers Alfatherm Description of Beta floor standing boilers and Sigma wall mounted gas boilers. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - malfunctions and repairs The Wolf boiler is installed. I noticed that over time, the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks, but found nothing. What else to check?

Gas boilers Junkers After 7 years of operation, the gas boiler Junkers ZW-23-KE has the following problems. When DHW starts working, it either turns off or stops working ...

Repair of boilers Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, no matter what the temperature is. To make sure that this is so, he raised the temperature in ...

Model reviews

After reading reviews about the Buderus gas boiler, you will be able to understand that it provides convenient control, stability under pressure drops and can heat large areas. All this is very popular with consumers, as well as the presence of a simulated fan, as well as electronic ignition.

The boiler is multifunctional, it can be used for heating water and heating. Flame control in the device is provided by an ionization electrode. The boiler makes noise during operation, but at a low level. It is adapted to Russian conditions, which is very much liked by the modern consumer who appreciates quality goods at an affordable cost.

The main advantages of Buderus boilers

The solid fuel heating boiler Buderus has earned its popularity due to the following advantages:

- Reliability of construction

- A wide range of capacities, allowing to heat premises from 50 to 500 sq.m.

- The ability to use several types of TT due to the design of the firebox;

- High efficiency, which in various models, according to the instructions, ranges from 74 to 86%, thanks to the use of special heat-insulating materials;

- Operational safety, which is ensured by reliable automation and a system of built-in cooling heat exchangers;

- Emissions to the atmosphere in negligible quantities;

- There is a mode of economical consumption of TT, in which two times less fuel is required, its availability is indicated in the instructions;

- Heating time, especially for pyrolysis models;

- Along with space heating, they can be used for hot water supply;

- Compatible with other heating systems, such as mains pumps;

- The design of the furnace, consisting of a large-diameter hopper for loading TT with an extended inlet, provides ease of use, including loading and cleaning. Diagrams of the device of all parts are given in the instructions;

- Possibility of quick and easy installation from scratch or by introducing into existing systems, guided by the recommendations of the assembly instructions;

- Minimal maintenance;

- Autonomy from power supply;

- Nice design;

- Affordable prices;

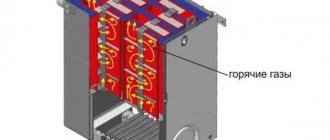

Fig. 5 An example of mounting the device on solid fuel Buderus in section

Review of the gas floor boiler brand Logano G334-73 WS

This model is a floor standing gas appliance, which is equipped with a modern atmospheric gas burner. The unit is used for heating houses and premises for various purposes. It can be installed in a boiler room, which is located on the roof or attic. By connecting a horizontal or vertical expansion tank to the equipment, it is possible to prepare hot water.

The heat exchanger of the gas boiler "Buderus" is made of high quality cast iron, it ensures durability and reliability. The system can be converted into a two-boiler installation. The unit is delivered assembled, which is very convenient.

Solid fuel models

Buderus Logano solid fuel floor boilers are used to heat large buildings and premises. They are often installed in the woodworking industry to use waste wood as fuel. First of all, it is worth noting the high quality of this equipment. Also, solid fuel boilers have environmentally friendly and economical modes, are easy to install and maintain, and have high power. For decades, they have been successfully used for heating schools, hospitals, residential and office buildings.

Customer reviews about the model

This device, according to consumers, is distinguished by its efficient operation and ease of control. Buyers consider additional benefits:

- assembled delivery;

- standardized utilization rate;

- ease of conversion into a boiler plant;

- the ability to operate the unit on natural gas.

The burner design extends the boiler's life. According to consumers, the boiler can be easily reconfigured to operate on other types of gas.