Corrugated pipes are quite popular, and the scope of their use is quite wide. Most often they are used to connect hoods to the ventilation system. Positive qualities are due to high performance characteristics, and the main advantage is ease of installation. The corrugation for the hood can be used for arranging chimneys or installing air ducts. This article will tell you about its types, characteristics, installation features.

The scope of application of corrugated pipes is quite extensive

Overview of air ducts for kitchen hoods

To connect the exhaust outlet to the vertical shaft opening, 3 types of boxes are used:

- flexible aluminum corrugation of the "Aluvent" type;

- PVC plastic channels of round and rectangular cross-section;

- metal boxes of various shapes.

Note. In general, ventilation systems use air ducts made of various materials, for example, fabric or three-layer with sound insulation. A complete overview of ventilation pipes is presented in a separate article.

Now we will analyze separately each group of exhaust ducts for the kitchen - we will list the characteristics, pros and cons of the products.

Aluminum corrugated pipes

The flexible channel is a soft wire frame covered with thin aluminum foil. Top layer of polyester for better sealing. The pipeline is transported and sold in a compressed state, after unpacking it is stretched to the required length (maximum 5 times).

Duct specifications:

- wall thickness - up to 100 microns, cross-section - round;

- maximum operating temperature - 250 ° C;

- allowable bending radius is 0.7D (D - diameter);

- range of diameters: 80, 100, 110, 120, 125, 130, 140, 150 mm.

The main trump card of aluminum hoses is a reasonable price, 1 meter of an air duct Ø100 mm in an extended form costs about 50 rubles. (0.9 conventional units). Thanks to a rich range of standard sizes, the ventilation duct can be easily matched to the outlet diameter of the hood and ventilation grill.

The corrugated exhaust duct is quick and easy to install. The pipe is stretched to the required length, one end is put on the union of the exhaust unit, the other on the grate. Then the corrugation is fixed with ordinary clamps, this is where the installation ends.

A flexible corrugated pipe is installed literally in 5 minutes, it is enough to fix the ends with clamps

Note. If the jacket is damaged, the sleeve can be cut and the pipe pulled out further. But it will not work directly to dock the ends of the 2 corrugations, you will need a hard intermediate pipe.

Disadvantages of flexible ducts:

- The appearance of the aluminum corrugation does not meet modern requirements for interior design. The box is suitable for a hood in the country, in a summer kitchen or in an apartment with a conventional renovation. In other cases, the pipe must be hidden behind a decorative casing or drywall sheathing.

- The wavy structure of the walls creates an increased resistance to air flow. The fan efficiency decreases.

- For the same reason, more fat deposits are retained inside the canal. It is unrealistic to clean the corrugation, it is easier to replace it.

- Aluminum foil is easily damaged by any sharp object.

The last negative point - during the operation of the hood, the corrugated pipe makes a lot of noise. The reason is the vibration of thin flexible walls plus a wavy profile that resists air.

On short sections, corrugated pipes look satisfactory, on longer channels all beauty is lost

Plastic ventilation ducts

For the manufacture of air ducts, white polyvinyl chloride (PVC) is used. The pipeline does not bend, therefore, the sections of the ventilation network are connected using shaped elements - couplings, nipples, elbows, tees and various adapters. Characteristics of plastic boxes:

- the maximum temperature of the transported medium is 200 degrees;

- sectional shape - round, rectangular (flat);

- diameters of round ducts suitable for hoods - 100, 125, 150 mm;

- "Running" dimensions of flat boxes - 55x110, 60x112, 60x204, 90x220 mm;

- the length of the standard section is from 35 cm to 2 m.

Reference. Here are the dimensions of the pipes of the household series. For a fee, you can order the manufacture of non-standard products, for example, a ventilation box Ø180 mm or a square channel 100 x 100 mm. Although to connect the hood you will need only 1-3 meters of the duct, it is easier to get by with the existing dimensions.

Plastic air ducts are connected to fittings in two ways:

- The round section is put on from the outside on the counterpart of the mounting element - bend, tee or nipple.

- Conversely, rectangular pipes are inserted inside the fittings. Couplings are used to join straight sections.

On the left, the diagram shows the nipple connection of a round PVC duct, on the right, rectangular sections of ventilation ducts are inserted into the tee couplings

In both cases, the joint is carefully sealed with a silicone compound. The cross-sectional shape of the ventilation duct can be changed at any point - install a straight or angled adapter, use a tee with different leads.

The price of plastic is noticeably higher than corrugations of a similar diameter. A meter of pipe Ø100 mm will cost about 180 rubles. (3.15 cu), a rectangular box of equivalent cross-section 110 x 55 mm - 185 rubles. (3.3 conventional units). Here you also need to add the cost of the fittings involved in the scheme.

Diy pipe masking

The installation of decorative boxes can be done by hand, even without having the great skills of a home craftsman. Here it is important to decide in advance on the option of finishing the pipe, to choose the right material and fasteners.

Required tools and materials

You will need the following set of tools:

- electric drill;

- screwdriver;

- puncher;

- scissors for working with metal;

- for working with wood and drywall - jigsaw;

- ruler;

- level.

For fasteners, you should purchase:

- dowels of the required size;

- self-tapping screws;

- metal profiles;

- mounting screws;

- clamps for fastening the air duct.

Before buying materials, you should determine the size of the structure and calculate the purchase volume.

Work progress

To hide the corrugations, a decorative plasterboard box is most often constructed.

- Work begins with measuring the space and air duct, sketching the installation project.

- Use a ruler and a level to mark up with a pencil on the wall. Along the wall, and then along the ceiling, guide profiles are attached with dowels, then vertical sections are attached to them with self-tapping screws.

- The corrugation sleeve is fixed in the holes of the hood and ventilation shaft, placing it inside the frame.

- The frame is sheathed along the profiles with plasterboard using self-tapping screws.

- The made box can be finished in accordance with the interior of the kitchen: paint, wallpaper, use other materials.

Recommendations for choosing an air duct

A significant selection criterion for homeowners remains the price, aesthetics and performance characteristics of ventilation ducts fade into the background. Flexible corrugation definitely wins here, it is much cheaper than other options, and fittings are not needed.

We will offer our recommendations on how to choose a ventilation duct for your hood:

- 2 types of channels are suitable for external laying - plastic and metal. The former are cheaper, but they look worse, it is better to hide them above cabinets or behind decorative cladding.

On the left in the photo is the installation of the ventilation duct behind the plasterboard sheathing, on the right is the gasket inside the furniture

- For a hidden gasket, you can take any duct: corrugation, PVC, galvanized. If you don't care about the noise level, use a cheap aluminum sleeve.

- In a country house, summer kitchen or veranda with a stove, connect the hood with a corrugated pipe. Plastic in such rooms quickly becomes dirty, yellowness is difficult to remove.

- If an expensive renovation is made in the apartment, you cannot save money and disfigure the interior. Match the steel box, fittings and grill to the color of the hood. Stainless steel is perfect for a nickel-plated surface, copper is golden.

Advice. There is one way to remove yellowness from white plastic. Try wiping off stains with 647 thinner or acetone, these chemicals will decompose the top layer of plastic. Old, deep-seated dirt cannot be removed.

Correct connection of the hood

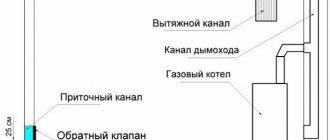

To purchase the required number of pipes and fittings, draw up a diagram of the connection of the unit's exhaust outlet to the ventilation shaft. Follow these simple rules:

- Ideally, the total length of the boxes should not exceed 2 m: 1 meter in height + 1 m horizontally to the receiving opening. Longer lengths will reduce the performance of the hood (although the user will not notice the difference as there is nothing to compare with).

- The optimal number of 90 ° turns is two. The more knees, the weaker the fan "pulls" due to the increase in the resistance of the air ducts.

- Consider the route of the gasket in such a way that the duct does not intersect with the gas pipe connected to the stove. If intersections cannot be avoided, walk around the riser using 45 ° elbows rather than right angles.

An example of a layout for laying a long exhaust duct from an umbrella to a shaft opening

Tips and tricks required for the installation and purchase of corrugated hoods

The end result of the installation work is the flawless functioning of the entire ventilation system. To achieve it, experts recommend adhering to a number of rules:

If you install a pipe that is too narrow, it will create a heavy load on the fan.

- In cases where the ventilation hole is located at a considerable distance from the hood, it is better to place the pipe under the ceiling itself, which will eliminate the presence of sharp corners in the structure and, as a result, ensure reliable and efficient operation of the system. It is better to hide such a structure under a false ceiling.

- It is necessary to take a responsible approach to the choice of the diameter of the corrugation: a narrow pipe will lead to a greater load on the fan and worsen its operation.

- For round hoods, it is impractical to buy a pipe with a rectangular cross section. This will negatively affect the efficiency of the system and will require the installation of additional adapters, which, in turn, will also reduce the permeability of the air duct.

- Aluminum corrugation is a versatile material, since there is no need to worry about pipe overheating. It can be used for channels for the outflow of combustion products when installing gas water heaters or heating boilers. In this case, the heating devices themselves will work for a long time and efficiently.

- Steel pipes are used to equip fireplaces, stoves or other heating systems.

- You should not save on buying a pipe. The better the product, the longer the ventilation system will work.

- Incorrect operation of a drain pipe made of poor-quality material can contribute to the ingress of carbon monoxide into an apartment and entail sad consequences.

- The length of the duct should be no more than 3 m, and its bends should not exceed 90 °.

It is better to give preference to the corrugation made of aluminum, because it is universal.

Duct selection parameters

For the normal functioning of the ventilation system using the hood, it is necessary to correctly calculate the parameters of the duct. In most cases, for household purposes, you can pick up plastic boxes of standard shapes and sizes.

Calculation of the optimal section of the ventilation duct

The main parameter of the ventilation duct is its inner section. The speed of the flow through the channel depends on it and on the power of the exhaust. The cross section is selected based on the maximum volume of transmitted air.

There are no normative documents regulating the speed for household plastic air ducts, therefore, they are guided by values that have been tested in a practical way, equal to 3-7 meters per second.

The size of the section of the duct is taken equal to or slightly larger than that of the exhaust duct, the size of which is indicated in the passport of the device.

If the regular switching on of the maximum mode is not planned, then in this case a proportional decrease in the section of the ventilation duct relative to the size of the outlet is permissible.

So if S - cross-sectional area of the exhaust duct branch pipe, N - the volume of passed air at the maximum mode of the device, M - the volume of passed air in the planned mode, then the required sectional area of the duct is calculated by the formula:

P = S * (M / N)

Insufficient size of the duct section leads to significant air velocities and an increase in frictional force.

This is fraught with the following negative effects:

- there is an increase in the load on the ventilation mechanisms of the hood, which leads to a decrease in the operational resource of the device and additional costs of electricity;

- due to an increase in resistance, a decrease in maximum performance occurs, which reduces the circulation of air in the room;

- as a result of aerodynamic effects in the ventilation duct, the noise level during operation increases;

- there is an increase in air pressure from the inside on the elements of the system, as well as the occurrence of vibrations, which requires more reliable fastening and sealing.

If the section of the box is larger than necessary, then this will not negatively affect the functioning of the forced ventilation system, but will lead to unnecessary financial costs.

In addition, ventilation ducts and other large units are more difficult to install and integrate into the design of the premises.

Taking into account the shape and size

Plastic ventilation boxes are round or rectangular. A circle has the smallest perimeter compared to other geometric shapes with the same area.

We should start with why a ventilation duct is needed at all. The presence of an air duct in the kitchen is indispensable, unless you are a fan of continuous general cleaning to wash off greasy deposits on all kinds of planes close to and far from the stove (for "fans" to permanently shine on the surface of the kitchen set and even on the stretch ceiling).

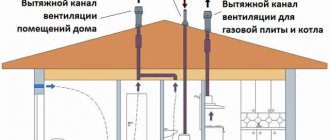

All vapors and fumes must be removed from the kitchen space as quickly as possible, whatever the option is chosen - the final exhaust through a specialized section in the window opening or discharge into the ventilation shaft - in all cases, a ventilation duct will be required.

Methods for masking pipes

Instead of corrugation, you can use a plastic pipe of round or rectangular cross-section, suitable size for the diameter of the channel. To connect short sections, adapters of various configurations are used. The disadvantage of a plastic pipeline is the loss of traction with its long length. Therefore, it is recommended to use such a plastic box only if there is a ventilation hole near the hood.

You can decorate the corrugated sleeve in the following ways.

- A plasterboard box. It is built on a frame of metal profiles and then painted in a color that matches the design of the kitchen.

- Built-in furniture. The air duct is inconspicuously located in the walls of a tall wall cabinet suspended above the stove. This option is suitable in the case of a built-in hood, fixed at the bottom of such a cabinet.

Both options can be beaten with LED lighting, which will add comfort and brightness to the lighting in the kitchen.

- Kitchen set with cornice. The chimney is passed close to the wall along the top of the kitchen furniture, and it becomes closed behind the cornice.

- Suspended or stretch ceiling. In this case, the corrugated pipe will be completely hidden. The ceiling height will lose from 13 to 15 cm.

- Decorative elements or painting the corrugation, which will act as an element of the kitchen interior.

If your kitchen is designed in a high-tech style, the aluminum corrugation can be left as is, without masking. It goes well with this style.

Plastic boxes

In essence, there is no need to invent anything here. These sections of various cross-sections can be bought at any building supermarket (for example, in Leroy Merlin), and individual parts are very easy to assemble yourself.

At the same time, there is no need to install a separate decorative box - the duct pipes are quite attractive and conceptual in appearance. In addition, they are of different types: from the largest section to completely invisible.

The standard sizes of boxes, which are most often presented in stores, regardless of the material of manufacture, are 110x55 mm, 120x60 mm and 204x60 mm for rectangular; 80 mm, 100 mm, 125 mm, 150 mm in diameter - for round.

Advantages of plastic hoods in the kitchen:

- lowering the overall noise level from the operation of the exhaust system;

- durability due to the fact that the plastic does not corrode;

- ease of installation;

- hygiene (such pipes are relatively easy to care for).

A feature of the installation is that the pipes fit perfectly on the existing surfaces: for example, on the upper plane of kitchen shelves. As a last resort, there is the option of constructing support brackets.

Metal boxes

Modern, fashionable and brilliant (literally) look air ducts for kitchen exhaust ducts, which are made of polished stainless steel.

The price of stainless steel is high, but its use is justified here if your goals coincide with those listed below:

- so as not to breed rust in the kitchen (hygiene);

- the ventilation box in the kitchen in this case becomes a design accent that attracts the attention of the observer.

A stainless steel hood box in the kitchen is much less difficult to assemble than a plastic one.

Therefore, it is recommended here, firstly, to buy custom-made boxes, and secondly, the installation of the hood should be entrusted to qualified performers who specialize in this. (Ideal: the one who makes the whole system, he should make the installation).

The obvious disadvantages of metal boxes (in addition to the difficulty of installation and the relative severity of the elements) include:

- the presence of resonance (noise) from the operation of the hood itself;

- the glossy surface perfectly catches and retains small droplets of fat, convecting along with the air currents, and after that it becomes clearly noticeable how dust adheres to this surface.

Drywall

However, ventilation boxes may not always have an aesthetically pleasing appearance. Metal air ducts may have a completely non-glossy surface, and plastic boxes may not be in harmony with the chosen style at all, as a result of which the kitchen space immediately becomes unsightly.

The main thing to remember is that only a decorative box for an exhaust hood in the kitchen (that is, for functional air ducts) can be made from plasterboard sheets.

Firstly, it is very difficult to arrange direct channels for the passage of air from gypsum plasterboard, and secondly, such an air duct will quickly lose its shape and collapse due to the fact that the gypsum absorbs moisture and fat and begins to lose its shape.

A feature and complexity of the construction of a plasterboard box is the need to install a rack frame, which in itself is extremely laborious. At the same time, air ducts should be chosen on the basis of functionality and cheapness - without regard to their appearance. You also need to remember that the box is a structure that must fit into the interior design of your kitchen. Most likely, you will not be able to "stick" the box wherever you like, without prejudice to the appearance of the room, and to mask the passage of the internal air channel only along one upper corner, you will have to make a box around the entire perimeter of the kitchen.

How to hide corrugation from a hood in the kitchen: secrets of disguise

Quite often, it is the pipes under the ceiling with a noticeable and peculiar shine that spoil the stylish and harmonious look in a new kitchen, so the final process in installing corrugated pipes is their masking. This process has no functional background, but is considered an important condition for the aesthetic design of the kitchen.

Inventive builders and furniture manufacturers (if the set is made to order) can offer several profitable options at once, allowing you to hide unpresentable pipes. The most popular ones are:

- use of a special plastic box;

- construction of a plasterboard structure;

- masking pipes with a suspended or stretch ceiling;

- building hoods and pipes into kitchen cabinets;

- coating pipes with paint or other decorative elements.

In order not to spoil the interior of the kitchen, it is better to hide the corrugated pipe

A creative solution can be a loft-style kitchen design, when the corrugation is not hidden, but on the contrary, they focus on it. Experienced modern designers will tell you how to correctly beat the shiny corrugated pipe in the interior so that it does not spoil the appearance of the kitchen, but, on the contrary, becomes its decoration and highlight. Fans of classic styles are better off choosing one of the camouflage methods. How to implement each of them, we will consider below.

We mask the corrugated pipe for extraction into boxes

One of the most popular options for masking corrugation is a special plastic box. It is sold in hardware stores. Manufacturers offer a wide range of models, designs and colors, which allows it to fit into any interior. Sometimes such designs are decorated with original lighting, creating additional comfort. This option is most often used in the case of a close location of the ventilation shaft and in the absence of right angles.

You can hide the air duct under a structure made of plasterboard sheets, which is designed to perform not only a masking, but also a decorative function.Placing a curly and original composition under the ceiling will give the interior a special elegance, and the room - additional comfort. At the same time, the drywall box should not stand out particularly in the interior, so as not to create the impression of a cluttered space. Decorating the structure is done using the same materials that are used for the entire kitchen.

Masking a pipe using a box is one of the easiest and most affordable ways.

Masking with drywall sheets is performed in several stages. First, a crate is created according to the dimensions of the pipe, for this you can use ordinary metal profiles. Next, the frame is sheathed with plasterboard sheets and fixed on one side to the wall, and on the other to the ceiling. The box can be of various sizes and looks good as an addition to a suspended ceiling, consisting of several levels, which is also mounted from plasterboard.

Helpful advice! When creating a camouflage structure, you should remember about the malfunctions that may occur during the operation of the air duct. In order to eliminate them, you will have to dismantle the box behind which the pipes are hidden.

How to hide ventilation corrugation under the ceiling

In addition to the plasterboard ceiling structure, you can simply hide the chimney above the suspended ceiling. But in this case, it will descend to a distance equal to the diameter of the corrugation, which is at least 120 mm, plus the thickness of the material itself and gaps of several millimeters. In the same way, there is a disguise under a stretch ceiling. If, in the case of a suspension system, space is stolen, then the glossy surface of the tensioning structure will visually increase it due to its reflective properties.

The ventilation pipe can be placed above the false ceiling

Thanks to this advantage, the ceiling option is considered the most successful. The main nuance lies in the impossibility of partial dismantling of the ceiling in the event of a breakdown in the system. Then you will need to change the entire structure, and this will entail considerable financial costs. The stretch ceiling will simply have to be reinstalled.

The most economical option for masking the exhaust pipe is considered to be ordinary painting. It is enough to choose a color that is in harmony with the overall interior. It is important to choose shades that are not very bright and catchy, so as not to draw too much attention to the pipe. Another budget option is to glue the pipe with leftover materials from the decor. However, this design will look less aesthetically pleasing.

Hood corrugation, disguised in a wall cabinet

A modern option for masking air ducts is the use of hinged kitchen cabinets. This is the most acceptable method for concealing built-in hoods. You can lay a pipe in the space between the wall cabinets and the ceiling, decorating the distance with a raised door or a wide strip made of the appropriate material.

So that the hood and the pipe are not visible at all, they are placed in wall cabinets

However, most often the hood, along with the pipe, is hidden directly in the headset cabinet. At the same time, there is still enough space in the middle of the hanging furniture for placing kitchen items and dishes. In this case, it would be more appropriate to manufacture custom-made furniture, where the masking of the pipe is provided for by the headset project. The module is designed in such a way that it is possible to trim the side and rear walls to the required dimensions, and the facades of the cabinets will serve as the main masking element. As a result, the headset fits harmoniously into the interior and looks organic. It is quite easy to replace and dismantle pipes in such a structure.

A hanging cabinet located directly above the hob is often used to install (inside) circulation-type hoods. In this case, only the housing of the ventilation equipment will need to be hidden, only the control panel will remain outside.The absence of a pipe means using the space in the cupboard for storing kitchen utensils.

Helpful advice! Under the hood, as a rule, they take a rounded corrugation. Rectangular air ducts are used in production or warehouses.