The ventilation system is one of the main components in the general system of engineering support for the life of buildings. Its main purpose lies in the term itself, translated from Latin meaning "airing". Normal operation of ventilation should provide comfortable and sanitary and hygienic living conditions for the population, and for industrial enterprises - compliance with regulatory and design indicators for the content of harmful substances, gas pollution, permissible emissions, and safety.

The functions of ventilation systems include ensuring the balance of the volumes of incoming and outgoing air in compliance with the required air exchange rate, ensuring the required temperature, humidity, and cleanliness of the air environment.

Classification of ventilation systems

Ventilation systems are classified both by purpose and by the way of organizing air exchange.

The following types of ventilation exist for their intended purpose:

- Supply air, which supplies a certain amount of air to a building or room.

- Exhaust, providing removal of exhaust air.

- Supply and exhaust - a combined system, which includes elements of both types.

According to the method of organizing air exchange, ventilation is divided into:

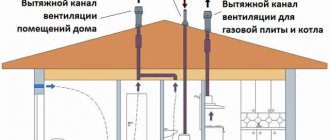

- Natural, in which the degree of air exchange is determined by the difference in air pressure outside and inside the building. In this case, natural ventilation can be unorganized, in which air exchange is carried out through leaks or open doors, windows, vents, or organized - through a system of ventilation shafts, channels, openings.

- Mechanical, in which the pressure difference is created by the fan, and the operability is ensured by various devices and equipment - filters, noise dampers, regulators.

The advantages of using such a device

Now let's figure out what the sewer air valve gives.

It is worth saying that this device has several functions:

- Unpleasant odor neutralization. We have already spoken about this, and once again we note that this is the main function of such a device.

- Saving. The fact is that when laying a sewage system, it becomes necessary to install a reverse type line. If you use the valve described by us, then you can neglect such a costly procedure.

- Facilitate work. It does not need to be installed on the roof. Sometimes this turns out to be a very problematic procedure.

Clearly presented operating principle

- Increasing the efficiency of the line. If the house has a relatively large number of plumbing elements (at least 5), then the presence of such a device is simply necessary. Otherwise, the sewerage system will not cope with the task at hand.

Reverse thrust problem

The development of new building technologies characteristic of the last decades, the emergence of new building materials and products, advanced and sophisticated household appliances forced the population to expand their knowledge in the theoretical and practical terms of organizing the ventilation of their living space. The fight against "reverse thrust" has become relevant for the owners of apartments and private houses.

Reverse thrust - violation of the normal mode of air exchange, in which there is a decrease in the rate of air removal up to the return flow through the exhaust ducts into the room.The reasons may be design miscalculations, natural causes (pressure drops both towards rarefaction and towards hurricane gusts), various defects in building elements (clogging, freezing, destruction of channels), as well as spontaneous changes in the design and design mode of the system.

An example of the latter reason is a standard high-rise building for which an organized natural type of ventilation has been established by the project. More than one generation is familiar with wooden doors and window frames with vents, seasonal campaigns for their insulation, puttying and gluing. The calculation of air exchange of entrances and risers was carried out taking into account the structural leakage of these elements. The massive installation of sealed plastic windows and metal doors that are denser in comparison with wooden doors has made adjustments to the established balance.

Another factor was the active installation of exhaust fans - on ventilation windows in bathrooms or as part of hoods above a gas stove, the result of which was the mutual exchange of a bouquet of odors between neighbors, which also indicates a disturbed balance of air exchange.

Protection system

One of the most effective methods of dealing with backdraft is the installation of a check valve, which allows the medium to pass in one direction and does not allow it to move in the opposite direction. In technical terms, these devices refer to protective fittings and are used in hydraulic and pneumatic systems, which include ventilation systems.

Industrial ventilation systems are mandatory equipped with non-return valves, therefore, in order to meet the emerging needs of the population for these products, it was not necessary to reinvent the wheel. The existing types of structures were taken as a basis and adapted for domestic needs, taking into account the required costs, dimensions and design requirements. The main structural designs used in industry turned out to be applicable for the household sphere:

- Petal, in which the working body is a disc fixed on the axis. The weight of the disc is designed to open it with a stream of air in normal operation and flop in the event of reverse thrust.

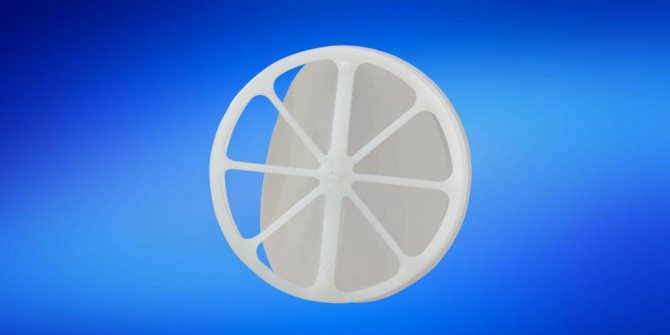

- Louvers... Working lamellar sashes are mounted on axles, opening and closing occurs from the air movement in the forward or reverse direction.

- Diaphragm valves they work on the principle of a lattice, the flaps are one or two membranes made of soft material (film, plastic, rubber), fixed on one side.

The listed structures can be used in systems with both natural and supply and exhaust ventilation, and according to the mechanism of action they are passive, in contrast to the next one, which contains an active element.

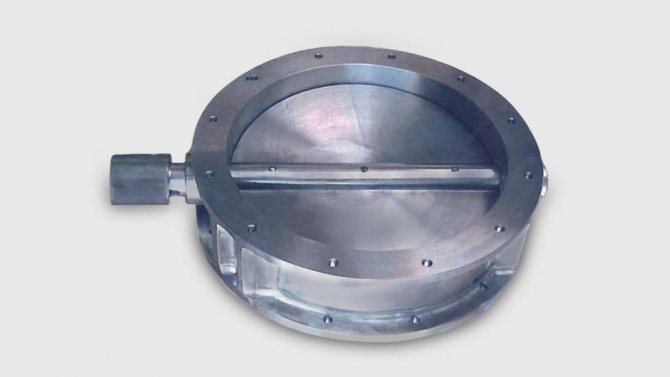

- Butterfly check valve (butterfly type for industrial valves) is a two-disc (equivalent to two-leaf, double-leaf) with springs that ensure the tightness of the shutters. To open, the springs are designed for a certain pressure of the air flow, as a rule, created by the fan, therefore, butterfly valves are practically not used for natural ventilation.

The main characteristics of the check valve, which determine the possibility of its application, are the flow area, flow capacity and the tightness of the shutter at actuation.

The first two parameters should provide the standard air exchange rates determined by sanitary and building regulations. For living rooms, this figure is 3 cubic meters / hour per 1 square meter. area or 30 cubic meters / hour for 1 person, for a standard kitchen with a 4-burner gas stove at least 90 cubic meters / hour. For domestic ventilation systems, check valves with a diameter of 50 to 150 mm (or the corresponding size for a square or rectangular design) are mainly used.

Unfortunately, manufacturers of valves produced for the population practically do not indicate the throughput or the coefficient of throughput Ksv in their passports, in contrast to manufacturers for industrial purposes. It remains to either trust their professionalism and responsibility, or independently check the valve's performance.

Standard indicator for checking normal thrust in the ventilation duct there is a flame of a match or a lighter or a notebook sheet. The burning torch should deflect in the direction of the thrust, the sheet should be held by the vacuum force. If you lean against the ventilation opening of any type of non-butterfly valve, its flaps (louvers, membrane) should open. If you repeat the operation, turning the valve 180 °, the thrust should be enough to close it, and the tightness can be checked with the same lighter.

The specified method is suitable only for checking the exhaust check valve of ventilation as an independent product. For convenience and ease of installation, modular options are increasingly being offered - a ventilation grill with a check valve, they are also with a fan, an air duct unit with them with a built-in filter, a temperature sensor, and so on.

Types of check valves

- Gravitational - do not require an additional source of energy to operate.

- Forced - powered by electricity.

Positive pressure valves provide slightly more isolation than gravity valves. They cover the canal more tightly and this can be important in production facilities. But in everyday life, this difference is almost imperceptible.

Valve shape

The valves are of various shapes. The most common:

- "Membrane" - a plate made of soft plastic

- "Single-leaf" - a round (usually) plate made of hard plastic or metal

- "Bivalve" - 2 rounded (usually) plates made of hard plastic or metal. They are sometimes called "butterflies"

- "Blinds" - strips made of hard plastic or metal. Household fans usually use plastic.

The valve shape is less critical. However, a diaphragm valve in a kitchen or other area with contaminants requires more frequent maintenance. And no matter how you take care of it, it will fail earlier than valves of other forms, because the membrane itself is very "delicate". The rest of the forms are about the same in terms of reliability and ease of maintenance.

Residential ventilation problems

As a rule, check valves are installed on exhaust ducts or ventilation openings, and much less often as supply ones. This is understandable, since initially it is assumed that clean and fresh air will enter the house or apartment, and protection devices must be installed on the side of removing polluted or exhaust air.

In general, the ventilation device or the solution to the problems that have arisen must be approached in a comprehensive manner. Backdraft problems are most often the result of errors or irregularities during installation or operation. The lack of an integrated approach is again characteristic of the previously mentioned high-rise buildings. Unlike power supply, water supply and heating systems, the ventilation system is not under the control of any utilities or inspections and is not controlled by management companies. As a result, the tenants each solve problems in their own way, layering their mistakes on those of others, including "locking" the air movement with the help of fans and valves to both neighbors and themselves.

It is for this reason that the involvement of specialists is simply necessary for these works, from calculations and design to the commissioning of systems and devices.

Properties

It is quite difficult to imagine a toilet (or bathroom) without any foreign odors.This creates a certain discomfort, in connection with which an air check valve for sewage was invented. It allows you to deal with many problems.

The causes of the smell

Surely many people are wondering where this unpleasant smell comes from. Of course, when there is a blockage in the line, everything is clear. However, what if it's not there?

In fact, everything is very simple - the reason is the simultaneous drain from several devices. As a result, air pressure appears in the pipes, and it is able to squeeze out all the liquid from the gates. As a result, the air moves freely throughout the system, and with it some stench.

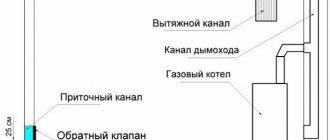

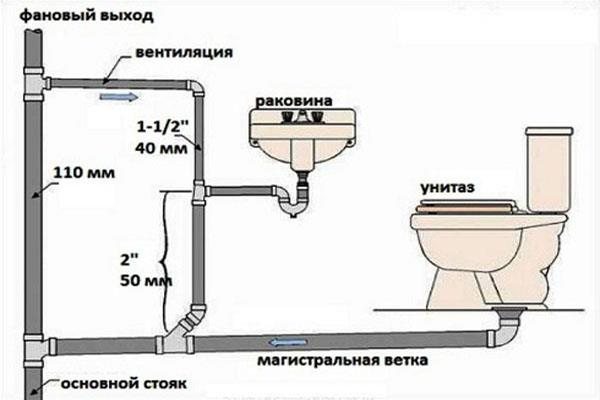

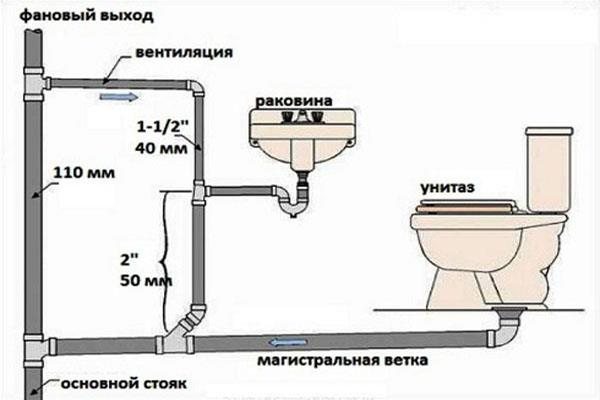

Here you can see a diagram of the organization of competent ventilation.

Earlier, when the air valve for the sewage system had not yet been invented, there was only one solution to this problem - the outlet of the ventilation of the riser to the attic (or roof). At the same time, such a measure did not give the proper efficiency, because at low temperatures it froze and did not cope with its task at all. Fortunately, the product we are describing came to the rescue.

Device and principle of operation

The instruction below will explain how such a mechanism works (see also the article "Telephone sewerage: features of construction and operation").

It consists of the following elements:

- Stock. It is the main structural element that opens (and closes) the side opening, if necessary.

- Housing with holes located on the side. They are needed for air intake. In most cases, this element is made of plastic, because the price of such a material is the lowest, but there are other options.

Advice: PVC is resistant to moisture and most chemically aggressive substances, but it is very afraid of mechanical stress (it is easy to break). Therefore, some people purchase metal counterparts that have a longer lifespan.

In this photo you can see all the components (from bottom to top): body, air intake, stem, gasket, protective cover

- Rubber gasket. It is needed to ensure maximum sealing of the device.

- Protective cover.

In most cases, these mechanisms are available in two sizes: 110 and 50 mm (for connecting individual elements). However, today you can find others, for example, the sewer air valve 100. This is due to the fact that now there are countless different plumbing equipment, the dimensions of which may be non-standard.

The principle of operation of the product we are describing is as follows:

- When draining from several devices, a vacuum is formed in the system. This means that the pressure rises sharply at first, and then also quickly decreases.

- If the common pipe does not ventilate, then the stem slightly opens the hole located on the side. As a result, a certain amount of air enters the riser.

- When the pressure in the system returns to normal, the device returns to its original position.

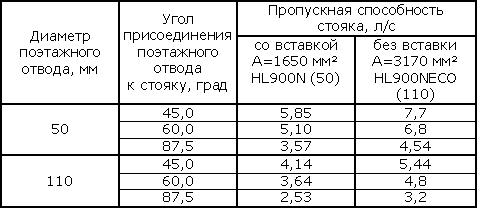

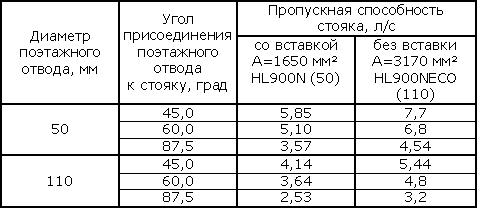

In this table you can find some very important technical characteristics

As a result, this, simple at first glance, product provides pressure control throughout the entire line. As a result, unpleasant odors from below do not get outside.

Varieties

Now in stores you can find several varieties at once:

- Air automatic. It has a rather weak bandwidth, therefore it is used only in the private sector. Provides only air release.

- Anti-vacuum. Used for any number of pipes. Provides both air release and air inlet.

- Combined.

If funds allow, you can safely take an anti-vacuum even for one private house. This will ensure maximum efficiency.

Two words about editing

If this is the first time you are going to work with such a mechanism with your own hands, then you probably want to know how it connects.

In fact, there may be two options:

Scientifically, this device is called aerator

- We install one valve directly on the common riser, which is responsible for all the air in the system... It is mounted using various fittings (they are selected depending on the material and shape of the pipes). In this case, purchase a product with a diameter of 110 mm.

Important! Do not forget to treat all joints with a sealant (it is better to use silicone samples).

- If you want to achieve maximum efficiency, you can install it separately on each plumbing fixture (toilet, sink, bathtub, washing machine, etc.)... In this case, preference should be given to a diameter of 50 mm.

Output

Now you will certainly be able to choose a suitable air valve for sewage 110. However, if you could not understand all the subtleties, then do not be discouraged (see also the article “Why do you need a cable duct and how it is laid”).

In the video presented in this article, you will find additional information on this topic, which will allow you to understand everything.

Did you like the article? Subscribe to our channel Yandex.Zen

ERA D 100 range hood overview

Before purchasing a bathroom hood with a check valve, you should familiarize yourself with its main characteristics and features. An excellent example is the ERA D 100 model. Its cost is 750 rubles. The equipment is capable of performing periodic and constant ventilation in premises for various purposes, including:

- bathrooms;

- shower rooms;

- bathrooms;

- kitchens.

The product has a sturdy housing. The motor has built-in thermal protection and a bronze bushing. The manufacturer completes the equipment with a non-return valve. On the front panel there is an indicator showing the operation of the product.

Features of valve manufacturing

Despite the fact that the price is not high for a check valve for an exhaust hood, you can also make it yourself. To do this, you should take care of the availability:

- ventilation grill;

- soft plates;

- thermo gun with glue.

As for the plates, then a film from a fluorographic apparatus can act as them. It is necessary to glue the plates on the inner side of the grill so that they are fixed on opposite sides. The middle parts should move freely. This device is the simplest check valve. The grate is installed in place, and it will work without letting air out of the shaft.

Hood overview with valve: ERA D 125

You can purchase this device for 1,400 rubles. It is an axial fan that can be installed in bathrooms, bathrooms and kitchens. The premises will be protected from moisture from neighboring apartments and unpleasant odors thanks to a non-return valve. The design has a removable ultra-thin front panel, which is based on white ABS plastic, which is compatible with most interiors. Installation is carried out to the wall using screws.