Gas boiler beretta error 01 what to do?

Beretta boilers, unlike others, have a peculiarity: the same error a01

described in the instruction manual twice:

- lack of flame;

- control board malfunction

In fact, one of the most common problems that users are looking for information is that there is no ignition of the boiler burner. In this particular situation, you first need to check which actuators are triggered before the error appears.

If the pump, fan is running, there are characteristic clicks of arcing - most likely, a malfunction of the control board can be excluded (but not always).

The boiler resumes operation (errors are cleared) by moving the switch to the “off” position for 5-6 seconds. If the reset does not help eliminate error a01, you need to start troubleshooting.

What are the Beretta boilers?

The manufacturer tried to satisfy any needs - the company produces several lines, in each of which heaters are presented in a wide range of capacities. You can find models for a huge country cottage, a small apartment, or a production facility. All devices manufactured by Beretta can be classified according to the following criteria:

- Installation method - floor and wall. The latter are compact, they can be installed in residential premises. Floor standing are more powerful and cumbersome, they are installed in houses of a large area, in a separate room.

- The principle of operation is classic and condensation. The second, in addition to the energy obtained from the combustion of fuel, use the heat of the exhaust gases to heat the coolant. The efficiency of condensing units reaches 107%.

- The type of combustion chamber is atmospheric and turbocharged. The first ones have the letter "A" in the marking, the second - "S".

- The number of contours - with one and two contours. Single-circuit in the marking usually have the letter "R", it comes first, double-circuit - "C". Heaters with two circuits can also differ in the type of heat exchanger: it can be separate or bithermal. A single-circuit boiler is designed only for heating, but just in case it is equipped with a special outlet for connecting a boiler.

The design is directly related to the heating performance. The company offers boilers:

- Wall mounted. The power range is 11,000–32,000 watts.

- Cast iron. With atmospheric (open) burners. 24,000-279,000 watts.

- Flowing. 18,000-29,500 watts.

Prices for Beretta gas equipment depend on the capacity. The price range is 30,000–95,000 rubles.

What should I check if there is a problem with the boiler firing up (beretta a01 error)?

To check the health of some boiler components, special equipment and skills are required, therefore, if you are not sure that you understand what this material is about, it is better to follow the manufacturer's instructions and call a service specialist. What you need to check:

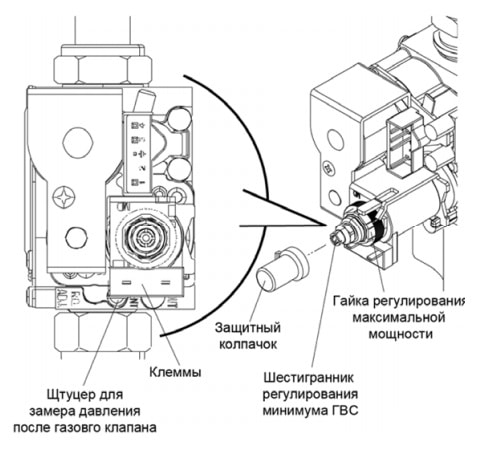

- availability of gas supply and gas pressure at the outlet of the gas valve (the user can independently check only the condition of the gas valve). If necessary, adjust the gas valve according to the instructions, check the resistance of the valve windings (service specialist);

- correct electrical connection (some Beretta boilers require phase and neutral polarity). The boiler body, gas supply and other metal elements must be reliably grounded;

- Poor contact or no signal with the flame detection electrode.In some boilers, the ignition unit can be taken out separately, therefore, it is necessary to check the reliability of the contacts and the integrity of the insulation of the wires before and after the ignition unit;

- Defective flame detection electrode (contamination, breakage). This can be checked visually;

- If all of the above checks did not help localize the malfunction and find the cause of the error, then most likely the cause of the error is still a breakdown of the electronic board. Most often, the relays that are responsible for turning on and off the boiler mechanisms (ignition block, gas valve, fan) fail.

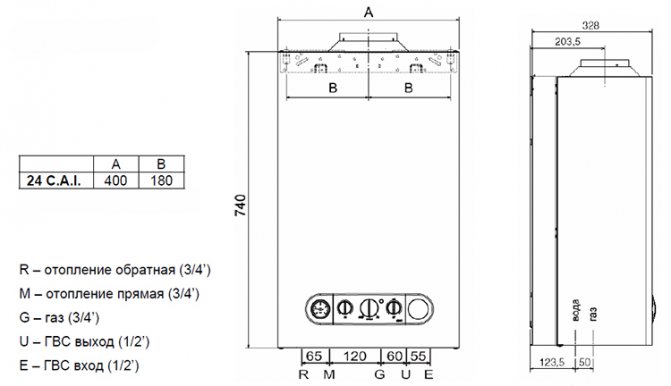

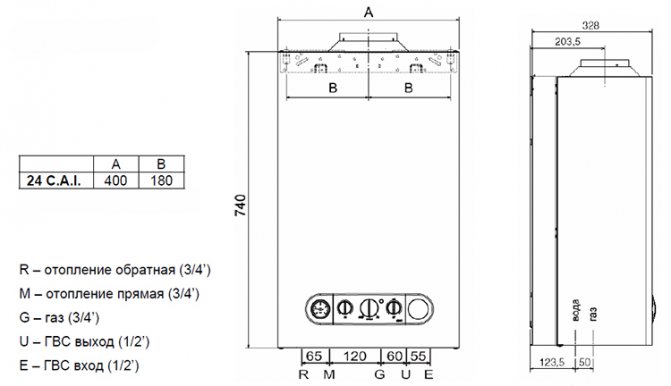

Specifications

Almost all modifications include the following:

- With a small readjustment, natural gas can be replaced with liquefied gas.

- The material of the burners is stainless steel.

- Weather-dependent automation - after connecting the temperature sensor, the device selects a mode based on weather data.

- The built-in circulation pump has an automatic air vent.

- Due to the operation of the hydraulic unit, the safety valve is activated.

- Equipped with pressure gauges.

- Expansion tank of membrane type.

- Electronic ignition for volatile versions.

- Self-diagnosis is provided: tests the traction and pressure of water, checks for the presence of gas.

- Frost protection starts: if the coolant cools down to +5 ° C, it automatically turns on and the water is heated to +21 ° C.

Heat carrier temperature:

- minimum - +40 ° C;

- maximum - +80 ° C.

DHW temperature:

- minimum - +37 ° C;

- maximum - +60 ° C.

In the heating circuit, a pressure of no more than 3 atm is allowed. For built-in boilers - 8 atm.

Board repair or replacement with a new one?

The electronic board of any boiler is an expensive device and it is not advisable to replace it with a new one in case of any malfunction, especially since the beretta boards do not have the most complex circuit diagram.

We offer our clients board repair because it is primarily beneficial, since the cost in most cases does not exceed 30% of the price of the new board. For the repair we have professional equipment, diagrams, original spare parts and experience.

To carry out diagnostics, special stands are organized that simulate a real unit, on which the boards are checked after repair.

We do not just repair boards, but give a substantial warranty period for work, because we have repaired more than one such board and are confident in the result.

Benefits of Beretta boilers

In addition to the high build quality, which practically eliminates any malfunctions, Beretta boilers have the following distinctive advantages:

- Stylish design with flowing lines.

- All equipment is fully adapted for Russian operating conditions.

- A wide range of models, which includes floor-standing and wall-mounted, single and double-circuit devices.

- Compact size and loyal pricing policy.

- Detailed instructions will allow you to correctly install and connect the equipment and will help to eliminate some malfunctions.

All this makes Beretta gas boilers very popular. Let's take a look at some of the most popular boiler models of this brand.

How does the self-diagnosis system work?

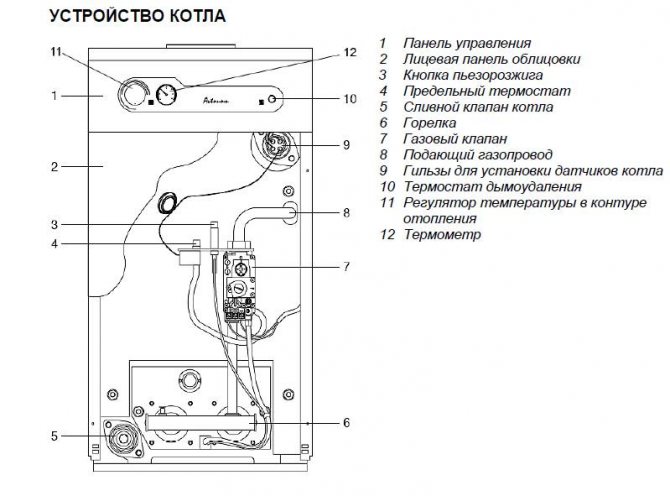

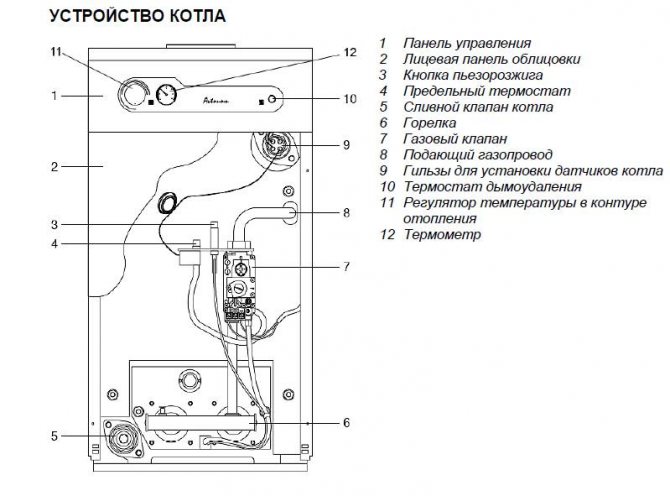

In Beretta boilers, the self-diagnosis system consists of a network of monitoring sensors located on the main working units of the units.

After turning on the boiler, the sensors begin to function in a continuous mode, they do not need an additional special start. By the same principle, disconnecting sensors is impossible without stopping or blocking the gas boiler.

In all the main components of the Beretta gas boiler there are sensors (sensors) that send signals to the display with an error code when a malfunction is detected

When the monitored parameters change or a unit malfunction occurs, signals from the sensors are sent to the control module, which blocks the equipment.At the same time, an error code is shown on the display, allowing the owner of the boiler to determine the type of malfunction and take measures to eliminate it.

In addition to the display, malfunctions of Beretta boilers are signaled by special indicators located depending on the design features of different models of heating equipment.

Beretta CIAO 24 CSI

The Beretta brand is the property of one of the leaders of the European heating industry - the Italian company Riello, whose age is approaching its 100th anniversary.

Beretta boilers are manufactured using modern technologies and fully comply with European safety, economy and efficiency requirements. The CIAO 24 CSI model is made in accordance with the most promising technical developments and is able to meet the needs of a modern residential building.

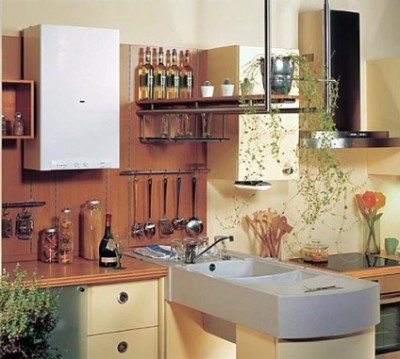

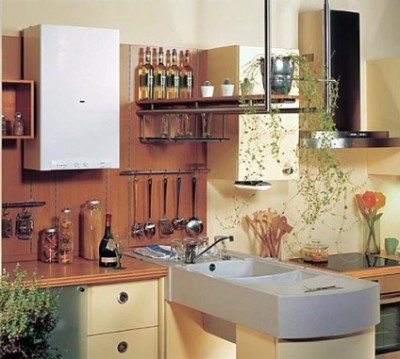

The units are manufactured in a wall-mounted design, have a compact and visually attractive body, which allows them to be installed directly in the kitchen and not have a separate room for the boiler room.

NOTE! The successful combination of price and quality of the Beretta CIAO 24 CSI model is highly appreciated by specialists and users, which confirms the steady demand and demand.

User's manual

Before the installation process, it is necessary to collect technical documentation: an agreement on the supply of fuel for the developer and an installation project. Technical conditions are agreed with the employee of the gas service.

After a personal check of the facility for the correct gas supply, the specialist concludes that all safety rules have been observed. On this basis, it will be possible to slightly open the shut-off valves that are connected to the boiler. The heating system is pressed down to a pressure of 1.8 bar.

Floor heating equipment is installed on the floor surface 10 cm from the wall, which is made of non-combustible materials. Otherwise, there is a need for a special protective material. Only if the above rules are observed, the gas service will give permission to install the boiler and connect it to the main pipeline.

Beretta boilers are connected exclusively to metal pipes. Flexible hoses are only permissible for connecting additional consumers.

Wall-mounted Beretta boilers are installed in special rooms that meet all safety requirements. In private cottages, a boiler room can be installed on any floor, except for living rooms, bathrooms and bathrooms. The area of the boiler room depends on the heating capacity of the heating device and the capacity of the boilers.

In the event that the boiler is equipped with a closed combustion chamber, the area of the boiler room can be any, the presence of window openings is also not monitored. However, care must be taken to supply and remove oxygen in the required quantities.

The boiler room must be equipped with a gas analyzer, which will make it possible to detect possible gas leaks. The gas analyzer must have an electric valve to be able to shut off the gas supply. In apartment buildings, installation of a heating device in the basement is strictly prohibited.

Beretta gas boilers are quite simple to operate. After studying the manufacturer's instructions, you can understand how to connect the equipment. After installing the boiler, the temperature regime of the heat carrier must be set.

After the end of the cold season, boilers with two circuits must be switched to summer mode, while only the hot water supply system is functioning.

See below for details.

Floor units

Beretta floor standing boilers are available in two versions:

- volatile equipment with automation;

- non-volatile boilers without complex automation.

Series NOVELLA AVTONOM (Novella Autonomous)

The gas floor boiler of this series is distinguished by its simplicity of design and reliability. To achieve complete autonomy, the operating manual (instruction) recommends using a heating system with natural circulation of the coolant.

Also, the floor-standing single-circuit device of the Novella Autonom series has the following design features:

- Power range from 24 to 71 kW, which allows heating large cottages.

- The cast iron heat exchanger is highly durable and corrosion resistant.

- The main burner is monitored by a constantly burning igniter.

FABULA E series (Fable E)

This series presents a floor-standing double-circuit boiler with a built-in boiler, which allows you to receive large volumes of hot water without compromising heating power. This manual highlights the following design features that this floor-standing unit possesses:

- The built-in boiler-heat accumulator has a volume of 80, 90 or 120 liters.

- The power of this series boilers ranges from 27 to 43 kW with electronic flame modulation on the burner.

- For the heating circuit, a cast-iron heat exchanger is installed, for the DHW circuit - a steel one with a magnesium anode, which additionally protects the boiler from scale and precipitation.

Advice! Such Beretta boilers have two expansion tanks (separate for each circuit) and a special connector through which the boiler is cleaned.

Beretta boilers are distinguished by their reliability and build quality. For each home, you can choose the optimal model from a wide range of products offered. For example, for remote villages, you can choose a non-volatile floor-standing option, and for a small apartment, a compact wall-mounted model.

Reviews about the rules for installing a gas boiler

Many people like the products of the Beretta trademark. A gas boiler from this manufacturer can be purchased at an affordable cost. Before you start installing the device in a private house, you will need to prepare some documentation, as well as carry out certain actions. Thus, a contract for the supply of gas for the developer, a project for the installation will be required. Specifications must be agreed with the gas service representative.

Design documentation is most often developed by specialists from institutes who work under an appropriate license. Gas equipment should be installed by professional installation companies.

According to users, the engineer of the district organization must visit the site in order to check whether the gas is correctly supplied to the kitchen and the furnace, whether the requirements are met. Recently, quite often, consumers have chosen Beretta products, and a gas boiler is no exception.

After the specialist is convinced that all standards are met, he will issue a conclusion, on the basis of which it will be possible to open the valve that leads to the equipment. The heating system must be pressurized to P = 1.8 atm.

It will be important to de-air the heating system. Experienced users emphasize that the connections must be checked for leaks, it is necessary to install a voltage stabilizer for the equipment and a source that will be responsible for it.It should be remembered that antifreeze must in no case be added to the heating medium.

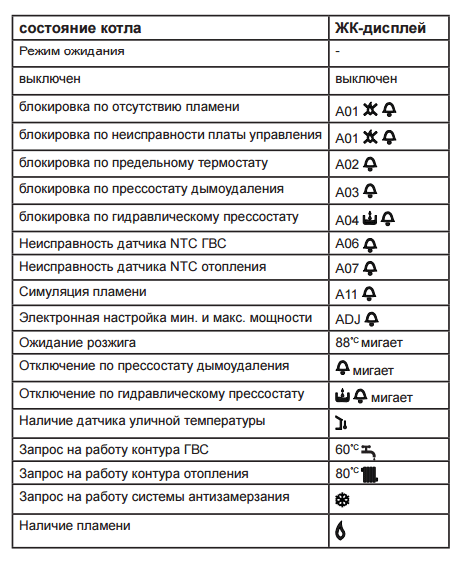

Beretta boilers - Error codes and their meaning

___________________________________________________________________________________________

- Errors of Baksi boilers

- Errors of wolf boilers

- Ferroli boiler errors

- Errors and malfunctions of boilers Fondital

To resume the boiler operation, switch the operation mode toggle switch to the ON position, wait five to six seconds, then turn it back to the desired position. After that, it will start automatically. If normal operation cannot be resumed, call a service technician. Error A01 - Blocking due to lack of flame. Termination of work due to malfunction of the control board. Five unsuccessful ignition attempts. Make sure the gas valve is open. Make sure between the two ignition electrodes.

Error A02 - Blocking by the limit thermostat.

Error A03 - Termination of work on the smoke exhaust pressure switch.

Error A04 - Blocking by the hydraulic pressure switch.

Error A06 - Malfunction of the NTC DHW sensor.

Error A07 - Malfunction of the heating NTC sensor.

Error A11 - Flame simulation.

Error A 20 - After the gas valve closes, it takes too long for the flame to disappear. Check the correct operation of the gas valve. Replace the gas valve.

Error A 24 - Fan error. The measured fan speed changes too quickly compared to the read speed. Check the fan. Check the electrical connection of the fan. Replace fan. Malfunctions causing the final shutdown of the Beretta boiler

The unit needs to be restarted using the Reset button. Error 10 - Blocking due to lack of flame.

Error 11 - False flame simulation.

Error 20 - The limit thermostat is damaged.

Error 21 - Burner thermostat malfunction (MIX CSI models).

Error 22 - The flue gas thermostat is inoperative (CAI models).

Error 30 - Defective smoke exhaust pressure switch (MIX CSI models).

Error 40 - Insufficient pressure in the heating system.

Error 42 - The water pressure sensor is defective.

Error 50-59 - The electronic board is malfunctioning. Temporary faults, the Beretta boiler in automatic mode tries to restart operation Error 31 - Smoke exhaust pressure switch (MIX CSI models).

Error 41 - Insufficient pressure in the heating system.

Error 60 - The DHW temperature sensor is damaged.

Error 71 - Malfunction of the temperature sensor in the heating system.

Error 77 - The low temperature thermostat is faulty. Errors that are automatically reset E23 - Internal error. Replace main control board.

E34 - The mains frequency is not 50 Hertz.

E02 - NTC-1 is open (sensor at the output of the device). The sensor on the flow line in the primary circuit is not connected or has an open circuit.

E04 - NTC-3 open (DHW sensor). The DHW sensor is not connected or there is an open circuit in it.

E18 - NTC-1 - short circuit. Short circuit on the flow line sensor in the primary circuit.

E20 - NTC-3 short circuit. Short circuit on the DHW sensor.

E33 - Phase and neutral are reversed. Connect the phase and neutral wires correctly.

E34 - Reset button error. The button was pressed more than 7 times within 30 minutes. Wait until the error goes away. If the error is still present after a maximum of 40 minutes, replace the board.

E35 - Error of the differential water pressure switch (contact open). Make sure that the water flow in the circuit of each unit is at the correct value. Each unit must have a flow rate of 2 m3 / h. Replace the water pressure switch (setting 500 liters / hour).

E37 - Flame detection error. Clean the electrodes. Replace electrode.

E38 - Short circuit of the flue gas sensor. Check the flue gas sensor connector. Replace the flue gas sensor.

E39 - The contact of the flue gas sensor is open. Check the flue gas sensor connector. Replace the flue gas sensor.

E40 - Check the frequency in the power line. Other symbols that appear on the display and their meanings ADJ - Electronic setting of minimum and maximum power.

The 88 degrees symbol is on - Waiting for ignition.

Flashing bell symbol - Shutdown by hydraulic pressure switch.

P - The DHW preheating function is activated.

Flashing P - Request for DHW preheating.

The 60 degrees symbol is on - Request for the operation of the DHW circuit.

The 80 degree symbol is on - Request for heating circuit operation.

Repair and service

Trouble-free and long-term operation of Beretta boilers can only be ensured by regular service. Its duration during the main season, due to the poor quality of utilities and the long duration of the cold season, should be increased compared to the requirements of the manufacturer's instructions.SC repairs Beretta boilers of the following models: Ciao 24 csi n, 28 csi, 24 cai n. Ciao 28 cai, 24 c. City 24 csi, 24 rsi, 24 cai, 28 csi. City 28 rsi, 35 csi, 50 rsi green. Beretta Novella 31 rai, 64 rai, 45 rai. Novella 35 e rai, Maxima 244 rai. Novella Avtonom 24 rag, 36 rag. Avtonom 55 rag. Exclusive mix 35 csi, 28 cai. Exclusive mix 30 rsi, mix 26 csi. Beretta Fabula. The main maintenance activities are: - cleaning of work surfaces; - setting up automation; - strapping diagnostics; - control of the chemical composition of waste gases; - determination of the quality and suitability of filter elements; - fuel pressure and quality control; - control of the intensity of circulation and the temperature of the coolant. Practice shows that the main malfunctions occur for the following reasons: - installation errors; - power surges in the network; - inept service; - low quality of preparation of the coolant. Aggregates and their systems require special service after major repairs, modernization or replacement with another model. In these cases, additional calibration of the automation is required. It is important for owners to follow the rules prescribed in the operating instructions. Otherwise, there is a possibility of equipment failure before the end of the warranty period. Scheduled inspection of the boiler by specialists will increase the service life, increase the efficiency of the boiler equipment to the calculated values, and prevent accidents and breakdowns. For example, unlubricated axle bushings dry out, increasing friction and increasing the supply of current to the starter winding. The result of this may be a breakdown of the fan relay with a burned out coil, requiring its replacement.

The maximum gas pressure switch protects the equipment from an uncontrolled increase in pressure on the burner, which can lead to burnout of the combustion chamber, which is not designed for a high local temperature load. By correctly installing it, pressure surges and possible malfunctions are prevented.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alpha Calor, Thermotechnik. Adjustment of gas automatics Eurosit 630. Replacement of the thermocouple and maintenance of the ignition burner.

Malfunctions and repairs of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Gas heating boilers Bosch Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Options for setting functions and modes.

Repair recommendation Navien Models Deluxe Coaxial, Deluxe Plus, GA. Errors and malfunctions. Work with remote control Ksital. System control. Setting work on temperature and pressure.

Floor standing boilers Buderus Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vilant boilers Turbotec Atmotec pro / plus VU / VUW INT models. Components and work functions. Adjustment programs. Gas system. Installation and assembly. Maintenance and prevention.

Floor standing boilers Protherm Repair of the Bear models KLOM, KLZ, TLO, PLO with a capacity of 20 to 50 kW. Breakdowns and malfunctions. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and settings Models of gas floor boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automatic equipment Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted coppers of Protherm Repair of the Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repair and adjustment Repair and operation of boilers Ciao, City, Novella, Exclusive. Wall and floor models. Malfunctions and error codes. Working functions and setting of service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of an automatic pellet burner APG-25, 36, 42. Settings of operating modes.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes. Troubleshooting tips. Operating modes and setting of service parameters. Maintenance.

Heating boilers Alfatherm Description of Beta floor-standing boilers and Sigma wall-hung gas boilers. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - malfunctions and repairs The Wolf boiler is installed. I noticed that over time, the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks but found nothing. What else to check?

Gas boilers Junkers After 7 years of operation, the gas boiler Junkers ZW-23-KE has the following problems. When DHW starts working, it either turns off or stops working ...

Repair of boilers Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, no matter what the temperature is. To make sure that this is so, he raised the temperature in ...