Features of Vesuvius furnaces

Vesuvius models are distinguished by the complete absence of sharp corners. The design of the stove has a rounded shape, which allows heat radiation to be evenly distributed throughout the room, warming up the air to the specified temperatures. The outer casing of the unit is an all-welded steel plate construction. The thickness of the metal is 8 mm. The plates are bolted. The fastening provides increased product strength.

Thanks to the outer mesh, the stones in the oven are heated evenly. They extinguish the infrared radiation of the hot metal. The downside of the outdoor mesh is dry steam. It is impossible to get a light wet cloud without additional devices. For lovers of the Russian steam room, it is better to give preference to models with a closed heater. The full use of an open-type heater in a Russian bath involves the additional installation of a steam generator.

The body of the Vesuvius furnace is coated with a protective organosilicon compound. The coating protects it from high temperatures and humidity. Some models are decorated with forged details. Typical for models with fireplace function. If necessary, you can hide the equipment behind a brick screen; models without complex decor are purchased.

All Vesuvius models have a standard chimney diameter of 115 mm and a combustion tunnel depth of 290 mm. This is useful when replacing assemblies.

The warranty period for cast iron models is 35 years.

Vesuvius stove model The Legend is constructed of 3 cast iron parts. The thickness of the material is 12 mm. The joints of the fragments are sealed with a ceramic cord. The operating temperature that the cord can withstand is 1200 degrees. This is enough for a sauna stove. All parts are bolted. The branch pipe is separated from the chimney firebox by a baffle.

The stone net is installed outside. When heated, stones give a uniform heat and shields the radiation of the firebox. The large mass of stones provides light steam. The humidity of the vapor cloud depends on the heating temperature and the amount of water in the tank. You can add water to the stones from above. In this case, the steam will turn out to be heavy, watery. The steam room is heated for an hour.

In the Legend series, the manufacturer produces furnace models with forged elements.

The manufacturer gives a 30-year guarantee for the Vesuvius Legend model. The model from the Forging series has a remote firebox. The element makes it possible to heat the steam room from the adjacent room.

Furnace Vesuvius Scythian

A series of models "Vesuvius" Skif - a budgetary line of the manufacturer. They are constructed from engineered steel. Sheet thickness 12 mm. This type of steel has a long service life. The walls do not bend outward, do not deform. The stove is made according to Finnish technology. The joints are laid with a heat-resistant cord. The part can withstand temperatures up to 1200 degrees. The parts are bolted together. The furnace is portable. The steam room is heated from the adjacent room.

The stone net is installed outside. The steam is dispersed. Due to the design of the oven, it is suitable for a Finnish steam room. For a classic Russian steam room, the unit lacks moisture. This is compensated by the additional installation of a steam generator or piping system. The steam room for the standard model ranges from 8 to 18 square meters.

The advantage of the Skif oven is its price. It is cheaper than a cast iron product. The warranty period is 2.5 - 3 years.

Vesuvius 16

Vesuvius 16 is a closed heater. Consists of three elements: body, firebox, pipe. The parts are fastened with a bolted connection. It increases the strength of the structure. A ceramic cord is laid at the joints. The working temperature of the wire is 1200 degrees.

The model is equipped with a sealed cast iron door. The design provides for heat-resistant glass. The body is made of steel. The ventilated oven casing is made of textured metal sheets. They are coated with a heat-resistant bronze color. The oven is heated from a room adjacent to the steam room. For this, it is equipped with a combustion tunnel.

A steam room up to 18 cubic meters in size Vesuvius 16 will warm up in 50 minutes. The heat-resistant glass built into the door allows you to watch the wood burning in the stove.

Instruction of the stove fireplaces Meta

Installation of the Meta fireplace stove

Meta fireplace stoves can only be installed in rooms and in such a position, which excludes the occurrence of a fire hazard. The area of the room must be sufficient for normal operation and maintenance of the oven. A supply of fresh air must be provided in the amount necessary for the operation of the Meta fireplace stove.

Meta fireplace stoves cannot be installed on floors with insufficient load-bearing capacity.

The floor surface must be protected or made of non-combustible materials at a distance of at least 500 mm in front of the oven and 300 mm at the sides. The distance from a wall made of non-combustible materials must be at least 200 mm. When installing the stove, Meta fireplaces in the corner, the distance to the walls made of flammable materials should not be less than 600 mm.

The installation of the chimney must be carried out in accordance with fire safety regulations by qualified specialists.

The first chimney connected to the Meta fireplace stove must be single-circuit, and removed from wall cladding elements or structural elements made of combustible materials by at least 400 mm. Then you can put double-circuit pipes "sandwiches". For double-circuit pipes with insulation of at least 20 mm, a distance of 100 mm is sufficient. The connecting pipe with a 90 ° elbow must have an inspection hole for cleaning.

Items made of combustible materials should not be located no closer than 800 mm from the stove.

What you need to know when you first light up the Meta fireplace stove

During the first fire, the varnish covering the outer surface of the Meta fireplace stove is sintered and hardened. In order to avoid damage to the varnish and cracking of fireclay bricks protecting the structure of the furnace from the inside, the fire during the first kindling should be low (laying firewood no more than 2 logs, with a total weight of up to 2 kg), and the kindling time is short 1-1, 5 hours.

With the second, third, fourth firebox, you can gradually increase the amount of firewood up to 2.5-3 kg. Initial lighting should only be done in a well-ventilated area.

THE TOP PANEL OF THE FIREPLACE OVEN WITH VENTILATION HOLES IS EXCESSIVELY HOT. SPECIFICATIONS OF PAPER, PLASTIC, POLYETHELENE AND OTHER COMBUSTIBLE MATERIAL IN EXCEPTIONAL CASES MAY RESULT IN A FIRE. BE EXTREMELY Vigilant.

Adjusting the combustion air in the stove fireplace Meta

The combustion air supply to the inside of the furnace is controlled by knob 7 (see fig.). When the handle is in "fully open" position, the air damper is open. In this position, the maximum amount of air is supplied to the firebox - heated “secondary air,” enters through the hole inside the stove of the Meta fireplace.

With the handle in the middle position, a limited amount of air enters the oven. At the same time, the optimal efficiency of the Meta fireplace stove is achieved. The amount of air supplied is sufficient to prevent soot deposits on the inner surface of the door. The position of the handle, which determines the flow of air into the furnace, depends on various parameters: the amount of firewood, draft in the chimney, combustion phase. When the handle is in "fully open" position, the air damper is closed.

Knob 6 (see fig.) Controls the air supply for blowing the door glass.

Lighting up your fireplace will be very easy if you follow the instructions:

1. The air knob will be in the fully open position. The door is slightly (1-2 cm) ajar;

2. Put in the combustion chamber a small amount of paper (without printing), on top of a few dry splinters (preferably pine or spruce) and then a few small dry birch chips (alder or logs of fruit trees can be used);

3. Light a fire in the stove;

4. After 2-5 minutes after the fire has started, add 2-3 pieces of wood, cut up and close the door.

5. After 15 minutes, put 3-5 logs with a total weight of up to 3 kg;

6. If the draft in the pipe is very strong, you can reduce it by gradually moving the air damper control knob;

7. Additional logs can be added when the first load of firewood is burnt out;

8. All dampers must be closed when the stove is not heated.

Meta fireplace stove during the transition period

During the transition period (spring-autumn), with sharp fluctuations in the outside air temperature, with a sharp pressure drop in the chimney, vortices can form, preventing the free removal of combustion products into the atmosphere.

During this period, it is necessary to heat the stove with only a small amount of dry wood with the door slightly open and the air supply damper fully open. The door and damper of the Meta fireplace stove can be opened slightly only after a stable draft has been achieved.

Combustion control

The combustion process depends on the amount and quality of fuel in the furnace and on the amount of air supplied to the furnace. Never try to reduce the combustion rate by cutting off the air supply too much. This leads to improper combustion, tar formation, increased soot formation and contamination of the door glass. In addition, there is a danger of micro-explosions, ignition of exhaust gases. The door must always be closed during combustion to prevent uncontrolled air flow.

The efficiency of the combustion process in the Meta fireplace stove also depends on the height of the section and the shape of the chimney, corresponding to the development surrounding the building, on the strength and direction of the wind, temperature and humidity of the outside air.

IF THE CHIMNEY HAS BEEN INSTALLED WITHOUT REQUIREMENTS, NO CONTROL OF THE COMBUSTION PROCESS IN THE FIREPLACE STOVE DOES NOT COMPENSATE FOR THESE DISADVANTAGES.

Firewood consumption per hour

To avoid deformation of the steel body of the Meta fireplace stove, discoloration of the paintwork, it is necessary to avoid overloading the stove with fuel.

THE OPTIMUM AMOUNT OF BURNED FUEL SHOULD NOT EXCEED 2 KG. IN HOUR.

Artificial firewood from wood waste compressed under high pressure has a high specific heat output. Therefore, the amount of such firewood should not exceed 1.6-1.7 kg.

Do not use rotten and rotten fuel. Use only fuel cut into logs with a maximum thickness of 8 cm and a length of 25-33 cm, no more. It is better to put a small amount of firewood as it burns and not to overload the fireplace in one place. The quality of the fuel can be determined by the ash and smoke coming out of the chimney. The ash should be whiter. The dark color of the ash indicates incomplete combustion. The smoke from the chimney should be as invisible as possible. Dark smoke, like dark ash, indicates incomplete combustion. During normal combustion, the fireclay tiles inside the furnace will be light, not smoked. The optimum moisture content of the wood is 14%.

ATTENTION! IT IS FORBIDDEN TO HEAT THE META STOVE:

- firewood with moisture over 18%

- the remains of harpsichord products with paintwork

- firewood or wooden products impregnated with various (for example protective) compounds

- coal, exotic woods (mahogany, etc.), plastic and other artificial materials.

To obtain normal fuel, firewood cut into logs should be stored in a well-ventilated area, or under a shed, protected from moisture. In the stacks of wood piles, air must circulate unhindered.

How is the Meta fireplace stove arranged?

The Meta fireplace stove is arranged as follows: the stove body (number 1 in the diagram) is made of heat-resistant steel. The body has double walls. There are channels between the walls along which air moves. Cold air gets there from the room where the stove is installed. Then, warming up, it goes back into the room through the ventilation holes located in the upper part of the stove. Thus, the Meta fireplace stove belongs to the convection type models. The firebox, the fireplace, is lined with fireclay or vermiculite panels from the inside. For what? In order for the stove to serve for at least 10 years. To smooth out temperature differences inside the stove, in order to optimize the combustion process, so that the heat given off to the room is softer. Thus, it turns out that every Meta fireplace stove is maintainable. If for some reason one panel or several are damaged, they can be easily replaced. The bottom of the furnace, namely the grate, is made of heat-resistant cast iron. The furnace has a closed structure. A door is inserted into the firebox (number 2 in the diagram). It is convenient to monitor the combustion process through heat-resistant glass (number 3 in the diagram) or just watch a beautiful flame and dream. In front of the glass there is a firewood holder (number 4 in the diagram), it is necessary so that the firewood does not fall over the glass. There is also a pull-out ash drawer behind the door (number 5 in the diagram). It is necessary for collecting ash, it can be pulled out at the time of kindling the fireplace stove in order to facilitate ignition. On top of the stove (number 8 in the diagram) there is a hole for connecting a chimney. Some models have two holes at the top and back for a flexible installation process. The connection branch is made of heat-resistant cast iron. You can change the direction of the smoke yourself by turning the pipe over (do not forget to unscrew a couple of bolts first). At the bottom of the stove, there is a dedicated place for storing chopped firewood for ignition. Now a little about the process of controlling the furnace. For ignition and adjustment of blowing, air supply, a lever is provided in the design of the furnace (number 7 in the diagram). With this mechanism you will be able to regulate the degree of combustion air supply. Another lever is shown in the figure (number 6). It serves to regulate the air supply to the glass. This design feature is called the Clean Glass system.

- 1.Body;

- 2. The door of the combustion chamber;

- 3.Heat-resistant glass;

- 4. Firewood limiter;

- 5. The cover of the ash pan behind the door;

- 6. A handle for adjusting the air supply to the glass ("clean glass" system);

- 7.Knob for adjusting the air supply to the combustion chamber;

- 8. Hole for connecting the chimney.

What is “Vesuvius” so fond of the bathhouse attendants?

The stove is being developed by domestic engineers and enjoys considerable success both in Finnish saunas and in classic Russian baths. The Vesuvius stove is an all-welded convection-type design, durable and practical. The firebox is made of high-strength steel and is 8 mm thick. In the lower part there is a high-quality cast iron grate. And it is placed in the Vesuvius bathhouse so as to heat it from a room adjacent to the steam room.

These are the main advantages of these loudly named ovens:

- Balanced efficiency of heating stones and air;

- The heater has a large enough capacity;

- Minimum load of stones on the collector;

- Stylish ergonomic design;

- Complete absence of sharp corners;

- Self-cooling door with a huge heat-resistant glass, and even with a self-cleaning system.

These bath stoves are also praised for the fact that it is very convenient to use the convection control dampers in them, the casing of the stove does not "fade" at all, as the bath attendants like to say, and the heat in the steam room literally reaches 80 ° C in an hour and a half and lasts long enough.

Installing the Vesuvius furnace

The installation of the stove is the most important event. The equipment interacts with combustible materials in the room. During installation, fire safety standards must be strictly observed. But before describing the installation process, a few words should be said about choosing a model.

The market offers the installation of metal heaters in the bathhouse and stone ones. Metal models win with their practicality and safety. The choice of model depends on factors:

- the volume of the paired room;

- type of insulation;

- the area of the entire bath;

- desired values of temperature and humidity in the steam room;

- heating time.

Attention! Having decided to install the device yourself, you need to carefully read the manufacturer's instructions. It specifies the installation features of a specific model.

The first step is to prepare the floor. The installation area of the furnace is covered with a metal sheet, or brickwork is mounted. Indents are made by 15-20 centimeters on all sides. The top is covered with a steel sheet or a cement screed is poured.

The oven is installed on the surface, observing the indents. They are spelled out in the installation instructions for a particular model.

Important! The distance from the stove to the ceiling is 120 centimeters, from the heater to the partitions at least 32 cm.

It is possible to reduce the distance by a few centimeters if there is additional protection in the form of a metal sheet.

When installing the stove, take into account the direction of the heating chamber. Models may involve stowing fuel from adjacent rooms. This condition complicates the installation, but provides more advantages in the operation of the furnace.

The next step is the installation of a hinged tank. It is installed in an adjacent room, or, in accordance with the instructions, to a specific furnace model.

The heat exchange system consists of the following parts:

- heat exchanger;

- fittings;

- remote tank;

- connection elements.

During the installation of the heat exchange system, you should not use flexible plastic or rubber liners. In order to avoid freezing of water in the system in winter, a drain valve is built into the lower part of the fitting.

The last step is to install the pipe. It must be at least 5 meters long. It is worth paying attention to the chimney pipe. It is made from refractory materials. The height of the pipe should be higher than the level of the roof of the nearest houses.

The oven is only started after a thorough check of all connections and fasteners. When heating for the first time, an unpleasant smell of burning and chemical products may be felt. This burns the oils that got into the unit during the manufacturing process. It is worth heating for an hour. During this time, the tank, the heat exchange system and other parts of the furnace are checked.

Design

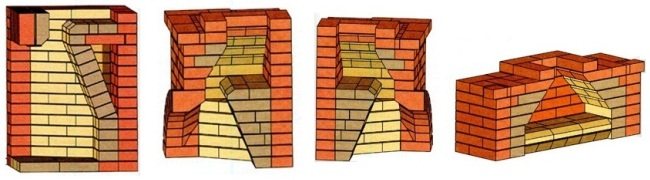

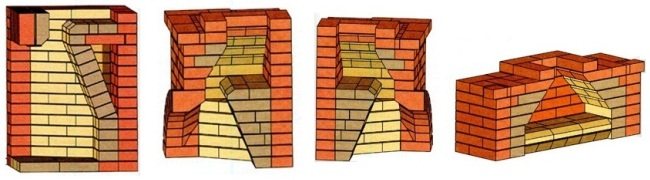

Until now, in some sources, a fireplace diagram may slip, in which the described protrusion is completely absent. This is due to the fact that some even experienced craftsmen do not quite understand why it is needed.

We suggest that you familiarize yourself with Mounting the lining on the clamps: how to fasten with the clamps, how to choose the fasteners, the subtleties of the clamping

Explanations saying that with the help of a fireplace tooth an obstacle to the lowering of smoke is provided can hardly convince a sane person, because the speed is not so high and there is a lot of free space through which the smoke is destined to enter the room. Therefore, this design feature was often ignored.

Smoke Tooth Laying Options

- Each subsequent row of the protrusion hangs over the previous one, forming a slope of the rear wall in the form of a stepped surface.Not forgetting that our task is to remove smoke without hindrance, they try to get away from such a tooth model.

- The projections in the form of sills are removed, having previously cut off the corners of the brick. The result is a flat plane, but you need to manage to process all the bricks at one strictly defined angle. The disadvantage is the fact that the brick is facing the fire with a cut, which is not recommended.

- The brick itself turns to the desired angle. This picture resembles the formation of an arch in a fireplace portal. The disadvantage of this method is that such a structure is weakened.

- Another option is represented by processing three faces of a brick standing on an edge. A whole, intact edge forms a slope and is directed towards the flame.

It is impossible to single out the dominance of one of the methods. It can be seen that each of them has its own advantages and disadvantages. The choice of the method of forming a smoke tooth depends on the skill of the stove-maker.

Often in disputes you can hear such a statement that a fireplace without a tooth works normally, but no one claims otherwise. Perhaps other external conditions have such a favorable effect on traction that the buoyancy force independently copes with the removal of combustion products, or the height of the portal is excessively high. This allows the smoke at the top to acquire enough kinetic energy to leave the smoke box.

But one cannot hope for such accidents and gifts from nature. Therefore, to ensure reliable traction in all weather conditions, experienced craftsmen must perform a ledge. In some cases, professional repairmen, seeing the presence of a tooth, state that the fireplace is made by a competent and experienced craftsman.

We suggest that you familiarize yourself with Installing a vat for a bath with your own hands

Heat exchanger for Vesuvius furnace

The heat exchanger for the Vesuvius oven looks like a geometric stainless steel tank. Material thickness 1 mm. It is intended for heating water in rooms adjacent to the steam room. The heat exchanger is attached to heating and water supply systems using a union. To prevent depressurization of the welds, water is poured into the heat exchanger before starting the system.

Plastic pipes must not be brought close to the heat exchanger. The material is not able to withstand high temperatures. A metal corrugated pipe is used for the tank.

So which model should you choose?

When developing the Rusich model range, engineers relied on the experience of foreign and domestic manufacturers, choosing what works and what is effective. And here's the bottom line: a voluminous ventilated heater that heats stones from four sides in record time. And the process is helped by an external casing-convector, which forms a rather powerful convection flow in the steam room. In fact, "Rusich" is the fastest stove for heating a bath.

In the Skif model range, it was decided to combine the advantages of metal and brick ovens: to make an extra-large convection-ventilated casing for a huge amount of stones that will heat up to 350˚C. And those - for a long time to accumulate valuable heat. And the stones in these models are placed in a casing on all sides of the firebox, protecting it at the same time from hard infrared radiation, which is difficult to get rid of in conventional metal furnaces. A simple and at the same time unique solution.

The Lava models differ from others in their special structural steel and ventilated casing with spectacular forging elements. Such ovens warm up the steam room almost as quickly as Rusich.

Recently, the “Vertical” model line has also become popular - it is in it that advanced technologies are 100% incorporated: a combustion chamber with afterburning of exhaust gases, double flame circulation and, as a result, increased efficiency of the furnace.In fact, this is generally the only stove in Russia that has a double circulation of the flame and afterburning of gases - it is not for nothing that it is chosen first of all by those who really understand sauna stoves and their functioning, and not only determine something by one external design.

But for true connoisseurs of the spirit of the Russian bath, the Vesuvius "Premium" lineup was specially created. Convection-ventilated lining made of pure mountain coil is the secret of such ovens. They warm up quickly, and keep warm and stable temperature for a really long time. Plus, the stylish appearance of the stone and the healing properties of the coil itself.

But for a real Russian bath with its special humid microclimate, the model "Russian steam" is most suitable - its name speaks for itself. In the upper part of the stove there is a stove designed for 60 kg of stones - and they will heat up to 400˚С. As a result, the steam is fine, dispersive and very light. Here we can safely say to the owners of such ovens - with light steam!

Masonry firebox of the stove (brick firebox).

Traditional brick ovens also include brick ovens. Their chamber - walls, base and vault - is laid out of fireclay (refractory) bricks, and the door and grate (grate for fuel through which air enters) are usually made of cast iron.

Advantages of a brick firebox. It is made of the same material as the kiln solid and is built into it. As a result, in addition to heating the flue gases, there is a gradual spread of heat from the walls of the furnace to the inside of the furnace.

Disadvantages of a brick firebox... Unfortunately, bricks often crack, so they have to be gouged out and replaced periodically, which is quite laborious and generally inconvenient. Another disadvantage of the brick firebox is the loose fit of the door to the frame inserted into the mouth. Both are made of cast iron, which reacts differently to heat than brick. Over time, the design of the furnace firebox looses, the door warps and ceases to tightly close the firebox, as a result of which smoke begins to enter the room.

- 1 of 1

On the picture:

It is difficult at first glance to imagine exactly where the firebox of this stove is located.

Furnace in the finished oven

(potbelly stove, stove) is an integral part of it. The entire structure is made of metal - most often cast iron. Such stoves heat a smaller area than brick ones, respectively, and the size of the firebox is smaller. In addition, they are not faced with the task of accumulating heat - it only needs to be transferred to the walls during the burning of the wood, so the walls of the furnace become the outer walls of the furnace itself. When burning fuel, in this case, it is not the intensity of the flame and the high temperature that is important, but the uniformity and duration of the process. A special mode of long burning was created, in which one bookmark of firewood lasts for several hours, which required a modification of the air intake system. Usually there are no problems with a door for such fireboxes, since it is attached directly to the body. Moreover, they began to supply it with panoramic glass, which makes it possible to admire the flame.

Photo: model F 3 TD from the Jotul factory.

Recommendations for use

The manufacturer of equipment for steam rooms "Vesuvius" in the instructions for the models prescribes recommendations for the operation of the device. They should be consulted in advance and followed strictly. This affects the life of the device and the company's warranty obligations. When working with the company's equipment, it is prohibited:

- Use peat, coke, gaseous and liquid materials as fuel. This is not in accordance with fire safety regulations. The combustion temperature may exceed that for which the appliance is designed.

- The firewood must not exceed the permissible dimensions of the firebox.

- Do not use the device if the tank is not filled with water.

- Install in residential areas for heating.

- The chimney can only be shut off when the fire is completely out.

- Do not burn soot from the smoke channel.

- Make changes to the original design of the oven.

Important! To prevent the destruction of cast iron, you should familiarize yourself with the rules for laying stones. Water the steaming stones at a minimum interval of 5 minutes.

If these simple requirements are met, the company undertakes to eliminate all defects or replace the device free of charge during the entire warranty period.

Chimney fire signs

Even if you have not seen a fire coming out of your chimney, this does not mean that it has never been there. There are several effective ways to find out if your chimney has caught fire or not.

- Cracks or other damage to the chimney. You can also observe the absence of small pieces of tiles.

- Damaged or distorted weather vane

- Finding creosote flakes on a roof or ground

- Damage to roofing material

- Cracks in the outer masonry

We hope this information will help you prevent the chimney from catching fire.

Testimonials

The quality of Vesuvius ovens depends on the model and compliance with the operating rules. Skif class models are a budget option. They require careful attitude and periodic maintenance. Cast iron stoves "Legend" are highly resistant to temperature extremes. Consider the reviews.

Banshchikov Zakhar, 53 years old, Moscow.

I have installed a stove - fireplace "Vesuvius" Legend of cast iron. It has been worth it for three years. No changes have occurred in it during use. I tint the grille once a year to avoid rusting. Drown for a long time. There are no other complaints.

Kravtsov Ilya, 30 years old, Kamyshin.

I bought a Skif oven. Burned out after a year and a half of operation in two places.

Bondarenko Roman, 30 years old Nizhny Novgorod.

Vesuvius "Skif" 28. Provide a two-year warranty. In the third year, three walls burned out. You can't brick it up. The walls are jarring with waves. The distant support burned out. The unit is only suitable for garbage.

Problems with the formation of holes in the stove body can be associated with improper placement of stones. Dense, mosaic distribution of stones without ventilation, leads to the formation of holes in the walls of the case. The second reason for the problem is the frequent watering of stones with water in order to get a steam cloud.

Reviews of Vesuvius bath stoves are different. The quality of the model depends on the material from which it is made and the nuances of operation. The cheapest models of the Skif line are considered the "weakest" in the line. These are simple aggregates. They are suitable for those who rarely heat the bath, do not bring it to high temperatures.

How long the oven will last depends on the installation. Incorrect installation can shorten the service life of the system several times.

Owner reviews

As it often happens, some of the owners speak positively about the products, and some negatively. The video below shows a disgruntled customer sawing a new Vesuvius-16 Skif oven to prove that the thickness is less than stated in the instruction manual.

It is indicated in black and white that the thickness of the main elements of the firebox reaches 12 mm, but it is not entirely clear what is meant by "main elements". It can be assumed that we are talking about the arch of the firebox.

Personally, after watching the video, it was not the fact that the thickness became less than the declared one, but the fact that some of the seams were not welded. This suggests that there are problems with quality control in the production of Vesuvius ovens (alas, this is typical of many domestic manufacturers).