How the hood works

The very name “hood” means drawing hot, polluted air from the kitchen and removing it from the room. The air is removed into the ventilation ducts of the building, therefore, when buying or making a hood with your own hands, you need to take care of the proper condition of ventilation throughout the house. The efficiency of the system is directly dependent on traction.

Along with proper ventilation, it is necessary to ensure sufficient air flow into the room. For example, if you have metal-plastic windows with a high level of tightness installed, then for efficient operation of the hood, experts recommend using the micro-ventilation function, or installing supply ventilation valves on the windows.

Types of kitchen hoods

The modern technology market offers a large number of models of hoods. It is quite natural that before making a cooker hood in the kitchen with your own hands, you will familiarize yourself with what they are in general in order to choose the best design option.

Mode of operation

All devices for this purpose are divided into two large groups:

- Passive hoods are dome-type. They remove air solely by upward thrust. There are no electric motors or fans inside such devices. The hood of this type will work only if the ventilation ducts of the house are in good condition or due to a high ventilation pipe.

- Active hoods are powered by an electric motor installed inside. These devices work stably, but they also consume a lot of electricity.

Connection

By type of installation, hoods are distinguished:

- Suspended (flat) fastened under the cabinet above the stove.

- Wall-mounted - mounted above the slab on the wall. The case design may vary.

- Built-in - fit into any design, as they are installed inside a wall cabinet or on a table.

- Corner - installed in a corner.

- Island hoods. This type of device is intended for kitchens with an island. You can fix the device anywhere in the room by hanging it from the ceiling.

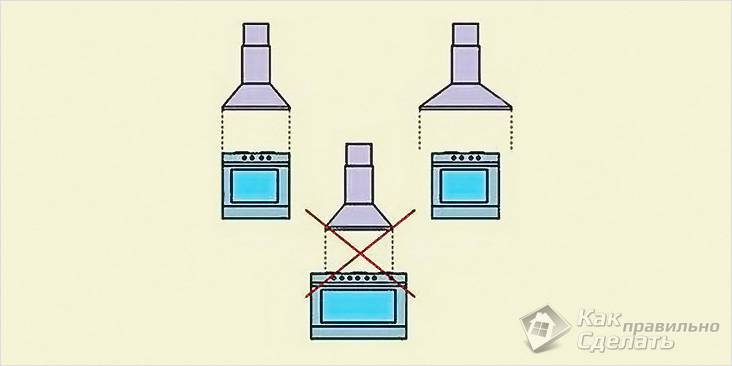

Tip: The installation of a kitchen hood, regardless of the type, should be 70 cm above the hob and 80 cm above the gas stove.

Ventilation method

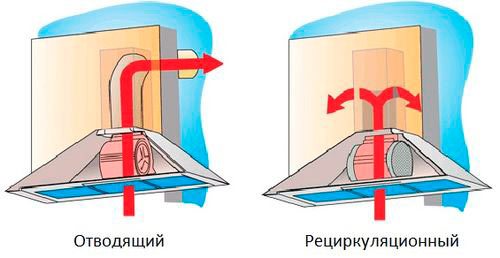

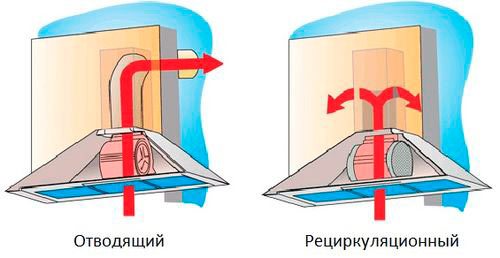

According to the ventilation mode, the devices are divided into:

- Flow-through - they draw air from the kitchen into the ventilation shaft. This type of ventilation is called exhaust ventilation. It is the most productive and efficient.

- Circulating hoods - pass air through the charcoal filters located in the housing. Fresh air is discharged at the outlet. For such a device, ventilation in the kitchen is not required, so its installation is much easier, but the hood itself is less effective in terms of cleaning. The disadvantage of such hoods is the lack of fresh air, since as a result of processing by filters, the same, but purified air enters the kitchen. In addition, filters need to be cleaned and replaced periodically.

Tip: When choosing a cooker hood that you make with your own hands, consider each of these points. Only in this case will you provide yourself with comfortable cooking conditions and convenient operation of the equipment.

How to connect the hood to the mains

The final stage is connecting the hood to the mains. It is done in two ways:

- Through an outlet

- Through the safety machine

It is very important to remember about grounding, which was already mentioned in the article above. Thanks to it, you can remove the voltage from the case and the hood fan.

As soon as everything is ready, you can arrange the hood in a decorative cap and protective air ducts and safely use all the advantages of this equipment.

The device of a kitchen hood is a fairly simple procedure, especially if all electrical safety rules are observed and the necessary tools and materials are available. And the only thing that will then be required is to clean the equipment from grease and soot 2 times a year to prevent a fire.

Passive drywall hood

If you already have certain skills in assembling various household items, you should not be afraid of a new job. You will completely master this task and be able to make a high-quality cooker hood for the kitchen with your own hands. To do this, follow the scheme below.

You will need:

- Moisture resistant drywall. From this material we will make a box for placing the air duct, as well as the dome of the device.

- Galvanized metal profiles. This material will be needed for the frame of the dome and box itself.

- Corrugated pipe. We will use this material as an air duct.

- Perforated metal corner - to decorate the corners of the fixture.

- Fasteners.

- Insulating material (for wrapping corrugated pipes).

- Paint and putty for finishing the dome.

- Tool set: Perforator;

- Metal scissors;

- Screwdriver;

- Level and tape measure;

- Brushes, spatulas.

Stage 1. Room layout

You will need to place not only an extractor hood on the wall, but also an air duct hidden in a drywall box, so find a ventilation hole in the kitchen:

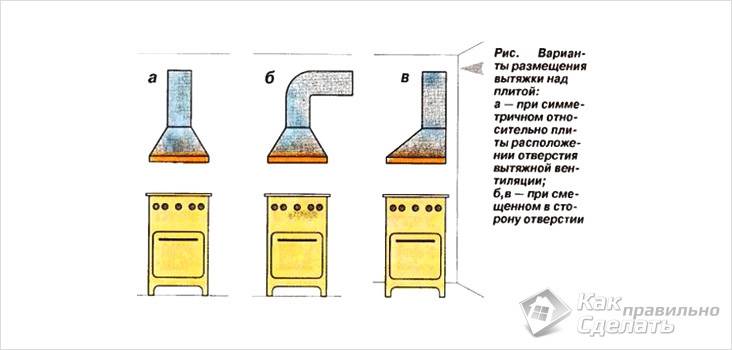

- if the ventilation is above the stove itself, then the markings are almost ready;

- if the hole is to the side, then it is necessary to mark the position of the duct on the wall for laying the air duct.

Advice: If the repair plans include a suspended plasterboard ceiling, then the duct can not be hidden, but run under the ceiling sheathing.

Stage 2. Fabrication of a frame for an air duct:

- Mark the bottom of the duct surface on the wall.

- At the level of the lower part, attach a galvanized metal starter profile. For fastening, use an anchor with a plastic sleeve 6 mm.

- Attach the starting profile to the ceiling according to the marked markings.

Tip: If you have planned a curved duct box, then cut and bend the profile before fastening.

- Down from the starting profile, lower a few vertical fragments of the main profile.

- Use self-tapping screws to attach the vertical pieces to the starting profile.

- Form the frame for the box: install another panel of the starting profile on the prepared suspensions.

- Place the cross bars on the bottom of the resulting profile.

Stage 3. Manufacturing of the hood body:

- Make the lower frame of the hood from the starter profile.

- Secure the frame to the kitchen wall.

Tip: If you are installing a kitchen hood in a niche, it is quite easy to fix it, and if in a different place, then additionally fix the side parts of the frame to the box.

- Cut out the frame elements of the future structure from the main profile.

- Connect the frame pieces to the bottom frame.

- Reinforce the side surfaces of the hood with crossbars from the profile. This will add reliability to the design.

- Connect the air duct (corrugated pipe) to the ventilation hole.

Tip: To keep the air duct from making noise during operation, wrap it with batting or prepared soundproofing material.

Stage 4. Hood finish:

- Cover the housing and duct box with plasterboard.

- Protect the corners of the structure with a metal perforated corner.

- Treat the drywall structure with putty, mask the joints of the drywall sheets, as well as the fasteners.

- Paint the hood in any color of your choice or decorate in any other way.

Tip: The above-described hood manufacturing technology is suitable not only for a passive device, but also for the production of an active type hood. It is enough to install an electric motor inside the housing at the inlet to the air duct and connect it to the network.

Selecting the operating mode of the hood

The installation method of this device will depend on its operating mode, of which there are 2 in total:

- Retract mode

- Recirculation mode

The hood installation, which operates in the exhaust mode, includes the outlet of the air duct to the ventilation system. For this, it is very important to choose the correct diameter of the duct - it should not exceed the permissible parameters of 120-150 mm.

Advice! When installing the duct, it does not need to be bent or lengthened, since all this significantly increases the loss of power: each turn reduces power by as much as 10%.

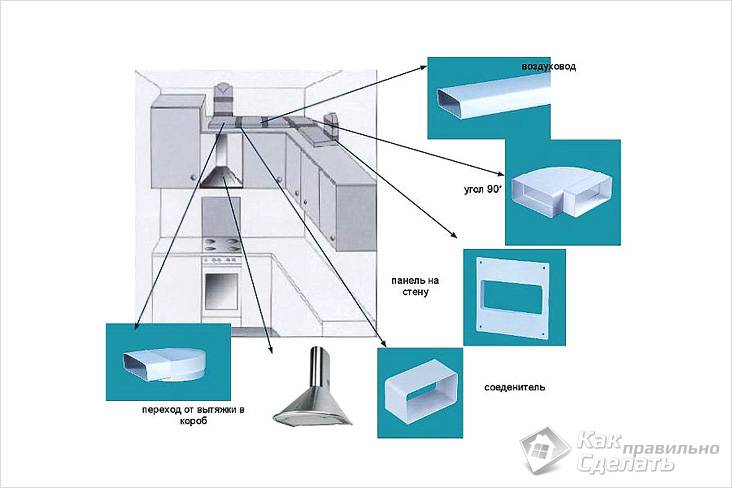

Choosing an air duct, you need to give preference to those that have a smooth surface, because corrugated rigid pipes "sound" too loudly during the operation of the equipment.

Installing a hood with a carbon filter does not require venting, because all the air that enters it is purified and returned to the room. Installation of such a hood is quite simple, but you will have to periodically change the filters.

It is equally important how exactly the hood will be attached, it depends on its type.

Active extraction from plywood

Another way to make a kitchen hood with your own hands from improvised means is also very simple to perform. Choose the option that is more convenient for you and proceed.

You will need:

- An old but workable hood (an inexpensive new model can be purchased);

- Thin plywood for dome walls;

- Glue;

- Putty;

- Paint, varnish;

- Electric motor;

- Clamps with soft plastic (or rubber) attachments;

- Brushes, spatula.

Assembly instructions

- On the basis of the old hood, we assemble the main elements: a lower frame with an exhaust grille, an electric motor.

Tip: Do not worry about the appearance of the structure, as all the details will be hidden behind the cladding.

- Place the frame elements made of curly planks on the base.

Tip: You can make any shape of the frame, if only the air duct fits inside the dome.

- Cut the walls of the hood out of thin plywood.

- Cover the frame with the made elements.

Tip: For a neat bonding of the dome, use the clamps with attachments.

- Allow time for the adhesive to fully cure.

- Apply a putty to the plywood dome.

- Paint the cooker hood in the color of your choice or treat it with varnish.

- Attach the fixture to the wall.

Tip: If you were using the old structure, then the wall mounts should have been preserved.

- Connect the air duct to the device.

- Cover the duct with a decorative box. We described above how to do it.

How to install a cooker hood on a kitchen wall

In the case of mounting the device not in a cabinet, but directly on the wall, you can use the built-in mounts or build a U-shaped frame from the corners. Such a frame will serve as a reliable support for the hood body.

In some cases, ordinary dowels are not suitable for fastening, this is a fairly common problem for those whose gas stove pipes interfere with normal fastening. To solve the problem, you need to use long self-tapping screws. At one end, they have a thread with a nut to which the device body can be screwed.

What do you need to know for ventilation to work efficiently?

In order for a self-made kitchen hood to be effective and you do not have to be puzzled by the problem of optimizing it in the near future, carefully read the information below.

Required device power

First of all, the power depends on the size of the kitchen - its area and height. If the hood is curved, then the power of the air ducts is lost by a third. Therefore, it is necessary to calculate the power and depending on the shape of the device.

Tip: Power is the cleaning performance. It is measured in cubic meters per hour. According to the established norms, the air in the room must be renewed 12 times per hour. Calculate the required power using a simple formula:

Kitchen area * ceiling height * 12

For example, if your kitchen has an area of 10 m2, and the ceiling height is 3 m, then the calculation looks like this:

10 * 3 * 12 * 1.3 = 468 m3

(If the shape of the hood is straight, then you do not need to multiply by 1.3).

Electrical safety

During operation, grease and splashes enter the hood, which can cause a short circuit. Moisture accumulates in the kitchen and, with constantly high humidity, the chance of electric shock increases if the device is incorrectly connected to the network, so a hand-made hood must be connected to the network with three wires:

- land;

- phase;

- zero.

The standard grounding should be colored yellow and have a green stripe.

Tip: To make it easy for you to cope with the task, consider the following recommendations:

- If the house has a ground loop, and there are euro sockets, then there are no problems: when connecting the device, connect the wire to the ground terminal, which is designated by the word “ground” or strips of different lengths.

- If the equipment does not have a connector for grounding, then screw the wire to the metal case.

- If you do not have euro sockets, then do it yourself: connect it to a dead neutral.

- You cannot connect a neutral wire to pipes and batteries.

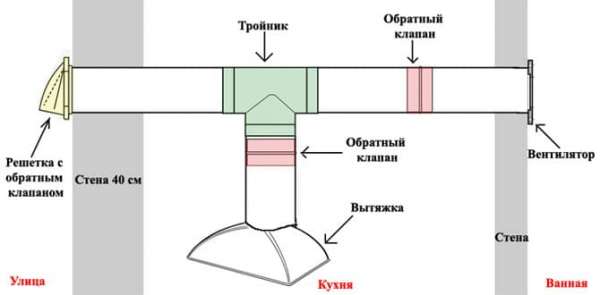

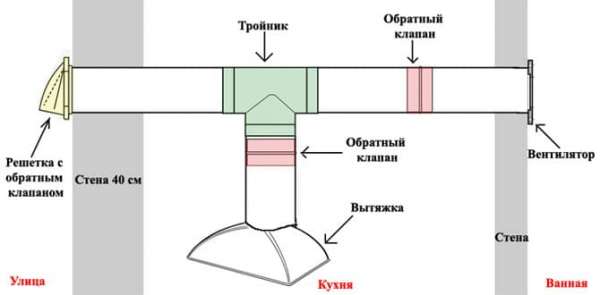

Connecting the air duct to the ventilation duct ↑

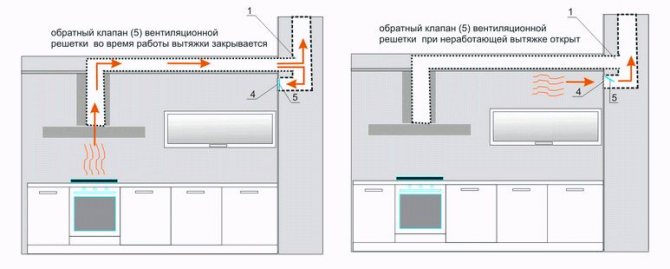

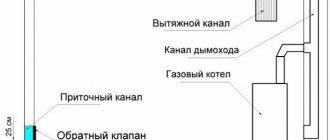

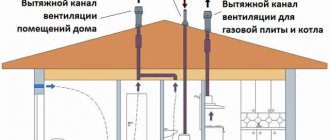

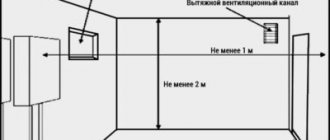

Competent connection of the air duct to the ventilation duct is a guarantee of the absence of unpleasant odors in the kitchen. But this is not as easy as it might seem at first glance. The difficulty is that, by connecting the forced exhaust to the ventilation duct, not to disrupt the work of natural ventilation. There are two ways to solve the problem.

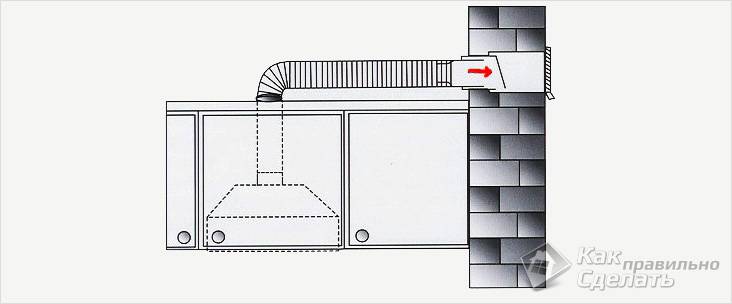

If possible, it is best to lead the kitchen hood ventilation pipe out through the wall by making a hole in it.

In the presence of an additional ventilation duct ↑

Ideally, there are two ventilation ducts in the room, which is found in pre-war houses. Then one of them will work as natural ventilation, and the extractor hood is connected to the second. In a private house, it is better not to touch the vertical ventilation duct and punch an additional hole in the outer wall, into which the horizontal air duct will be led from the device. Outside, we recommend installing a non-return valve to prevent cold air from entering the pipe and the grate that closes the hole from precipitation.

If there is no additional ventilation duct in the kitchen, this cannot be done! Such installation of the hood largely deprives the room of natural ventilation.